Brilliant! Classic Kiwi lateral thinking turning the tables.

Lead mass damping with the diving weights is smart. Id use sand bags myself. Cheaper. Easily recycled into the garden at the end of the project. Non toxic. Better able to absorb resonance vibrations.

I wonder where the best mounting points are to attenuate resonance? I guess there will be two types of resonance. One is a rocking of the entire upper panel around the lower bend forward and back. To dampen that the lead could be mounted as high as possible to inrease the lever arm and rotational inertia. The second might be higher frqiency modes of the panel. Mounting the bags on the panel at modal points with good coupling should work.

Can you do some measurements?

Recently I had the incredible luck of having an Altec 1505b and 288c fall into my lap for next to nothing.

The driver needed a new replacement diaphragm, so I ordered one from GPA, cleaned the compression driver, bug screen, etc. and put in the new diaphragm.

Always wanting a better system in my workshop I decided to build a mono rig there with the 1505b/288c covering ~500hz - ~8000hz, an alnico JBL 2402 handling ~8000hz and up, and 4 Alpha 15a's (series parallel) in a ~48"x48" baffle.

I am using a UTC A-20 to mix L and R signals from my iphone (streaming from Tidal) into a single mono signal. That's currently being fed into a Crown D-45 that's driving the rig. I plan to build a tube powered amp for the 1505 and 2402 combo and likely keep the crown for the open baffle.

The crossover is still being tweaked, hence all the wires, resistors(l-pads) and jumpers dangling all over the place.

I am very pleased with the sound, and frankly surprised how much I'm enjoying it. I may add side wings to the baffle, there is a small top 'wing' I added, mostly to mitigate dust falling down into the back of the 15a's.

The long beam going up on the left side of the baffle is a support that goes to the ceiling. I didn't want to put a support from the back of the baffle to the wall behind it as that would make it difficult for me to get back to my clamp storage 😀

The driver needed a new replacement diaphragm, so I ordered one from GPA, cleaned the compression driver, bug screen, etc. and put in the new diaphragm.

Always wanting a better system in my workshop I decided to build a mono rig there with the 1505b/288c covering ~500hz - ~8000hz, an alnico JBL 2402 handling ~8000hz and up, and 4 Alpha 15a's (series parallel) in a ~48"x48" baffle.

I am using a UTC A-20 to mix L and R signals from my iphone (streaming from Tidal) into a single mono signal. That's currently being fed into a Crown D-45 that's driving the rig. I plan to build a tube powered amp for the 1505 and 2402 combo and likely keep the crown for the open baffle.

The crossover is still being tweaked, hence all the wires, resistors(l-pads) and jumpers dangling all over the place.

I am very pleased with the sound, and frankly surprised how much I'm enjoying it. I may add side wings to the baffle, there is a small top 'wing' I added, mostly to mitigate dust falling down into the back of the 15a's.

The long beam going up on the left side of the baffle is a support that goes to the ceiling. I didn't want to put a support from the back of the baffle to the wall behind it as that would make it difficult for me to get back to my clamp storage 😀

Attachments

Last edited:

I've come to love efficient speakers and small amps. There's some magic in sound from 15" drivers, it seems to set the table, rather than spraying things into the room.

That makes my 511B pair look puny!

That makes my 511B pair look puny!

Open back baffle no baffle

Air mass loaded Neo 10, with series connected Neo 3/Neo 8.

Crossover points 2500hz, 325hz. Spare parts project, wanted some tiny satellites, and some headroom with 10 watt amps.

These work far better than expected, with corner loaded Onkens as bass bins.

Air mass loaded Neo 10, with series connected Neo 3/Neo 8.

Crossover points 2500hz, 325hz. Spare parts project, wanted some tiny satellites, and some headroom with 10 watt amps.

These work far better than expected, with corner loaded Onkens as bass bins.

Attachments

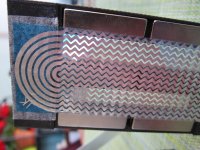

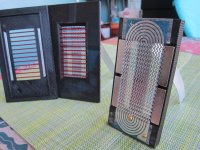

Here's some pictures of my new dipole tweeter. The membrane is made of 8 uM alu laminated to Mylar. Usable frequencies: 1,5 to 35 kHz.

It took me 3 years to come up with a method to produce perfect 5 ohm tracks!

The membrane is only attached at the short sides, which lowers the distorsion.

Cool possibility: Using the visible ends of the red protecting rods to indicate date of production in binary form!

It took me 3 years to come up with a method to produce perfect 5 ohm tracks!

The membrane is only attached at the short sides, which lowers the distorsion.

Cool possibility: Using the visible ends of the red protecting rods to indicate date of production in binary form!

Attachments

Any particular reason not to make them 4 or 8 ohms?

Something to do with phase angles in a passive crossover to a dynamic driver?

Something to do with phase angles in a passive crossover to a dynamic driver?

Its not that they are at 5 ohm that is important, its that they have identical values.

So, for example, that they will have the same voltage sensitivity...

So, for example, that they will have the same voltage sensitivity...

Here's some pictures of my new dipole tweeter. The membrane is made of 8 uM alu laminated to Mylar. Usable frequencies: 1,5 to 35 kHz.

It took me 3 years to come up with a method to produce perfect 5 ohm tracks!

The membrane is only attached at the short sides, which lowers the distorsion.

Cool possibility: Using the visible ends of the red protecting rods to indicate date of production in binary form!

Wow these are really neat! Is there a topic about these somewhere, would love to build something similar!

No topic, what I know of....

But if You have a 3d printer, I can send the STL files for the magnet holder assy and the front baffle. The magnets are:

Q-40-10-10-N: Block magnet 40 x 10 x 10 mm - supermagnete,

Six of them in each tweeter.

The big problem are the membranes, they are a pain in the 🙄 to make....

But if You have a 3d printer, I can send the STL files for the magnet holder assy and the front baffle. The magnets are:

Q-40-10-10-N: Block magnet 40 x 10 x 10 mm - supermagnete,

Six of them in each tweeter.

The big problem are the membranes, they are a pain in the 🙄 to make....

Cool, I have a 3d printer so that part is covered. I also have acces to a lasercutter that would maybe be handy for making the membranes?

How did you made them? They look really neat

EDIT: Plotting would maybe be better I think

How did you made them? They look really neat

EDIT: Plotting would maybe be better I think

The membranes are made by cutting a self adhesive foil and then use this as an etch mask. I've tried different lasers/methods, but they are useless on this thin material.

concrete open baffle

my first attempt making a open baffle

before this i owned the emerald physics cs2

never have build any speaker or open baffle before

so i am still learning and must have read al there is on open baffles on diyaudio forum .but still trying to wrap my head around it 🙂

for this one i just wanted to make something that could rattle the house but not the baffle 🙂 and looks cool also \at least i think it looks cool 😉

baffle and waveguide made out of concrete

drivers used are / ea dipole15/bms 4550 on a custom concrete seos 18 waveguide

active crossover and eq on computer

macbook logic audio and fabfilter pro q and rme ucf

my next one will be a 3 way by adding a midrange driver

work in progress.....😀

my first attempt making a open baffle

before this i owned the emerald physics cs2

never have build any speaker or open baffle before

so i am still learning and must have read al there is on open baffles on diyaudio forum .but still trying to wrap my head around it 🙂

for this one i just wanted to make something that could rattle the house but not the baffle 🙂 and looks cool also \at least i think it looks cool 😉

baffle and waveguide made out of concrete

drivers used are / ea dipole15/bms 4550 on a custom concrete seos 18 waveguide

active crossover and eq on computer

macbook logic audio and fabfilter pro q and rme ucf

my next one will be a 3 way by adding a midrange driver

work in progress.....😀

Attachments

Last edited:

i used liquide silicone that i poured in the original waveguide

and before put some vasalin in the waveguide

and than i put the mould upside down and with wood made the outside contour

silicon does not stick on concrete so getting in out was easy

for the mounting of the driver i used a aluminium horn adapter cutted of the 1” screw pipe and put boulds in the 3 not used holes those are now fixed in the poured concrete

forgot to make pictures of the process 🙂

and before put some vasalin in the waveguide

and than i put the mould upside down and with wood made the outside contour

silicon does not stick on concrete so getting in out was easy

for the mounting of the driver i used a aluminium horn adapter cutted of the 1” screw pipe and put boulds in the 3 not used holes those are now fixed in the poured concrete

forgot to make pictures of the process 🙂

This is a 12 " OB bass driver, a future product coming from SB Acoustics, first mentioned in another thread elsewhere, I cannot remember where so I thought I'd mention it again out of general interest.

Nice to have something made for the purpose. Two in parallel might be needed to get the sensitivity up though.

SB Acoustics :: 12” SB34NRX75-16

C.M

Nice to have something made for the purpose. Two in parallel might be needed to get the sensitivity up though.

SB Acoustics :: 12” SB34NRX75-16

C.M

Last edited:

Amazing! I would love to do thisi used liquide silicone that i poured in the original waveguide

and before put some vasalin in the waveguide

and than i put the mould upside down and with wood made the outside contour

silicon does not stick on concrete so getting in out was easy

for the mounting of the driver i used a aluminium horn adapter cutted of the 1” screw pipe and put boulds in the 3 not used holes those are now fixed in the poured concrete

forgot to make pictures of the process 🙂

my first attempt making a open baffle

baffle and waveguide made out of concrete

drivers used are / ea dipole15/bms 4550 on a custom concrete seos 18 waveguide

active crossover and eq on computer

macbook logic audio and fabfilter pro q and rme ucf

work in progress.....😀

Very nice!

Are they full concrete or hollow concrete?

Sweet set of active setup.

This is a 12 " OB bass driver, a future product coming from SB Acoustics, first mentioned in another thread elsewhere, I cannot remember where so I thought I'd mention it again out of general interest.

Nice to have something made for the purpose. Two in parallel might be needed to get the sensitivity up though.

SB Acoustics :: 12” SB34NRX75-16

C.M

I think they are made for multiple, at 16 Ohms. Two gets you at 8 Ohms, four at 4 Ohms with a nice boost.

- Home

- Loudspeakers

- Multi-Way

- Ultimate Open Baffle Gallery