Tube rectifiers have an internal resistance that will cause loss of supply stiffness, and since the capacitors cannot be large on a tube rectifier, the B+ voltage bounces with the music, which may impart a characteristic sound to it.

> Tube rectifiers have an internal resistance that will cause loss of supply stiffness, and since the capacitors cannot be large on a tube rectifier, the B+ voltage bounces with the music, which may impart a characteristic sound to it.

I wanted to look into this for my 300B-SE. Partly because of the lack of supply stiffness, and partly because of the relatively poor stability, lifetime, and sound of smaller high-voltage consumer-grade electrolytic caps.

My 300B-SE uses the oversized Sowter SA-08S (OT spec: 25W@20Hz, 0.5% THD), that allows much better bass than standard OTs for 300B.

SA08 SINGLE ENDED OUTPUT TRANSFORMER

With this OT, the 300B's internal anode-resistance of <800Ω would be better fed from a supply with bigger cap than even damper diodes can support.

A few years ago the Kemet ALS61 series caps were on sale for a low price, and I built a new supply based around the ALS61 550V 820µF parts. This means a reactance of near 10Ω at 20Hz - that's better.

The ALS & ALC series were acquired from BHC, and I know of these from designing them into professional equipment. They have a lifetime of well over 10000 hours at moderate temperatures, and the electrolyte has a neutral pH, so they do not degrade or need re-forming with anything like the same speed that consumer electrolytics do. Not to mention that 550V is able to withstand no-load conditions for many anode supply set-ups.

I built the supply with rectifiers in a bridge:

Wolfspeed C4D02120A, SiC Schottky Diode, 1200V 10A, 2-pin TO-220

the ramp-up current pulses are still a bit marginal for these, so the supply was run with a 35Ω-loop (including PT resistance), and little clip-on heatsinks for each diode (these need some mass, rather than surface area, since the real stress is at start-up). I used a cap-multiplier to give a slow rise-time, similar to damper diodes, to further reduce the initial diode-heat, and because I don't like abrupt application of HV to any circuit.

Now the supply looks like:

SiC Bridge → 27Ω [20W wirewound] → 820µF/550V → Cap-multiplier → 820µF/550V → small L → 100µF Audio MKP → PT.

This supply has been running for over five years, without problems, and with excellent consistency of sound. I don't believe it loses anything, compared to the polar opposite previous design: choke-input using a huge oil-filled 14H choke (from the Bletchley Park radio rally) , 6CJ3 dampers and LC stage filtering. It can play any kind of music, including pounding club 12" plates (that cause 300B-SEs to usually sound merely flatulant) - though mostly it plays symphonies.

Sound-wise I don't have a very definite preference, but I will say that using high-quality 550V ALS (now, choose ALC10 series) caps gives confidence that the sound is consistent over time that 47-100µF consumer caps do not give; but it seems that the ALC10 series is now available all the way down to 68µF (ALC10A680BC550) if you want to investigate these on a damper set-up.

I wanted to look into this for my 300B-SE. Partly because of the lack of supply stiffness, and partly because of the relatively poor stability, lifetime, and sound of smaller high-voltage consumer-grade electrolytic caps.

My 300B-SE uses the oversized Sowter SA-08S (OT spec: 25W@20Hz, 0.5% THD), that allows much better bass than standard OTs for 300B.

SA08 SINGLE ENDED OUTPUT TRANSFORMER

With this OT, the 300B's internal anode-resistance of <800Ω would be better fed from a supply with bigger cap than even damper diodes can support.

A few years ago the Kemet ALS61 series caps were on sale for a low price, and I built a new supply based around the ALS61 550V 820µF parts. This means a reactance of near 10Ω at 20Hz - that's better.

The ALS & ALC series were acquired from BHC, and I know of these from designing them into professional equipment. They have a lifetime of well over 10000 hours at moderate temperatures, and the electrolyte has a neutral pH, so they do not degrade or need re-forming with anything like the same speed that consumer electrolytics do. Not to mention that 550V is able to withstand no-load conditions for many anode supply set-ups.

I built the supply with rectifiers in a bridge:

Wolfspeed C4D02120A, SiC Schottky Diode, 1200V 10A, 2-pin TO-220

the ramp-up current pulses are still a bit marginal for these, so the supply was run with a 35Ω-loop (including PT resistance), and little clip-on heatsinks for each diode (these need some mass, rather than surface area, since the real stress is at start-up). I used a cap-multiplier to give a slow rise-time, similar to damper diodes, to further reduce the initial diode-heat, and because I don't like abrupt application of HV to any circuit.

Now the supply looks like:

SiC Bridge → 27Ω [20W wirewound] → 820µF/550V → Cap-multiplier → 820µF/550V → small L → 100µF Audio MKP → PT.

This supply has been running for over five years, without problems, and with excellent consistency of sound. I don't believe it loses anything, compared to the polar opposite previous design: choke-input using a huge oil-filled 14H choke (from the Bletchley Park radio rally) , 6CJ3 dampers and LC stage filtering. It can play any kind of music, including pounding club 12" plates (that cause 300B-SEs to usually sound merely flatulant) - though mostly it plays symphonies.

Sound-wise I don't have a very definite preference, but I will say that using high-quality 550V ALS (now, choose ALC10 series) caps gives confidence that the sound is consistent over time that 47-100µF consumer caps do not give; but it seems that the ALC10 series is now available all the way down to 68µF (ALC10A680BC550) if you want to investigate these on a damper set-up.

Good to have your contribution, Rod. I have my eye on those Wolfspeed C4D02120A diodes. My usual PSU is (small) C>L>C>R>C. Main capacitors are 47uF polypropylene motor run. Choke is whatever I have, bigger the better. HT is 300-350v.

Can I just use the diodes alone with appropriate heatsinks? Or is there anything I should add to the rectification circuit in the way of resistors/small caps?

My capacitor sizes are way smaller than yours - could you comment on that, and the value of using polypropylene caps?

Can I just use the diodes alone with appropriate heatsinks? Or is there anything I should add to the rectification circuit in the way of resistors/small caps?

My capacitor sizes are way smaller than yours - could you comment on that, and the value of using polypropylene caps?

hello Andy - the diodes were bought five years ago, so better ones may be available.

Supplies like yours can work well, but if the OT can handle powerful bass like the Sowter can, if may be worth trying a high-C supply.

Supply resistance from the transformer to the first cap is important, and the easiest thing is to put the PT resistance into PSUD2 and model the current during startup. You'll see that chokes have little effect on the current, and so resistance must be added to keep the diodes safe, if large Cs are used.

Motor-run caps should be given to the poor of the parish, IMHO. The worst sound I have ever heard from my SEs was using a pair of large MKPs of this type. The problem is the mechanical construction, & I believe that's what the Audio MKP parts concentrate on. Try some ClarityCaps. Or any other types, but so-so electrolytics are better than the average motor-run. They vary all over the place, but are notably bad when placed near the rectifier.

Supplies like yours can work well, but if the OT can handle powerful bass like the Sowter can, if may be worth trying a high-C supply.

Supply resistance from the transformer to the first cap is important, and the easiest thing is to put the PT resistance into PSUD2 and model the current during startup. You'll see that chokes have little effect on the current, and so resistance must be added to keep the diodes safe, if large Cs are used.

Motor-run caps should be given to the poor of the parish, IMHO. The worst sound I have ever heard from my SEs was using a pair of large MKPs of this type. The problem is the mechanical construction, & I believe that's what the Audio MKP parts concentrate on. Try some ClarityCaps. Or any other types, but so-so electrolytics are better than the average motor-run. They vary all over the place, but are notably bad when placed near the rectifier.

Supply resistance from the transformer to the first cap is important, and the easiest thing is to put the PT resistance into PSUD2 and model the current during startup. You'll see that chokes have little effect on the current, and so resistance must be added to keep the diodes safe, if large Cs are used.

Motor-run caps should be given to the poor of the parish, IMHO. The worst sound I have ever heard from my SEs was using a pair of large MKPs of this type. The problem is the mechanical construction, & I believe that's what the Audio MKP parts concentrate on. Try some ClarityCaps. Or any other types, but so-so electrolytics are better than the average motor-run. They vary all over the place, but are notably bad when placed near the rectifier.

I don't have PSUD2 since I use a Mac, so I can't check all this. Are you suggesting a resistor in series before the diode bridge? Or does the fact that I use 47uF caps mean that the diodes won't be stressed anyway?

It's a while since I experimented with PSU caps but to my ears the motor runs sounded better than electrolytics. The worst were some large computer grade electrolytics which were slow and dull sounding. I don't know why we have such a difference of opinion here. Maybe I should check the caps again.

My speakers don't go down as far as deep bass, so that's not a priority for me. The mids and treble are much more important - clarity and smoothness. I listen to a lot of classical and opera.

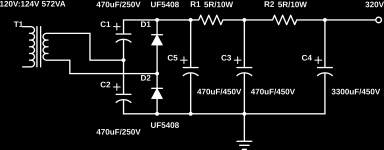

This is what I use for my monoblocs that use 4 6P45S in push pull for 115 watts @ 30Hz working into ~ 1k plate to plate. ~480mA idle current.

No hum, excellent dynamics and bass.

Too easy?

No hum, excellent dynamics and bass.

Too easy?

Attachments

Last edited:

@Rod Coleman

Thanks for detailing your experience. The Kemet ALS6n series parts are 85o C. rated. Mouser lists, but does not stock, other Kemet series that are 105o C. rated. Listed, but not stocked, also applies to the ALS6n series. 🙁 Huge $ investments in parts are (IMO) out of the question for retiree hobbyists, like me. Still the info. about what should be pounced on, if and when opportunity knocks, is appreciated.

FWIW, I've favored Panasonic and Nichicon 'lytics. I look for 105o C. rating, long service life, high ripple current, and low ESR. Obviously, finding parts that excel in all the parameters is "front page NY Times news". 😉

BTW, the references to Chemistry and Physics are definitely making me smile.

Thanks for detailing your experience. The Kemet ALS6n series parts are 85o C. rated. Mouser lists, but does not stock, other Kemet series that are 105o C. rated. Listed, but not stocked, also applies to the ALS6n series. 🙁 Huge $ investments in parts are (IMO) out of the question for retiree hobbyists, like me. Still the info. about what should be pounced on, if and when opportunity knocks, is appreciated.

FWIW, I've favored Panasonic and Nichicon 'lytics. I look for 105o C. rating, long service life, high ripple current, and low ESR. Obviously, finding parts that excel in all the parameters is "front page NY Times news". 😉

BTW, the references to Chemistry and Physics are definitely making me smile.

Hi Eli,

The ALC10A471EH550 is a 470µF 550V part that costs the equivalent of about USD 15.00 at Farnell, but I don't know why they are almost double that at Mouser or DigiKey.

I would say that it's a good deal, for the quality. Take the lifetime: 18000 hours at full 550V, 3.05A of ripple current applied, and 85 °C, or 29000 stressed for voltage and 85 °C only.

For audio use, and keeping the temperature to say, 50 °C the lifetime exceeds that of most of us. And multiple times the usual 2-7000 hours or so for consumer grade parts.

If you can avoid getting near 85 °C for these parts (which is easy, in an amplifier), 105 °C parts are not required, when the lifetimes are this high.

I thought it worth mentioning the effect of pH on stability of performance, since I obtained this snippet from a design staffer at BHC.

The ALC10A471EH550 is a 470µF 550V part that costs the equivalent of about USD 15.00 at Farnell, but I don't know why they are almost double that at Mouser or DigiKey.

I would say that it's a good deal, for the quality. Take the lifetime: 18000 hours at full 550V, 3.05A of ripple current applied, and 85 °C, or 29000 stressed for voltage and 85 °C only.

For audio use, and keeping the temperature to say, 50 °C the lifetime exceeds that of most of us. And multiple times the usual 2-7000 hours or so for consumer grade parts.

If you can avoid getting near 85 °C for these parts (which is easy, in an amplifier), 105 °C parts are not required, when the lifetimes are this high.

I thought it worth mentioning the effect of pH on stability of performance, since I obtained this snippet from a design staffer at BHC.

> Maybe I should check the caps again.

Yes, Andy, I think so, given that you seem to be sensitive to different valve and resistor types. For example you could compare your 47uF to one of the ClarityCaps and the ALC10A680BC550 at Farnell.

The supply caps that are exposed to the greatest fluctuations in current are worth concentrating on - the one at the rectifier, & the one nearest the OT feed, in an SE amp.

Yes, Andy, I think so, given that you seem to be sensitive to different valve and resistor types. For example you could compare your 47uF to one of the ClarityCaps and the ALC10A680BC550 at Farnell.

The supply caps that are exposed to the greatest fluctuations in current are worth concentrating on - the one at the rectifier, & the one nearest the OT feed, in an SE amp.

> If a group of buyers that ordered 3+ blocks could be assembled, the price per part begins (IMO) to become feasible.

A challenge for willing participants in North America!

Are you a Chemist, Eli ?

A challenge for willing participants in North America!

Are you a Chemist, Eli ?

Are you a Chemist, Eli ?

I was educated as a Chemist (not Apothecary), but spent my working days in electronic data processing (EDP), AKA information technology (IT). I'm a retired mainframe system programmer that specialized in CICS. IBM does its CICS development at Hursley, England.

Andy - PSUD2 is now available for the Mac, depending on the operating system.I don't have PSUD2 since I use a Mac, so I can't check all this.

Download

I downloaded the native Mac version to my laptop, which is old but uses a slightly newer operating system than my desktop, which is an even older Mac Mini. I use the Wineskin software to make it work on the desktop, which is what I prefer to use.

It's been very helpful but I've only used its basic functions. Unfortunately, there doesn't seem to be a truly comprehensive, or even semi-comprehensive, manual.

I was under the impression that the current in a SE amp, being Class A, is relatively stable. Are the "greatest fluctuations" really all that great?The supply caps that are exposed to the greatest fluctuations in current are worth concentrating on - the one at the rectifier, & the one nearest the OT feed, in an SE amp.

I think this is the first time I've heard anyone suggest that an electrolytic (of any type) in the PS will outperform a film cap.

I've used a variety of caps in PS including motor runs (which are polypropylene in oil, I believe), some 45uf 500v Panasonic films, as well as electrolytics from Nichicon or Panasonic.

I try to use electrolytics that are rated at 105 degrees for 10,000 hours. I would think that they would be just as long lived as a cap rated at 85 degrees for 18,000 hours. In practical terms, when used in a typical amp build, I would think that any technical differences would be insignificant, in terms of lifespan and reliability.

And film caps are supposed to be even more reliable are they not?

I've never built anything with SS diodes for rectification but I have some vintage amps that use them. I've always thought that their best use was in higher powered PP amps, where "sag" in the power supply (as the guitar amp guys call it) might be more of an issue. If I was going to build something along those lines, I'd probably lean in that direction.

In a preamp or a SE amp, where current is (supposedly) much more stable, I like to use indirectly heated tube rectifiers.

If long term reliability is a concern, I would think that the slow start characteristics would be advantageous. And if you're using tubes that are no longer in production and may be difficult and/or expensive to replace, I would think that a PS configuration that minimizes stress on the tubes would be even more important.

Last edited:

> I was under the impression that the current in a SE amp, being Class A, is relatively stable. Are the "greatest fluctuations" really all that great?

With a class-A SE stage the average supply current is stable, up to the point of non-negligible distortion setting in at higher power.

The averaging is performed by the supply capacitor. The stable-looking DC voltage hides this from a oscilloscope, but the work of the capacitor is not be be overlooked: the capacitor(s) sees a current swing of ca. 2x the idle-current, nominally.

> I think this is the first time I've heard anyone suggest that an electrolytic (of any type) in the PS will outperform a film cap.

A designed-for-audio film cap should really be best, if you can stand the size and cost.

But the cheaper MKPs made for motor applications can be very unpleasant. Think about the construction: a film is sprayed with Aluminium and rolled up. The rolling might be done super-rapidly, to reduce cost, and then the tension is likely to be variable. Now you are liable to find mechanical resonances.

Similarly, when the electrodes are ultra-thin, to save cost, and the termination are made at only one point on the electrode, the inductance can be high enough to introduce electrical resonances.

It's all very variable, but one should not be surprised if bad parts are to be found.

Concerns over lifetime have little to do with risk of outright failures. Rather, it is the fact that the caps degrade, even if unused. high quality parts with pH-neutral electrolytes degrade much slower, and their performance stays stable for longer.

Although electrolytics don't like heat, the self-heating is usually low in valve designs, and more so if a low ESR part is selected. In this case, the extra cost of 105 °C parts does not achieve anything, in typical amp designs - it is better to spend this extra on choosing from a better range with an 85 °C rating.

I like the ALC/ALS range personally, but there may well be others. See if the vendor will tell you anything about how long you can store the part before the leakage current will typically exceed its rating.

With a class-A SE stage the average supply current is stable, up to the point of non-negligible distortion setting in at higher power.

The averaging is performed by the supply capacitor. The stable-looking DC voltage hides this from a oscilloscope, but the work of the capacitor is not be be overlooked: the capacitor(s) sees a current swing of ca. 2x the idle-current, nominally.

> I think this is the first time I've heard anyone suggest that an electrolytic (of any type) in the PS will outperform a film cap.

A designed-for-audio film cap should really be best, if you can stand the size and cost.

But the cheaper MKPs made for motor applications can be very unpleasant. Think about the construction: a film is sprayed with Aluminium and rolled up. The rolling might be done super-rapidly, to reduce cost, and then the tension is likely to be variable. Now you are liable to find mechanical resonances.

Similarly, when the electrodes are ultra-thin, to save cost, and the termination are made at only one point on the electrode, the inductance can be high enough to introduce electrical resonances.

It's all very variable, but one should not be surprised if bad parts are to be found.

Concerns over lifetime have little to do with risk of outright failures. Rather, it is the fact that the caps degrade, even if unused. high quality parts with pH-neutral electrolytes degrade much slower, and their performance stays stable for longer.

Although electrolytics don't like heat, the self-heating is usually low in valve designs, and more so if a low ESR part is selected. In this case, the extra cost of 105 °C parts does not achieve anything, in typical amp designs - it is better to spend this extra on choosing from a better range with an 85 °C rating.

I like the ALC/ALS range personally, but there may well be others. See if the vendor will tell you anything about how long you can store the part before the leakage current will typically exceed its rating.

Interesting discussion about capacitors. I don't know if I'm reading this correctly, but from what Rod is saying I'm wondering about an ALC/ALS cap as main cap after the bridge, and a more costly designed-for-audio film cap at the end of the chain before the OPT. We haven't talked about the large square paper in oils that turn up in some DIY amps and are getting quite pricey these days for the larger values.

Add yet another "player" to the PSU filter cap. roster. DC link caps. have drawn their fair share of favorable "press".

FWIW, I view with favor using a DC link part in the 1st position of a CLC filter that's being employed in an engineering change from vacuum to SS rectification. See Mike Samra's Heath SA-2, where a truly simple cap. I/P, not Π section of any sort, filter was OEM. An amount of capacitance just sufficient to keep the rail voltage up maximizes conduction angle and allows a bit more current to be squeezed out of the power trafo's rectifier winding. Obviously, TANSTAAFL applies and LOTS of capacitance has to be employed, for both ripple suppression and energy storage, in the reservoir position. The Kemet stuff Mr. Coleman has pointed the community towards is clearly a candidate for the reservoir role. FWIW, I have something like this in mind for the 1st smallish position.

FWIW, I view with favor using a DC link part in the 1st position of a CLC filter that's being employed in an engineering change from vacuum to SS rectification. See Mike Samra's Heath SA-2, where a truly simple cap. I/P, not Π section of any sort, filter was OEM. An amount of capacitance just sufficient to keep the rail voltage up maximizes conduction angle and allows a bit more current to be squeezed out of the power trafo's rectifier winding. Obviously, TANSTAAFL applies and LOTS of capacitance has to be employed, for both ripple suppression and energy storage, in the reservoir position. The Kemet stuff Mr. Coleman has pointed the community towards is clearly a candidate for the reservoir role. FWIW, I have something like this in mind for the 1st smallish position.

DC Link parts like TDK's have design-aim low parasitic inductance, as well as esr, which should make them relatively free of resonances - certainly worth trying.

Andy, if you don't need to try the large-cap solution for bass, you can forget the electrolytics.

But I would expect gains if you use better MKPs at the OT end, and the same, or the DC Link at the rectifier

But I would expect gains if you use better MKPs at the OT end, and the same, or the DC Link at the rectifier

- Home

- Amplifiers

- Tubes / Valves

- Tube rectifier versus 1200v SIC diodes?