Consider the source. Not the non-US poster here, but his link to stackexchange thread that starts "I got shocked" (because the SE poster was ignorant).I was mislead by this statement:

Wikipedia uses "split-phase"; is that more intuitive?

This IS the oldest commercial distribution system, back to Tommy Edison and his DC, we should not be baffled.

3-phase is of course totally different.

Ok I've moved on (I'm the original poster). This thread has gone down a couple or rabbit holes and gotten in the ditch a time or two. 3 phase power was never the subject and is not related to my question. Single phase power is only sort of 1 leg of 3 phase power (did I mention that I'm an engineering manager at an electric utility?). The "2 phase 120" is not just 2 phases of a 3 phase system as that would be nominally 208 since they would be 120 out of phase rather than 180. Here is where we could discuss Y and Delta transformers, but we won't.

Bottom line is, this is one of the most misunderstood subjects, so much so that EVERY internet forum discussion eventually degrades into disagreement. It just isn't as simple as people think it is.

I'm continuing to happily listen to music on my amp plugged into 240ish volts achieved by putting the red leg and the black leg of my home electrical system into a standard 3 pin 220 outlet (no neutral needed for European equipment--oh my, we hadn't even discussed the neutral).

Thanks again for everyone's help but I'm not going to referee the discussion. Good luck, Jerry

Bottom line is, this is one of the most misunderstood subjects, so much so that EVERY internet forum discussion eventually degrades into disagreement. It just isn't as simple as people think it is.

I'm continuing to happily listen to music on my amp plugged into 240ish volts achieved by putting the red leg and the black leg of my home electrical system into a standard 3 pin 220 outlet (no neutral needed for European equipment--oh my, we hadn't even discussed the neutral).

Thanks again for everyone's help but I'm not going to referee the discussion. Good luck, Jerry

Same math. But because our systems are older than good rubber, we like lower voltages.V * SQRT 3

Why is physics in the USA different?

A 3-phase wYe system tapped to give 120V each leg will give 208V between the hot ends of two legs. Root 3.

This was a problem at my school because the photo dept was buying 240V coolers and the electricians were giving them 208. The 208 actually worked fine next door on an electric oven, or downstairs in the pottery kiln--- the elements just took longer to get to heat, or ran a higher duty-cycle to satisfy the thermostat. It's not a major problem for a table-saw (not doing production work). But the Freon pumps would grunt and strain and (after warranty!) fail. And between artists and civil-servant sparkies, it took a while to de-muddy the language gap.

My concern was that there IS a true 2-phase. 90 degree shift. Root-2 between leg-ends. It is not directly more efficient, except that it allows doubling line capacity without discarding existing investment. But it was the original distribution in many areas because it tells motors which way to spin, something any single-phase can't do. Do they no longer teach true 2-phase? Yes, it probably exists only on one corner in the old side of Cleveland, stub bypassed by 3-phase conversion. But a LOT of industry started that way. And some hydrogeneration may still be 2-phase at the core, because at scale it is not that hard to convert to 3-phase with clever tappings.

Thanks for that link PRR. I can't say that I've ever seen or heard of this system in North America.

From reading the Wikipedia link this may be the old biphasé system I knew in France. It was 4 wire, each wire 110V above ground. Metering between the correct 2 legs gave 220V, but between mismatched legs something like 170V. I don't remember the exact voltage.

FWIW, Thomas Edison had an early system in Paris, but I don't know the technical details or dates. The current system counts its origins to 1889, in the Paris Electric Company, now called EDF - Électricité de France.

From reading the Wikipedia link this may be the old biphasé system I knew in France. It was 4 wire, each wire 110V above ground. Metering between the correct 2 legs gave 220V, but between mismatched legs something like 170V. I don't remember the exact voltage.

FWIW, Thomas Edison had an early system in Paris, but I don't know the technical details or dates. The current system counts its origins to 1889, in the Paris Electric Company, now called EDF - Électricité de France.

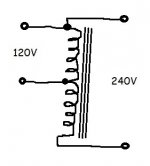

Another update. I finally did receive a 5000W transformer that put out actual European voltages (0, 240V). I ran the amplifier on it for a few hours to confirm there was no difference. I monitored the heat generation and it was the same. I was surprised that I could not tell any difference in the sound. I also monitored current. I was very surprised that current in the line approximately doubled. My amp is 400w load (not output) and with the transformer in the line the load doubled to 800W. The transformer also had an annoying hum--the bigger a transformer gets the more likely it is to hum. Transformer is now gone back and I'm glad the amp works fine on US voltages. --Jerry

Did you measured how much transformer consumed without load ,without amplifier ?My amp is 400w load (not output) and with the transformer in the line the load doubled to 800W.

No, I didn't measure that. I thought about that after I boxed it up but didn't want to unbox it. However the transformer didn't heat up much sitting there plugged in so without load, I think it was not a load itself. But I didn't leave it plugged in and turned on for an extended time.

Sometimes transformers are wound with increased magnetic field , reduced turns count ,increased hum and heat ... In example microwave oven transformers are so ugly ,eating 200W with no load ,even with secondary winding removed .It have about 600-1000w output high voltage ,but if rewound it properly ,according core size ,using calculations ,can output only 70-150W ... Huge difference at cost of complete efficiency loss . Maybe yours 5000w was made using similar strategy ,so i didn't wonder if 400w load doubled - its very possible that it consumes another 400w for core magnetisation ,and for 5000w those 400w is less than 10% loss ,so overall it may have even 90% efficiency .But not for so small loads like yours .

- Home

- Amplifiers

- Power Supplies

- Transformer for a European Amplifier