Power Strip Distributor ATL Hi-Fi PSD-08 Maty's edition

About the star connections, last month he made a power strip to a spanish friend.

Power Strip Distributor ATL Hi-Fi PSD-08 Maty's edition

About the star connections, last month he made a power strip to a spanish friend.

Power Strip Distributor ATL Hi-Fi PSD-08 Maty's edition

The amp is quiet at 110 volts, tolerable at 115, and quite noisy at 120. My line... is 123.6...

Your results support the idea that there was no real problem, just that your amplifier did not have mechanical quietness as a priority when it was built for sound reinforcement.

Which confirms my earlier comments and reassures me - but doesn't help you much.

Can you mount the transformer on a rubber damper pad or similar to help quieten it?

Best wishes

David

DCB proto

Finally, to close the round

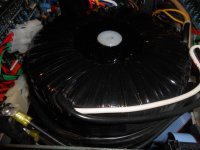

The first DCB "Maty Edition", with EPCOS 15000 microF 85ºC, aka prototype.

Without clarified the photo is dark.

The second DCB was build with EPCOS 18000 microF 105ºC and the sound is better than the proto. Trust me, they are expensive (€12.5 + tax) but the improvement in sound justifies the premium. Well, if you have more DC and ripple.

The big capacitors are glued to PCB in all "M E".

By the way, Aleksandar is well known at Bulgarian DIY community and has more designs than you can see at the eBay page.

Finally, to close the round

The first DCB "Maty Edition", with EPCOS 15000 microF 85ºC, aka prototype.

Without clarified the photo is dark.

The second DCB was build with EPCOS 18000 microF 105ºC and the sound is better than the proto. Trust me, they are expensive (€12.5 + tax) but the improvement in sound justifies the premium. Well, if you have more DC and ripple.

The big capacitors are glued to PCB in all "M E".

By the way, Aleksandar is well known at Bulgarian DIY community and has more designs than you can see at the eBay page.

Last edited:

Hey maty, please, I'm feeling uncomfortably after so much superlatives

Andrew, if you ask about the blue "things", they are standard spade tongue terminals like this one: 165012 - TE CONNECTIVITY / AMP - TERMINAL, SPADE TONGUE, 16-14AWG | Farnell element14 ????????

Regards

Alex

Andrew, if you ask about the blue "things", they are standard spade tongue terminals like this one: 165012 - TE CONNECTIVITY / AMP - TERMINAL, SPADE TONGUE, 16-14AWG | Farnell element14 ????????

Regards

Alex

I was hoping Maty could tell us that the spades were NOT metal and that they did NOT carry Mains voltage.

The pics of the other receptacles do not have similar pointy bits.

The pics of the other receptacles do not have similar pointy bits.

The amp is quiet at 110 volts, tolerable at 115, and quite noisy at 120. My line voltage is 123.6 this morning.

Regardless of what the spec sheet says ( 100 to 240 VAC), the sticker on the amp says 120 VAC. With careful inspection of the transformer, I have accounted for all the leads, and I can see only 2 wires for the primary, so I don't think it has been set up on a 100 Volt tap.

I may still attempt to measure the B + Voltages, but my feeling is that operating the amp at a line voltage which does not produce buzz, will compromise performance.

Hi Peter,

There you have it....

You can custom order a stepdown Autoformer set to 115~117Vac from 124Vac. It should not be too expensive, and if it`s twice powerful as the amp, it would not degrade performance. Besides, this stepdown may prove useful for your future amps as well...

Yuval.

Variac "Maty Edition"

Or a good -no chinese- variable transformer (variac) with own voltmeter (output), slow fuse, varistor... maybe with DCB too .... like I was thinking to me if the DCBx4 does not satisfy 100%.

I spent weeks hesitatin about what should come first but after that Friday which forced me to try with four DCB I had no doubt.

And then a new, maybe, very good DIY amplifier immune to my main problems.

Or a good -no chinese- variable transformer (variac) with own voltmeter (output), slow fuse, varistor... maybe with DCB too .... like I was thinking to me if the DCBx4 does not satisfy 100%.

I spent weeks hesitatin about what should come first but after that Friday which forced me to try with four DCB I had no doubt.

And then a new, maybe, very good DIY amplifier immune to my main problems.

Last edited:

If you step down the voltage by 10% the theory says you should loose 19% of the power. That actually will barely matter. The loss will be less as the BH loop of the transformer's core is already reducing the peak voltage.

So to make the noise go away use a 12 volt transformer in auto transformer mode to drop the line voltage. It probably doesn't need to handle maximum current draw, just close to it.

So to make the noise go away use a 12 volt transformer in auto transformer mode to drop the line voltage. It probably doesn't need to handle maximum current draw, just close to it.

Just make sure the 12V transformer isn't also a source of noise. Something designed for a battery charger might buzz even more than the toroid in the amplifier. I would suggest a 240:24V transformer run off 120 to give 12 volts. That will be damn quiet, even if it's noisy at full primary voltage. 20 amp current rating will probabaly suffice.

I wonder also. Can anybody give me a trustworthy explanation?Hi maty; Could you explain what the purpose of the 33 ohm resistor is. Can you do with out it? Does it not tend to defeat the purpose- pass DC?

Also, why does your filter go from pin 1, on input, to pin 3 of the output ?

Just make sure the 12V transformer isn't also a source of noise. Something designed for a battery charger might buzz even more than the toroid in the amplifier. I would suggest a 240:24V transformer run off 120 to give 12 volts. That will be damn quiet, even if it's noisy at full primary voltage. 20 amp current rating will probabaly suffice.

If you wire it as an autotransformer then the secondary will also take the primary voltage down! So it should not buzz.

This will do it 1182T12 Hammond Manufacturing | Mouser

If the transformer works properly from 110VAC but not the 123VAC that you have, and the transformer is sealed so adding primary turns is not an option, then perhaps there is the possible option of using a smaller second transformer to buck the line voltage to the primary of the toroid transformer down to 110VAC. Find an old junker transformer that is 12-15VAC secondary with a current rating greater than the primary current rating of the toroid and connect the secondary in series with the toroid primary but in opposite phase to the line. Also include the DC filters because this is important too. Because the toroid is so large, this second transformer would be fairly large and need to be in an enclosure and properly isolated. This is the same principle as using a transformer to boost the voltage to something like a sump pump motor that is on a long wire with a voltage drop and would end up running low volts.......very bad for induction motors.

as is running high volts to a toroid transformer.

Over all power efficiency of the transformers may go down a bit but this is still better than a damn buzzing transfo.

as is running high volts to a toroid transformer.

Over all power efficiency of the transformers may go down a bit but this is still better than a damn buzzing transfo.

Attachments

Last edited:

Take a look at this data sheet, the Hammond 168 Series, the last one on this document.

It`s a multiple input output Autotransformer for making line voltage adjustments in small steps, Up or down in the 125VAC to 85VAC range...

Not inexpensive, but may be useful in the long run.

http://www.hammondmfg.com/pdf/5c0073.pdf

Enjoy..

It`s a multiple input output Autotransformer for making line voltage adjustments in small steps, Up or down in the 125VAC to 85VAC range...

Not inexpensive, but may be useful in the long run.

http://www.hammondmfg.com/pdf/5c0073.pdf

Enjoy..

Last edited:

Hi Guys;

Thanks David, regarding isolation mounts for the toroid, I believe the noise is airborne, from the windings and not coming from the (nylon) core which is bolted to the cabinet. I have this overwhelming urge to inject some kind of (varathane) under those plastic tap wrappings, (see attached picture).

Can you or anyone let me know if this could be detrimental? (other than a waste of time)

I could imagine that if the windings were completely immersed in varathane, there could be some cooling issues(?)

I realize it could take some weeks to dry (lack of air in the crevices) I could elevate the temperature somewhat, but I do not want to distort the plastic connectors etc.

Also, is there a concern that the varathane could dissolve the existing insulation on the windings?

I was told that 'air tight' is sound proof. My thinking is to lock all those windings together in an airtight mass of varathane. my 'stethoscoping' is pointing me to the heavy gauge windings. If the inner iron core laminations were the source, I have a strong feeling that would also be transmitted, to some degree, to the centre mounting core.

I realize this horse is beyond beaten, It's 'fubar'ed, but thanks for all your help.

Regarding the auto transformer configuring; The Crest has a max primary current of 36 amps, (at least 15 amps in my set-up; stereo-8 ohms, not bridged) If I used a 12 transformer in the auto trans configuration, wouldn't the primary AND secondary of this additional transformer have to carry at least 15 amps?

Thanks David, regarding isolation mounts for the toroid, I believe the noise is airborne, from the windings and not coming from the (nylon) core which is bolted to the cabinet. I have this overwhelming urge to inject some kind of (varathane) under those plastic tap wrappings, (see attached picture).

Can you or anyone let me know if this could be detrimental? (other than a waste of time)

I could imagine that if the windings were completely immersed in varathane, there could be some cooling issues(?)

I realize it could take some weeks to dry (lack of air in the crevices) I could elevate the temperature somewhat, but I do not want to distort the plastic connectors etc.

Also, is there a concern that the varathane could dissolve the existing insulation on the windings?

I was told that 'air tight' is sound proof. My thinking is to lock all those windings together in an airtight mass of varathane. my 'stethoscoping' is pointing me to the heavy gauge windings. If the inner iron core laminations were the source, I have a strong feeling that would also be transmitted, to some degree, to the centre mounting core.

I realize this horse is beyond beaten, It's 'fubar'ed, but thanks for all your help.

Regarding the auto transformer configuring; The Crest has a max primary current of 36 amps, (at least 15 amps in my set-up; stereo-8 ohms, not bridged) If I used a 12 transformer in the auto trans configuration, wouldn't the primary AND secondary of this additional transformer have to carry at least 15 amps?

Sometimes I get an idea in my head that I can't shake, until the authorities step in.

My considered plan is to fill a syringe, fitted with a plastic straw (from a wd-40 can etc) with varathane (or something) and inject it between the plastic wrappings of the toroid windings. The toroid wound be removed from the amp, of course. It looks like it would be easy to get the thin tube between the plastic wrappings (see attachment)

Could this damage the toroid in any way?

Thanks again for all your patience and advice.

My considered plan is to fill a syringe, fitted with a plastic straw (from a wd-40 can etc) with varathane (or something) and inject it between the plastic wrappings of the toroid windings. The toroid wound be removed from the amp, of course. It looks like it would be easy to get the thin tube between the plastic wrappings (see attachment)

Could this damage the toroid in any way?

Thanks again for all your patience and advice.

Attachments

...I believe the noise is airborne...

I expect there is airborne noise, but often it is made worse if the vibrations can use a flat plate as a sound board. Maybe you could unbolt temporarily and place it on a resilient pad as a test.

Some transformer manufacturers do essentially this as an option....inject some kind of (varathane) under those plastic...

Can you or anyone let me know if this could be detrimental? (other than a waste of time)...

It is not practical to use a solvent based varnish, they often use a lowish temperature heat-set resin, infused under vacuum.

No solvent or excessive heat to cause problems and the thermal properties may even improve, resin is probably not as bad as air.

You may be able to find a transformer manufacturer to do this, shouldn't be too expensive, perhaps Plitron in Canada?

Best wishes

David

You could, of course, try to vacuum infuse the tranny yourself.

I haven't tried this yet but a small vacuum system doesn't look difficult, so it's on my list.

The best low viscosity, solvent free resin is probably an epoxy.

Last edited:

Hi everyone and thanks again.

I started the amp with the variac. The (1 amp FSD) meter was pegged as I ramped up the voltage. BTW, the 'fact' sheet mentioned that the amp draws 3 amps idling.

The amp is quiet at 110 volts, tolerable at 115, and quite noisy at 120. My line voltage is 123.6 this morning.

Regardless of what the spec sheet says ( 100 to 240 VAC), the sticker on the amp says 120 VAC. With careful inspection of the transformer, I have accounted for all the leads, and I can see only 2 wires for the primary, so I don't think it has been set up on a 100 Volt tap.

I may still attempt to measure the B + Voltages, but my feeling is that operating the amp at a line voltage which does not produce buzz, will compromise performance.

PS; I have seen the clip light flash several times with some Steely Dan. I am addicted to bass, and the system has not been properly EQ'd for some time, but this is a topic for another thread.

That is a huge toroid to be operating from 120V mains. A real 'light dimmer' for sure. 😛 I may have missed somewhere in the thread the mention of needing a dedicated circuit to run this thing at full power... a 30A breaker!!😱 House wiring in the Great White North should be similar to down here further south and are typically wired 120V split phase, 20A breaker/12ga Romex. It would be prudent to either limit the power draw or add a dedicated circuit to the amp with 30A breaker/10ga Romex, the stuff you use to wire up say, a clothes dryer.🙂

However, in the case of using a bucking transformer, it would need to have at least 30A secondary rating but at only 12V, which is 360VA. Big transformer out of an old car battery charger or something similar from a dumpster diving adventure. Two equal 6V transformers of current rating in series would even work. Or you could buy one......

. I wouldn't but just because I'm a cheapskate😀 For 12V secondary, the primary of the bucking transformer would conduct 3A from the mains at full power. n=120V/12V=10. 30A/10=3A. When the amp is at idle, the toroid primary current is 3A which is in series with bucking transformer secondary, so bucking transformer primary current would be 3A/10=300mA. To buck 9V off of the mains would only be 270VA, and for 15V would be 450VA. The more you buck from the line, the more efficiency you loose, but since you are only a few volts off, you shouldn't loose that much in wasted transformer heat. Besides, isn't winter setting in up there by now?😀

. I wouldn't but just because I'm a cheapskate😀 For 12V secondary, the primary of the bucking transformer would conduct 3A from the mains at full power. n=120V/12V=10. 30A/10=3A. When the amp is at idle, the toroid primary current is 3A which is in series with bucking transformer secondary, so bucking transformer primary current would be 3A/10=300mA. To buck 9V off of the mains would only be 270VA, and for 15V would be 450VA. The more you buck from the line, the more efficiency you loose, but since you are only a few volts off, you shouldn't loose that much in wasted transformer heat. Besides, isn't winter setting in up there by now?😀This really is a job where 240V mains is more apt. 🙄

Last edited:

I would let go of the urge to do DIY 'varnish injection', esp since somebody used the potting in the middle which is now working against any/all of your efforts. chances are the laminations are buzzing against one another so a real vacuum and fully curing Eg pro solution might not even help /but no guarantees offered from anyone im sure.

1) XFMR transplant

2) sell it and move on

Nelson Pass has spoken about these issues > has incoming inspection power them up and he sends the rejects back to the OEM based on their purchase agreements.

1) XFMR transplant

2) sell it and move on

Nelson Pass has spoken about these issues > has incoming inspection power them up and he sends the rejects back to the OEM based on their purchase agreements.

Last edited:

- Status

- Not open for further replies.

- Home

- Amplifiers

- Solid State

- Toroidal Transformer Noise