sir tony anu po ginamit nyo na electrostic shield na gamit nu???

😀

mods will probably react, this is an english speaking thread.....

i used copper sheet for electrostatic shielding, in other traffos i have dismantled, single layer copper coils were used......😀

Last edited:

damn that is nice trafo, nice finish!

thanks Luka, i must grive credit to YvesM, i first saw him did this although on smaller traffos.....this one has a 2inch center leg, so i guess this is pretty much justified....😀

thank.

thank sir tony. maybe the mod wont mind it. some are speaking there home language once in a while. you think could i use aluminum foil used in wrapping food?

thank sir tony. maybe the mod wont mind it. some are speaking there home language once in a while. you think could i use aluminum foil used in wrapping food?

yes, i used aluminum duct tapes on some occasions......just make sure you don't create shorted turns.....

sir what is the largest EI core can i find at deeco.?

do they have a 3 inch tounged E core?

the biggest core available at Deeco is 2inches....anything bigger than that youhave to go to Evangelista Street and try your luck there....

last time i was there they had 40kgs of 2 1/2 inch cores.....

the largest core i've used is a 2 1/4 inch core....

^i was at Raon/Evangelista this morning.......i was told by Marlon that he has 50kg stock of 3inch center leg cores....they are located opposite the Bearing center in Evangelista street.

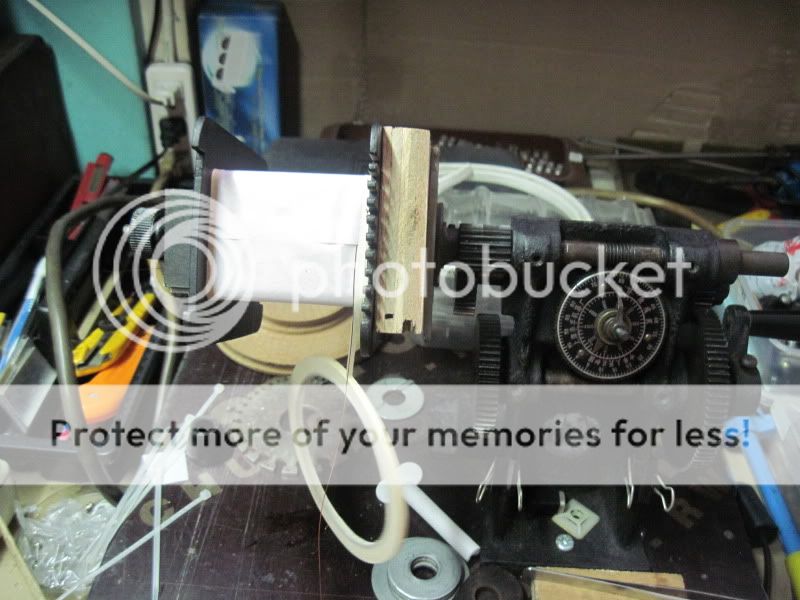

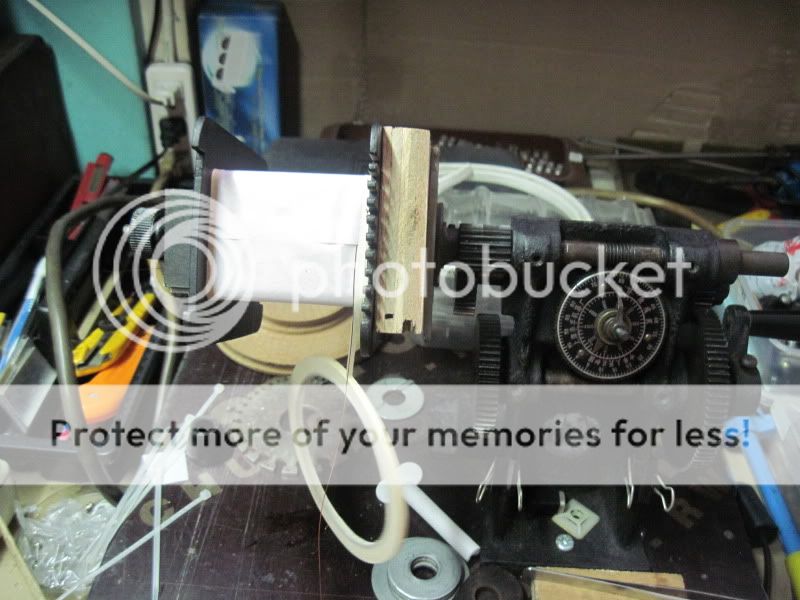

wooden mandrels:

i have bobbins for 1 3/4 and 1 1/2 inch cores, so to facilitate winding, i made some wooden mandrels...

i have bobbins for 1 3/4 and 1 1/2 inch cores, so to facilitate winding, i made some wooden mandrels...

Attachments

Wow very impressive transformers! Thanks for the great photos. I find this idea of making your own transformers very intriguing. That winding device looks very interesting.. I see there is a counter to keep track of the number of turns. I would really love to see a video of the winding process in action!

I would also like to learn how to construct my own transformers as well. I am wondering if it's practical to wind a transformer with 4 secondary windings, say two 12v @ 100mA for an op-amp preamp with split power supply and two 30v @ 2.5A for a power amp with split supply. This just for example, I haven't worked out the exact voltage and current requirements yet... but I'm wondering if it's a good idea or not to use one transformer to run both sets of power supplies. I am thinking I would regulate at least the preamp supplies.

I would also like to learn how to construct my own transformers as well. I am wondering if it's practical to wind a transformer with 4 secondary windings, say two 12v @ 100mA for an op-amp preamp with split power supply and two 30v @ 2.5A for a power amp with split supply. This just for example, I haven't worked out the exact voltage and current requirements yet... but I'm wondering if it's a good idea or not to use one transformer to run both sets of power supplies. I am thinking I would regulate at least the preamp supplies.

output trafo winding turns?

Hi sir Tony and brilliant trafo guys here....need your help please...

I'm really obsessed in building one small tube PP amp using russian 6P3S-E (6L6 equiv) but my biggest problem is the output trafo. I have 2 1x1 sq inch trafo to wind but i hardly can't calculate how much turns in the primary and on the 8/16 ohm output. I don't know how much wattage it can handle on 8 ohms using 320v Plate voltage (main trafo specs is 240v/200VA). Can you help me out. I'm confused on reading some references on the net.

I am new to winding output trafo, if you can give some simplified calculations maybe i can give a try and I will appreciate it very much..

Hi sir Tony and brilliant trafo guys here....need your help please...

I'm really obsessed in building one small tube PP amp using russian 6P3S-E (6L6 equiv) but my biggest problem is the output trafo. I have 2 1x1 sq inch trafo to wind but i hardly can't calculate how much turns in the primary and on the 8/16 ohm output. I don't know how much wattage it can handle on 8 ohms using 320v Plate voltage (main trafo specs is 240v/200VA). Can you help me out. I'm confused on reading some references on the net.

I am new to winding output trafo, if you can give some simplified calculations maybe i can give a try and I will appreciate it very much..

^hi, the 6L6 tube likes 6.6k anode to anode loads....at that B+ of 320 volts, 15 to 20 watts in class ab1 is possible....

^hi, the 6L6 tube likes 6.6k anode to anode loads....at that B+ of 320 volts, 15 to 20 watts in class ab1 is possible....

Thanks sir fo the info....the 6.6k is the total impedance or center tap output (3.3k +3.3k) is that right sir? At what core area must be the proper output trafo and i need to know how many turns the primary and secondary ...if you mine sir? thanks

sir tony,

can pls help me out?

i want to wind my own traffo for H900

80-40-0-40-80 20 amper.

can u pls tell me about EI core size,bobin size, and also a copper wire guege,turns of primery,n also the sec. tapping.

can pls help me out?

i want to wind my own traffo for H900

80-40-0-40-80 20 amper.

can u pls tell me about EI core size,bobin size, and also a copper wire guege,turns of primery,n also the sec. tapping.

sir tony,

can pls help me out?

i want to wind my own traffo for H900

80-40-0-40-80 20 amper.

can u pls tell me about EI core size,bobin size, and also a copper wire guege,turns of primery,n also the sec. tapping.

sure, what EI core are you using and what it the grade? note also that in your country you use the British standards wrt wire sizes...what power are you expecting to achieve?

Hi all,

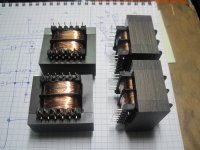

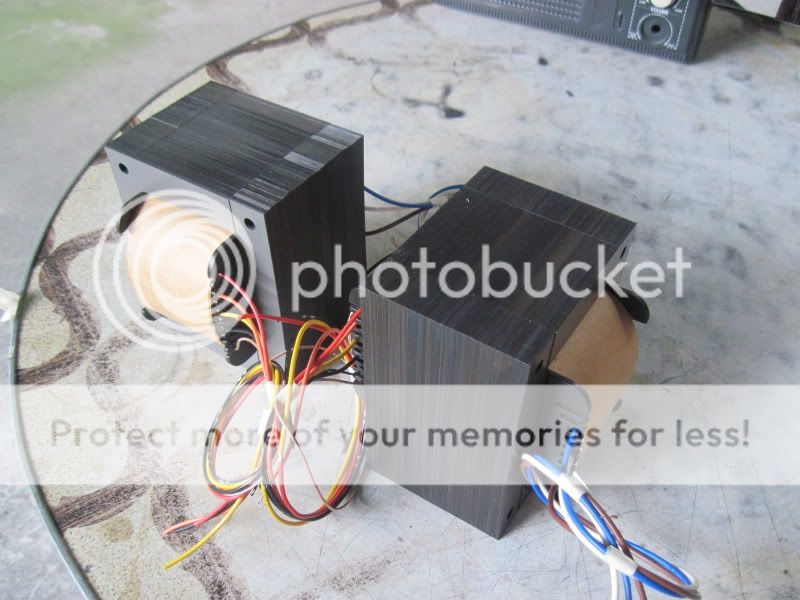

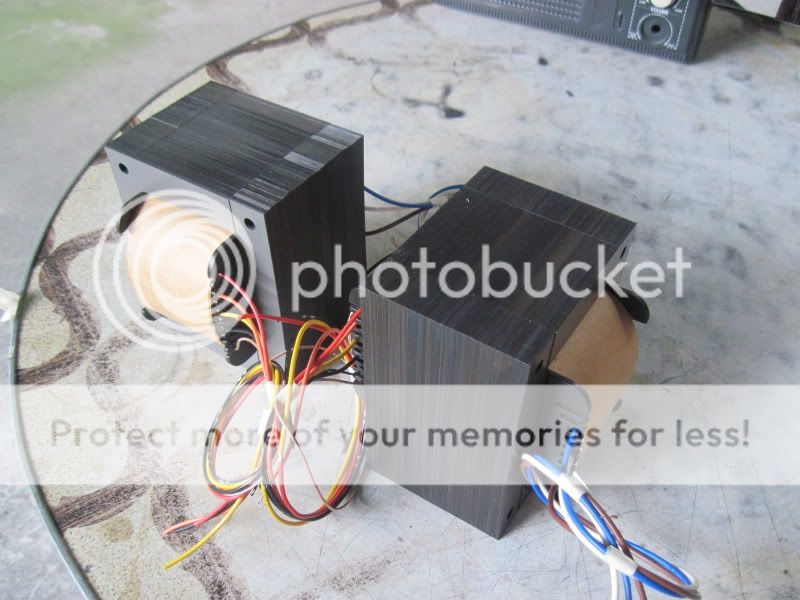

these are 2 OPT's for a tube amp i am building, it has a 1.75in center leg stacked to 3.125inches, using Edrel's Z11(M6) cores.....

finally put to use, to give you an idea, the core is about 15kg at P500 per kilogram and copper at about 2.5kgs at about P700 per kilo......

bobbins used also supplied by Edrel and is nylon type.....

the use of wooden mandrels allowed me to wind the coils in sections, winding one coil after the other to avoid errors and ensure identical traffo build...

materials used includes:

Kapton tape, polypropylene plastic inter-layer insulation, 1/8 inch masking tapes to provide additional creapage distance:

one of 4 primary coils and 1 of 4 secondary coils done:

winding the rest of the coils

stacking the E and I's to complete the build up:

these are 2 OPT's for a tube amp i am building, it has a 1.75in center leg stacked to 3.125inches, using Edrel's Z11(M6) cores.....

finally put to use, to give you an idea, the core is about 15kg at P500 per kilogram and copper at about 2.5kgs at about P700 per kilo......

bobbins used also supplied by Edrel and is nylon type.....

the use of wooden mandrels allowed me to wind the coils in sections, winding one coil after the other to avoid errors and ensure identical traffo build...

materials used includes:

Kapton tape, polypropylene plastic inter-layer insulation, 1/8 inch masking tapes to provide additional creapage distance:

one of 4 primary coils and 1 of 4 secondary coils done:

winding the rest of the coils

stacking the E and I's to complete the build up:

- Home

- Amplifiers

- Power Supplies

- Tony's latest traffo DIY build