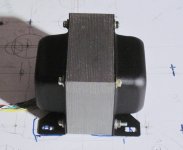

hard to tell from pictures alone....when i am unsure of the core on hand i assume they are noss....

goss are ussually 0.35mm or thinner and are also pin striped...

goss are ussually 0.35mm or thinner and are also pin striped...

I will use some steel wool to remove the coating on this one lamination and see what is underneath.

I am really unsure now what thickness they are. I ran a few tests with my caliper. On a piece of standard printer paper I was getting between .22 and .09 for thickness. Each time I turned it off, turned it on, then zero'ed it, I would get something completely different measuring the same piece of paper in the same place.

I am really unsure now what thickness they are. I ran a few tests with my caliper. On a piece of standard printer paper I was getting between .22 and .09 for thickness. Each time I turned it off, turned it on, then zero'ed it, I would get something completely different measuring the same piece of paper in the same place.

definitely not pin striped, but it is silicone steel. So noss it is then. I guess these will make good chokes and power transformers.

I will use some steel wool to remove the coating on this one lamination and see what is underneath.

I am really unsure now what thickness they are. I ran a few tests with my caliper. On a piece of standard printer paper I was getting between .22 and .09 for thickness. Each time I turned it off, turned it on, then zero'ed it, I would get something completely different measuring the same piece of paper in the same place.

hi lexx21

may i just suggest a little u may have relied on your caliper i think it was digital type just do it manually coz for me i always use the manual and digital to be sure.

i would suggest you clean atleast 10 pcs of it joined then make the measurement if 10pcs will have thickness of 3.5mm divide by 10, thus your core thickness was 0.35mm per piece.

same as if 10pcs. will have 5mm thick then divide 10 that is 0.5mm per piece.

i hope that helps.

One of my next purchases will be a good caliper. Good idea though. What I am finding with my caliper is that accuracy falls when you get to the right of the decimal point. I think a good metric dial caliper is in order.

rewinding machine from Pakistan, thanks to Norman Santos.......note the 13mm shafting compared to the 10 mm of the china rewinder...

the shaft can carry heavier coils....

Guess you still need individual prismatic mandrels for each bobbin?

Best regards!

Guess you still need individual prismatic mandrels for each bobbin?

Best regards!

yes. i am making several more wooden manrels for 2 1/4 to 3 inch center leg cores...

rewinding machine from Pakistan, thanks to Norman Santos.......note the 13mm shafting compared to the 10 mm of the china rewinder...

the shaft can carry heavier coils....

...wish i can have one...😉

sorry. i have no links.....

that rewinder was a gift to me by Norman working in the middle east,

that rewinder was a gift to me by Norman working in the middle east,

- Home

- Amplifiers

- Power Supplies

- Tony's latest traffo DIY build