Been looking around for refences to testing one can do on a tonearm and drawn a blank, so thought time for a thread on it. I have to admit that I'd never really worried about this until I started getting angst over the (very nicely made) stock arm on my KD-550 second turntable. Japanese S-arms with detachable headshells had a bad press in the 90s, so I had always considered it a step below the straight one piece arms that became vogue. Then I inherited the KD-550 when my father gave up vinyl...

So what can one measure, what should one measure, and what can you do about it? My initial thoughts were

1. Bearing friction/cable snagging over operating arc

2. Resonant modes

3. Damping of said modes.

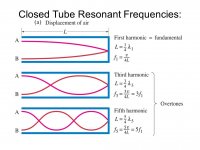

Of these only the resonant modes seems to be covered with the sort of test suite (test record) that we have as you should be able to see anomalies in a frequency sweep. If this is indeed the case then there is the question of where they are occuring to damp them. In a straight tube this should be easy as will effectively be pipe modes, but in a J or S arm with an SME connector at one end it may be a little harder.

For damping you need some sort of chirp test, which isn't on test records so you need to find another stimulus method. I've never seen a waterfall plot for a tonearm, so I assume this is either considered not important or non-trivial.

I've also been looking at accelerometer options but not found anything small enough to tape onto a tube.

So what can one measure, what should one measure, and what can you do about it? My initial thoughts were

1. Bearing friction/cable snagging over operating arc

2. Resonant modes

3. Damping of said modes.

Of these only the resonant modes seems to be covered with the sort of test suite (test record) that we have as you should be able to see anomalies in a frequency sweep. If this is indeed the case then there is the question of where they are occuring to damp them. In a straight tube this should be easy as will effectively be pipe modes, but in a J or S arm with an SME connector at one end it may be a little harder.

For damping you need some sort of chirp test, which isn't on test records so you need to find another stimulus method. I've never seen a waterfall plot for a tonearm, so I assume this is either considered not important or non-trivial.

I've also been looking at accelerometer options but not found anything small enough to tape onto a tube.

I've also been looking at accelerometer options but not found anything

small enough to tape onto a tube.

Arm tests

Last edited:

Problem I see with that is you are measuring what is going on but not where. Maybe that is all we have to work with.

I also wonder about the modes they show* as I am sure I saw an analysis somewhere on pipe modes that showed that the dominant mode has two maxima along the tube (hence why audiomods put two reinforcing washers in their RB300. As usual I didn't save the link.

*They claim on their graph a main mode of 280Hz but a hoofing great peak at 4x that frequency. I assume they mean 'first mode' in which case the 4th harmonic does matter as per audiomods

Maybe George's accelerometer interface setup would work. I worry about the added mass.

I also wonder about the modes they show* as I am sure I saw an analysis somewhere on pipe modes that showed that the dominant mode has two maxima along the tube (hence why audiomods put two reinforcing washers in their RB300. As usual I didn't save the link.

*They claim on their graph a main mode of 280Hz but a hoofing great peak at 4x that frequency. I assume they mean 'first mode' in which case the 4th harmonic does matter as per audiomods

Maybe George's accelerometer interface setup would work. I worry about the added mass.

Measuring Unipivot Tonearms would be interesting. Specially torsional movements and designs that damp/resist it. I like design of Morgan Jones DIY Tonearm very much.

Regards

Regards

Thanks for the link. Very interesting. Shame they seem to be making the usual errors about compliance, although that is forgivable given the definitions are lost in the mists of time. I shall read, digest and consider.

Last edited:

My compliments, very interesting and at the same time showing how careful one should be to come to conclusions.

Measuring and listening are in many cases leading to different results.

Trying to "fit" the measured- onto the auditory results seems the way to go just until some impossible result knocks the theory completely to the ground.

But very instructive is to read how the design of an arm can largely affect reproduced sound.

Hans

It also shows how much misunderstanding there is about CLD!

But nonetheless a fine starting point for me. Affordable accelerometers is the next challenge. Anyone know if there are Mems setups accurate enough? A 3-axis measurement would be a nice uplift in measurement capability, if only to prove it might not be needed 🙂

But nonetheless a fine starting point for me. Affordable accelerometers is the next challenge. Anyone know if there are Mems setups accurate enough? A 3-axis measurement would be a nice uplift in measurement capability, if only to prove it might not be needed 🙂

It is interesting, and thoughtful, thank you jcarr for bring it to our attention. Adds some fuel to the fire surrounding my current unease with vinyl playback in general, and the fact that we probably understand a good deal less than we think.

I read a couple of entries in the blog, and signed up.

Dave and Bill both know more or less where I'm at. 😀

I read a couple of entries in the blog, and signed up.

Dave and Bill both know more or less where I'm at. 😀

Me? Surely not 🙂. I just remain amazed that vinyl works at all. Let's face it, if you gave a group of engineers the challenge of retrieving microscoping information from grooves who had never seen a record player they would probably come up with something that looked more like a lathe than what we recognise as turntable.

On the cycle home I was mulling the bearing resonances measured, mainly because it could end up costing me money. The SME damper actually bolts to the bearing housing so it damping at the bearings. This means it could have influence beyond taming the arm/cart resonance. But I doubt anyone has measured that.

I should also note in the ongoing 'do MC put more energy into the arm' debate I have a shure SC35C weighing in for the MM side. 4-5g VTF and 5cu compliance. I bought it as much as anything to see if I could tame it 🙂

On the cycle home I was mulling the bearing resonances measured, mainly because it could end up costing me money. The SME damper actually bolts to the bearing housing so it damping at the bearings. This means it could have influence beyond taming the arm/cart resonance. But I doubt anyone has measured that.

I should also note in the ongoing 'do MC put more energy into the arm' debate I have a shure SC35C weighing in for the MM side. 4-5g VTF and 5cu compliance. I bought it as much as anything to see if I could tame it 🙂

Interesting measurements. I wonder how this translates to audibility. I know some arm effects as eg here

New Lamps for Old

I also have a slight peak around 350-370 Hz in my Moerch UP-4 but it is just above the background noise and no effect on the fr response.

New Lamps for Old

I also have a slight peak around 350-370 Hz in my Moerch UP-4 but it is just above the background noise and no effect on the fr response.

Re-reading the articles by Morgan Jones on the making of his tonearms he also needs the 4th mode of the armtube as the potentially problematic one. He had found that a strip of electrical tape around the tonearm at the resonant Maxima was enough to damp things.

As to where these maxima are it appears to be 5th harmonic. as the tube is effectively 'closed' by the bearings. This leads to the question, if you have a townsend style damping trough at the front is that enough to make the armtube appear as a closed pipe? I suspect it might.

As to where these maxima are it appears to be 5th harmonic. as the tube is effectively 'closed' by the bearings. This leads to the question, if you have a townsend style damping trough at the front is that enough to make the armtube appear as a closed pipe? I suspect it might.

Attachments

Few more titbits from past

Deck Vibrations And Tone Arms - Vinyl Engine

One of LDs early attempts to look at this

Flat Tonearm on a NAD 5120 - Vinyl Engine

An interesting section in here on the ill fated NAD 5120 floppy tonearm. Interesting mainly because on the Korf blog they are experimenting with flexure bearings and the NAD floppy tonearm was effectively a large flexure bearing.

Deck Vibrations And Tone Arms - Vinyl Engine

One of LDs early attempts to look at this

Flat Tonearm on a NAD 5120 - Vinyl Engine

An interesting section in here on the ill fated NAD 5120 floppy tonearm. Interesting mainly because on the Korf blog they are experimenting with flexure bearings and the NAD floppy tonearm was effectively a large flexure bearing.

I suspect the 'do MC put more energy into the arm' debate is diverting our attention from the real issues. The more accurate question would be "do low compliance cartridges with lots of stylus suspension damping put more energy into the arm"? The only work a 1mg effective mass stylus should be called upon to do is move the active element enough to generate a millivolt or few of signal. It shouldn't be putting any excess energy into the arm at all. I look forward to seeing your experimentation results with the SC35C.I should also note in the ongoing 'do MC put more energy into the arm' debate I have a shure SC35C weighing in for the MM side. 4-5g VTF and 5cu compliance. I bought it as much as anything to see if I could tame it 🙂

Ray K

I look forward to finding time to complete the groundwork to start this. As you know it is much easier to collect projects than to finish them 🙂. But I have examples of tonearms and cartridges from low compliance and heavy to high compliance and very light. Around a 7:1 ratio between extremes. I am hoping to eventually find out that it doesn't matter as long as you optimise accordingly.

Bill. I had this thread re-opened as I'm in process of designing a new tonearm and was wondering if you devised or came across a methodology to test tonearm modes without using an accelerometer??

Wow, never seen this one. Very useful links here. Especially now when so many tonearms are NLA. I am surprised that RB300 is not that bad at all!

- Home

- Source & Line

- Analogue Source

- Tonearm testing