Yeah, she's definitely the real deal. No question. And guys, when I take over the world, you all have first dibs on "henchman."

One MILLyun dollars.

Dave

One MILLyun dollars.

Dave

If I get snappy hand tailored suits along with the title of "Henchman", it's a deal.

Eagerly awaiting news of your adventures with the Bandsaw.

Eagerly awaiting news of your adventures with the Bandsaw.

opportunity missed

The thing about using another guy's tools is that he won't let you touch 'em. I think he was ticked that his wife had volunteered his tools like that, so...

He wouldn't bother to let me explain the concept to him (oh, he didn't have no stinking bandsaw, either. It was a nice 12" miter saw, though), and as soon as he learned that we were going to have to try to cut the pipe from both sides, he just bluntly said, "Oh, we can't do that!" Before I had a chance to actually explain how it WAS possible without just guessing, he had the saw unplugged and was vacuuming the PVC chips we had made.

Man, he didn't even line the thing up or use a miter box of sorts or anything. I'm very disappointed. You guys have definitely spoiled me.

Dave

Back to the miter box.

The thing about using another guy's tools is that he won't let you touch 'em. I think he was ticked that his wife had volunteered his tools like that, so...

He wouldn't bother to let me explain the concept to him (oh, he didn't have no stinking bandsaw, either. It was a nice 12" miter saw, though), and as soon as he learned that we were going to have to try to cut the pipe from both sides, he just bluntly said, "Oh, we can't do that!" Before I had a chance to actually explain how it WAS possible without just guessing, he had the saw unplugged and was vacuuming the PVC chips we had made.

Man, he didn't even line the thing up or use a miter box of sorts or anything. I'm very disappointed. You guys have definitely spoiled me.

Dave

Back to the miter box.

Methinks you might have walked into the middle of a family quarrel. Consider yourself lucky to have escaped physically intact. 😀 😀

Back to the box.

Back to the box.

Official update

Our offense is really clicking now. I've got a pretty good system going where I cut a piece, measure the long side, then turn 11°. After that I find the 90° point on the pipe so that my saw cuts at precisely that point. Then I eyeball the long-side measurement into the jig guide, carefully adjust till I have it at exactly perpendicular using the 90° mark, then start sawing.

I've cut two pieces perfectly (give or take less than a 16th!), hitting all my marks precisely.

I would use the 5.5° thing, but I didn't want to spend more time cutting another jig.

There won't be any photos tomorrow. I was so mad at that guy I had to stop and cool off (I cut my finger on the saw being stoopid mad, tho not bad a bad cut or anything, just drew some blood), so I have a grand total of 2 pieces.

I wasted the day lugging PVC pipe all over South St. Louis, so I can't get enough done to warrant putting together a pipe.

Anyway, I could use a Boddington's and Law and Order is on, so I'll check back in a few.

We're almost there!

Dave

* * EDIT * *

NOOOOOOO! Law and Order comes on an hour earlier on Sundays!

Our offense is really clicking now. I've got a pretty good system going where I cut a piece, measure the long side, then turn 11°. After that I find the 90° point on the pipe so that my saw cuts at precisely that point. Then I eyeball the long-side measurement into the jig guide, carefully adjust till I have it at exactly perpendicular using the 90° mark, then start sawing.

I've cut two pieces perfectly (give or take less than a 16th!), hitting all my marks precisely.

I would use the 5.5° thing, but I didn't want to spend more time cutting another jig.

There won't be any photos tomorrow. I was so mad at that guy I had to stop and cool off (I cut my finger on the saw being stoopid mad, tho not bad a bad cut or anything, just drew some blood), so I have a grand total of 2 pieces.

I wasted the day lugging PVC pipe all over South St. Louis, so I can't get enough done to warrant putting together a pipe.

Anyway, I could use a Boddington's and Law and Order is on, so I'll check back in a few.

We're almost there!

Dave

* * EDIT * *

NOOOOOOO! Law and Order comes on an hour earlier on Sundays!

Kneadle:

You have cable? Law and Order is on about 12 times a day.

I love the show myself. Sure, it's addictive, but fortunately you are never more than an hour away from a fix.

You have cable? Law and Order is on about 12 times a day.

I love the show myself. Sure, it's addictive, but fortunately you are never more than an hour away from a fix.

What method did you finally decide on to measure the 11° angle?

Also, do you think it would help to mark the centerline before you cut?

Also, do you think it would help to mark the centerline before you cut?

umm...I'll do this longhand.

1) I mark the point at which the saw should cross the 7.25" mark.

2) I turn the pipe toward me 11° (I mark it with a string I prepared) I call that -11°. I mark it with a thin line that is about 2 inches long.

3) I use my string to find the 90° mark with relation to the -11° mark. I make a line about 3 inches long.

4) I orient the pipe in the jig so that I'm fairly certain the -11° mark is in the guide and the 90° is the first thing the saw touches. Right so far!

5) I saw.

6) I find the -11° mark, then measure 7.25" and mark it.

7) I repeat 2-6.

In essence, the -11° mark of the old segment is the new centerline for each new segment, from which I vary another 11°. Does that sound right?

Dave

1) I mark the point at which the saw should cross the 7.25" mark.

2) I turn the pipe toward me 11° (I mark it with a string I prepared) I call that -11°. I mark it with a thin line that is about 2 inches long.

3) I use my string to find the 90° mark with relation to the -11° mark. I make a line about 3 inches long.

4) I orient the pipe in the jig so that I'm fairly certain the -11° mark is in the guide and the 90° is the first thing the saw touches. Right so far!

5) I saw.

6) I find the -11° mark, then measure 7.25" and mark it.

7) I repeat 2-6.

In essence, the -11° mark of the old segment is the new centerline for each new segment, from which I vary another 11°. Does that sound right?

Dave

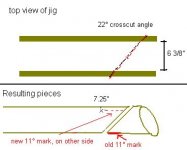

I see that you shifted the pipe length from 7 3/32" to 7.25". As long as you get the 22.5° angle right, I cannot see this being any problem at all. As long as you are using a jig to cut by angle-not by measuring sides-it was probably a good idea, for ease-of-measuring purposes.

Okay, I am trying to visualize this.

A) Step 2: " I turn the pipe toward me 11° (I mark it with a string I prepared) I call that -11°. I mark it with a thin line that is about 2 inches long."

Where are you standing when you say that you turn the pipe toward you? Are you standing in front of the part of the pipe that will be The Long Side?

B) Is this the clay jig that your wife made for you? If so, does it have a provision to cut the pipe at 22.5° from the second end? If not, I wonder why no mention is made if turning the pipe 180°, or thereabouts. If you can cut from only one end, and you are not rotating the pipe 180°, things are going to be off.

Does the jig you have resembe the double-sided Jig A or the single sided Jig B?

MSPaint picture below.

Okay, I am trying to visualize this.

A) Step 2: " I turn the pipe toward me 11° (I mark it with a string I prepared) I call that -11°. I mark it with a thin line that is about 2 inches long."

Where are you standing when you say that you turn the pipe toward you? Are you standing in front of the part of the pipe that will be The Long Side?

B) Is this the clay jig that your wife made for you? If so, does it have a provision to cut the pipe at 22.5° from the second end? If not, I wonder why no mention is made if turning the pipe 180°, or thereabouts. If you can cut from only one end, and you are not rotating the pipe 180°, things are going to be off.

Does the jig you have resembe the double-sided Jig A or the single sided Jig B?

MSPaint picture below.

Attachments

I said it wrong.

In step 6, there should be a 180° turn in between "I find the 11° mark" and the new measurement. The 11° mark still functions as the centerline for the segment, and is the basis for the 180° turn for the 7.25" measurement (my margin of error is almost 1/16th of an inch, so I figured to go by 8th inches).

You'll see on the pic that I mark the 7.25" on the 180 from the old 11 (small dash), then move it -11 (x marks the spot).

Lemme know if this makes sense. Need sleep.

Dave

In step 6, there should be a 180° turn in between "I find the 11° mark" and the new measurement. The 11° mark still functions as the centerline for the segment, and is the basis for the 180° turn for the 7.25" measurement (my margin of error is almost 1/16th of an inch, so I figured to go by 8th inches).

You'll see on the pic that I mark the 7.25" on the 180 from the old 11 (small dash), then move it -11 (x marks the spot).

Lemme know if this makes sense. Need sleep.

Dave

Attachments

Ah! You figured out my method after all. 😉

It appears he's rotating the pipe 180-11 = 179° after making the cut.

Tim (speaking of being tired )

)

It appears he's rotating the pipe 180-11 = 179° after making the cut.

Tim (speaking of being tired

)

)D'oh!!

Lol...actually...that could be read as intentional, I miss by 10 but then I say I'm tired...showing just how tired I am...

But nah, I'm too tired to construe something so intricate 😛

Lol...actually...that could be read as intentional, I miss by 10 but then I say I'm tired...showing just how tired I am...

But nah, I'm too tired to construe something so intricate 😛

Kneadle:

Well, your method certainly looks sound from what I can gather tonight. I'll look at it again tomorrow morning, but looks good now. 🙂

Well, your method certainly looks sound from what I can gather tonight. I'll look at it again tomorrow morning, but looks good now. 🙂

Sch3mat1c said:D'oh!!

Lol...actually...that could be read as intentional, I miss by 10 but then I say I'm tired...showing just how tired I am...

But nah, I'm too tired to construe something so intricate 😛

Yeah, and I couldn't figure out what the wizard was talking about last night. 7 and 3/32 is close to 7 1/8. which is 7.25", right?!?

Riiiight.

All better now. See anything odd with that pic? Otherwise, it's the way I'm going.

Dave

7 1/8" is 7.125" I think. That's what I'm using. 7 1/8", or something really close to 7 3/32"

Dave

Dave

7 1/8" is even better. 7 3/32" exactly is obviously unobtainable.

The only reason I made a big deal about the outside dimensions and cuts is that before you built this jig, you were measuring the The Long Side and the The Short Side, and cutting between them. In other words, you were going by the outside measurements, and using them to create your angle.

You were going by The Short Side dimensions that were off. They would not create the necessary 22.5° angle, so the octagon was not going to end up correctly.

However, now the jig cuts the angle correctly, so a little bit extra here or there is not critical.

Of course, I could be a wise guy and say that if you, as a graduate student, are having these problems, then you're the best argument for going (ugh!) Metric I 've come across lately. 😀 😀

The only reason I made a big deal about the outside dimensions and cuts is that before you built this jig, you were measuring the The Long Side and the The Short Side, and cutting between them. In other words, you were going by the outside measurements, and using them to create your angle.

You were going by The Short Side dimensions that were off. They would not create the necessary 22.5° angle, so the octagon was not going to end up correctly.

However, now the jig cuts the angle correctly, so a little bit extra here or there is not critical.

Of course, I could be a wise guy and say that if you, as a graduate student, are having these problems, then you're the best argument for going (ugh!) Metric I 've come across lately. 😀 😀

Spare us!

Nature occurs in fractions, not decimals.

There's an inside joke for us pro linguists in that statement. Imagine a roomfull of unkempt professor types chuckling to themselves...

Dave

Nature occurs in fractions, not decimals.

There's an inside joke for us pro linguists in that statement. Imagine a roomfull of unkempt professor types chuckling to themselves...

Dave

I have a confession. Until last night, I didn't realize that once you get past the end piece, each cut you make is the second cut for one piece and the first cut for the next piece. You are not making two cuts per piece. Once you make the first cut in the 8 foot long PVC pipe, you are then making one cut per piece.

So, by twisting 180° in the jig, you are using 11 cuts to create 10 pieces. Clever.

Therefore, what you are doing is moving the 11° offset line over as you move down the line. Every cut must be offset 11° from the previous cut, and you move down the 8 foot PVC piece in that fashion, turning the PVC pipe approximately 180° each time.

I would say that your setup is fine. One thing-you did check to make sure the jig gives a 22.5° cut, correct? If that angle is correct, then your setup is fine.

So, by twisting 180° in the jig, you are using 11 cuts to create 10 pieces. Clever.

Therefore, what you are doing is moving the 11° offset line over as you move down the line. Every cut must be offset 11° from the previous cut, and you move down the 8 foot PVC piece in that fashion, turning the PVC pipe approximately 180° each time.

I would say that your setup is fine. One thing-you did check to make sure the jig gives a 22.5° cut, correct? If that angle is correct, then your setup is fine.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- TL Design I can't build