Peter Daniel said:They work alright, and are only slightly warm when pushed. Also the temperature is uniform along the whole length of a heatsink assembly. I would also expect that in horizontal position, the heat dissipation is much better from inbetween the fins.

That's what's weird. Fins work better in a vertical orientation that same way a heat pipe does, but they contradict theirselves in the SUN SPARC HeatPipe.

Oh I'm sure they work great in this application. I'm trying to figure out how to fit a pair into a design I'm working on 😎 I'm also thinking about Peltier Junctions with P4 heatsinks epoxied on for an "invisible sink" amp chassistiroth said:Hmm are these not SPARC-type processor sinks? I believe they were designed for horizontal use. At any rate they are quite sufficient to the task.

What happened to this thread?

It was raving for 139 pages which i read in it's entirity and now have several grand ideas to implement into the gainclone scheme of things.

Now it seems to be dead. And i had a hard *** time finding it, is it hidden or something?

It was raving for 139 pages which i read in it's entirity and now have several grand ideas to implement into the gainclone scheme of things.

Now it seems to be dead. And i had a hard *** time finding it, is it hidden or something?

Scribble said:What happened to this thread?

Now it seems to be dead.

This thread was reborn as an entire forum...

dave

Hi,

Now if you could adopt that shape for the knobs that would look much better.

Cheers,😉

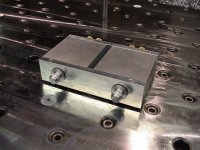

This is what the PSU is going to look like. (proto type)

Now if you could adopt that shape for the knobs that would look much better.

Cheers,😉

Jerry T. said:This is what the PSU is going to look like. (proto type)

drool! It is one fabulously looking amp.

How thick is the front plate? I would use 1" and over plate to just make this thing a high-end amp.

Playing your game milwood:

This amp can never be high end as it's using $5 chip intended for low end aplications. So 1" or thicker plate is useless.

This amp can never be high end as it's using $5 chip intended for low end aplications. So 1" or thicker plate is useless.

I like the machining Job but the knobs as nice as they are dont suit the chassis in my opinion.

I like the knob with the LED...that looks slick

I like the knob with the LED...that looks slick

Peter Daniel said:This amp can never be high end as it's using $5 chip intended for low end aplications.

it couldn't have been more false.

My Audi uses 3 cents engine bolts. But most people, me included, would consider it a luxury car, whether or not it has a 1" plate or not.

A high-end amp can use devices intended for low-end applications. A Bryston using a carbon resistor is still a high-end piece. a Radio Shack boombox, no matter how many gold-plated foot or how thick of a front plate it uses, how beaitifully machined it is, is still a low-end product.

Unless, of course, you define "high-end" or "low-end" drastically different from the rest of the world.

millwood,

I'm only playing your game. Decide what you want to say:

I'm only playing your game. Decide what you want to say:

millwood said:

on the same token, I don't recall national suggesting dual / mono transformers, fast recovery diodes, diamond heatpads and Egyptian maple casing either, .

The chip was probably designed for low-end applications and it wouldn't help its cause had National suggested all those "hi-end" stuff.

Plus, it just may not benefit from lots of high-end stuff.

millwood said:

Now, the datasheet is a marketing tool and a technical document. Just because it says "high performance" doesn't means it delivers high performance and is not intended for low-end applications. I trust that those engineers at JBL know better about those chips than you and I.

planet10 said:The knob on this is really a nice piece of kit. Gold plated (aluminum i think) from Audio Note.

dave

Partsconnexion are selling those knobs.

The knobs are a bit retro looking IMHO

What is the base its sitting on?

Pic's of the guts?

From what ive seen nice work, i actually thought it was a peter daniels one first 😉

EDIT: well it seems i got lost and my computer didnt catch up on all the other post's so this looks out of place. Dont laugh @ me 😛

What is the base its sitting on?

Pic's of the guts?

From what ive seen nice work, i actually thought it was a peter daniels one first 😉

EDIT: well it seems i got lost and my computer didnt catch up on all the other post's so this looks out of place. Dont laugh @ me 😛

Peter Daniel said:Partsconnexion are selling those knobs.

Yep, that is where they came from.

dave

I'm making 2 of these, but sadly enough i don't know much about electronics. Maarten at platenspeler.com is kind enough to take care of that part. So, to be fair "we" are making 2.

I think i will have to make other knobs now, i've got some idea for realy good looking one's. I'll post a pic when the're finished.

This is a pic of the guts, Maarten has this proto type now, so he can do his thing.

I think i will have to make other knobs now, i've got some idea for realy good looking one's. I'll post a pic when the're finished.

This is a pic of the guts, Maarten has this proto type now, so he can do his thing.

Attachments

Im waiting on some funds to come through so i can buy a good soldering station and a new multimeter. Then i can start building my GC's. Hey it gives me time for research at least 🙂

Im also doing an "experiment" of such in which im going to buy the cheapest, meanest parts i can find from dicksmiths and knock up a stereo GC. Then invest in blackgates and holco, riken and what ever exotic components others have mentioned to improve sound and do a comparison and see how bad the cheapo one actually sounds.

Shall be interesting.

Im also doing an "experiment" of such in which im going to buy the cheapest, meanest parts i can find from dicksmiths and knock up a stereo GC. Then invest in blackgates and holco, riken and what ever exotic components others have mentioned to improve sound and do a comparison and see how bad the cheapo one actually sounds.

Shall be interesting.

JOE DIRT® said:I like the machining Job but the knobs as nice as they are dont suit the chassis in my opinion.

I like the knob with the LED...that looks slick

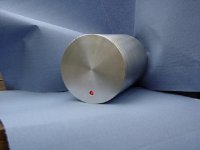

Hmm, Joe that's not a knob, thats the housing for the power supply. It's large enough for two Amplimo/Plitron transformers of 225VA. I'll post a picture when ready with the PSU, still thinking how best to get the bridge section fastened in the tube.

An externally hosted image should be here but it was not working when we last tested it.

This is the inside of the proto amp for the moment:

An externally hosted image should be here but it was not working when we last tested it.

- Status

- Not open for further replies.

- Home

- Amplifiers

- Chip Amps

- This is not just another gainclone