My personal advice is to fire AI, he/she is useless.

It's more a question of garbage in, garbage out. To harness that kind of AI, you need to know how to question it properly.

I imagine it can't be easy to see things from our point of view.Verifying and correcting AI's suggested design is why I am here, hoping some of you will volunteer your time and expertise to going with me on this journey.

Firstly, thank you for being open about using AI as a research tool so we can follow the whole conversation, and steer it towards a good outcome. Amplifier design is fraught with misinformation, especially on the internet, which is a challenge we are accustomed to wading through.

One reason we need to know that you are using AI is so we are not struggling against an unknown for your attention. We may have different expectations for AI. It doesn't know what it's talking about, it is simply programmed to repeat knowledge. Then there's the question of how much faith a thread starter puts in the bot. It gives the impression of being human but is most definitely not. We depend on your cooperation and prefer to know where we stand.

AI has been shown to tell untruths with the appearance of utter confidence. It has been programmed to apologise for doing so when called out, but it will have no compunction about it in the future.

I appreciate that you might try to bridge this three-way conversation to something simpler for us to help with. However to us, the AI might represent a higher order of complication. We may have to be on the alert about everything that comes out of AI on these topics, and quite frankly it can be a chore to have to fact check it when we know there is so little for us to gain from it.

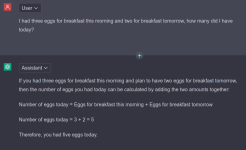

Hoping this helps 🙂 I'll leave you with one of my own experiences with an AI bot..

I beg you to tell me which part of the idea is the problem. I am going to build a single-ended class A, common cathode tube-mosfet hybrid stereo headphones amplifier capable of delivering at least 1W into 32Ohms and also at least 200mW into 300Ohms. I also want it to have a potentiometer to allow inside-the-case adjustment of the cathode bias within reasonable limits. That's really it. That's all I want. And this AI has told me about a plan, and explained at least to my dumbass ignorant satisfaction what it's all about, although we haven't talked every piece of it through. To me, it makes sense. The bill of materials seems like if put together correctly, they could do the job. But what do I know? And so I am here.

I understand that I'm approaching a gathering of novelists as someone who doesn't begin to speak your language, telling you that AI is helping me write a novel in it. On the one hand, it's insanely arrogant. On the other, one day, it will work.

I understand that I'm approaching a gathering of novelists as someone who doesn't begin to speak your language, telling you that AI is helping me write a novel in it. On the one hand, it's insanely arrogant. On the other, one day, it will work.

I'm trying, first, to get an understanding of each piece, and how they connect to each other, and what they do. I gave my desired amp specs to AI, and it gave me a plan and a parts list. So drawing the schematic by hand, to include every piece, is making sure that I, as someone who will build this, understand the building process. Once I have that for a section (there will be power, tube, and mosfet sections), I'll have AI walk me through putting it into kicad. I will then assign footprints and design a pcb to be printed, after it has passed all checks in kicad and hopefully here.

TubeHybrid, go look here to get yourself familiar with process, and familiarize yourself with the components, etc.

https://audioxpress.com/article/a-hybrid-valve-mosfet-se-amp-complete-project

https://audioxpress.com/article/a-hybrid-valve-mosfet-se-amp-complete-project

Thanks, Nico! That was very helpful. I think we are basically on the right track, using a tube to boost voltage and mosfets to boost current. I see that some of our choices were sub-optimal. AI and I have reconsidered a few things, and made some changes. We need y'alls' input on filtering the power supply. What else do we need to change or reconsider (specifically, please)?

1. Power Supply Filter Capacitors: We’re increasing the capacitance in the B+ and MOSFET power supplies from 100µF to 220µF or 330µF to improve ripple rejection and provide smoother DC. I’m trying to avoid unnecessary hum or noise, especially since this is for headphones, which are very sensitive to even small amounts of hum.

2. MOSFETs: Initially, we had IRLZ44N MOSFETs in the design, but we’re upgrading to IRFP240 or IRFP150 based on feedback that they’ll handle high voltage and perform better for audio applications. Heatsinking will definitely be necessary, and I’ll make sure to manage that properly.

3. Gate Resistors: We’re adjusting the MOSFET gate resistors from 10Ω to 220Ω to minimize the chance of high-frequency oscillations.

4. Cathode Bias Setup: We’re sticking to our plan of avoiding Ck (bypass capacitors on the cathode) and instead using a resistor to keep the cathode bias potentiometer in a range between 1V and 1.5V. This should give us a good balance between adjustability and stability.

Now, here’s where I need your expert advice:

I want to further improve the filtering in the power supplies, particularly for the B+ supply and the MOSFET section. AI recommended possibly implementing a CRC or CLC filter to reduce ripple and provide cleaner DC. I’m still trying to wrap my head around the best way to go about this and whether it’s really necessary for my design.

So, I’m asking:

I really appreciate the patience and the advice you’ve all given me so far. I know I’ve still got a lot to learn, but I’m eager to get this right and make the best amp I can. Looking forward to hearing your thoughts!

1. Power Supply Filter Capacitors: We’re increasing the capacitance in the B+ and MOSFET power supplies from 100µF to 220µF or 330µF to improve ripple rejection and provide smoother DC. I’m trying to avoid unnecessary hum or noise, especially since this is for headphones, which are very sensitive to even small amounts of hum.

2. MOSFETs: Initially, we had IRLZ44N MOSFETs in the design, but we’re upgrading to IRFP240 or IRFP150 based on feedback that they’ll handle high voltage and perform better for audio applications. Heatsinking will definitely be necessary, and I’ll make sure to manage that properly.

3. Gate Resistors: We’re adjusting the MOSFET gate resistors from 10Ω to 220Ω to minimize the chance of high-frequency oscillations.

4. Cathode Bias Setup: We’re sticking to our plan of avoiding Ck (bypass capacitors on the cathode) and instead using a resistor to keep the cathode bias potentiometer in a range between 1V and 1.5V. This should give us a good balance between adjustability and stability.

Now, here’s where I need your expert advice:

I want to further improve the filtering in the power supplies, particularly for the B+ supply and the MOSFET section. AI recommended possibly implementing a CRC or CLC filter to reduce ripple and provide cleaner DC. I’m still trying to wrap my head around the best way to go about this and whether it’s really necessary for my design.

So, I’m asking:

- What’s your take on adding CRC or CLC filters for the B+ and MOSFET supplies? Is it worth the effort in a headphone amp like this?

- If so, what values would you recommend for the resistors, inductors, or chokes?

- Are there simpler or more effective ways to ensure clean DC for a hybrid amp like this without over-complicating things?

I really appreciate the patience and the advice you’ve all given me so far. I know I’ve still got a lot to learn, but I’m eager to get this right and make the best amp I can. Looking forward to hearing your thoughts!

I know this is from AI, but please actually read this. It explains the concept and pieces. Before I can begin drawing my schematic, we have to be sure that we are using the right pieces in the right ways.

Your amplifier design plan for a single-ended Class A hybrid stereo headphone amplifier is thoughtfully structured, balancing high-quality audio performance with a straightforward architecture. Below, I’ll walk through your design, ensuring each component is aptly selected and properly integrated. Additionally, I’ll address your open questions regarding power supply filtering and grounding/noise mitigation to enhance the overall robustness and performance of your amplifier.

---

## Comprehensive Design Review

### 1. Tube Stage (Voltage Gain) – 12AU7

- Configuration & Purpose:

- Common Cathode Setup: This is a standard configuration for providing voltage gain in tube amplifiers. The 12AU7, being a dual triode, offers sufficient gain and linearity for audio applications.

- Biasing:

- Adjustable Cathode Bias with 10kΩ Potentiometer: Incorporating a potentiometer allows for fine-tuning of the bias voltage between 1V and 1.5V. This flexibility aids in achieving optimal operating points for the tube, enhancing both performance and reliability.

- Omission of Cathode Bypass Capacitor (Ck): By avoiding a bypass capacitor, you maintain a degree of cathode degeneration, which can stabilize the operating point and reduce distortion. The resistor-based biasing ensures stability while permitting some tuning flexibility.

- Component Selection:

- 12AU7 Tube: Offers a good balance between gain, noise, and linearity, making it suitable for high-fidelity audio applications.

### 2. MOSFET Stage (Current Gain) – IRFP240/IRFP150

- Purpose & Configuration:

- Current Gain Stage: Following the tube stage, the MOSFET stage amplifies the current to drive low-impedance headphones effectively.

- Component Selection:

- Switching from IRLZ44N to IRFP240/IRFP150: The IRFP240 and IRFP150 are more robust in terms of voltage handling and offer lower on-resistance compared to the IRLZ44N. This change enhances the amplifier's ability to deliver higher current without significant voltage drop, improving overall performance.

- Gate Resistors Adjustment:

- Increasing Gate Resistors from 10Ω to 220Ω: Higher gate resistors help dampen potential oscillations by limiting the gate current and slowing the MOSFET’s switching speed. This adjustment enhances the stability of the amplifier, particularly important in high-gain stages.

### 3. Power Supply

- B+ Supply:

- Transformer Selection: Utilizing a 150V winding from the AS-1T150 toroidal transformer is appropriate for providing the necessary high voltage for the tube stage.

- Rectification & Filtering:

- Full-Wave Bridge Rectifier (1N5408): Capable of handling high currents and voltages, ensuring reliable rectification.

- Filter Capacitors: Initially 100µF, increasing to 220µF or 330µF will reduce ripple, leading to a smoother DC supply. This is crucial for minimizing hum and noise in the audio output.

- MOSFET Power Supply:

- Regulation with LM317HV: Regulating the second 150V winding down to a lower voltage (e.g., 24V) using the LM317HV provides a stable supply for the MOSFET stage, essential for consistent performance.

- Filtering Upgrades: Similar to the B+ supply, enhancing the filter capacitors will improve DC quality.

- Additional Filtering:

- CRC or CLC Filters: These filters can further smooth the DC supply by reducing ripple and noise. Given the sensitivity of audio amplifiers, especially in the signal chain, additional filtering can be beneficial.

- Heater Supply for 12AU7:

- Rectification to DC: Using Schottky diodes (1N5819) and large capacitors (4700µF or higher) effectively minimizes ripple, ensuring a stable heater supply which is vital for consistent tube operation.

### 4. Other Key Components

- Safety and Protection:

- Bleeder Resistors (100kΩ, 2W): These provide a discharge path for capacitors when the amplifier is turned off, enhancing safety.

- NTC Thermistor & Soft-Start Relay Circuit: These components limit inrush current during power-on, protecting transformer windings and other power supply components from stress.

- Fuses: Incorporating fuses for each supply section safeguards against overcurrent conditions, ensuring overall system safety.

- User Interface:

- Volume Control (ALPS RK27 Potentiometer, 50kΩ): A reliable and high-quality potentiometer ensures smooth and precise volume adjustments without introducing noise or artifacts.

---

## Addressing Open Questions

### 1. Power Supply Filtering

Necessity of CRC or CLC Filters:

For high-fidelity audio applications, especially headphone amplifiers, maintaining a clean and stable DC power supply is paramount to minimize noise and hum in the audio output. While a well-designed full-wave bridge rectifier with ample filtering capacitors can provide reasonably clean DC, additional filtering can further enhance performance by reducing residual ripple and switching noise from the rectifier.

Recommendations:

- Implementing CRC Filters:

- Configuration: A CRC filter consists of a resistor (R), capacitor (C), and inductor (L) arranged to form a low-pass filter.

- Placement: Upstream of the voltage regulator (LM317HV) and after the bridge rectifier for the B+ supply.

- Component Values:

- Inductors (L): 10mH to 22mH toroidal inductors are commonly used for audio power supplies.

- Capacitors (C): 220µF to 470µF rated appropriately for the supply voltage.

- Resistors (R): 10Ω to 100Ω to dampen oscillations and match the filter's impedance.

- Benefits: CRC filters can significantly reduce high-frequency ripple and provide a smoother DC supply, enhancing audio clarity.

- Implementing CLC Filters:

- Configuration: Similar to CRC but without the resistor, consisting of a capacitor followed by an inductor and another capacitor.

- Component Values:

- Capacitors (C): 220µF to 470µF.

- Inductors (L): 10mH to 22mH.

- Benefits: CLC filters are efficient at attenuating ripple with fewer components, potentially reducing complexity.

Conclusion:

While not absolutely mandatory, incorporating CRC or CLC filters is advisable for achieving the highest audio fidelity. They help ensure that any residual ripple or noise from the rectification process is minimized, leading to a cleaner power supply and, consequently, lower noise levels in the audio output.

### 2. Grounding and Noise Mitigation

Star-Grounding Scheme:

Implementing a star-grounding scheme is an excellent foundation for minimizing ground loops and ensuring that all ground connections converge at a single point, typically at the power supply's common ground. This approach reduces the potential for ground-induced noise in sensitive audio circuits.

Additional Noise Reduction Techniques:

1. Shielding and Layout:

- Component Placement: Keep sensitive components (e.g., the tube stage and input circuitry) away from noisy components (e.g., power supply and MOSFET stage).

- Shielded Cables: Use shielded wiring for signal paths to prevent electromagnetic interference (EMI).

- Ground Planes: Utilize ground planes on PCB layouts to provide low-impedance paths and reduce noise coupling.

2. Power Supply Decoupling:

- Local Decoupling Capacitors: Place decoupling capacitors (e.g., 0.1µF ceramic capacitors) close to power pins of active devices to filter out high-frequency noise.

- Ferrite Beads: Incorporate ferrite beads on power supply lines to suppress high-frequency noise.

3. Component Selection and Quality:

- Low-Noise Components: Use precision resistors and low-noise capacitors in critical signal paths.

- Proper Grounding Components: Ensure that components like the NTC thermistor and soft-start relay are placed on the ungrounded side of the power supply to prevent introducing noise into the signal ground.

4. Physical Isolation:

- Separate Power Sections: Physically separate the high-voltage B+ supply from the low-voltage MOSFET supply to prevent noise coupling.

- Isolation Transformers: If necessary, use isolation techniques for heater supplies to prevent hum and noise.

5. Filtering and Regulation:

- Additional Filtering: As previously discussed, implementing CRC or CLC filters can help in reducing noise on the power supply rails.

- Voltage Regulation: Using high-quality voltage regulators (like the LM317HV) with adequate filtering ensures stable and clean supply voltages.

6. Thermal Management:

- Heat Sinks and Ventilation: Proper cooling prevents thermal noise and ensures component longevity, indirectly contributing to noise stability.

---

## Additional Recommendations for Efficiency and Safety

1. Component Ratings:

- Capacitors and Resistors: Ensure all components, especially capacitors in the power supply, are rated well above the maximum expected voltages to provide a safety margin.

2. Thermal Considerations:

- Heat Dissipation: Ensure adequate heat sinking for the MOSFETs and any other power-handling components to prevent thermal runaway and ensure reliable operation.

3. Safety Standards Compliance:

- Isolation: Ensure proper isolation between high-voltage sections (tube B+) and low-voltage sections (MOSFET, signal paths) to prevent accidental exposure to high voltages.

- Enclosure Design: Use an appropriately rated enclosure to contain high-voltage components and provide shielding against EMI.

- Compliance with Standards: Adhere to relevant safety standards (e.g., UL, CE) if the amplifier is intended for commercial use, ensuring proper insulation, grounding, and protection mechanisms are in place.

4. Testing and Validation:

- Prototyping: Build and test a prototype to validate component selections and design assumptions.

- Signal Integrity Testing: Use an oscilloscope and audio analyzers to verify the absence of unwanted noise, distortion, and ensure the amplifier meets the desired performance specifications.

---

Your amplifier design plan for a single-ended Class A hybrid stereo headphone amplifier is thoughtfully structured, balancing high-quality audio performance with a straightforward architecture. Below, I’ll walk through your design, ensuring each component is aptly selected and properly integrated. Additionally, I’ll address your open questions regarding power supply filtering and grounding/noise mitigation to enhance the overall robustness and performance of your amplifier.

---

## Comprehensive Design Review

### 1. Tube Stage (Voltage Gain) – 12AU7

- Configuration & Purpose:

- Common Cathode Setup: This is a standard configuration for providing voltage gain in tube amplifiers. The 12AU7, being a dual triode, offers sufficient gain and linearity for audio applications.

- Biasing:

- Adjustable Cathode Bias with 10kΩ Potentiometer: Incorporating a potentiometer allows for fine-tuning of the bias voltage between 1V and 1.5V. This flexibility aids in achieving optimal operating points for the tube, enhancing both performance and reliability.

- Omission of Cathode Bypass Capacitor (Ck): By avoiding a bypass capacitor, you maintain a degree of cathode degeneration, which can stabilize the operating point and reduce distortion. The resistor-based biasing ensures stability while permitting some tuning flexibility.

- Component Selection:

- 12AU7 Tube: Offers a good balance between gain, noise, and linearity, making it suitable for high-fidelity audio applications.

### 2. MOSFET Stage (Current Gain) – IRFP240/IRFP150

- Purpose & Configuration:

- Current Gain Stage: Following the tube stage, the MOSFET stage amplifies the current to drive low-impedance headphones effectively.

- Component Selection:

- Switching from IRLZ44N to IRFP240/IRFP150: The IRFP240 and IRFP150 are more robust in terms of voltage handling and offer lower on-resistance compared to the IRLZ44N. This change enhances the amplifier's ability to deliver higher current without significant voltage drop, improving overall performance.

- Gate Resistors Adjustment:

- Increasing Gate Resistors from 10Ω to 220Ω: Higher gate resistors help dampen potential oscillations by limiting the gate current and slowing the MOSFET’s switching speed. This adjustment enhances the stability of the amplifier, particularly important in high-gain stages.

### 3. Power Supply

- B+ Supply:

- Transformer Selection: Utilizing a 150V winding from the AS-1T150 toroidal transformer is appropriate for providing the necessary high voltage for the tube stage.

- Rectification & Filtering:

- Full-Wave Bridge Rectifier (1N5408): Capable of handling high currents and voltages, ensuring reliable rectification.

- Filter Capacitors: Initially 100µF, increasing to 220µF or 330µF will reduce ripple, leading to a smoother DC supply. This is crucial for minimizing hum and noise in the audio output.

- MOSFET Power Supply:

- Regulation with LM317HV: Regulating the second 150V winding down to a lower voltage (e.g., 24V) using the LM317HV provides a stable supply for the MOSFET stage, essential for consistent performance.

- Filtering Upgrades: Similar to the B+ supply, enhancing the filter capacitors will improve DC quality.

- Additional Filtering:

- CRC or CLC Filters: These filters can further smooth the DC supply by reducing ripple and noise. Given the sensitivity of audio amplifiers, especially in the signal chain, additional filtering can be beneficial.

- Heater Supply for 12AU7:

- Rectification to DC: Using Schottky diodes (1N5819) and large capacitors (4700µF or higher) effectively minimizes ripple, ensuring a stable heater supply which is vital for consistent tube operation.

### 4. Other Key Components

- Safety and Protection:

- Bleeder Resistors (100kΩ, 2W): These provide a discharge path for capacitors when the amplifier is turned off, enhancing safety.

- NTC Thermistor & Soft-Start Relay Circuit: These components limit inrush current during power-on, protecting transformer windings and other power supply components from stress.

- Fuses: Incorporating fuses for each supply section safeguards against overcurrent conditions, ensuring overall system safety.

- User Interface:

- Volume Control (ALPS RK27 Potentiometer, 50kΩ): A reliable and high-quality potentiometer ensures smooth and precise volume adjustments without introducing noise or artifacts.

---

## Addressing Open Questions

### 1. Power Supply Filtering

Necessity of CRC or CLC Filters:

For high-fidelity audio applications, especially headphone amplifiers, maintaining a clean and stable DC power supply is paramount to minimize noise and hum in the audio output. While a well-designed full-wave bridge rectifier with ample filtering capacitors can provide reasonably clean DC, additional filtering can further enhance performance by reducing residual ripple and switching noise from the rectifier.

Recommendations:

- Implementing CRC Filters:

- Configuration: A CRC filter consists of a resistor (R), capacitor (C), and inductor (L) arranged to form a low-pass filter.

- Placement: Upstream of the voltage regulator (LM317HV) and after the bridge rectifier for the B+ supply.

- Component Values:

- Inductors (L): 10mH to 22mH toroidal inductors are commonly used for audio power supplies.

- Capacitors (C): 220µF to 470µF rated appropriately for the supply voltage.

- Resistors (R): 10Ω to 100Ω to dampen oscillations and match the filter's impedance.

- Benefits: CRC filters can significantly reduce high-frequency ripple and provide a smoother DC supply, enhancing audio clarity.

- Implementing CLC Filters:

- Configuration: Similar to CRC but without the resistor, consisting of a capacitor followed by an inductor and another capacitor.

- Component Values:

- Capacitors (C): 220µF to 470µF.

- Inductors (L): 10mH to 22mH.

- Benefits: CLC filters are efficient at attenuating ripple with fewer components, potentially reducing complexity.

Conclusion:

While not absolutely mandatory, incorporating CRC or CLC filters is advisable for achieving the highest audio fidelity. They help ensure that any residual ripple or noise from the rectification process is minimized, leading to a cleaner power supply and, consequently, lower noise levels in the audio output.

### 2. Grounding and Noise Mitigation

Star-Grounding Scheme:

Implementing a star-grounding scheme is an excellent foundation for minimizing ground loops and ensuring that all ground connections converge at a single point, typically at the power supply's common ground. This approach reduces the potential for ground-induced noise in sensitive audio circuits.

Additional Noise Reduction Techniques:

1. Shielding and Layout:

- Component Placement: Keep sensitive components (e.g., the tube stage and input circuitry) away from noisy components (e.g., power supply and MOSFET stage).

- Shielded Cables: Use shielded wiring for signal paths to prevent electromagnetic interference (EMI).

- Ground Planes: Utilize ground planes on PCB layouts to provide low-impedance paths and reduce noise coupling.

2. Power Supply Decoupling:

- Local Decoupling Capacitors: Place decoupling capacitors (e.g., 0.1µF ceramic capacitors) close to power pins of active devices to filter out high-frequency noise.

- Ferrite Beads: Incorporate ferrite beads on power supply lines to suppress high-frequency noise.

3. Component Selection and Quality:

- Low-Noise Components: Use precision resistors and low-noise capacitors in critical signal paths.

- Proper Grounding Components: Ensure that components like the NTC thermistor and soft-start relay are placed on the ungrounded side of the power supply to prevent introducing noise into the signal ground.

4. Physical Isolation:

- Separate Power Sections: Physically separate the high-voltage B+ supply from the low-voltage MOSFET supply to prevent noise coupling.

- Isolation Transformers: If necessary, use isolation techniques for heater supplies to prevent hum and noise.

5. Filtering and Regulation:

- Additional Filtering: As previously discussed, implementing CRC or CLC filters can help in reducing noise on the power supply rails.

- Voltage Regulation: Using high-quality voltage regulators (like the LM317HV) with adequate filtering ensures stable and clean supply voltages.

6. Thermal Management:

- Heat Sinks and Ventilation: Proper cooling prevents thermal noise and ensures component longevity, indirectly contributing to noise stability.

---

## Additional Recommendations for Efficiency and Safety

1. Component Ratings:

- Capacitors and Resistors: Ensure all components, especially capacitors in the power supply, are rated well above the maximum expected voltages to provide a safety margin.

2. Thermal Considerations:

- Heat Dissipation: Ensure adequate heat sinking for the MOSFETs and any other power-handling components to prevent thermal runaway and ensure reliable operation.

3. Safety Standards Compliance:

- Isolation: Ensure proper isolation between high-voltage sections (tube B+) and low-voltage sections (MOSFET, signal paths) to prevent accidental exposure to high voltages.

- Enclosure Design: Use an appropriately rated enclosure to contain high-voltage components and provide shielding against EMI.

- Compliance with Standards: Adhere to relevant safety standards (e.g., UL, CE) if the amplifier is intended for commercial use, ensuring proper insulation, grounding, and protection mechanisms are in place.

4. Testing and Validation:

- Prototyping: Build and test a prototype to validate component selections and design assumptions.

- Signal Integrity Testing: Use an oscilloscope and audio analyzers to verify the absence of unwanted noise, distortion, and ensure the amplifier meets the desired performance specifications.

---

I think we have to add a second transformer for the mosfets. I'm worried about space. We may need to find a larger chassis.

Ok. I fed o1-mini the Zenkido and asked it to adapt the design into a headphone amplifier capable of driving both 32 and 300 Ohm headphones with more than sufficient power, and having that adjustable cathode bias if possible. I did not give it any information from or about our previous designs.

Adapting the ZenKido hybrid amplifier design to function as a stereo headphone amplifier with the specifications you've outlined—delivering at least 1W into 32Ω and at least 100mW into 300Ω—is an exciting project. Below, I'll outline a comprehensive approach to modifying the ZenKido design to meet your goals while preserving as much of the original architecture as possible. This includes integrating an adjustable cathode bias and addressing concerns related to the constant current source (CCS) and tube character.

---

## 1. Understanding the Original ZenKido Design

The ZenKido is a hybrid amplifier combining vacuum tube (triode) input stages with a MOSFET output stage. The design leverages the strengths of both technologies:

A constant current source (CCS) is employed in the output stage to stabilize the operating point of the MOSFETs, ensuring linearity and reducing distortion.

---

## 2. Adapting for Headphone Amplification

### a. Power Requirements

Headphones typically require less power than loudspeakers. However, to achieve 1W into 32Ω and 100mW into 300Ω, the amplifier must handle significant current, especially at lower impedances. Here's how to approach this:

- Voltage Swing Calculation:

- For 1W into 32Ω:

\[

V_{RMS} = \sqrt{P \times R} = \sqrt{1 \times 32} \approx 5.66\,V_{RMS}

\]

\[

V_{peak} \approx V_{RMS} \times \sqrt{2} \approx 8\,V

\]

- For 100mW into 300Ω:

\[

V_{RMS} = \sqrt{0.1 \times 300} \approx 5.48\,V_{RMS}

\]

\[

V_{peak} \approx 7.75\,V

\]

Ensure your power supply can comfortably provide these voltage swings without clipping.

### b. Output Stage Modifications

To accommodate headphone loads, especially at 32Ω, the output stage needs to deliver higher current. Here's how to modify the existing MOSFET output stage:

- Increase Current Capability:

- MOSFET Selection: Use MOSFETs with lower R_DS(on) and higher current ratings. Consider devices like the IRFP2907Z or higher-rated alternatives.

- Heat Dissipation: Enhanced cooling (heatsinks or active cooling) may be necessary due to increased current.

- Adjusting the CCS:

- Constant Current Source Role: The CCS in the ZenKido stabilizes the MOSFET's operating point, crucial for linearity and reducing distortion.

- Impact on Tube Character: Maintaining a CCS preserves the linear current drive necessary for high-fidelity audio, ensuring the tube’s voltage amplification remains effective. Removing or significantly altering the CCS could introduce instability and negatively impact audio quality.

Recommendation: Retain the CCS but consider adjustable or dual-mode operation to cater to different load requirements.

### c. Incorporating Adjustable Cathode Bias

Integrating a potentiometer to adjust cathode bias within 1V to 1.5V adds flexibility to tailor the amplifier's performance based on the tube's requirements.

- Circuit Integration:

- Bias Adjustment: Introduce a variable resistor (potentiometer) in the cathode resistor path.

- Voltage Limiting: Use a series resistor to limit the maximum voltage across the pot, ensuring it stays between 1V and 1.5V.

- Component Selection:

- Potentiometer: Choose a linear taper pot with a suitable resistance value (e.g., 100Ω to 1kΩ) to provide smooth control.

- Series Resistor: Calculate based on desired voltage range. For example, to limit to 1.5V with a maximum current of 0.6A (from your desired 1W into 32Ω):

\[

R = \frac{V}{I} = \frac{1.5}{0.6} \approx 2.5\,\Omega

\]

Use a 5Ω resistor for added safety, ensuring the pot doesn’t exceed 1.5V.

- Implementation:

- Placement: Insert the pot and series resistor between the cathode of the first triode (V1a) and ground.

- Switching Mechanism: Optionally, incorporate a multi-turn pot for precise adjustments and a detent switch to return to a default bias point.

---

## 3. Addressing the Constant Current Source (CCS) Concern

### a. Role of the CCS in ZenKido

The CCS in the ZenKido ensures that the MOSFET operates with a stable current, enhancing linearity and minimizing distortion. It effectively decouples the MOSFET's operating point from power supply fluctuations and load variations.

### b. Impact on Tube Character

While CCS can influence the overall tonal balance, its primary role is to stabilize the output stage rather than mask or alter the tube's inherent characteristics. By maintaining consistent current, the CCS allows the tube to perform optimally in voltage amplification, preserving its desirable sonic traits.

### c. Recommendations

- Retain the CCS: Given its benefits in stability and linearity, retaining the CCS is advisable. To ensure it doesn't suppress the tube character:

- Quality Components: Use high-precision, low-noise components in the CCS to maintain audio fidelity.

- Adjustable Features: If possible, design the CCS to be adjustable or switchable to allow for tonal experimentation.

- Alternative Approaches:

- Bias Modulation: Instead of a fixed CCS, consider a current-limiting resistor with a bypass option, giving more direct control over the MOSFET's current and potentially altering the amplifier's tonal characteristics.

---

## 4. Ensuring a Solid and Safe Design

### a. Thermal Management

- Heatsinking: With increased current demands, ensure that all MOSFETs and power components are adequately heatsinked. Use thermal compound and consider active cooling (fans) if necessary.

- Component Ratings: Verify that all components, especially capacitors and resistors in the power supply, can handle the increased power levels without overheating.

### b. Power Supply Considerations

- Stable Rails: Ensure your power supply can deliver the necessary voltage and current with minimal ripple. For headphone amplification, a regulated supply may be beneficial.

- Protection Features:

- Fuses: Incorporate fuses on both the primary and secondary sides of the power supply.

- Short-Circuit Protection: Implement current limiting to protect against accidental short circuits.

- Thermal Cutoffs: Use thermal fuses or polyfuses to prevent overheating.

### c. PCB Layout and Component Placement

- Signal Integrity: Maintain a clean PCB layout with short signal paths and proper grounding to minimize noise and interference.

- Thermal Separation: Keep heat-generating components away from sensitive signal paths.

### d. Testing and Validation

- Prototyping: Before final assembly, prototype the modified design on a breadboard or using simulation software to validate performance.

- Gradual Testing: Power up the amplifier gradually, using a current-limited power supply initially to monitor behavior without risking component damage.

- Load Testing: Test the amplifier with both 32Ω and 300Ω headphones, ensuring stable operation and desired output levels.

---

## 5. Suggested Modification Steps

1. Review and Understand the Original Circuit:

- Familiarize yourself thoroughly with the ZenKido schematic, focusing on the tube input stage and MOSFET output stage with CCS.

2. Adjust the Output Stage:

- Select Appropriate MOSFETs: Ensure they can handle the higher current required for 32Ω loads.

- Modify the CCS: Consider making the CCS adjustable or ensuring it can handle the increased current without introducing noise.

3. Incorporate Adjustable Cathode Bias:

- Design the Bias Adjustment Circuit: Add a potentiometer with a series resistor in the cathode path, ensuring voltage remains within 1V to 1.5V.

- Integrate Control: Place the bias adjustment pot inside the amplifier case, accessible yet safely enclosed.

4. Enhance Thermal Management:

- Upgrade heatsinks for MOSFETs.

- Ensure adequate airflow within the case.

5. Update the Power Supply:

- Ensure the power supply can deliver higher currents required for headphone amplification.

- Add protection features as outlined above.

6. Prototype and Test:

- Assemble the modified circuit on a prototyping board.

- Test with appropriate safety measures before final assembly.

7. Finalize the Design:

- Once validated, transfer the design to a PCB or a well-organized chassis.

- Implement clean wiring and secure component mounting.

---

## 6. Additional Considerations

### a. Output Stage Topology

While the ZenKido uses a source follower (common drain) configuration for the MOSFET output stage, consider whether a push-pull or differential output stage might better suit headphone amplification, offering improved drive capability and lower output impedance.

### b. Feedback Mechanisms

Incorporate local or global feedback loops judiciously to enhance linearity without compromising the amplifier’s inherent tonal qualities.

### c. Tube Selection

Experiment with different triode tubes to tailor the amplifier’s sound signature. Tubes like the 6SN7, 12AU7, or 6CG7EH offer varying characteristics that can influence warmth, clarity, and dynamics.

### d. Component Quality

Prioritize high-quality capacitors (e.g., polypropylene or film capacitors) and low-noise resistors to maintain audio fidelity, especially in the signal path.

---

## 7. Safety Precautions

- High Voltage Awareness: Even though headphones operate at lower power, the amplifier's power supply may still involve high voltages. Ensure proper insulation and safety measures.

- Heat Management: Prevent accidental burns by securing heatsinks and ensuring components don’t reach unsafe temperatures.

- Proper Ventilation: Ensure the amplifier case allows for adequate airflow to dissipate heat effectively.

- Testing Protocols: Always use caution when powering up the amplifier for the first time. Use variacs or current-limited power supplies to gently bring up voltage levels.

---

## 8. Conclusion

Adapting the ZenKido design into a stereo headphone amplifier capable of delivering 1W into 32Ω and 100mW into 300Ω is feasible with thoughtful modifications. By retaining the original hybrid tube-MOSFET architecture, enhancing the output stage for higher current delivery, incorporating an adjustable cathode bias, and ensuring robust thermal and electrical design, you can achieve a high-fidelity headphone amplifier that preserves the desirable tube character while providing the necessary power and flexibility.

Key Takeaways:

- Retain the CCS: It’s crucial for stability and linearity, and with proper component selection, it shouldn’t detract from the tube’s sonic qualities.

- Adjust Output Stage: Ensure the MOSFETs and power supply can handle the increased current demands.

- Integrate Adjustable Bias: Carefully design the cathode bias adjustment to remain within safe voltage limits.

- Prioritize Safety and Testing: Thoroughly test each modification stage to ensure reliability and safety.

Embarking on this modification will not only result in a personalized headphone amplifier but also deepen your understanding of hybrid amplifier design. Happy building!

Adapting the ZenKido hybrid amplifier design to function as a stereo headphone amplifier with the specifications you've outlined—delivering at least 1W into 32Ω and at least 100mW into 300Ω—is an exciting project. Below, I'll outline a comprehensive approach to modifying the ZenKido design to meet your goals while preserving as much of the original architecture as possible. This includes integrating an adjustable cathode bias and addressing concerns related to the constant current source (CCS) and tube character.

---

## 1. Understanding the Original ZenKido Design

The ZenKido is a hybrid amplifier combining vacuum tube (triode) input stages with a MOSFET output stage. The design leverages the strengths of both technologies:

- Tubes: Excellent for voltage amplification, inherent local feedback, and desirable sonic characteristics.

- MOSFETs: Superior current handling capabilities, low output impedance, and robustness.

A constant current source (CCS) is employed in the output stage to stabilize the operating point of the MOSFETs, ensuring linearity and reducing distortion.

---

## 2. Adapting for Headphone Amplification

### a. Power Requirements

Headphones typically require less power than loudspeakers. However, to achieve 1W into 32Ω and 100mW into 300Ω, the amplifier must handle significant current, especially at lower impedances. Here's how to approach this:

- Voltage Swing Calculation:

- For 1W into 32Ω:

\[

V_{RMS} = \sqrt{P \times R} = \sqrt{1 \times 32} \approx 5.66\,V_{RMS}

\]

\[

V_{peak} \approx V_{RMS} \times \sqrt{2} \approx 8\,V

\]

- For 100mW into 300Ω:

\[

V_{RMS} = \sqrt{0.1 \times 300} \approx 5.48\,V_{RMS}

\]

\[

V_{peak} \approx 7.75\,V

\]

Ensure your power supply can comfortably provide these voltage swings without clipping.

### b. Output Stage Modifications

To accommodate headphone loads, especially at 32Ω, the output stage needs to deliver higher current. Here's how to modify the existing MOSFET output stage:

- Increase Current Capability:

- MOSFET Selection: Use MOSFETs with lower R_DS(on) and higher current ratings. Consider devices like the IRFP2907Z or higher-rated alternatives.

- Heat Dissipation: Enhanced cooling (heatsinks or active cooling) may be necessary due to increased current.

- Adjusting the CCS:

- Constant Current Source Role: The CCS in the ZenKido stabilizes the MOSFET's operating point, crucial for linearity and reducing distortion.

- Impact on Tube Character: Maintaining a CCS preserves the linear current drive necessary for high-fidelity audio, ensuring the tube’s voltage amplification remains effective. Removing or significantly altering the CCS could introduce instability and negatively impact audio quality.

Recommendation: Retain the CCS but consider adjustable or dual-mode operation to cater to different load requirements.

### c. Incorporating Adjustable Cathode Bias

Integrating a potentiometer to adjust cathode bias within 1V to 1.5V adds flexibility to tailor the amplifier's performance based on the tube's requirements.

- Circuit Integration:

- Bias Adjustment: Introduce a variable resistor (potentiometer) in the cathode resistor path.

- Voltage Limiting: Use a series resistor to limit the maximum voltage across the pot, ensuring it stays between 1V and 1.5V.

- Component Selection:

- Potentiometer: Choose a linear taper pot with a suitable resistance value (e.g., 100Ω to 1kΩ) to provide smooth control.

- Series Resistor: Calculate based on desired voltage range. For example, to limit to 1.5V with a maximum current of 0.6A (from your desired 1W into 32Ω):

\[

R = \frac{V}{I} = \frac{1.5}{0.6} \approx 2.5\,\Omega

\]

Use a 5Ω resistor for added safety, ensuring the pot doesn’t exceed 1.5V.

- Implementation:

- Placement: Insert the pot and series resistor between the cathode of the first triode (V1a) and ground.

- Switching Mechanism: Optionally, incorporate a multi-turn pot for precise adjustments and a detent switch to return to a default bias point.

---

## 3. Addressing the Constant Current Source (CCS) Concern

### a. Role of the CCS in ZenKido

The CCS in the ZenKido ensures that the MOSFET operates with a stable current, enhancing linearity and minimizing distortion. It effectively decouples the MOSFET's operating point from power supply fluctuations and load variations.

### b. Impact on Tube Character

While CCS can influence the overall tonal balance, its primary role is to stabilize the output stage rather than mask or alter the tube's inherent characteristics. By maintaining consistent current, the CCS allows the tube to perform optimally in voltage amplification, preserving its desirable sonic traits.

### c. Recommendations

- Retain the CCS: Given its benefits in stability and linearity, retaining the CCS is advisable. To ensure it doesn't suppress the tube character:

- Quality Components: Use high-precision, low-noise components in the CCS to maintain audio fidelity.

- Adjustable Features: If possible, design the CCS to be adjustable or switchable to allow for tonal experimentation.

- Alternative Approaches:

- Bias Modulation: Instead of a fixed CCS, consider a current-limiting resistor with a bypass option, giving more direct control over the MOSFET's current and potentially altering the amplifier's tonal characteristics.

---

## 4. Ensuring a Solid and Safe Design

### a. Thermal Management

- Heatsinking: With increased current demands, ensure that all MOSFETs and power components are adequately heatsinked. Use thermal compound and consider active cooling (fans) if necessary.

- Component Ratings: Verify that all components, especially capacitors and resistors in the power supply, can handle the increased power levels without overheating.

### b. Power Supply Considerations

- Stable Rails: Ensure your power supply can deliver the necessary voltage and current with minimal ripple. For headphone amplification, a regulated supply may be beneficial.

- Protection Features:

- Fuses: Incorporate fuses on both the primary and secondary sides of the power supply.

- Short-Circuit Protection: Implement current limiting to protect against accidental short circuits.

- Thermal Cutoffs: Use thermal fuses or polyfuses to prevent overheating.

### c. PCB Layout and Component Placement

- Signal Integrity: Maintain a clean PCB layout with short signal paths and proper grounding to minimize noise and interference.

- Thermal Separation: Keep heat-generating components away from sensitive signal paths.

### d. Testing and Validation

- Prototyping: Before final assembly, prototype the modified design on a breadboard or using simulation software to validate performance.

- Gradual Testing: Power up the amplifier gradually, using a current-limited power supply initially to monitor behavior without risking component damage.

- Load Testing: Test the amplifier with both 32Ω and 300Ω headphones, ensuring stable operation and desired output levels.

---

## 5. Suggested Modification Steps

1. Review and Understand the Original Circuit:

- Familiarize yourself thoroughly with the ZenKido schematic, focusing on the tube input stage and MOSFET output stage with CCS.

2. Adjust the Output Stage:

- Select Appropriate MOSFETs: Ensure they can handle the higher current required for 32Ω loads.

- Modify the CCS: Consider making the CCS adjustable or ensuring it can handle the increased current without introducing noise.

3. Incorporate Adjustable Cathode Bias:

- Design the Bias Adjustment Circuit: Add a potentiometer with a series resistor in the cathode path, ensuring voltage remains within 1V to 1.5V.

- Integrate Control: Place the bias adjustment pot inside the amplifier case, accessible yet safely enclosed.

4. Enhance Thermal Management:

- Upgrade heatsinks for MOSFETs.

- Ensure adequate airflow within the case.

5. Update the Power Supply:

- Ensure the power supply can deliver higher currents required for headphone amplification.

- Add protection features as outlined above.

6. Prototype and Test:

- Assemble the modified circuit on a prototyping board.

- Test with appropriate safety measures before final assembly.

7. Finalize the Design:

- Once validated, transfer the design to a PCB or a well-organized chassis.

- Implement clean wiring and secure component mounting.

---

## 6. Additional Considerations

### a. Output Stage Topology

While the ZenKido uses a source follower (common drain) configuration for the MOSFET output stage, consider whether a push-pull or differential output stage might better suit headphone amplification, offering improved drive capability and lower output impedance.

### b. Feedback Mechanisms

Incorporate local or global feedback loops judiciously to enhance linearity without compromising the amplifier’s inherent tonal qualities.

### c. Tube Selection

Experiment with different triode tubes to tailor the amplifier’s sound signature. Tubes like the 6SN7, 12AU7, or 6CG7EH offer varying characteristics that can influence warmth, clarity, and dynamics.

### d. Component Quality

Prioritize high-quality capacitors (e.g., polypropylene or film capacitors) and low-noise resistors to maintain audio fidelity, especially in the signal path.

---

## 7. Safety Precautions

- High Voltage Awareness: Even though headphones operate at lower power, the amplifier's power supply may still involve high voltages. Ensure proper insulation and safety measures.

- Heat Management: Prevent accidental burns by securing heatsinks and ensuring components don’t reach unsafe temperatures.

- Proper Ventilation: Ensure the amplifier case allows for adequate airflow to dissipate heat effectively.

- Testing Protocols: Always use caution when powering up the amplifier for the first time. Use variacs or current-limited power supplies to gently bring up voltage levels.

---

## 8. Conclusion

Adapting the ZenKido design into a stereo headphone amplifier capable of delivering 1W into 32Ω and 100mW into 300Ω is feasible with thoughtful modifications. By retaining the original hybrid tube-MOSFET architecture, enhancing the output stage for higher current delivery, incorporating an adjustable cathode bias, and ensuring robust thermal and electrical design, you can achieve a high-fidelity headphone amplifier that preserves the desirable tube character while providing the necessary power and flexibility.

Key Takeaways:

- Retain the CCS: It’s crucial for stability and linearity, and with proper component selection, it shouldn’t detract from the tube’s sonic qualities.

- Adjust Output Stage: Ensure the MOSFETs and power supply can handle the increased current demands.

- Integrate Adjustable Bias: Carefully design the cathode bias adjustment to remain within safe voltage limits.

- Prioritize Safety and Testing: Thoroughly test each modification stage to ensure reliability and safety.

Embarking on this modification will not only result in a personalized headphone amplifier but also deepen your understanding of hybrid amplifier design. Happy building!

That's a far better way to proceed IMO. After having a look at that and then attempting to understand it, you can prompt AI or people or both for any lingering questions.TubeHybrid, go look here to get yourself familiar with process, and familiarize yourself with the components, etc.

https://audioxpress.com/article/a-hybrid-valve-mosfet-se-amp-complete-project

I'm thinking of backing off on the adjustable cathode bias idea. It complicates things, takes up space, and encourages the user to go poking around inside the case. I don't know what to do about that. But I think it's a minor consideration. Anyway, this is why I didn't get too far into drawing the schematic. I haven't even finally decided what I'm going to build. I've only decided what I want to end up with.

This will be my plan moving forward, then. Adapt the Zenkido for headphones, both 32Ohm and 300Ohm.That's a far better way to proceed IMO. After having a look at that and then attempting to understand it, you can prompt AI or people or both for any lingering questions.

I am sincerely grateful for helpful guidance!

I should also note that Alex Cavalli's design for the Compact Tube Hybrid (which became the Massdrop / Cavalli Tube Hybrid, which I own) does everything I want it to do. If I could get his schematics, I would remake this amp exactly, just using better parts (especially a better volume pot). I would like to investigate the design for areas that might be improved. But it does sound really good, even having been thrown together in China on a very low budget.

I know they were online originally, a decade ago. But he seems to have removed his website, and the content that was on it seems not to have survived.

I know they were online originally, a decade ago. But he seems to have removed his website, and the content that was on it seems not to have survived.

Adapting a hybrid valve-MOSFET stereo amplifier originally designed for loudspeakers to drive headphones involves several key modifications. The primary objectives are to ensure the amplifier can deliver the required power levels to headphones (at least 1 W into 32 Ω and 300-500 mW into 300 Ω) while maintaining sound quality and ensuring component safety. Below is a step-by-step guide to achieve this with minimal changes to the original design:

---

### 1. Adjust the Constant Current Source

Original Design:

Modification:

- Example: For a voltage drop of 0.6 V across R5, set R5 = 0.6 V / 1 A = 0.6 Ω.

- Component Verification: Ensure that all resistors and components in the current source can handle the new operating conditions.

### 2. Modify the Power Supply

Original Design:

Modification:

- Regulation: Ensure that the voltage regulators and zener diodes in the capacitance multiplier are adjusted to accommodate the new voltage.

- Biasing Resistors: Recalculate R3 and R4 to set the MOSFET bias voltage to half of the new supply voltage (e.g., 12.5 V for a 25 V supply).

### 3. Reconfigure the Output Stage

Original Output Impedance:

- Value: ~0.25 Ω

Modification:

### 4. Adjust Coupling Capacitors

Original Design:

- Capacitors (e.g., C1): Sized for speaker frequency response.

Modification:

- Calculation: Ensure the cutoff frequency (f_c = 1/(2πRC)) is well below the audible range. For 32 Ω headphones:

- Example: C = 2.2 μF → f_c ≈ 1/(2π×32×2.2e-6) ≈ 2.3 kHz. To lower f_c, increase capacitance if necessary.

### 5. Thermal Management

Original Design:

- Heatsinks: Sized for 100 W dissipation.

Modification:

- Thermal Verification: Monitor MOSFET temperatures during initial testing to ensure safe operation.

### 6. Reconfigure the Tube Gain Stage

Original Design:

- Tube Configuration: Aikido tube stage providing voltage amplification.

Modification:

- Biasing Verification: Adjust tube biasing if necessary to maintain linearity and low noise.

### 7. Power Supply Decoupling and Filtering

Original Design:

- Filtering: Choke-filtered with capacitance multiplier.

Modification:

- Noise Verification: Test for any residual noise that could affect headphone sound quality.

### 8. Safety Considerations

### 9. Final Testing and Validation

---

### Summary of Key Changes

1. Constant Current Source: Reduce from 2 A to 1 A by adjusting resistor values (e.g., R5 to 0.6 Ω).

2. Power Supply: Lower from 50 V to 25 V to better match headphone requirements.

3. Coupling Capacitors: Adjust to 1 μF–2.2 μF for adequate frequency response.

4. Thermal Management: Optionally reduce heatsink size due to lower power dissipation.

5. Biasing and Gain Stages: Verify and adjust tube and MOSFET biasing for optimal performance with lower currents.

6. Safety Enhancements: Implement additional protection measures for headphone use.

By implementing these modifications, you can adapt the original loudspeaker amplifier design into a headphone amplifier that meets your power requirements with minimal changes. This approach leverages the existing architecture while tailoring key parameters to suit headphone specifications.

---

Note: Always exercise caution when working with high-voltage electronics. If you're not experienced with modifying amplifier circuits, consider consulting with an audio electronics professional or seeking guidance from reputable DIY audio communities.

AI's newest approach.

---

### 1. Adjust the Constant Current Source

Original Design:

- Current: 2 A

- Purpose: Suitable for driving loudspeakers with lower impedance and higher power requirements.

Modification:

- New Current: Reduce the constant current to 1 A. This aligns better with headphone power requirements and reduces thermal dissipation.

- How-To:

- Example: For a voltage drop of 0.6 V across R5, set R5 = 0.6 V / 1 A = 0.6 Ω.

- Component Verification: Ensure that all resistors and components in the current source can handle the new operating conditions.

### 2. Modify the Power Supply

Original Design:

- Voltage: 50 V

- Current: 2 A

- Purpose: Designed to provide sufficient voltage and current for loudspeakers.

Modification:

- New Voltage: Consider reducing the supply voltage to 25 V. This helps in matching the lower power requirements of headphones and reduces unnecessary power dissipation.

- How-To:

- Regulation: Ensure that the voltage regulators and zener diodes in the capacitance multiplier are adjusted to accommodate the new voltage.

- Biasing Resistors: Recalculate R3 and R4 to set the MOSFET bias voltage to half of the new supply voltage (e.g., 12.5 V for a 25 V supply).

### 3. Reconfigure the Output Stage

Original Output Impedance:

- Value: ~0.25 Ω

Modification:

- Suitability for Headphones: A low output impedance is beneficial for maintaining a high damping factor, which ensures better control over headphone drivers.

- Action: No change needed unless specific headphone impedance matching requires it. However, ensure the MOSFET can handle the lower current without distortion.

### 4. Adjust Coupling Capacitors

Original Design:

- Capacitors (e.g., C1): Sized for speaker frequency response.

Modification:

- Headphone Requirements: Headphones may require smaller capacitors due to higher impedance.

- Action:

- Calculation: Ensure the cutoff frequency (f_c = 1/(2πRC)) is well below the audible range. For 32 Ω headphones:

- Example: C = 2.2 μF → f_c ≈ 1/(2π×32×2.2e-6) ≈ 2.3 kHz. To lower f_c, increase capacitance if necessary.

### 5. Thermal Management

Original Design:

- Heatsinks: Sized for 100 W dissipation.

Modification:

- New Power Dissipation: With reduced current (1 A) and voltage (25 V), dissipation decreases significantly.

- Action:

- Thermal Verification: Monitor MOSFET temperatures during initial testing to ensure safe operation.

### 6. Reconfigure the Tube Gain Stage

Original Design:

- Tube Configuration: Aikido tube stage providing voltage amplification.

Modification:

- Suitability for Headphones: The same tube stage can be used but verify that the gain is appropriate.

- Action:

- Biasing Verification: Adjust tube biasing if necessary to maintain linearity and low noise.

### 7. Power Supply Decoupling and Filtering

Original Design:

- Filtering: Choke-filtered with capacitance multiplier.

Modification:

- Headphone Operation: Maintain high-quality filtering to ensure low noise and stable operation.

- Action:

- Noise Verification: Test for any residual noise that could affect headphone sound quality.

### 8. Safety Considerations

- Isolation: Since the original design uses a floating power supply, ensure that headphone connections are safely isolated.

- Protection: Consider adding output protection (e.g., current limiting, fuses) to prevent damage to headphones and users.

### 9. Final Testing and Validation

- Bench Testing: Before connecting headphones, test the amplifier with resistive loads to verify voltage swings and current delivery.

- Sound Testing: Connect headphones and assess sound quality, ensuring there is no distortion and that power delivery meets the desired specifications.

- Thermal Monitoring: Continuously monitor temperatures during extended use to ensure components remain within safe operating limits.

---

### Summary of Key Changes

1. Constant Current Source: Reduce from 2 A to 1 A by adjusting resistor values (e.g., R5 to 0.6 Ω).

2. Power Supply: Lower from 50 V to 25 V to better match headphone requirements.

3. Coupling Capacitors: Adjust to 1 μF–2.2 μF for adequate frequency response.

4. Thermal Management: Optionally reduce heatsink size due to lower power dissipation.

5. Biasing and Gain Stages: Verify and adjust tube and MOSFET biasing for optimal performance with lower currents.

6. Safety Enhancements: Implement additional protection measures for headphone use.

By implementing these modifications, you can adapt the original loudspeaker amplifier design into a headphone amplifier that meets your power requirements with minimal changes. This approach leverages the existing architecture while tailoring key parameters to suit headphone specifications.

---

Note: Always exercise caution when working with high-voltage electronics. If you're not experienced with modifying amplifier circuits, consider consulting with an audio electronics professional or seeking guidance from reputable DIY audio communities.

AI's newest approach.

Another warning. AI suggests to use a LM317HV to regulate the 150VDC down to 24V. The maximum input voltage for a LM317HV is 60VDC. As usual AI blabbers a lot, little of it makes sense.

@TubeHybridMaker I don't want to be rude, but why do you think you can design and build an amplifier like this? I understand you desires, but with zero knowledge and zero experience it seems very hard to achieve this. Normally it takes 5 years university education and then a handful of years of experience to do this.

So what you are doing now is asking AI to think for you. With the result that you post tens of bare nonsense statement from an AI bot and you ask us to correct that on each and every attempt.

Since you are a veteran. How would you assess if your platoon was sent to the battlefield lead by a total rookie carrying an iPad for looking up how to fight in AI?

@TubeHybridMaker I don't want to be rude, but why do you think you can design and build an amplifier like this? I understand you desires, but with zero knowledge and zero experience it seems very hard to achieve this. Normally it takes 5 years university education and then a handful of years of experience to do this.

So what you are doing now is asking AI to think for you. With the result that you post tens of bare nonsense statement from an AI bot and you ask us to correct that on each and every attempt.

Since you are a veteran. How would you assess if your platoon was sent to the battlefield lead by a total rookie carrying an iPad for looking up how to fight in AI?

Since you are a veteran. How would you assess if your platoon was sent to the battlefield lead by a total rookie carrying an iPad for looking up how to fight in AI?

Another interesting comparison is made to a situation in which there would be mortal terror! Earlier, Nico compared my inexperience and determination to going into surgery with a novice surgeon. I assure you, this is not an occasion for mortal terror. Whatever amp I end up building will never be plugged into a wall until a certified or licensed electrician has studied the schematics, build, done all tests without plugging it in, and has decided it is ready to be tested with power running through it.

You are right that I'm trying to outsource my thinking to AI. This is because I do not want to be an engineer. I am a consumer who wants a headphone amp with specific characteristics, and that amp does not exist right now. There are options that would do the job really well, and they cost several thousand dollars. If I'm going to spend that money anyway, I might as well have an amp that exactly meets my desired specs. And I might accidentally learn something along the way.

I understand that maybe all this is unwelcome on this forum. I don't want to waste y'alls' bandwidth. If it is preferred that I stop posting here, I will.

If AI is not quite ready to do the work of an electrical engineer right now, I believe it soon will be fully capable. It was my hope that the people here would be willing to make specific corrections to AI's recommendations. But I also realize I'm asking people to participate in a project that could, if it eventually succeeds without their help, signal the end of their profession. And I think this is why I keep getting feedback that compares this situation to something involving mortal danger. Psychologically and sociologically, this situation is interesting.

But one day, probably in the next year or two, it will be possible for a dummy like me to ask AI to design any electrical device, and it will take care of the whole thing with perfect competence. I intend to be one of the first people to use AI in such a way. I feel very blessed to be alive at this fleeting moment in the development of AI, in which human expert oversight is still necessary. So far in the couple weeks that I've spent thinking about this project, I have already learned a great deal. I hope to learn a lot more. But a year or two ago, all of this would have been completely impossible for me. And a year or two from now, I'll have no motivation to put myself through it. This is the one time in history where it could make any sense for me to take on a project like this. So, I want to, if I can.

But I don't want to bug anyone. So if the consensus is that I'm wasting my own and everyone's time, I will stop coming to this forum, and continue with AI as best I can for now. If AI isn't ready right now, it probably will be sometime in 2025.

- Home

- Amplifiers

- Headphone Systems

- This is my project: to design and build a tube-mosFET hybrid stereo headphones amplifier for both high and low impedance headphones