I am building a thin 3-way 24x24" wallspeaker, and the backplate can only be 1/4" (6mm) thick. Only 1/4" MDF acts as a drum and resonates violently (even with some internal stiffening construction) at these large dimensions for low frequencies, so what material/construction should I use ? I even considered cork, rubber or vinyl.

Any ideas ?

Any ideas ?

Last edited:

even with some internal stiffening construction

How much stiffening did you use? What is the approximate free span you had remaining in 1/4" material? And how much bracing can your design accommodate?

For example, can you layer on another piece of 1/2" MDF everywhere except where your deepest driver's magnet is (assuming you're using standard dynamic drivers)?

If not that, can you do something similar with a windowpane-style brace where you have a grid of 1/2" MDF with 4"ish square holes cut in it that's glued to your current back? This would leave something like 1" ribs spaced on 5" centers in both directions, so you'd only have about a 4" free span of 1/4" material.

With a 24" total span, if you want the enclosure relatively dead you may want additional bracing even with a 3/4" thick panel, so even after implementing something like the above, you may want to tie the front and back panels together in multiple spots. There are diminishing returns once you get to a reasonably non-resonant panel. Your call on where that is though.

1/4 inch Hardiebacker cement board might work for you. It's very stiff, however a little on the heavy side. Can be found at most home construction stores like Lowes or Home Depot.

Thank you for your replies. I think I will go with mattstatt and layer on another piece of MDF everywhere except where the deepest driver's magnet is and add some stiffening. This will cost 10% volume, but I think that is acceptable. How much space is recommended behind the depest driver (both depthwise and around) ?

Thanks. I have another question about using 2 passive radiators facing same side as driver in the same shallow cabinet - should I open a new tread or continue here ?

Since you're dealing with a shallow cabinet, some things are inherently compromised when it comes to space around drivers (in comparison to an "ideal" scenario). I wouldn't get excessively worried about that aspect though. The KEF R5 has some pretty tight geometry around the midrange driver, and they're getting away with it. About 3/4 of the way down this page they have a picture of the internals for models in this line:

R5 Compact Three Way Floorstanding Speaker | KEF

Practically speaking, whatever you need for clearance for fit is likely to be OK around the magnet. Given typical woodworking methods and some room for error, 1/4" clearance should cover mechanical fit even with relatively imprecise work. If you can work tighter, half that should be OK. Some designs mount by the magnet now (instead of/in addition to the flange), so in that case zero clearance would be OK (if your pole piece is vented this could be a problem though).

Around the basket cutouts, keep things as open as you reasonably can. I'd probably try to include some acoustical foam if it'll fit in the area within a few inches of the driver. Keep the foam about an inch away from the basket openings. You want a free path from the driver to the enclosure volume/passive radiators, but it doesn't have to be huge. Foam might help absorb some of the back wave and prevent it from bouncing right back through the cone. When things are very close though, some of these effects are pushed higher in frequency where they're less likely to get through the cone material. Higher frequencies are also easier to absorb, so there's some benefit there.

And a final thought: closed-back/can-style midranges are a thing, and have been used successfully, so very close enclosure walls can work.

R5 Compact Three Way Floorstanding Speaker | KEF

Practically speaking, whatever you need for clearance for fit is likely to be OK around the magnet. Given typical woodworking methods and some room for error, 1/4" clearance should cover mechanical fit even with relatively imprecise work. If you can work tighter, half that should be OK. Some designs mount by the magnet now (instead of/in addition to the flange), so in that case zero clearance would be OK (if your pole piece is vented this could be a problem though).

Around the basket cutouts, keep things as open as you reasonably can. I'd probably try to include some acoustical foam if it'll fit in the area within a few inches of the driver. Keep the foam about an inch away from the basket openings. You want a free path from the driver to the enclosure volume/passive radiators, but it doesn't have to be huge. Foam might help absorb some of the back wave and prevent it from bouncing right back through the cone. When things are very close though, some of these effects are pushed higher in frequency where they're less likely to get through the cone material. Higher frequencies are also easier to absorb, so there's some benefit there.

And a final thought: closed-back/can-style midranges are a thing, and have been used successfully, so very close enclosure walls can work.

Last edited:

Thanks Mattstat. Unfortunately I also expect that we need to consider the position of the two 5" radiators in this. Hope it is ok ?

I want to use a 5" woofer together with two 5" passive radiators facing the same side as the woofer. Remember the enclosure is only 30mm deep inside. It is my experience that the position of the radiators compared to the woofer is critical to get constructive resonance from the radiators. The resonance frequence is about 75 hz.

I would like to go bigger i.e. 32x32" to get more volume for the woofer (fs = 62 hz), but I think it would be impossible to stop the back and front plates (9mm MDF) from vibrating/resonating violently ? I wish there was some 3D honeycomb material I could put inside to strengthen the construction, but allow airflow.

How would you stiffen the construction, if I went this big ?

How would you stiffen the construction, if I went this big ?

Last edited:

It is my experience that the position of the radiators compared to the woofer is critical to get constructive resonance from the radiators. The resonance frequence is about 75 hz.

I'm not sure what your experience was on this front, but that's not what I would expect. At 75 Hz, a wavelength is 15 feet long, so getting appreciably out of phase takes a lot of distance (in speaker enclosure terms).

Passive radiators don't typically have much output outside a narrow band in their resonance region, so given your tuning frequency, practically anywhere you want to put them on the enclosure should be fine. Also remember that the distance to the listener will likely be essentially equal in your case, as your woofer and passive radiators will be in the same plane.

Consider that ports and passive radiators perform the same basic function. Ports are often on the rear or bottom of large speakers that have front-facing woofers.

How would you stiffen the construction, if I went this big ?

What tools do you have at your disposal and how tightly can you work? Laser? CNC router? Jigsaw? Angry beaver? Without knowing how you're going to cut parts, it's hard to suggest a construction method. Some are painfully complex if doing things by hand, but easy if you are using more advanced tools.

How much patience you have for tedious construction is worth knowing too.

Also, please confirm that your enclosure is only going to be 30 mm deep inside with 1/4" MDF walls. The restricted depth limits some options as well.

Shapeoko XXL CNC 🙂

Actually only 27mm, after I changed the backplate from 6mm to 9mm

I hope you are not suggesting the old matrix technology that B&W used, that is a hazzle

Actually only 27mm, after I changed the backplate from 6mm to 9mm

I hope you are not suggesting the old matrix technology that B&W used, that is a hazzle

Last edited:

I'm not sure what your experience was on this front, but that's not what I would expect. At 75 Hz, a wavelength is 15 feet long, so getting appreciably out of phase takes a lot of distance (in speaker enclosure terms).

I had a version where I increased the inner volume and distance between the woofer and radiators, and experienced that the radiators were not moving at all. I unsuccessfully looked for air leaks, but could not find any. In this case the radiators were mounted in a gasket, so maybe the gasket restricted the airflow somehow. I have now dropped the gasket, mounting the pistons directly

Last edited:

And I hope you're not thinking there's an easy or novel way to cram a lot of bracing into something. Most of it has been done before.

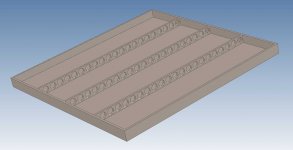

Whatever you want to call it, a ribbed construction method is one way to do it and it's easy with a CNC. It doesn't have to be interlocking like B&W used. It can be simple linear ribs with circular cutouts in them. Basic idea in attached image. How far apart the ribs have to be will depend on what frequencies you're going to put into that section. In the bass range, you can probably get away with spacing them 3-6 inches apart. You only need to push the resonance up beyond the range your woofer is going to play. With a 3-way design, that should be reasonably low.

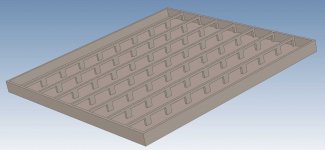

If you don't like circles, you could also do a comb design. Image also attached with higher density ribs. This is similar to dowel-braced construction, but a lot easier to assemble.

Whatever you want to call it, a ribbed construction method is one way to do it and it's easy with a CNC. It doesn't have to be interlocking like B&W used. It can be simple linear ribs with circular cutouts in them. Basic idea in attached image. How far apart the ribs have to be will depend on what frequencies you're going to put into that section. In the bass range, you can probably get away with spacing them 3-6 inches apart. You only need to push the resonance up beyond the range your woofer is going to play. With a 3-way design, that should be reasonably low.

If you don't like circles, you could also do a comb design. Image also attached with higher density ribs. This is similar to dowel-braced construction, but a lot easier to assemble.

Attachments

I had a version where I increased the inner volume and distance between the woofer and radiators, and experienced that the radiators were not moving at all. I unsuccessfully looked for air leaks, but could not find any. In this case the radiators were mounted in a gasket, so maybe the gasket restricted the airflow somehow. I have now dropped the gasket, mounting the pistons directly

That's different than what I thought you were describing previously. Sorry for the confusion.

Typical air leaks don't cause large decreases in output or passive radiator motion (big leaks can, obviously). I can't judge what you had going on with the gasket with the info you've provided, so don't know if that was the issue. One way to check for leaks is to press on the woofer cone and make sure the passive radiator moves in response. Optimally the passive won't re-center for a few seconds or until you let go of the woofer.

Are you using a lot of added mass on the passive radiators? That can significantly impact their output.

At some point, I imagine the internal air friction in a narrow enclosure of long enough distance might impact things, but I don't know where that point is. My gut feel is you're probably OK at about an inch tall inside, but without testing it directly I can't say for certain if you had an issue like that in your previous test.

Last edited:

- Home

- Loudspeakers

- Planars & Exotics

- Thin backplate material for 24" x 24" 3-way speaker