Well folks, got my "missing" drivers that I've been waiting to have the money freed up to purchase. Sometimes it's OK to have a birthday so close to Father's Day - LOL. Gotta get some wood and the dimensions from X...

Hey X's I'm going active too and what help can you give on the crossover besides the 400hz and 4khz crossover points?

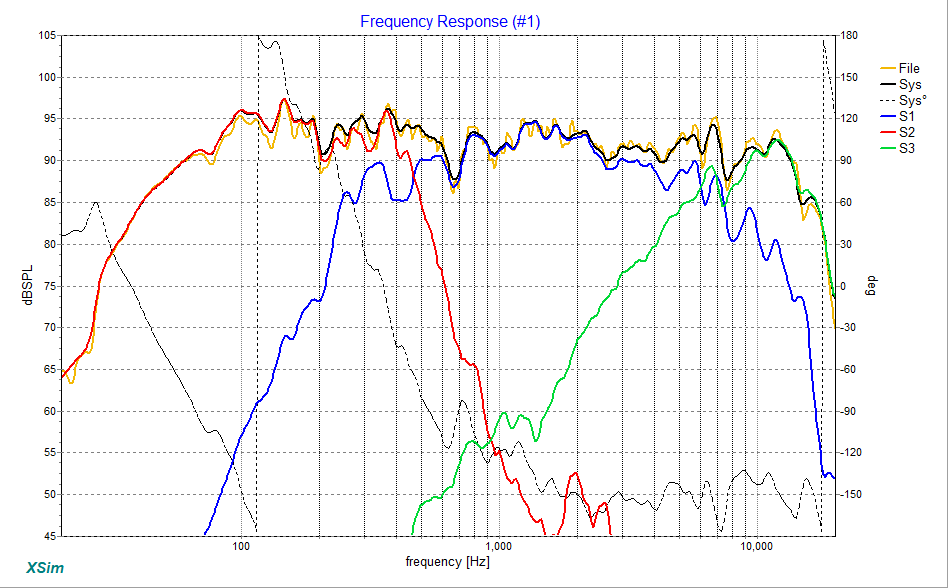

Try low pass 2nd order at 470Hz for woofers. This will coincide with natural falloff from slot and give you 4th order electro acoustic slope for price of 2nd order.

High pass 470Hz 2nd order mid range; low pass 5000Hz 2nd order mid range. Probably pad amplitude down -2.5dB to -4dB or so, adjust to taste.

Tweeter high pass at 5000Hz 2nd order, pad amplitude about -3dB to -5dB. Adjust to taste.

Time alignment will require microphone and adjust as needed.

You can try higher order if you like. I like to keep lower order electrical to reduce phase wrapping.

I have not done this in DSP myself so these are just starting places. Once I have a new XSD on premises again, I’ll try to setup a DSP and see what the filters look like.

High pass 470Hz 2nd order mid range; low pass 5000Hz 2nd order mid range. Probably pad amplitude down -2.5dB to -4dB or so, adjust to taste.

Tweeter high pass at 5000Hz 2nd order, pad amplitude about -3dB to -5dB. Adjust to taste.

Time alignment will require microphone and adjust as needed.

You can try higher order if you like. I like to keep lower order electrical to reduce phase wrapping.

I have not done this in DSP myself so these are just starting places. Once I have a new XSD on premises again, I’ll try to setup a DSP and see what the filters look like.

Last edited:

X,

What are you thinking about using to go active as far as amps, power per frequency band and especially how to handle the woofers? I have considered using either 1 or 2 of the 50wx4 amp boards to drive the woofers wired together or completely separately. What are your thoughts on doing this cheaply ie: best bang for the buck as far as actively amping all the drivers? Thanks

What are you thinking about using to go active as far as amps, power per frequency band and especially how to handle the woofers? I have considered using either 1 or 2 of the 50wx4 amp boards to drive the woofers wired together or completely separately. What are your thoughts on doing this cheaply ie: best bang for the buck as far as actively amping all the drivers? Thanks

Ideally: I would go with a 250W Class D or 300W AB for woofers and 40W Class A or 100W Class AB for the midrange and 25W Class A or 50W Class AB for the tweeters.

But if you wanted to make it simple, just use three TPA3255 amps and you will do fine. You can use my highly rated amp boards that are used in the Warp-1. But you could save money and get no name Chinese ones for a lot less but they so t sound as good of course.

Other good amps are TDA8932 Class D for mid range and tweeter and IRS2092 250W for woofers.

Class AB chip amps like the Xmas amp are great.

But ultimately I would recommend you go with a passive XO that I designed and a 150W amp. My personal opinion is that the passive will sound better. It will adhere to the voicing that I designed and there will be no doubt you are listening to the speaker as it was intended. Passive XO’s have lower noise floor, less fuss, you can swap out amps, and you only need 1 amp!

Hope that helps.

But if you wanted to make it simple, just use three TPA3255 amps and you will do fine. You can use my highly rated amp boards that are used in the Warp-1. But you could save money and get no name Chinese ones for a lot less but they so t sound as good of course.

Other good amps are TDA8932 Class D for mid range and tweeter and IRS2092 250W for woofers.

Class AB chip amps like the Xmas amp are great.

But ultimately I would recommend you go with a passive XO that I designed and a 150W amp. My personal opinion is that the passive will sound better. It will adhere to the voicing that I designed and there will be no doubt you are listening to the speaker as it was intended. Passive XO’s have lower noise floor, less fuss, you can swap out amps, and you only need 1 amp!

Hope that helps.

The new Tru-Ply birch veneer plywood flatpack arrived. I think this wood looks great. I didn’t have any issues with voids. The exterior birch is smooth and clean. The midrange cutout fits perfectly. The woofer could still use +2mm more on diameter. I’ll fix with a Dremel later but production ones will be bigger.

Wings and ledgers:

Woofer arrays:

Midrange rebate on back:

Midrange roundover on front:

Tweeter waveguide fit check:

Midrange fit check:

Starting to glue:

It would have helped to have alignment peg holes:

Wings and ledgers:

Woofer arrays:

Midrange rebate on back:

Midrange roundover on front:

Tweeter waveguide fit check:

Midrange fit check:

Starting to glue:

It would have helped to have alignment peg holes:

Looking good, buy yourself a glue roller you get a much more consistent layer of glue. I also like the silicone brushes used for basting, buy an extra for your wife or it will disappear. The people at Veneer Supplies are very nice to deal with for different supplies, pre-glued banding makes edge banding a snap and buy the veneer trimmer it will make life simpler. Nice flooring our house had tile in it when we bought it, went vInyl threw out so much easier to keep clean.

Thanks WW. I used a small flat paintbrush. The boards wiggle when clamped and that’s my bigger problem. So on next Rev I will definitely have 3 to 4 dowel alignment holes. Should make assembly a snap.

Once you have a solid woofer array block it serves as the backbone of the speaker and holds the baffle and base together. I’m going to use PL Premium glue to fill gaps and make an incredible bond. It’s looking good though. The CAD and CNC cuts are all perfect and angles coming out right.

Once you have a solid woofer array block it serves as the backbone of the speaker and holds the baffle and base together. I’m going to use PL Premium glue to fill gaps and make an incredible bond. It’s looking good though. The CAD and CNC cuts are all perfect and angles coming out right.

Second bass array being glued. Experience has given me slightly better alignment but still not perfect. Dowel locator pins will make this a snap.

While waiting for the glue to dry, on the cooking bench tonight, I assembled a new BBQ grill and baked it out. The smells of summer…

While waiting for the glue to dry, on the cooking bench tonight, I assembled a new BBQ grill and baked it out. The smells of summer…

I did put dowel holes in mine, definitely stabilized glue up. Using glue roller made for no gaps as well, not such a thing as to many clamps. Be sure to dry fit woofers before glue up, saves fussing with them when assembled ( would have saved me a few hours). We grill outside 99 % of the time keeps kitchen cleaner. Since we only eat beef once a week we pay a little more for the good stuff and usually split a steak.

Last edited:

Perfect name for your new grill X…

Amplifire!!

Btw, the XSD cabs are looking great!

Amplifire!!

Btw, the XSD cabs are looking great!

This is the first time I have glued up some thing that took this many clamps. I actually just bought these. I have only had the two C clamps up to now. But yes, one can never have too many clamps.

I only have 2 clamps as well. Also have some c clamps, but not large enough for this, so I need to go clamp shopping.

Seeing these pics of flat packs is giving new excitement!

Russellc

Seeing these pics of flat packs is giving new excitement!

Russellc