Those speakers look just the ticket for a tri-amp project. Mind you, I can't hear past 14kHz.

I don't think many over 30 can hear much over 16Khz. I can still hear the old CRT oscillator (15,750hz) but it is now more of a "presence" than a tone. I can discern over 16k on my synth , but it is also a "presence".

A "realization" just came to me listening to the BX (carlo's clone). I plugged them into a cold amp , they sounded grand. After an hour , as the amp warmed up , I noticed the sound was not "as it was". I noticed the bias creeped up to almost 100ma/device , the BX has a different VAS current than the AX. I lowered it back to 12mV/50ma ... the sound was again "right". I never heard this on the AX , even with under or over bias conditions. TMC must be both negating both the GM doubling and the underbiased Xover artifacts in the AX , I hear no difference from 10mA to over 100ma.

I guess I bias the BX on the "low side", GM doubling sounds almost as bad as class B x-over "garbage".

These new drivers bring out the bad as well as the good. 😱

OS

A "realization" just came to me listening to the BX (carlo's clone). I plugged them into a cold amp , they sounded grand. After an hour , as the amp warmed up , I noticed the sound was not "as it was". I noticed the bias creeped up to almost 100ma/device , the BX has a different VAS current than the AX. I lowered it back to 12mV/50ma ... the sound was again "right". I never heard this on the AX , even with under or over bias conditions. TMC must be both negating both the GM doubling and the underbiased Xover artifacts in the AX , I hear no difference from 10mA to over 100ma.

I guess I bias the BX on the "low side", GM doubling sounds almost as bad as class B x-over "garbage".

These new drivers bring out the bad as well as the good. 😱

OS

In this thread http://www.diyaudio.com/forums/solid-state/180619-advantage-jfets-ltp.html you mentioned about the "SILVER CABLE BLESSERS". The further argument was that two or any number of properly built amps will sound the same and if it sounded different, one is probably listening to equalisers rather than amps.

I hope this opens some skeptics eyes and ears that one or more bottle-necks in the audio chain can prevent one from hearing obvious differences. And just because in that setup the difference was not heard, it cannot be wrongly concluded that there is no sonic difference at all. In the current case, an upgrading of your speakers have enabled you to notice the sonic differences between the AX and BX amps.

In this thread http://www.diyaudio.com/forums/solid-state/180619-advantage-jfets-ltp.html you mentioned about the "SILVER CABLE BLESSERS"

Sorry, previous message split in two.

the "SILVER CABLE BLESSERS" are mine😀😀😀.

OS is not responsible al least for that.

And I would add that here we are speaking of a factual, measurable problem due to a real non-mystical cause like wrong bias current.

bye , effebi

the "SILVER CABLE BLESSERS" are mine😀😀😀.

OS is not responsible al least for that.

And I would add that here we are speaking of a factual, measurable problem due to a real non-mystical cause like wrong bias current.

bye , effebi

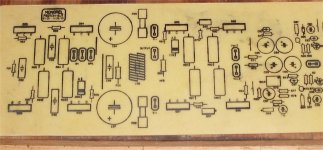

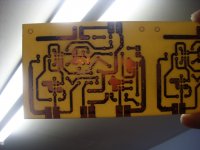

I trade the "silver cable blessin' " for more amps. 😀 I just completed the CLX , EX , and LX (below 1-6). I guess I do this both - "because I can , and because I want to"... 😀 (not to make better amps). Still , they should perform well. My first adventure in fully complimentary topology , the CLX/LX is a draw between the Leach VAS (LX) and the artu/tilbrook (CLX) VAS , performance wise. The leach does have much tighter current regulation in the VAS (pix 7).

The EX is another symasym , I just want to see how it will perform in it's purest form (Sigma - by dr. bora). As can be seen , I am using Rod Elliot's KIS technique , "Keep It Simple". All these are no PPM amps , but have monotonically "correct" FFT's. (pix 8)

OS

The EX is another symasym , I just want to see how it will perform in it's purest form (Sigma - by dr. bora). As can be seen , I am using Rod Elliot's KIS technique , "Keep It Simple". All these are no PPM amps , but have monotonically "correct" FFT's. (pix 8)

OS

Attachments

Last edited:

have you try these kits, they work very well from: MG chemicals

Photofabrication Kit

416-K

Buy this product now

Produce printed circuit boards using the positive photofabrication process.

Photofabrication Kit

Includes:

* One 3"x5" cat# 603 presensitized single sided PCB

* One 4"x6" cat# 606 presensitized single sided PCB

* One 6"x6" cat# 609 presensitized single sided PCB

* One 475ml bottle cat# 418 Developer | Click here for MSDS

* One 475ml bottle cat# 415 Ferric Chloride | Click here for MSDS

* Two cat# 416-S Foam Brushes

* Plastic development tray

* Rubber gloves

* Instruction sheet

Additional items required:

* Exposure source and transparent weight

* Etchant tank, or glass tray, or plastic tray (for etching purposes)

* Artwork laser printed on a transparency.

* Eye protection

Available Sizes

Catalog Number Description

416-K Kit

If you want more info let me know...

Photofabrication Kit

416-K

Buy this product now

Produce printed circuit boards using the positive photofabrication process.

Photofabrication Kit

Includes:

* One 3"x5" cat# 603 presensitized single sided PCB

* One 4"x6" cat# 606 presensitized single sided PCB

* One 6"x6" cat# 609 presensitized single sided PCB

* One 475ml bottle cat# 418 Developer | Click here for MSDS

* One 475ml bottle cat# 415 Ferric Chloride | Click here for MSDS

* Two cat# 416-S Foam Brushes

* Plastic development tray

* Rubber gloves

* Instruction sheet

Additional items required:

* Exposure source and transparent weight

* Etchant tank, or glass tray, or plastic tray (for etching purposes)

* Artwork laser printed on a transparency.

* Eye protection

Available Sizes

Catalog Number Description

416-K Kit

If you want more info let me know...

That was the point of my post... For the same $40-70 , I can get to the 99% perfection of the kit. I can also build a whole lot more , a 1/4 sheet FR-4 (24 X36") is $80 . I could get a lot of amps from that.

Just the laser printer , glossy mags , Iron , gallon of HCL , a quart of H2O2. 😀

OS

Just the laser printer , glossy mags , Iron , gallon of HCL , a quart of H2O2. 😀

OS

Member

Joined 2009

Paid Member

A "realization" just came to me listening to the BX (carlo's clone). I plugged them into a cold amp , they sounded grand. After an hour , as the amp warmed up , I noticed the sound was not "as it was". I noticed the bias creeped up to almost 100ma/device , the BX has a different VAS current than the AX. I lowered it back to 12mV/50ma ... the sound was again "right". I never heard this on the AX , even with under or over bias conditions. TMC must be both negating both the GM doubling and the underbiased Xover artifacts in the AX , I hear no difference from 10mA to over 100ma.

Are you peddling TMC as the new Vanishing Cream ?

Anyhow, is this simply a case that the better sounding option has more OLG available to 'correct' the consequences of the bias error - the TMC is just extending your OLG to higher frequencies and any approach that did the same thing (such as more native OLG without two pole compensation) would be just as effective ?

Why is the bias creeping up to 100mA - something isn't working ?

I guess I do this both - "because I can , and because I want to"... 😀

Atta boy! Now you are learning 😉

(pressed down too hard , but it will do)

OS

Looks great OS! Nice to see silkscreen on there. Making them look more pro will definitely improve the sonics!

🙂

Are you peddling TMC as the new Vanishing Cream ?

Anyhow, is this simply a case that the better sounding option has more OLG available to 'correct' the consequences of the bias error - the TMC is just extending your OLG to higher frequencies and any approach that did the same thing (such as more native OLG without two pole compensation) would be just as effective ?

Why is the bias creeping up to 100mA - something isn't working ?

Cold amp , and carlo's BX clone does not have the rock solid CCS that the AX does (different standing current). Also , I just "plugged it in".. didn't check it.

😀😀😀😀

Looks great OS! Nice to see silkscreen on there. Making them look more pro will definitely improve the sonics!

I did this for 2 "backwoods" reasons ... First "because I wanted to", second.. so I would not screw up if I stuffed the boards while drunk or stoned. How they sound ??? They all sound good with enough grogg.

OS

Now THAT'S the spirit!

🙂

John

You make exceptionally exquisite boards, you have to make a YouTUbe video of your special techniques to share with us all, so we can TOO.

John

You make exceptionally exquisite boards, you have to make a YouTUbe video of your special techniques to share with us all, so we can TOO.

Thanks 🙂

Making a video looks like a lot of work and time and most of my techniques are pretty simple actually. With practice comes better results.

I would like to know what TMC & OLG mean ?

TMC = The Monkey Caper and OLG = Ocean Liner Girls.

I would like to know what TMC & OLG mean ?

Nah , Too Many Cocktails and Off -Line Gridlock.... 😀

really ,

OLG =(open loop gain) without feedback , the total gain of the amp.

TMC =(transitional miller compensation) A feedback method that corrects output stage distortions.

Making a video looks like a lot of work and time and most of my techniques are pretty simple actually. With practice comes better results.

There already is one (actually many) .. Toner Transfer Walkthrough

I just did this with the magazine. Comes out better every time. (pix 1-6)

I even screwed this one up and it came out near perfect.

OS

Attachments

In pix 5 do i see an aluminium pot ?

Do no use etchant in an aluminium pot try to find a

Non-metallic cookware can be used in both conventional and microwave ovens. Non-metallic cookware typically can't be used on the stovetop, but some kinds of ceramic cookware, for example Corningware, are an exception.

Ceramics

Glazed ceramics, such as porcelain, provide a nonstick cooking surface. Some unglazed ceramics, such as terra cotta, have a porous surface that can hold water or other liquids during the cooking process, adding moisture in the form of steam to the food. Historically some glazes used on ceramic articles have contained high levels of lead, which can possess health risks.

Glass

Borosilicate glass, such as Pyrex, is safe at oven temperatures. The clear glass also allows for the food to be seen during the cooking process.

Glass-ceramic

Glass ceramic is used to make products such as Corningware, which have many of the best properties of both glass and ceramic cookware. While Pyrex can shatter if taken between extremes of temperature too rapidly, glass-ceramics can be taken directly from deep freeze to the stove top. Their near-zero coefficient of thermal expansion makes them almost entirely immune to thermal shock.

Silicone

Silicone bakeware is light, flexible, and able to withstand sustained temperatures of 675°F (360°C).[18] It melts around 930°F (500°C), depending upon the fillers used. Its flexibility is advantageous in removing baked goods from the pan. This rubbery material is not to be confused with the silicone resin used to make hard, shatterproof children's dishware, which is not suitable for baking.

Do no use etchant in an aluminium pot try to find a

Non-metallic cookware can be used in both conventional and microwave ovens. Non-metallic cookware typically can't be used on the stovetop, but some kinds of ceramic cookware, for example Corningware, are an exception.

Ceramics

Glazed ceramics, such as porcelain, provide a nonstick cooking surface. Some unglazed ceramics, such as terra cotta, have a porous surface that can hold water or other liquids during the cooking process, adding moisture in the form of steam to the food. Historically some glazes used on ceramic articles have contained high levels of lead, which can possess health risks.

Glass

Borosilicate glass, such as Pyrex, is safe at oven temperatures. The clear glass also allows for the food to be seen during the cooking process.

Glass-ceramic

Glass ceramic is used to make products such as Corningware, which have many of the best properties of both glass and ceramic cookware. While Pyrex can shatter if taken between extremes of temperature too rapidly, glass-ceramics can be taken directly from deep freeze to the stove top. Their near-zero coefficient of thermal expansion makes them almost entirely immune to thermal shock.

Silicone

Silicone bakeware is light, flexible, and able to withstand sustained temperatures of 675°F (360°C).[18] It melts around 930°F (500°C), depending upon the fillers used. Its flexibility is advantageous in removing baked goods from the pan. This rubbery material is not to be confused with the silicone resin used to make hard, shatterproof children's dishware, which is not suitable for baking.

Can you do pcb for smd using this method?

Hi Macleod,

I have had very reasonable SMD success using this method. The photo in the link below shows a TQFP64 package before the surplus flux was removed.

http://www.diyaudio.com/forums/soli...i-am-trying-new-amplifier-57.html#post2073803

Regards,

currentflow

In pix 5 do i see an aluminium pot ?

Do no use etchant in an aluminium pot .

Thanks for materials primer , but the pot was just to heat the acid/peroxide mixture to 40C. The Glass jar is what contains the mixture.

The hotter you get it , the quicker the etch (don't go overboard). My "mix" is 1/3 H2O2 and 2/3 HCL. That equates to about 75% H2O , 23% HCL , and 2% H2O2 since neither ingredients are pure. Ace hardware muriatic is (67/33-HCL) and Walgreens peroxide is (97/3-H2O2).

BTW , I use a polyethylene tub and agitate by hand (like pannin' for gold).

OS

- Home

- Amplifiers

- Solid State

- The MONGREL (supersym II)