It is hard fighting against numbers.... especialy when they coincide with taste.

I hit the spreadsheets and calculator and went in the opposite direction again. 😀

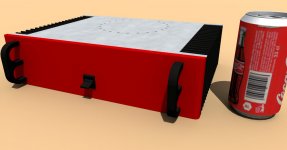

Same heatink, but the 0.8C/W 75mm high version. Cost is not all that much more, of coarse buying two transformers bites.

The case itself was streched a little and is now 300mm wide externaly. (220 internal).

Dissipation figures were as pointed out, 0.6x60=36C above ambient (in a perfect world).

Now it will be 0.8x30=24C above ambient (""""")

Plus it looks way sexy, and I have 'n even realy started playing with the looks and indicators yet, appart from choosing handles (pretty expensive little buggers, but they are realy cute, the top half is actualy cut in little teeth for grip, like a gear.

I hit the spreadsheets and calculator and went in the opposite direction again. 😀

Same heatink, but the 0.8C/W 75mm high version. Cost is not all that much more, of coarse buying two transformers bites.

The case itself was streched a little and is now 300mm wide externaly. (220 internal).

Dissipation figures were as pointed out, 0.6x60=36C above ambient (in a perfect world).

Now it will be 0.8x30=24C above ambient (""""")

Plus it looks way sexy, and I have 'n even realy started playing with the looks and indicators yet, appart from choosing handles (pretty expensive little buggers, but they are realy cute, the top half is actualy cut in little teeth for grip, like a gear.

Attachments

digits, i would be interested in building this as a headphone amp, i always love hybrid smd discrete projects (opc's version of the F5 is a great example). will you have any extra boards do you think?

I can etch you one when I get around to it, slightly busy right now, designing and putting together the cnc router to build the case with. If more people are interested we can I guess have some made at the factory but the setup fee before the first boards are made is somethiing like $60, the boards themselves would probably be under like $5 a pop.

I can etch you one when I get around to it, slightly busy right now, designing and putting together the cnc router to build the case with. If more people are interested we can I guess have some made at the factory but the setup fee before the first boards are made is somethiing like $60, the boards themselves would probably be under like $5 a pop.

I believe there may actually be enough interest to do a mini-GB (weak pun intended). I for one would be interested in a pair if the price is not outrageous. Maybe someone is willing to create a wiki sign-up sheet to check interest?

no rush at all, i have plenty of projects to keep me busy. i'm also actually quite interested in your cnc build, did you design it from the ground up, or did you use one of the project sites that are scattered around the net these days?

Forgot to ask..

How many watts can I reasonably get on a 12V rail?

What would be the size of the heatsink?

Thanks for helping

Roberto

How many watts can I reasonably get on a 12V rail?

What would be the size of the heatsink?

Thanks for helping

Roberto

Hi there, sorry for the delay, I had a house full of guests yesterday.

I'll get some quotes form the factory I use today.

P.S. the router will be a derivative of the free one you can download at makecnc.

Unfortunately all the parst are in imperial units, so I'm doing a conversion to metric parts. first and then I will modify it.

I'm not sure how good that mill is as it uses belts rather than threaded rods.

I will use it to make the next unit higher accuracy. Final plan is to scale it up to about dining table size.

I'll get some quotes form the factory I use today.

P.S. the router will be a derivative of the free one you can download at makecnc.

Unfortunately all the parst are in imperial units, so I'm doing a conversion to metric parts. first and then I will modify it.

I'm not sure how good that mill is as it uses belts rather than threaded rods.

I will use it to make the next unit higher accuracy. Final plan is to scale it up to about dining table size.

Forgot to ask..

How many watts can I reasonably get on a 12V rail?

What would be the size of the heatsink?

Thanks for helping

Roberto

Not sure if it can run from 12V rails, it can run from 12 transformers though. heatsink for 15V @ 1 amp would be in the 0.8 to 1.0 C/W range (or lower) 12V if it works could use 1.1 or so I guess.

If you want power from the units I'd build 4 channels and make a biamp system, it looses the losses in the speaker crossover network, (which are normaly subtractive of output SPL), further to that splitting the frequency range into a biamp system is about a 4 times increase in measurable output.

Member

Joined 2002

Not sure if it can run from 12V rails, it can run from 12 transformers though. heatsink for 15V @ 1 amp would be in the 0.8 to 1.0 C/W range (or lower) 12V if it works could use 1.1 or so I guess.

If you want power from the units I'd build 4 channels and make a biamp system, it looses the losses in the speaker crossover network, (which are normaly subtractive of output SPL), further to that splitting the frequency range into a biamp system is about a 4 times increase in measurable output.

12V is fine, it will be low power but it will run.

DIY Chip Amplifier Kits, PCB's, Components and Information.

Bottom of the page, is the psu boards and through hole set's for the aleph stuff.

Hi,

thanks for your help.

Does anyone know if the chipamp site is still active? I have tried to send a couple of emails but I got no reply yet...maybe just because it was sunday??

thanks for your help.

Does anyone know if the chipamp site is still active? I have tried to send a couple of emails but I got no reply yet...maybe just because it was sunday??

while shopping for heatsinks, I have found this company that seems interesting

what do you think?

TRE S SRL - heat sink with fixing clip system - series screwless

what do you think?

TRE S SRL - heat sink with fixing clip system - series screwless

Hi, sorry for not comming back yet, there was some miscommunication between me and the factory.

Anyhow, I think we would need to get a few more guys if we are going to pull of factory made boards cheaply.

As it stands now, the setup costs is about $75 dollars (which is more than the cost of the 10 boards I asked them to quote on. In tens the boards work out to about $5.50 each...

So lets hold on to the idea until we find more guys, I'll gladly share the eagle files after it is tested in construction...

Anyhow, I think we would need to get a few more guys if we are going to pull of factory made boards cheaply.

As it stands now, the setup costs is about $75 dollars (which is more than the cost of the 10 boards I asked them to quote on. In tens the boards work out to about $5.50 each...

So lets hold on to the idea until we find more guys, I'll gladly share the eagle files after it is tested in construction...

Hey there, I was a little bored this weekend, so I reworked the PCB for through hole components, also got it all single sided with 5 short wire jumpers, feeling just a little bit proud as it came in even smaller than my SMD version.... Will make the PCB's tommorrow, but have to wait for FETs ex UK.

Attachments

Last edited:

Member

Joined 2002

Hey there, I was a little bored this weekend, so I reworked the PCB for through hole components, also got it all single sided with 5 short wire jumpers, feeling just a little bit proud as it came in even smaller than my SMD version.... Will make the PCB's tommorrow, but have to wait for FETs ex UK.

are you selling boards ? id buy a few 🙂 Maybe you can work on a psu board too ?

It's becoming hard to get any thing from chipamp.com.

Pm if you wish to talk.

Jason

I don't think it would be right selling work that is not my own, appart from the layout.... First boards will just be iron on transfers as testing prototypes, but when I consider how much money goes into PSU and case, I am feeling quite strongly to have some boards made at my local fab house, they do good work, cheaper than asian counterparts, but is a hassle to deal with in that it is a micro business, and they offer less options like fancy colours and gold plateing, (they do do sterling silver though). Costs would be a little south from the previous indication, due to it now being single sided, allthough it would need silkscreen on both sides as there is a resistor underneath.... I reccon there is enough space to pop it onto the top now... just too lazy tonight.

Member

Joined 2002

I don't think it would be right selling work that is not my own, appart from the layout.... First boards will just be iron on transfers as testing prototypes, but when I consider how much money goes into PSU and case, I am feeling quite strongly to have some boards made at my local fab house, they do good work, cheaper than asian counterparts, but is a hassle to deal with in that it is a micro business, and they offer less options like fancy colours and gold plateing, (they do do sterling silver though). Costs would be a little south from the previous indication, due to it now being single sided, allthough it would need silkscreen on both sides as there is a resistor underneath.... I reccon there is enough space to pop it onto the top now... just too lazy tonight.

THe boards are your own, the layout is not, you are allowed to do that, if you ask nelson for permission.

However the propose to this, would be to get people mini a boards and put $$ back into diyaudio.com funds.

Asking nelson first will most likly get you a yes, doing behind his back pisses him and other's off 🙂

j

Yeah, don't worry mate I'll sort it all out with grandpa Nelson, as soon as the units are tested I'll let you know.

- Home

- Amplifiers

- Pass Labs

- The Mini-A