Since the fan is an important piece of this amp, cooling both the 833C output tube and the components in the chassis, failure must be detected before the excess heat melts down the 833C or overheats the components in the case.

I'm thinking of building the circuit in the attached link to sound an alarm or light a red LED in the case of fan failure.

Rather than implementing an audible or visual alarm, I suggest powering off the amp after, say, 10 seconds without a working fan. You can leave a "fan fail" LED on just to indicate what failed. If you're worried about an amp meltdown from the lack of airflow, don't design a safety system that requires the user to see/hear the alarm and take action.

According to Murphy's Law, odds are that you'll just have stepped outside for a second when the fan fails. You won't notice the alarm.

Looks like some cheap insurance.

Indeed.

You need to be able to inspect and clean the fans regularly. Forced air has a habit of packing your components with dust bunnies.

That's a good point - especially with the voltages involved on this project.

I enjoyed your EMI measurements, but as acceler8 points out, unless the EMI actually makes it to the amp output, there really is no problem here...

~Tom

Last edited:

I have 2 Noctua fans in my TubeLab SE.

I had a small fan in mine. My amp is built inside a tiny Lexan case and I initially had problems with the filament regulator shutting down, so I put in a giant heat sink with a tiny fan from a Pentium 1 chip. The 12 volt fan runs slow and quiet on the 6.5 volts for the filament regulator. It has been working great for several years. I recently noticed that the fan has died. The amp still works fine, so I just cut the fan wire to save the current.

Forced air has a habit of packing your components with dust bunnies.

We don't dust bunnies. We get gorillas. The fan still draws current and tries to run if I feed it 12 volts, so I assume that the heat, humidity, and dust killed the bearing.

One precaution; which could be a PITA with a super heavy case... You need to be able to inspect and clean the fans regularly. Forced air has a habit of packing your components with dust bunnies.

I thought about that. The chassis will be pretty much sealed except for the circular intake holes (2x80mm diameter) in the bottom panel at the rear of the box. Those holes will be covered with a low restriction intake filter and housing that pops open easily for cleaning/replacement of the filter element. So the strategy is to keep the dust out of the box in the first place; also helps to prevent HV arcing from dust as well.

Fan

The most important thing on the 833 is making sure that the SEALS on the Pins do not become comprised by too much heat...Since it is a worry (and rightfully so) I would suggest exploring using a great big Chunk of Aluminium (20 to 25 inches square 1/2 inch thick (or more if possible) as a Heat Sink.....attache the 833 Socket to this heat sink and use a Small Fan directly underneath it (directly under where the socket would be)....this will at least keep the Tube Seals from getting too hot in addition to conducting some of the heat away from the Bulb Envelope.....you might also consider using a Temperature Sensor attached to the Heatsink......you could have it switch the Fan from say 6 volts to 12 volts *assuming that you are going to run it at half power)...this particular setup I have used on 2 X 3500Z Tubes and worked fine in a 1 KW Linear for a number of years....anyway good luck

The most important thing on the 833 is making sure that the SEALS on the Pins do not become comprised by too much heat...Since it is a worry (and rightfully so) I would suggest exploring using a great big Chunk of Aluminium (20 to 25 inches square 1/2 inch thick (or more if possible) as a Heat Sink.....attache the 833 Socket to this heat sink and use a Small Fan directly underneath it (directly under where the socket would be)....this will at least keep the Tube Seals from getting too hot in addition to conducting some of the heat away from the Bulb Envelope.....you might also consider using a Temperature Sensor attached to the Heatsink......you could have it switch the Fan from say 6 volts to 12 volts *assuming that you are going to run it at half power)...this particular setup I have used on 2 X 3500Z Tubes and worked fine in a 1 KW Linear for a number of years....anyway good luck

The intake screens will clog quickly.. Be aware of that!

I have taken the dust filters off most of the PC's I service because they clog up in a week, where the heatsink won't get clogged for 6 months w/out the dust filters.

The way the big high availability servers overcome a good portion of the issue is to have the fans run at an EXTREME speed occasionally, to pull the dust through the system and blow it out the back.

I have taken the dust filters off most of the PC's I service because they clog up in a week, where the heatsink won't get clogged for 6 months w/out the dust filters.

The way the big high availability servers overcome a good portion of the issue is to have the fans run at an EXTREME speed occasionally, to pull the dust through the system and blow it out the back.

Last edited:

I enjoyed your EMI measurements, but as acceler8 points out, unless the EMI actually makes it to the amp output, there really is no problem here...

~Tom

Agreed, but I won't know that until the amp is built, then I'll have to unbuild/rebuild part of it to fix the problem. What I'm trying to do here is to identify the potential sources of problems and eliminate or reduce them before they become problems. So, I'll take some measurements and if $30 gets me lower noise fans that emit less EMI and 2-3X greater MTBF, then let's put them in the box in the first place.

There's nothing I hate more than building something neatly and cleanly, then having to take it apart and rebuild it because I didn't anticipate a problem; and it never looks as good after the rebuild, either ;-).

There's nothing I hate more than building something neatly and cleanly, then having to take it apart and rebuild it because I didn't anticipate a problem; and it never looks as good after the rebuild, either ;-).

I'm with you 100 % there. That's why I prototype circuits on a piece of plywood before committing to an enclosure.

In your case, it sounds like the $15 per fan will be well spent regardless of EMI. There's nothing worse than noisy fans.

~Tom

Magz,

attached is a drawing showing the Heat Sinks for the 833...I hope this explains it and gives you food for thought

The only problem with that is that the pins that need the cooling are on the top of the tube, especially the anode pin. I suppose the tube could be flipped over, though...

I have two big 8-finned machined aluminum heat dissipating top caps for each tube. The fan goes under the tube as you show it, and the tube is surrounded with a pyrex glass chimney, leaving about 0.4" air space all around the tube, through which the air from the fan will flow upward around the tube and the caps. That ought to do it; the 833C doesn't require fan cooling below 300W plate dissipation, and I'm only running it at 330W or so.

Fan

Hi Magz, understand that you need to cool the Plate and grid terminals...if you are using a Chimney then surely you will need to use a dedicated Blower and not a Fan...I can not see how a fan is going to blow enough air into the Chimney...If you must use a fan then you will be better of doing away with the Chimney altogether.....if you can get hold of a copy of any of the 1940 to 1960 ARRL Handbook it will give you all the information you need on Tube cooling

Hi Magz, understand that you need to cool the Plate and grid terminals...if you are using a Chimney then surely you will need to use a dedicated Blower and not a Fan...I can not see how a fan is going to blow enough air into the Chimney...If you must use a fan then you will be better of doing away with the Chimney altogether.....if you can get hold of a copy of any of the 1940 to 1960 ARRL Handbook it will give you all the information you need on Tube cooling

Hi Magz, understand that you need to cool the Plate and grid terminals...if you are using a Chimney then surely you will need to use a dedicated Blower and not a Fan...I can not see how a fan is going to blow enough air into the Chimney...If you must use a fan then you will be better of doing away with the Chimney altogether.....if you can get hold of a copy of any of the 1940 to 1960 ARRL Handbook it will give you all the information you need on Tube cooling

Well, I called it a chimney but in reality it's really just a straight glass cylinder around the tube, not pinched off at the top in any way, so there shouldn't be much pressure buildup. The idea is to protect against touching the high voltage and to provide some direction to the air flow from the fan to maximize the amount that flows past the top caps, rather than out into the room.

I suppose the tube could be flipped over, though

I was planning to flip the tube when I was thinking of making one. I had another reason in mind. I wanted to keep all the deadly electricity inside the box. That way everything above the deck is at low voltage levels.

I read a lot about these tubes, and yes, the plate seal is the one that fails, and I did find a dead tube that had failed in this manner. I read that some users inverted their tubes, and I read somewhere else that inverted tubes had another problem, but I can't remember what it was now.

Magz, I thought you might see the funny side of this......attached is the picture of a Blower that will certainly do the trick🙂

I thought I was the master of overkill!!

You could use oil cooling... They do that with computers now. 🙂

An externally hosted image should be here but it was not working when we last tested it.

I received the Noctua NF-R8 fan today and installed it using the soft mounts supplied with it (picture 1).

Compared to the Sunon fan, the Noctua is MUCH quieter, both audibly and electrically.

Audible Noise: At 7V, the Sunon noise is acceptable, but the Noctua is silent. In fact, I was able to turn the Noctua all the way up to 12V (31cfm) and leave it there, and it was still barely audible from a foot or so away. Since the tube/fan assembly will be surrounded by a 3/16" thick glass cylinder, I don't think noise will be an issue.

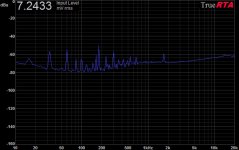

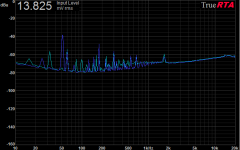

Electrical Noise: The Noctua is also much less noisy electrically than the Sunon. The Noctua at 7V unshielded is actually less noisy than the Sunon at 7V with TI-Shield between it and the probe! Picture 2 is the Noctua unshielded at 7V, Picture 3 is the Noctua unshielded at 12V, and Picture 4 is an overlay of the Sunon and the Noctua both unshielded at 7V.

Unfortunately, the Noctua is only available in their signature tan and brown color scheme, which I guess I will come to tolerate given its performance. I can always get little black screw head covers for the exposed flexible mounts.

The pitch of the Noctua blades is noticeably different from that of the Sunon, and it does seem to move air with less pressure than the Sunon, but it is so much quieter that I can afford to turn it up higher to make up for that.

Compared to the Sunon fan, the Noctua is MUCH quieter, both audibly and electrically.

Audible Noise: At 7V, the Sunon noise is acceptable, but the Noctua is silent. In fact, I was able to turn the Noctua all the way up to 12V (31cfm) and leave it there, and it was still barely audible from a foot or so away. Since the tube/fan assembly will be surrounded by a 3/16" thick glass cylinder, I don't think noise will be an issue.

Electrical Noise: The Noctua is also much less noisy electrically than the Sunon. The Noctua at 7V unshielded is actually less noisy than the Sunon at 7V with TI-Shield between it and the probe! Picture 2 is the Noctua unshielded at 7V, Picture 3 is the Noctua unshielded at 12V, and Picture 4 is an overlay of the Sunon and the Noctua both unshielded at 7V.

Unfortunately, the Noctua is only available in their signature tan and brown color scheme, which I guess I will come to tolerate given its performance. I can always get little black screw head covers for the exposed flexible mounts.

The pitch of the Noctua blades is noticeably different from that of the Sunon, and it does seem to move air with less pressure than the Sunon, but it is so much quieter that I can afford to turn it up higher to make up for that.

Attachments

Noctua Fan

Hi Magz,

Pleased that you have now got a quiet fan...and on behalf of everyone on here thank you for all the research you have done on this subject...I am sure that we will all be buying Noctua fans should we have a need for one. In addition to all of this this forum has given me the inspiration to revisit my abandoned 833 project of a few years back. I have thought about resuscitating it but this time I will be using a different Tube....I quite like the idea of going for broke and using the RCA 851...this is a real beast of a tube but the specs look good.

Hi Magz,

Pleased that you have now got a quiet fan...and on behalf of everyone on here thank you for all the research you have done on this subject...I am sure that we will all be buying Noctua fans should we have a need for one. In addition to all of this this forum has given me the inspiration to revisit my abandoned 833 project of a few years back. I have thought about resuscitating it but this time I will be using a different Tube....I quite like the idea of going for broke and using the RCA 851...this is a real beast of a tube but the specs look good.

Magz,

Does the fan case touch the amp chassis at all, or do the rubber mounts keep it off the metal?

Does the fan case touch the amp chassis at all, or do the rubber mounts keep it off the metal?

- Home

- Amplifiers

- Tubes / Valves

- The Midlife Crisis - My 833C Amp Build