Nope, they split because the rods were still in place and with the temperature change between the start of construction and the end, metal and wood expanded at different rates... hence the splitting.

If the rods would have been pulled after glueing, it wouldn't have split.

If the rods would have been pulled after glueing, it wouldn't have split.

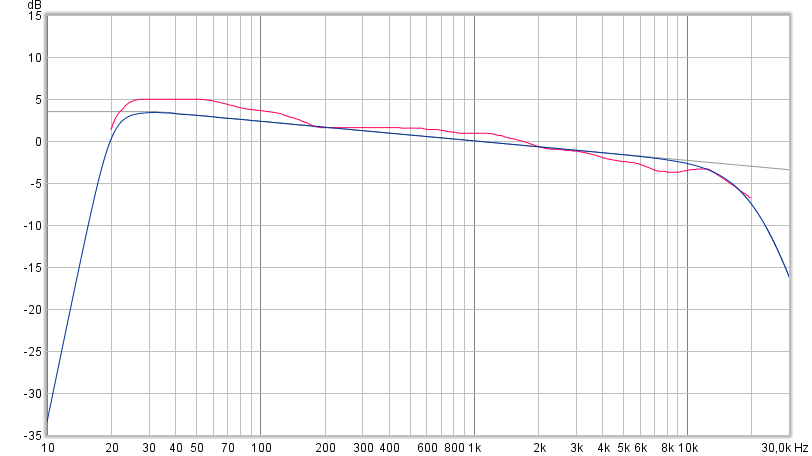

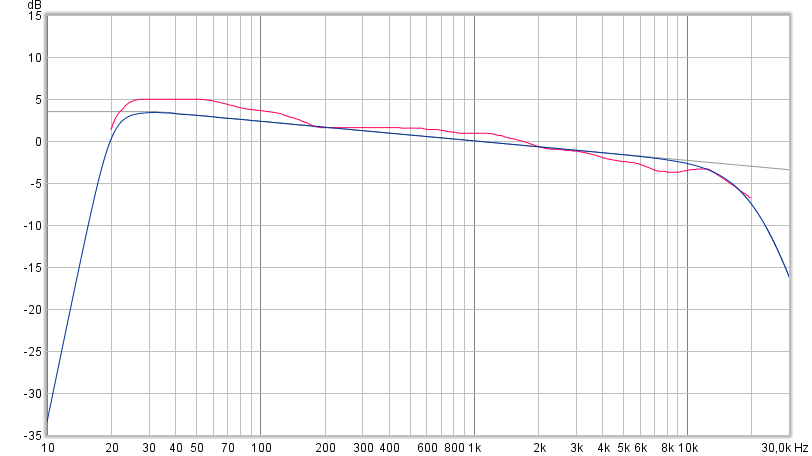

Had another look into that interesting preferred curve (red) from JBL study verse (grey) 7dB curve, think there is reason to think they have some similarities when reasonable stop bands are also added to 7dB curve which is at +3,5dB out to 30Hz point then strait declining line out to -3,5dB point at 30khz passing zero dB point at exactly 1kHz. High passed 7dB curve with a look alike of JBL study and low passed it dual 2nd order BW one at 20kHz say this is tweeter performance and one at 25kHz say this is microphone roll off and got below.

Hi BYRTT,

Whats a good way to specify this 7dB curve in rephase filters?

thanks

Hi BYRTT,

Whats a good way to specify this 7dB curve in rephase filters?

thanks

Think use some diy +20 EQs and you going 🙂 no just kidding here find my diy work in below attached zip folder as rephrase settings-file out to MHz, it is based upon a target frd-file from a pro equalizer.

Attachments

Nope, they split because the rods were still in place and with the temperature change between the start of construction and the end, metal and wood expanded at different rates... hence the splitting.

If the rods would have been pulled after glueing, it wouldn't have split.

But how would it have worked without the rods but with a baffle firmly attached? 😱

I was glad to have the rods in there, it was what held the shape together.

Most of the advise I got was to remove the rods. That was actually last on my mind. As I would have had a nightmare to attach any kind of baffle.

If I had to do it again, knowing what I know now, I'd still use rods, but slice up the enclosure like I ended up with.

The epoxy and alu have way less difference in any kind of expansion/contraction direction.

Those cabinets splitting just goes to show you the theory that plywood is superior for an enclosure like this is utter nonsense, the ply only has advantage in a single orthographic direction. I'd bet money you couldn't possibly hear the difference between the two methods and the mdf enclosure would be worlds easier to construct. Put one layer of glass/epoxy onto an mdf enclosure and I would say it would be much more stable than a few thousand layers of glued together sheets!

Still love your enclosures final look WeSaySo, just don't buy your original conclusions that drove your conclusions to build with that flawed method you used, it proved itself to you before you got out that hand saw!

ps.The only reason that ply is used in pro-audio speakers is the need for moving pro speakers from location to location and the fact that mdf will get damaged if dropped or mishandled and the actual final weight of the enclosures. MDF is heavy, hint higher mass, and a pain to move if it adds hundreds of pounds to an enclosure!

Not sure what you don't believe here... 🙂

My original plan, before starting the actual build was to build it using ply (because I like the firmness of the material) with a layer of epoxy/matt around it, no slices. The rods had rubber rings on top and bottom to deal with movement.

When I saw the bare wood sanded I changed from that plan. Figuring it would be a shame to cover up that beauty.

I was hoping to get away with it. Storing the enclosures inside proved that theory wrong. Everything that was in that enclosure design had play (designed) in it to deal with movement, just not that much! I had seen a centimetre of play (difference in length) over just one night with the bare wood, untreated. That was about the maximum I could deal with. (yes, I measured the length on a daily basis) I had hopes the PU floor paint would seal up the wood enough when used inside and out.

I don't think my original plan would have worked. I'm kind of glad I tried the bare wood look as it saved me in a way.

Picking up that hand saw was pretty weird. I'm still glad though I did not make any attempt to remove the rods.

I did consider using MDF, though all the times I have used it I never really liked working with it, I also wanted something more sturdy to be able to attach the baffles. When the plan of using aluminium for baffles came along I was even happier because that made attaching 25 drivers a whole lot more maintenance friendly. The aluminium is my favourite from the materials I worked with 🙂. I do not regret using ply and would do it again.

Last edited:

I must have missed the post where you used the rods to attach the baffle.

I meant, use the rods for the glueing and compressing all your layers, but once the glue is dry and settled, take the rods out.

Anyway, it is moot as we are way past that now! 🙂

I meant, use the rods for the glueing and compressing all your layers, but once the glue is dry and settled, take the rods out.

Anyway, it is moot as we are way past that now! 🙂

Sorry, not what I meant... The rods are not used for baffle mounting. But without the rods the all wood enclosure would expand/contract at a very different rate than that metal baffle. Even an all wood baffle would likely expand/contract at a different rate due to a different grain pattern if it's one big piece (of Birch ply).

The baffle itself is bolted to the enclosure at 52 points. It also has to seal off the enclosure. In my mind its not a good idea to have big differences in expansion rate between baffle and enclosure. I'd still risk a splitting of layers if that difference would be too large, it wouldn't ensure the seal and there would be nothing to hold it all together in case of a problem.

I looked into the material properties I could use before making the decision how to go on after the cracks in the enclosure. Matt + epoxy was the best fit i.m.h.o.

Not trying to defend anything here, as you said, for me it's all in the past anyway.

It could help or make a difference in the decision making of future builds if anyone ever gets as crazy as me to make a stacked enclosure of this size. This is how I would do it and why. I have no regrets being this crazy 😉.

The baffle itself is bolted to the enclosure at 52 points. It also has to seal off the enclosure. In my mind its not a good idea to have big differences in expansion rate between baffle and enclosure. I'd still risk a splitting of layers if that difference would be too large, it wouldn't ensure the seal and there would be nothing to hold it all together in case of a problem.

I looked into the material properties I could use before making the decision how to go on after the cracks in the enclosure. Matt + epoxy was the best fit i.m.h.o.

Not trying to defend anything here, as you said, for me it's all in the past anyway.

It could help or make a difference in the decision making of future builds if anyone ever gets as crazy as me to make a stacked enclosure of this size. This is how I would do it and why. I have no regrets being this crazy 😉.

I see.

So, I guess the idea you posted a little earlier, using foam gasket between each single driver enclosures, and keeping the rods inside might work well against the different expansion rates between the housing and the baffle.

Ok, back to your listening curve experiments... 🙂

So, I guess the idea you posted a little earlier, using foam gasket between each single driver enclosures, and keeping the rods inside might work well against the different expansion rates between the housing and the baffle.

Ok, back to your listening curve experiments... 🙂

I guess after working with both Baltic Birch and MDF I just don't have an issue working with either one. I'd like to see how the stacked height differences would compare between the two during expansion and contraction due to moisture changes before any wood is sealed.

As to using glass mat and epoxy that is a very unusual combination. I will tell you the only reason that worked was that the enclosure was a simple shape without any real contour changes. Glass mat is specifically made to work with polyester resin, the binder holding the mat together dissolves when soaked with polyester resin, epoxy will not soften the binder and on an odd shaped object you'll have a mess on your hands. Normally glass cloth is used with epoxy but I will add that would have caused some very different problems with what is called print through with glass cloth, you can see the pattern of the glass cloth on the surface of a normal laminate with epoxy/glass, would have ruined that pretty black finish WeSaySo so lovingly achieved!

As to using glass mat and epoxy that is a very unusual combination. I will tell you the only reason that worked was that the enclosure was a simple shape without any real contour changes. Glass mat is specifically made to work with polyester resin, the binder holding the mat together dissolves when soaked with polyester resin, epoxy will not soften the binder and on an odd shaped object you'll have a mess on your hands. Normally glass cloth is used with epoxy but I will add that would have caused some very different problems with what is called print through with glass cloth, you can see the pattern of the glass cloth on the surface of a normal laminate with epoxy/glass, would have ruined that pretty black finish WeSaySo so lovingly achieved!

Think use some diy +20 EQs and you going 🙂 no just kidding here find my diy work in below attached zip folder as rephrase settings-file out to MHz, it is based upon a target frd-file from a pro equalizer.

Thansks for sharing BYRTT

Is there a way to load these filters onto my existing per driver rephase filters and continue to use a single combined rephase file per driver?

saved each bank and then loaded them in my driver rephase setting files.

I will try this out.

Thanks.

I will try this out.

Thanks.

Normally glass cloth is used with epoxy but I will add that would have caused some very different problems with what is called print through with glass cloth, you can see the pattern of the glass cloth on the surface of a normal laminate with epoxy/glass, would have ruined that pretty black finish WeSaySo so lovingly achieved!

I used 4oz glass cloth and epoxy on my dark tinted wood surfboard, and I can't see the weave pattern at all. 🙂

First the enclosure was soaked in epoxy before applying the matt.

I wrapped the enclosure tight with plastic household foil after applying the epoxy to make it conform to the right shape. I got several tips how to do it from experienced boat builders. How to drench the matt with epoxy, what to watch for, removing excess epoxy etc.

After removing the foil several coats with micro-bubbles were applied with a boat lacquer roller to get the structured finish. After that it was sealed with boat paint to make it UV resistant.

I got the recipe by looking at what works in the boat industry. Epoxy does not shrink when hardening. That's the big plus.

I wrapped the enclosure tight with plastic household foil after applying the epoxy to make it conform to the right shape. I got several tips how to do it from experienced boat builders. How to drench the matt with epoxy, what to watch for, removing excess epoxy etc.

After removing the foil several coats with micro-bubbles were applied with a boat lacquer roller to get the structured finish. After that it was sealed with boat paint to make it UV resistant.

I got the recipe by looking at what works in the boat industry. Epoxy does not shrink when hardening. That's the big plus.

Last edited:

Had another look into that interesting preferred curve (red) from JBL study verse (grey) 7dB curve, think there is reason to think they have some similarities when reasonable stop bands are also added to 7dB curve which is at +3,5dB out to 30Hz point then strait declining line out to -3,5dB point at 30khz passing zero dB point at exactly 1kHz. High passed 7dB curve with a look alike of JBL study and low passed it dual 2nd order BW one at 20kHz say this is tweeter performance and one at 25kHz say this is microphone roll off and got below.

It's quite telling how little difference there is between the graphs. We are talking about a few dB's at most. Though over a large enough frequency spectrum, changes like these are obvious.

Just had a brief listen to play with mid/side levels and I have to say, I still love this balance I have now.

Over the last few weeks there have been more and more thoughts about using a single center speaker, above 700 Hz, with only one job: fill in the cross talk dips. It could be a small full range driver or tweeter with low enough Fs, maybe even in a B&O SAW like lens...

I don't expect I can "sell" that idea to my girl though. It could work for both music and Home Theatre and still be quite small. Targets the 1750 Hz dip and ~5500 Hz at most. It would need yet another channel of amplification.

Ah, well... we all must have something to dream about 🙂.

Last edited:

you could make the center speaker a "temporary" placement to try it out 🙂 or maybe style it as 3d art or maybe use a vase enclosure.

I have played around with different stereo upmixes because I was interested in the sound field shapes OmniDirectional - work in progress but mostly to compare them an omni.

The center speaker is a benefit and worth exploring.

I have played around with different stereo upmixes because I was interested in the sound field shapes OmniDirectional - work in progress but mostly to compare them an omni.

The center speaker is a benefit and worth exploring.

Its a shame that most center speakers are bulky and don't fit very well with TV or decor. I think people avoid them for this reason, especially when TVs are so thin these days.

A soundbar is thin and wide and may look better under a TV. If part of the LA concept is translated, you may be able to use a line of small speakers to "synthesize" a virtual larger driver. Possibly phased array to aim the thing to the middle. Complicated. Maybe a disguise is easier.

A soundbar is thin and wide and may look better under a TV. If part of the LA concept is translated, you may be able to use a line of small speakers to "synthesize" a virtual larger driver. Possibly phased array to aim the thing to the middle. Complicated. Maybe a disguise is easier.

Last edited:

Maybe you could try to find a Heil Air Motion Transformer and come up with a plan to incorporate it into the living room as a SteamPunk design... 🙂

Attachments

Last edited:

This concept could be interesting enough for a rough test 🙂.

I need to figure out what I would need for that, it should be as diffraction free as possible and only needs to play above ~700 Hz. The smaller, the better.

Some kind of directivity control would be a plus too.

A nice class A amplifier behind it...

Should be lots of fun! (does it ever end 😀)

I need to figure out what I would need for that, it should be as diffraction free as possible and only needs to play above ~700 Hz. The smaller, the better.

Some kind of directivity control would be a plus too.

A nice class A amplifier behind it...

Should be lots of fun! (does it ever end 😀)

- Home

- Loudspeakers

- Full Range

- The making of: The Two Towers (a 25 driver Full Range line array)