It may or may not have rubber caps on it.

if it has never been touched by anyone, the tworubber pads are always there.

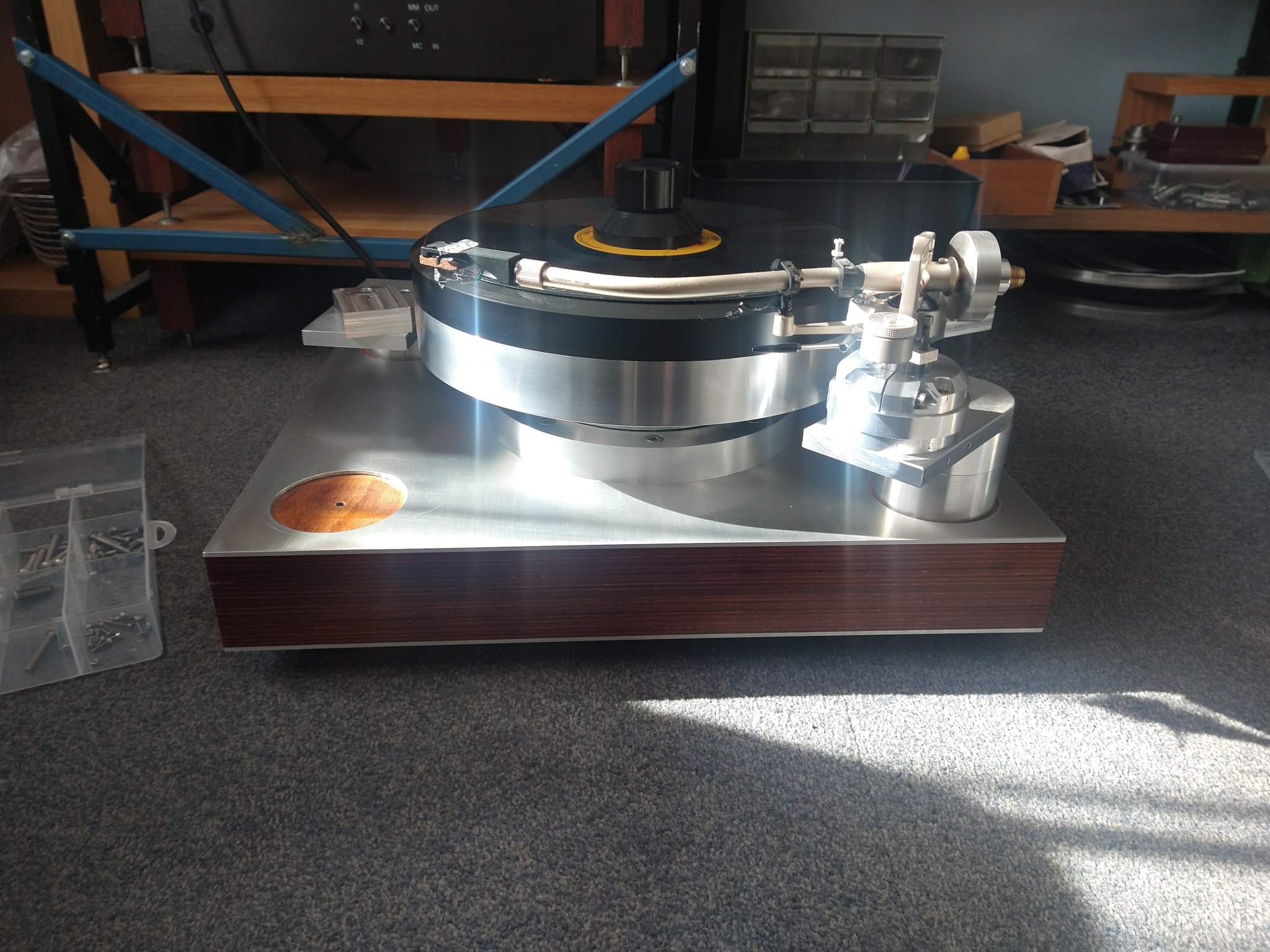

The inverted bearing motor is now installed in the plinth and operational. I need to modify the tonearm mounts to increase height as the platter now sits about 35mm higher. So there is still some work to do before I can sit down and listen to it.

I made a new de-coupled spindle and took finishing cuts on the platter which have improved runout from 0.03mm to about 0.01mm which is also repeatable removing and reinstalling the platter multiple times. I'm very happy with this result and it's a massive improvement over the stock mk2 platter wobble which the worst I have seen 0.2mm and best 0.1mm and all of the 12 units I've tested fall between these.

I made a new de-coupled spindle and took finishing cuts on the platter which have improved runout from 0.03mm to about 0.01mm which is also repeatable removing and reinstalling the platter multiple times. I'm very happy with this result and it's a massive improvement over the stock mk2 platter wobble which the worst I have seen 0.2mm and best 0.1mm and all of the 12 units I've tested fall between these.

Warren, intriguing work, very well done, please tell me about the dial gauge, why is set at an angle and what appears to be on the side of the spindle, which direction is the measurement, i thought it was axial with the shaft?

BTW, this is just for interest, the level of skill and capability to make this is way outside my capabilities!

BTW, this is just for interest, the level of skill and capability to make this is way outside my capabilities!

Hi Warrjon Congratulations on this venture and the end product it has produced.

To the casual onlooker, it will be extremely difficult to see where a SP10 MkII is responsible for such a finished design.

I like yourself have been expressing a keen interest in moving forward from the SP10 MkII Original design, I have not got up a few rungs on the ladder as of yet, but individuals I rely on to support me with my interests are established with where they want the investigations to go. I have also got myself in a position to experience a variant of a Kaneta Design using Panzerholz or Permali as the Chassis Material.

I have for a long time expressed an interest in a Platter Bearings rotation trueness, I have over the years had works undertaken on TT's to improve on the performance and am a advocate of this practice.

I for one, would really enjoy having been able to be demo'd a Bearings Spindle that is measured and maintaining a 0.01 rotation accuracy, Hats Off to You, You've earned a Beer for that effort. 🍺

The following image is a concept DD TT presented by Nick Gorman of Long Dog Audio at a Forum Annual Event I visited in 2019.

It does seem that a substantial Delrin / Acetal used on the Platter is one area where there is a design similarity.

To the casual onlooker, it will be extremely difficult to see where a SP10 MkII is responsible for such a finished design.

I like yourself have been expressing a keen interest in moving forward from the SP10 MkII Original design, I have not got up a few rungs on the ladder as of yet, but individuals I rely on to support me with my interests are established with where they want the investigations to go. I have also got myself in a position to experience a variant of a Kaneta Design using Panzerholz or Permali as the Chassis Material.

I have for a long time expressed an interest in a Platter Bearings rotation trueness, I have over the years had works undertaken on TT's to improve on the performance and am a advocate of this practice.

I for one, would really enjoy having been able to be demo'd a Bearings Spindle that is measured and maintaining a 0.01 rotation accuracy, Hats Off to You, You've earned a Beer for that effort. 🍺

The following image is a concept DD TT presented by Nick Gorman of Long Dog Audio at a Forum Annual Event I visited in 2019.

It does seem that a substantial Delrin / Acetal used on the Platter is one area where there is a design similarity.

Warren, intriguing work, very well done, please tell me about the dial gauge, why is set at an angle and what appears to be on the side of the spindle, which direction is the measurement, i thought it was axial with the shaft?

BTW, this is just for interest, the level of skill and capability to make this is way outside my capabilities!

The dial indicator is at an angle in order for the holder to clear the edge of the platter. The measurement is radial so it's measuring horizontal runout which would cause LP eccentricity.

If the horizontal runout is caused by spindle wobble it will translate into vertical wobble on the top of the platter.

I was fortunate to have a Goldmund Reference for a couple of months which allowed me to measure platter runout and it was 0.03mm vertical on the top of the platter. Spindle runout was negligible as the LP spindle was part of the bearing journal.

I have a Mk3 in a custom plinth. The plinth is roughly of the same size and dimensions as most that one sees.

I am seeking a maker of the flat-type dust covers. Probably don't need anything custom-designed....I suspect any that fit the usual Mk3 plinth tables will suit me as well. Just need a quality source.

That looks like a Dobbins plinth........

Hopefully finishing up my turntable build. I see there are many sp10 mk2 with Jelco SA-750E 10" arms. Anyone knows what is the best protractor for the cartridge alignment for that arm?

Than you!

Than you!

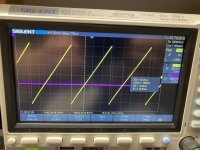

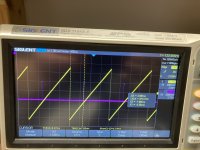

That's about as good as it gets.Does this look good? My first digital scope, pressing buttons figuring things out… had to change trim pots, those old were way unstable. 45rpm is at 5.3ms

Hopefully finishing up my turntable build. I see there are many sp10 mk2 with Jelco SA-750E 10" arms. Anyone knows what is the best protractor for the cartridge alignment for that arm?

Than you!

I'm a big fan of single-point protractors, which are a heck of a lot better than a two-point as they are agnostic to the arm length.

The sightline needs to point at the arm pivot, and thence the grid will be in the proper place for cartridge alignment. As long as the arm is mounted correctly pivot-to-spindle, it works perfectly.

Sure you could buy a MoFi Geodisc, a Feickert, or an eBay knock-off if you want, but in the short-term, look at this -

https://alignmentprotractor.com/sightline-protractor-generator

I find I prefer Stevenson over Baerwald, but try both and make up your own mind. The cost? 2 sheets of paper.

Yes, these really work.

🙂

I finally have the Franken SP10 finished. After playing a few well known LP's yesterday I can say my impression is that clarity has improved. My reference is live music I listen to every few weeks, especially un-amplified percussion. Drums and cymbals are now very close to live sound.

Very happy with the result.

Very happy with the result.

@warrjon, Very Very Nice to see the end product at work, and that it has something new to deliver that is for the better.

As an aside, if Clarity is sought, the use of PC Triple C Wire as a Signal Path Cable or Wire, has been proving to as a result of subjective evaluation to offer Clarity as a trait of the way the Copper has been produced.

As an aside, if Clarity is sought, the use of PC Triple C Wire as a Signal Path Cable or Wire, has been proving to as a result of subjective evaluation to offer Clarity as a trait of the way the Copper has been produced.

- Home

- Source & Line

- Analogue Source

- The Incredible Technics SP-10 Thread