Okay, that works for me. I think I can make it look decent. I will mill the baffle for the purify drivers then. But make them 7mm deep instead of 4mm. Do you know what kind of putty would be good to use? Plumbers putty comes to mind but it is grey. I could add some dye to it but I suspect there may be something better out in the world.

I don' t use lines anywhere, I couldn't see them anyways. I use templates for everything, but getting the templates right takes a little time. Once they are there, then things go pretty smoothly.

I do use modeling clay. It works very well. It seals the gaps and smooths the small variations quite nicely and doesn't harden. If you know that you are not going to change the driver then something more permanent might be better - like silicone or filler putty, but I am never that confident - so I use clay. It takes only a very small amount - less that a finger tip. As I said, the gap in...

I do use modeling clay. It works very well. It seals the gaps and smooths the small variations quite nicely and doesn't harden. If you know that you are not going to change the driver then something more permanent might be better - like silicone or filler putty, but I am never that confident - so I use clay. It takes only a very small amount - less that a finger tip. As I said, the gap in...

That is perfect. This stuff appears to be both black and non-hardening. So I will give it a shot. Even if it happens to harden a bit, I can simply scrape it out.I don' t use lines anywhere, I couldn't see them anyways. I use templates for everything, but getting the templates right takes a little time. Once they are there, then things go pretty smoothly.

I do use modeling clay. It works very well. It seals the gaps and smooths the small variations quite nicely and doesn't harden. If you know that you are not going to change the driver then something more permanent might be better - like silicone or filler putty, but I am never that confident - so I use clay. It takes only a very small amount - less that a finger tip. As I said, the gap in...

Thanks guys for the suggestions. I appreciate it

Mikerodrig27,

In addition to the modelling clay, here's another option:

https://www.amazon.com/Adhesive-Polyester-Protecting-Furniture-Surfaces/dp/B0BSFGBFY4/

This one has adhesive backing, there's 2 mm felt without adhesive too. Stick/glue around the inside of the cutout, and remove later when required.

Maybe do a couple of dummy driver cut outs on a piece of plywood and try out both? 🙂

In addition to the modelling clay, here's another option:

https://www.amazon.com/Adhesive-Polyester-Protecting-Furniture-Surfaces/dp/B0BSFGBFY4/

This one has adhesive backing, there's 2 mm felt without adhesive too. Stick/glue around the inside of the cutout, and remove later when required.

Maybe do a couple of dummy driver cut outs on a piece of plywood and try out both? 🙂

Last edited:

Thanks! That is a good suggestion as well. Yes, I intend to do a dummy cutout on some pieces of plywood for sure. I was actually thinking of making a template as the front baffle will be some nice wood, double checking measurements etc... I only have so much of that nice wood so can't afford to screw it up.

Now brings another question. I noticed some really nice designs of front baffles in the Elsinore Gallery on Joe's website.

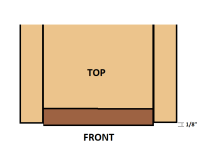

The sides are going to be Baltic birch and I was thinking of two things I could do to make the baffle more interesting. Looking at the attachment, I am thinking if set the side panels back say 3/16" or 1/8" that would be a nice little detail to separate the side panel end grain from the baffle with a little reveal. Do you think this would be too much edge diffraction? If so, I can nix the idea and just make things flush.

I am no speaker expert so I have to ask these questions 🙂

Now brings another question. I noticed some really nice designs of front baffles in the Elsinore Gallery on Joe's website.

The sides are going to be Baltic birch and I was thinking of two things I could do to make the baffle more interesting. Looking at the attachment, I am thinking if set the side panels back say 3/16" or 1/8" that would be a nice little detail to separate the side panel end grain from the baffle with a little reveal. Do you think this would be too much edge diffraction? If so, I can nix the idea and just make things flush.

I am no speaker expert so I have to ask these questions 🙂

Attachments

Mikerodrig27,

Joe stated earlier in the thread that he designed the Elsinores with a flat baffle to make it easy for DIY builders.

Our understanding is that chamfers/round overs/bevels on the sides of the baffle can help reduce the diffraction signature; again to be effective, they would need to be of a minimum size... possibly 1/2" chamfers don't help much, but probably they will not hurt. Bigger round over/chamfer might be better, but it should not make the effective baffle width narrower.

The way you are thinking of putting the baffle slightly recessed in relation to sides can make it look nice; also easy to fit the grills? 🙂 Many loudspeakers of the 70s and 80s had that aesthetic. But it is likely it will be a slight detriment to the diffraction - though the actual effect might not be very perceptible.

Joe stated earlier in the thread that he designed the Elsinores with a flat baffle to make it easy for DIY builders.

Our understanding is that chamfers/round overs/bevels on the sides of the baffle can help reduce the diffraction signature; again to be effective, they would need to be of a minimum size... possibly 1/2" chamfers don't help much, but probably they will not hurt. Bigger round over/chamfer might be better, but it should not make the effective baffle width narrower.

The way you are thinking of putting the baffle slightly recessed in relation to sides can make it look nice; also easy to fit the grills? 🙂 Many loudspeakers of the 70s and 80s had that aesthetic. But it is likely it will be a slight detriment to the diffraction - though the actual effect might not be very perceptible.

Another question for everybody in the USA. I am looking into the stuffing for the Elsinore's and would like to figure out where people are sourcing their stuffing from. I started looking around online with not much luck. I am getting ready to assemble the cabinets and would like to pre stuff a lot of them before closing them up.

zman01,

Yes, that makes sense. And If/when he responds, I suspect there will be this reaction and the thought "how many times do I have to tell these people to leave the baffle as is..." ha ha. Duly noted...

and the thought "how many times do I have to tell these people to leave the baffle as is..." ha ha. Duly noted...

In the past, he has said that a small roundover on the edge is acceptable as a means to increase the aesthetic. Something like a 6mm if I remember correctly. In this case, I will not be using a roundover. I also saw his notes on the baffle width and how the crossover would have to change to accommodate a different baffle whicn brings a few compramises.

I will skip the detail I talked about in my previous post. Sound comes first. I want to experience the Elsinore's in all their glory.

Thanks for the reply!

zman01,

Yes, that makes sense. And If/when he responds, I suspect there will be this reaction

and the thought "how many times do I have to tell these people to leave the baffle as is..." ha ha. Duly noted...

and the thought "how many times do I have to tell these people to leave the baffle as is..." ha ha. Duly noted...In the past, he has said that a small roundover on the edge is acceptable as a means to increase the aesthetic. Something like a 6mm if I remember correctly. In this case, I will not be using a roundover. I also saw his notes on the baffle width and how the crossover would have to change to accommodate a different baffle whicn brings a few compramises.

I will skip the detail I talked about in my previous post. Sound comes first. I want to experience the Elsinore's in all their glory.

Thanks for the reply!

Mikerodrig27:

I finished my Elsinores more than 6 years ago (time really does fly) and used a combination of 1" batting from Meniscus and 2" insulation (humanely made from recycled denim) called UltraTouch, which I purchased at my local Home Depot. Meniscus went out of business last year but UltraTouch still appears to be available -- indeed, I found several ads for 3.5" thick UltraTouch in a quick google search. You can undoubtedly find other thicknesses. Great stuff, highly recommended.

Regards,

Scott

I finished my Elsinores more than 6 years ago (time really does fly) and used a combination of 1" batting from Meniscus and 2" insulation (humanely made from recycled denim) called UltraTouch, which I purchased at my local Home Depot. Meniscus went out of business last year but UltraTouch still appears to be available -- indeed, I found several ads for 3.5" thick UltraTouch in a quick google search. You can undoubtedly find other thicknesses. Great stuff, highly recommended.

Regards,

Scott

SRMcGee, I remember meniscus shutting down shop. From what I understand, the business was doing well but they were wanting to sell or just shut down shop as it was just time... They were a great company. I had received some really impressive customer service from them.

It looks like Joe also talks about low density pure poly batting as well. I see the UltraTouch material. Rockwool looks tempting but I suspect it is far too dense even though it has great absorption qualities. The density seems to be of the biggest concern. I feel like fiberglass would work but with this being a ported cabinet, I don't know if that is the best idea... lol. I don't mind having extra batting material as I am going to make some more acoustic panels soon as well.

jayme, FrostKing looks like a good solution as well. Thank you!

----------------------------

I really appreciate all the answers that I have had to my questions so far. I am sure that I will have some more.

I think I am going to do a short writeup for people in the USA on making the elsinore's once I get through it all. The design for sure was curtailed to other countries which makes sense due to Joe's location. I actually had to go to both Home Depot and Lowes to find a measuring tape that had a metric scale... So my first suggestion would be to source a metric measuring tape.

It looks like Joe also talks about low density pure poly batting as well. I see the UltraTouch material. Rockwool looks tempting but I suspect it is far too dense even though it has great absorption qualities. The density seems to be of the biggest concern. I feel like fiberglass would work but with this being a ported cabinet, I don't know if that is the best idea... lol. I don't mind having extra batting material as I am going to make some more acoustic panels soon as well.

jayme, FrostKing looks like a good solution as well. Thank you!

----------------------------

I really appreciate all the answers that I have had to my questions so far. I am sure that I will have some more.

I think I am going to do a short writeup for people in the USA on making the elsinore's once I get through it all. The design for sure was curtailed to other countries which makes sense due to Joe's location. I actually had to go to both Home Depot and Lowes to find a measuring tape that had a metric scale... So my first suggestion would be to source a metric measuring tape.

Joe,

I will be adding a pair of SVS SB3000 subwoofers next week to help out the bottom octave on my ULDs for large scale orchestral music. My experiments with a summed mono ported sub with a F3 of around 20 Hz confirms the speakers do benefit from using a sub, since the ULD is not as full on the bottom as the MFD. The ULD is superior otherwise. Since you added a pair of subs to your system, I am curious about your integration approach. Presently, I am crossing over my mono sub at 40Hz, which roughly corresponds to the F3 of the ULD, and is as low as my plate amp will permit. But I have more options with stereo subs, with the DSP options on the SVS subs, and if positioned close to the Elsinores. For instance, I could plug the port and crossover the subs at 60Hz, which looks to be about the F6 for a sealed box, a 2nd order Linkwitz-Riley would in theory sum flat at the acoustic (Elsinore) + filtered (sub). Or I could just do what I am doing now, crossing over around 40Hz/4th order(or lower) augmenting the ULD running full range. Trying to avoid any active crossover (analog or digital) on the Elsinores. Anyway, your experience and advice would be helpful. Of course, I can experiment and find what works best for me and share the results.

David

I will be adding a pair of SVS SB3000 subwoofers next week to help out the bottom octave on my ULDs for large scale orchestral music. My experiments with a summed mono ported sub with a F3 of around 20 Hz confirms the speakers do benefit from using a sub, since the ULD is not as full on the bottom as the MFD. The ULD is superior otherwise. Since you added a pair of subs to your system, I am curious about your integration approach. Presently, I am crossing over my mono sub at 40Hz, which roughly corresponds to the F3 of the ULD, and is as low as my plate amp will permit. But I have more options with stereo subs, with the DSP options on the SVS subs, and if positioned close to the Elsinores. For instance, I could plug the port and crossover the subs at 60Hz, which looks to be about the F6 for a sealed box, a 2nd order Linkwitz-Riley would in theory sum flat at the acoustic (Elsinore) + filtered (sub). Or I could just do what I am doing now, crossing over around 40Hz/4th order(or lower) augmenting the ULD running full range. Trying to avoid any active crossover (analog or digital) on the Elsinores. Anyway, your experience and advice would be helpful. Of course, I can experiment and find what works best for me and share the results.

David

Joe,

A new NRX driver is out from SB Acoustics:

https://sbacoustics.com/wp-content/uploads/2025/03/6in-SB17NRX2L35-8.pdf

Would this work in the Elsinores?

A new NRX driver is out from SB Acoustics:

https://sbacoustics.com/wp-content/uploads/2025/03/6in-SB17NRX2L35-8.pdf

Would this work in the Elsinores?

Well, I'm not Joe (obviously), but I'm doubtful. These newer SB17NRX2C35-8 and SB17NRX2L35-8 variants appear to have higher break-up in the 4-8 kHz range than the older SB17NRXC35-8 driver, going by the datasheets anyway. I wonder if that might be an issue, given the low-order crossover approach used in the Elsinores. (Note that the new L variant has a bigger magnet than the old or new C versions.)

Last edited:

From what they have published and a quick look, it seems that they have increased the size of the magnet markedly and this has resulted in a few things. The voltage sensitivity is now up to 89dB which is where the original NRX driver was. The Qe of the driver is a LOT less as you would expect from a bigger magnet, which means it is much more damped electrically. Is the cone the same? It slightly shown as less mass at 13.4gr versus 13.9gr. Lighter cone would also mean a slightly lower Qe as well, but if it is the exact same cone, it could simply be explained by the fact they were not measured at the same time and exact same setup. I do see that the new driver seems to have a peak around 7KHz, again might not be a big deal. Some answers can only be gotten if I had a physical example of the driver here. CSD (waterfall) plots is one of the first things I would do.

Could it be used in the Elsinores? I fear that they are a bit to heavily damped for what I would like to see. The ULD are about Qts=0.33 (which is already a little bit on the low side for our purposes) and this NRX2L driver here is Qe=0.28 which is both the reason for higher sensitivity and greater electrical damping. For the uninitiated, the lower the number means greater damping. From what we can see, a bit too damped.

Could it be used in the Elsinores? I fear that they are a bit to heavily damped for what I would like to see. The ULD are about Qts=0.33 (which is already a little bit on the low side for our purposes) and this NRX2L driver here is Qe=0.28 which is both the reason for higher sensitivity and greater electrical damping. For the uninitiated, the lower the number means greater damping. From what we can see, a bit too damped.

Joe,

Sometimes we see that the manufacturer data shows a lower Qts vs third party/DIYer measurements; I am not saying that this will be case with this driver - only independent measurements can confirm that.

The Purifi drivers used in the Elsinore ULD - did you measure the Qts yourself or this is factory data?

Sometimes we see that the manufacturer data shows a lower Qts vs third party/DIYer measurements; I am not saying that this will be case with this driver - only independent measurements can confirm that.

The Purifi drivers used in the Elsinore ULD - did you measure the Qts yourself or this is factory data?

Sometimes we see that the manufacturer data shows a lower Qts vs third party/DIYer measurements; I am not saying that this will be case with this driver - only independent measurements can confirm that.

I hear you!

I can tell you that testing TS Params you can get different results based on just changing the levels alone. My own setup was kind of 'calibrated' by testing a bunch of drivers and finding a setup where the majority of drivers get near where they should be. The three drivers I have here, ULD plus the SB17MFC and the Vifa P17WJ, with these I get very close to where it needs to be. I set my level on Clio 6V every time. If I get a driver that significantly is different from what is published by the manufacturer, I trust my own measurement to be accurate to the driver I have in hand.

The Purifi drivers used in the Elsinore ULD - did you measure the Qts yourself or this is factory data?

Measured? Many times! And ALL of them?

Going by the datasheets, the other newish NRX driver, the 2C variant, has the same magnet as the original version Joe used, but the suspension is rather less compliant, so the Qts has gone the other way, up from 0.34 to 0.42.

Not sure if the suspension has changed, but the bigger magnet at least explain the major part of the Q.

- Home

- Loudspeakers

- Multi-Way

- The "Elsinore Project" Thread