If pain and frustration were my goal, then I am very good at it..😀

The desire is to provide enough energy to the pendulum to keep it moving without exceeding the strength of the wooden parts. Involute teeth are higher friction than cycloidal teeth. And cycloidal needs modification to tooth profile so as to limit engagement to the pitch circle as much as possible.

Measuring the delivered torque to the escape wheel is challenging, especially because the clock gears constantly switch from static friction to dynamic friction, and no lubrication can be allowed other than what the wood came with.

Aha!!! My current clock is a deadbeat escapement, which by design brings all the gears to a stop. If I add some recoil, then all the gears will back up a tad so when the pallets release the gears are already in forward movement and into dynamic friction. Hmmm, a little like de-tuning a car engine to accept lower quality gas...

Even brass movements have this static/dynamic issue, as the trick is to maintain a film of oil even when the arbors stop turning every click. Too thick, no click...too thin, metal wear.

Jn

Hey Deadbeat is what my wife calls me! John, had you considered vacuum wax impregnation to stabilize the wood?

Howie

If you use the CNC to create reference points through the work into the spoilboard, you can shift and pin the work at known offsets.

For example, if you are cutting a line array front panel with 9 4 inch drivers and 16 tweeters with a 2 inch square faceplate, the holes for the 4 incher screws could be the locators, using small pins.

My design will be vertical, and that would limit my ability to do that as the ceiling is under 6 foot in my basement.

But that made me think, if I make the CNC so that it can rotate, and add one leg that unfolds, I can store the CNC vertical, use it horizontal. Thanks for the idea...

Jn

My previous job had me designing and then making custom microscope stages, which were outside the size of our little CNC (precise though!). I pulled every registration trick in the book, so I know what you're talking about across the part shuffling to a new location point. I'm not sure if you're trying to hold microns, but that's where you quickly lose your mind. 🙂 Have fun with your new toy and ideas though!

No, I actually hadn't. When I make the laminate, I will coat both sides with epoxy, cover with wax paper, then peel the paper 24 hours later. If I don't coat the outer surfaces in epoxy, just cut the gear in it's entirety and vacuum impregnate, that waxes every single solitary surface. If the wax drops the friction coefficient as well as seals moisture out, that's a win win.

Thanks for the hint, I will research that.

Jn

Thanks for the hint, I will research that.

Jn

OMG, no. I do not have the ability to measure below .0005 inches, or 12.7 microns at home, and only that up to 3 inches. I would be happy with accuracies at the 5 mil level, or 127 microns at home. The calipers are 6 inch span, maybe .001 inch per inch. My mill dro goes to .0002 inch resolution, not sure what the inch per inch error is though.

Work, a different story entirely. Half a micron is where we schedule maintenance to fix the motion system. We give em 5 nanometer static repeatability, so the device has to mess up two orders of magnitude first. The scientists can't see any difference at 500 nanometer.

Jn

Work, a different story entirely. Half a micron is where we schedule maintenance to fix the motion system. We give em 5 nanometer static repeatability, so the device has to mess up two orders of magnitude first. The scientists can't see any difference at 500 nanometer.

Jn

When I was an apprentice toolmaker, we had a few terms for small increments. A favourite was half a gnats ****.🙂

Working at micron precision ain't easy, a friend of mine has a wire eroding company working at that level on aerospace, F1 stuff etc. 1 micron is 0.4 of a tenth in old money, nice units to work to..

Working at micron precision ain't easy, a friend of mine has a wire eroding company working at that level on aerospace, F1 stuff etc. 1 micron is 0.4 of a tenth in old money, nice units to work to..

Oddly on another thread we coined dBGnatfart as an almost immesurable different in audio.

You are stepping into treacherous waters, Bill! It almost sounds like you are implying that you can measure something that is so small it can't be heard? Where would audio be if we could measure everything more accurately than our hearing? Blasphemy!

😡😡😡

Howie

I though you were gonna say that it can't be smelt.😀

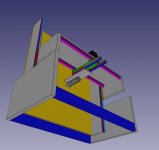

On a great note, I just found that my CNC machine model created in scad can be directly imported by the freecad software. I created the 3d drawing to see what it'll look like using the rails, router, and a rolling stand with tilt capability. For scale, the light blue rails are 1400mm, pink 1200mm, vertical working zone is 200mm, parts I have on hand.

Next I'll try to design some simple thing I can fit on the small cnc bed and try with some foam or balsawood.

Don't have the hang of conversion to a g-code file yet, I can't seem to get the icons needed to go active.

And translation and rotation are still unruly. Got it to rotate, but closed the program now I can't do it again.. One hack at a time..😱

jn

On a great note, I just found that my CNC machine model created in scad can be directly imported by the freecad software. I created the 3d drawing to see what it'll look like using the rails, router, and a rolling stand with tilt capability. For scale, the light blue rails are 1400mm, pink 1200mm, vertical working zone is 200mm, parts I have on hand.

Next I'll try to design some simple thing I can fit on the small cnc bed and try with some foam or balsawood.

Don't have the hang of conversion to a g-code file yet, I can't seem to get the icons needed to go active.

And translation and rotation are still unruly. Got it to rotate, but closed the program now I can't do it again.. One hack at a time..😱

jn

Attachments

Last edited:

+1Blasphemy!

Right on Howie. We all know the sound of singing Angels and whispering ghosts is not measurable yet paranormals hear it all the time. 😀

indra1 said:

"+1 Right on Howie. We all know the sound of singing Angels and whispering ghosts is not measurable yet paranormals hear it all the time."

I almost hate to riff off of this but I can't resist: does it require Parasound equipment for paranormals to hear it?

I know, sorry John, I am an intractable punster, I can't help it...a glass of wine doesn't help matters...

Since I am abnormal, I should start an audio brand called Absound...

Howie

"+1 Right on Howie. We all know the sound of singing Angels and whispering ghosts is not measurable yet paranormals hear it all the time."

I almost hate to riff off of this but I can't resist: does it require Parasound equipment for paranormals to hear it?

I know, sorry John, I am an intractable punster, I can't help it...a glass of wine doesn't help matters...

Since I am abnormal, I should start an audio brand called Absound...

Howie

Wait till the designer reads this.does it require Parasound equipment for paranormals to hear it?

Figured out how to create a g code toolpath.

It appears that to create a toolpath, first you have to specify a tool. Duh, obvious no???

Apparently they didn't think that little slightly important point had to be in the software manual. Sigh.

Software manual writers.... is there any wonder why most people don't try to read the instructions??

My gripe of the day.

Jn

It appears that to create a toolpath, first you have to specify a tool. Duh, obvious no???

Apparently they didn't think that little slightly important point had to be in the software manual. Sigh.

Software manual writers.... is there any wonder why most people don't try to read the instructions??

My gripe of the day.

Jn

Last edited:

Yes, I've spent too much of this afternoon delving once again into the myriad vagaries of AviSynth. (RTFM? Okay, which one?! 😕)

A tool is a hardware device, obviously not something a software manual writer would think of!

JN,

If it makes you feel worse, everyone here except for one warm body can write the G code for my turret press. So we had to get rid of the mouse that snuck in.

I did purchase a not inexpensive software package at the time I got the turret press. It was supposed to allow a graphic drawing to be turned into G code. I spoke to the folks when it didn't work. They explained to me how it decided to return the sheet after processing by moving it back by half of the maximum travel, that was after I gave them the correct code. Of course they didn't even consider fixing that. Ever try to remove work from the belly of a machine that is bigger than some cars?

The other even more useless function was they expected you when sending code to the machine to press a control panel button to accept it. (Like I am going to keep a high end drafting computer next to a machine tool!). Even more fun the software used a dongle. Anyone have a current computer using a parallel port dongle?

(I keep an otherwise obsolete computer around for my 3 axis milling machine that requires one!)

If it makes you feel worse, everyone here except for one warm body can write the G code for my turret press. So we had to get rid of the mouse that snuck in.

I did purchase a not inexpensive software package at the time I got the turret press. It was supposed to allow a graphic drawing to be turned into G code. I spoke to the folks when it didn't work. They explained to me how it decided to return the sheet after processing by moving it back by half of the maximum travel, that was after I gave them the correct code. Of course they didn't even consider fixing that. Ever try to remove work from the belly of a machine that is bigger than some cars?

The other even more useless function was they expected you when sending code to the machine to press a control panel button to accept it. (Like I am going to keep a high end drafting computer next to a machine tool!). Even more fun the software used a dongle. Anyone have a current computer using a parallel port dongle?

(I keep an otherwise obsolete computer around for my 3 axis milling machine that requires one!)

Last edited:

Well, the difference between you and me is..

I make ineptitude look good.😎

There is no visual difference between being the foundation upon which everything is built....and low man on the totem pole..

Having everyone in the shop understand and be able to use potentially very dangerous equipment makes for a very safe shop. Kudos to you.

Jn

Ps. How do you know the mouse could not do g-code? Didn't you watch hitchikers guide to the galaxy??

Jn

I make ineptitude look good.😎

There is no visual difference between being the foundation upon which everything is built....and low man on the totem pole..

Having everyone in the shop understand and be able to use potentially very dangerous equipment makes for a very safe shop. Kudos to you.

Jn

Ps. How do you know the mouse could not do g-code? Didn't you watch hitchikers guide to the galaxy??

Jn

Last edited:

I once met someone who could write user manuals from source code. She was slightly scary, but amazing at her job!Software manual writers.... is there any wonder why most people don't try to read the instructions??

- Home

- Member Areas

- The Lounge

- The Black Hole......