JN,

Shop safety is a multifaceted problem. The most dangerous tool in most shops is the table saw. I know folks with modified thumbs, not to mention thrown pieces causing injuries. I replaced my Delta Unisaw with a moving table Felder. The next biggie is of course the press brake, it uses triple relay safeguards along with requiring both hands on the controls to move the ram. Pretty sure the ram coming down on an arm would take it off with quite a bit of mess.

Third issue is the forklift, way too many ways to do a substantial injury.

Of course almost everyone here has taken the basic OSHA safety courses.

Still have to get the wood shaper up and running. On a per use time basis it is far more effective at removing fingers than a table saw!

Then there is the issue of one idiot sticking his head in front of the loudspeaker array as it was being powered up.

Strangely enough we get regular insurance inspections. One inspector was surprised our inspections are based on time since the last one, not as apparently normal following a claim.

We have had claims, one guy using his oversized knife cut his fingers trying to cut a cable tie. That made it to a hospital visit but no time off. Other incident was some one lowering a ladder with his finger not clear of the lowering rungs. Another hospital visit. Worst case was a fellow who smoked too much dope falling of a 5' off the ground scaffolding by managing to hold onto the safety rail and pivoting under it. That was a dischargable condition.

I have fired guys for standing on top of a ladder when they wanted to save time by not getting a longer ladder.

In 50 years at it I am pretty sure we are below average in injuries. Not as sure about fatalities!

Our most important rule is that if you make two silly mistakes of any kind, you are done for the day. The theory is the third silly mistake too often involves blood and hospital visits.

The second rule is fire stupid people! I had one fellow actually put his hand in a loudspeaker truss gap to see if it would move. Had it moved he would have lost fingers.

Shop safety is a multifaceted problem. The most dangerous tool in most shops is the table saw. I know folks with modified thumbs, not to mention thrown pieces causing injuries. I replaced my Delta Unisaw with a moving table Felder. The next biggie is of course the press brake, it uses triple relay safeguards along with requiring both hands on the controls to move the ram. Pretty sure the ram coming down on an arm would take it off with quite a bit of mess.

Third issue is the forklift, way too many ways to do a substantial injury.

Of course almost everyone here has taken the basic OSHA safety courses.

Still have to get the wood shaper up and running. On a per use time basis it is far more effective at removing fingers than a table saw!

Then there is the issue of one idiot sticking his head in front of the loudspeaker array as it was being powered up.

Strangely enough we get regular insurance inspections. One inspector was surprised our inspections are based on time since the last one, not as apparently normal following a claim.

We have had claims, one guy using his oversized knife cut his fingers trying to cut a cable tie. That made it to a hospital visit but no time off. Other incident was some one lowering a ladder with his finger not clear of the lowering rungs. Another hospital visit. Worst case was a fellow who smoked too much dope falling of a 5' off the ground scaffolding by managing to hold onto the safety rail and pivoting under it. That was a dischargable condition.

I have fired guys for standing on top of a ladder when they wanted to save time by not getting a longer ladder.

In 50 years at it I am pretty sure we are below average in injuries. Not as sure about fatalities!

Our most important rule is that if you make two silly mistakes of any kind, you are done for the day. The theory is the third silly mistake too often involves blood and hospital visits.

The second rule is fire stupid people! I had one fellow actually put his hand in a loudspeaker truss gap to see if it would move. Had it moved he would have lost fingers.

Last edited:

^ No slider on the shaper, Ed? That, to me, seems to be the ticket as it forces people to be far afield of the cutters. And a sled makes for a better cut, anyways.

No sliding table on a shaper. It uses a power feeder so you should not need to touch it. Typical use of a shaper is to make a 12 foot length of moulding. A 24 foot travel would be a bit much for most shops. Otherwise the use would be to make lock miter joints on loudspeaker enclosures.

On its' baby brother the router table there is a sliding table.

On its' baby brother the router table there is a sliding table.

I'm happy if I can get a 10 foot piece of wood into my basement. It has to be flexible..

I designed up a 30 tooth escape wheel in scad, imported it to freecad..well, tried to import..

Program locked up...so, diagnostic mode time...

1 tooth, 6.3 seconds to load.

2 teeth 8.12.

8 teeth, 50.6.

16 teeth, 7 minutes, 24 seconds..

Turns out it's exponential, 30 teeth requires 111 days (or 160,000 seconds) (according to excel).

Ok, scrap that method.

What is happening is scad is creating lots of mesh because I specify the number of facets for the cylinder wall. 5 facets makes a pentagon, 200 makes a reasonably smooth curve. Unfortunately scad doesn't pass on a cylinder, just the facet information. That is what freecad uses to make it's model. I had this issue when I made a 3-d print for a homing plate for a machine at work..when I turned over the scad file to the design room, their pullup had lots and lots of mesh elements..

The exponential relation still holds when I drop cylindrical resolution to 10 facets, but it gets 30 teeth down to 2:45. Made it to freecad, just doesn't look good.

So now I'm plowing through freecad to make the model. Works ok and looks good, just don't understand the heirarchy yet. Don't now how to duplicate a structure yet...

Ed, can you find me that mouse???

jn

I designed up a 30 tooth escape wheel in scad, imported it to freecad..well, tried to import..

Program locked up...so, diagnostic mode time...

1 tooth, 6.3 seconds to load.

2 teeth 8.12.

8 teeth, 50.6.

16 teeth, 7 minutes, 24 seconds..

Turns out it's exponential, 30 teeth requires 111 days (or 160,000 seconds) (according to excel).

Ok, scrap that method.

What is happening is scad is creating lots of mesh because I specify the number of facets for the cylinder wall. 5 facets makes a pentagon, 200 makes a reasonably smooth curve. Unfortunately scad doesn't pass on a cylinder, just the facet information. That is what freecad uses to make it's model. I had this issue when I made a 3-d print for a homing plate for a machine at work..when I turned over the scad file to the design room, their pullup had lots and lots of mesh elements..

The exponential relation still holds when I drop cylindrical resolution to 10 facets, but it gets 30 teeth down to 2:45. Made it to freecad, just doesn't look good.

So now I'm plowing through freecad to make the model. Works ok and looks good, just don't understand the heirarchy yet. Don't now how to duplicate a structure yet...

Ed, can you find me that mouse???

jn

Let's see if I understand this, a skilled craftsman could cut the gear by hand in way less time than the software would take to load?

My machinist training says a skilled craftsman can keep an accuracy of .005" by hand.

What pitch angle are you aiming for? Seems with four or more axis and the right bit routing out a gear should be much easier.

I always though a metal shaper was a completely obsolete piece of gear until I met a machinist who specialized in using them for gear cutting.

I do have an indexing head that uses guides. Of course for a bit of change you can get a continuously variable one.

Have you ever seen a gear being cut on a lathe?

Seems we have different approaches to cutting gears.

Next time I see the mouse....

My machinist training says a skilled craftsman can keep an accuracy of .005" by hand.

What pitch angle are you aiming for? Seems with four or more axis and the right bit routing out a gear should be much easier.

I always though a metal shaper was a completely obsolete piece of gear until I met a machinist who specialized in using them for gear cutting.

I do have an indexing head that uses guides. Of course for a bit of change you can get a continuously variable one.

Have you ever seen a gear being cut on a lathe?

Seems we have different approaches to cutting gears.

Next time I see the mouse....

Last edited:

Worse yet I just realized I have exceeded adding one tool a week to my personal collection over my lifetime so far! Good thing my small shop is a half acre!

No sliding table on a shaper. It uses a power feeder so you should not need to touch it. Typical use of a shaper is to make a 12 foot length of moulding. A 24 foot travel would be a bit much for most shops. Otherwise the use would be to make lock miter joints on loudspeaker enclosures.

On its' baby brother the router table there is a sliding table.

Makes sense -- and I hadn't realized how integrated you are in terms of product delivered (versus jobbing out the fab work).

Yes. It only takes me about an hour using the pin router. The guide fixture is the difficult thing, I make it in aluminum.Let's see if I understand this, a skilled craftsman could cut the gear by hand in way less time than the software would take to load?

The pin router fixturing is at that level. By hand, I would probably sever a finger.My machinist training says a skilled craftsman can keep an accuracy of .005" by hand.

None of the gears in a clock are involute, this due to friction. Cycloidal and epicycloidal rule, with slight mods of course.What pitch angle are you aiming for? Seems with four or more axis and the right bit routing out a gear should be much easier.

My pin router fixturing includes indexing plates. I have a 60 and 64 tooth set. If I need a count not available, my mill software comes with software that can setup N holes on an arbitrary circle.I do have an indexing head that uses guides. Of course for a bit of change you can get a continuously variable one.

I have. I had considered an indexer for the slide.Have you ever seen a gear being cut on a lathe?

No, we don't. building and running a CNC is not about production runs of wooden escape wheels. It's all about the learning curve needed for a CNC. At work, we make some very very sophisticated objects. If I tell the ME's I need something that cannot be fabricated, what good am I? Understanding what the mechanics can do, and the limitations, makes a better engineer.Seems we have different approaches to cutting gears.

As a hobby, the 3d printing is fun, but the accuracies are not that good when the print extrusion is line fit and 400 microns wide. Sometimes I'll need a part a tad more accurate.

Great.Next time I see the mouse....

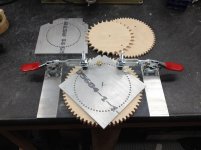

Here's one of the fixtures. Base is .250 alum 6 by 12, 600 grit emery glued to it to prevent sliding, plates are both indexing wheel and tooth profile. Granted, I can only do maybe 8 tooth profiles depending on radius.

jn

Bill, he's only being practical from a production point of view. If it exists out there and it reasonably priced, I'm sure he'll buy it. If it's custom or too expensive and in house is cheaper, that's what he'll do. (I would in that position).

For me, I'm getting ready to make a harmonic drive using the 3d printers. I need a good rotary stage for my EDM so just ordered the timing belts. Also, for the linear stage, an 8mm pitch leadscrew with a 1.8 degree stepper at 32 microsteps gives 1.25 micron resolution, but that is not a great way to get it open loop, microstepping is so dependent on friction.

Here is a vid explaining a harmonic drive build. He wasn't very tight on accuracy, just concept, he should have used offset cams to be able to adjust the bearing to belt fit.. I would make the rotary stage using a double conical bearing set, even ABEC 5's aren't good enough.

3d printed harmonic drive - Bing video

Attachments

Last edited:

Bill,

My rule on buying tools is that I have to spend more on the raw material that the tool used than on the tool. Usually we buy finished product and make things that fill out the bill of materials. The exceptions are things like loudspeaker mounting brackets that the loudspeaker manufacturers have made by others. That is quite simply I have a better equipped shop than the folks who make the brackets and the cost difference is almost unreal! A typical U bracket is $50 from the loudspeaker manufacturer and about $4.00 made in house. Rack panels cost me under a dollar and even commercial blank panels cost at least three times that. Look at the price of a custom one that holds say 4 XLR connectors and one RCA. The cheap way to buy that would be a panel with 12 XLR cutouts and fill 8 of them with blank covers, one drilled for the RCA.

JN,

We actually do gears differently. I like the blank vertical and cutting perpendicular to the blank. If I did it flat like you show I would use my CNC machine that is designed to engrave panels. That has resolution so fine I have no clue to the limit. I can do text well under 1:8".

Bill,

That reminds me my small CNC cost around $25,000. Paid for itself within a year as the going rate is about $.25 per engraved letter. I have gone through about 300 cutters at five resharpenings per and no less than 100 letters in stainless steel per sharpening! Probably one to three thousand plastic letters per sharpening. Pretty sure it had paid for itself.

My turret press is my most expensive tool. Each punch is good for at least three hundred punches per sharpening and some thousands. It does have a resettable hole counter. Haven't really paid attention to it. Figure I have punched at least 350 panels in the first year with a minimum of twelve holes to make a blank panel! At least double that for even the smallest panels at the market price of $1.00 per hole and allowing nothing for resale and that would require more than a few years for payback. So still working after 30 years I think I got my money's worth.

My rule on buying tools is that I have to spend more on the raw material that the tool used than on the tool. Usually we buy finished product and make things that fill out the bill of materials. The exceptions are things like loudspeaker mounting brackets that the loudspeaker manufacturers have made by others. That is quite simply I have a better equipped shop than the folks who make the brackets and the cost difference is almost unreal! A typical U bracket is $50 from the loudspeaker manufacturer and about $4.00 made in house. Rack panels cost me under a dollar and even commercial blank panels cost at least three times that. Look at the price of a custom one that holds say 4 XLR connectors and one RCA. The cheap way to buy that would be a panel with 12 XLR cutouts and fill 8 of them with blank covers, one drilled for the RCA.

JN,

We actually do gears differently. I like the blank vertical and cutting perpendicular to the blank. If I did it flat like you show I would use my CNC machine that is designed to engrave panels. That has resolution so fine I have no clue to the limit. I can do text well under 1:8".

Bill,

That reminds me my small CNC cost around $25,000. Paid for itself within a year as the going rate is about $.25 per engraved letter. I have gone through about 300 cutters at five resharpenings per and no less than 100 letters in stainless steel per sharpening! Probably one to three thousand plastic letters per sharpening. Pretty sure it had paid for itself.

My turret press is my most expensive tool. Each punch is good for at least three hundred punches per sharpening and some thousands. It does have a resettable hole counter. Haven't really paid attention to it. Figure I have punched at least 350 panels in the first year with a minimum of twelve holes to make a blank panel! At least double that for even the smallest panels at the market price of $1.00 per hole and allowing nothing for resale and that would require more than a few years for payback. So still working after 30 years I think I got my money's worth.

Ed, you need a 3D printer...not sure why the pic is sideways...

ps..those were printed at lowest resolution, if I use 120 micron slicing, it gets much better print quality just takes longer.

ps.. I have an 8 input mixing panel, a color coded snake 25 feet long..I recently purchased 1000 feet of belden (sumptin) and will make a 125 foot snake, the stage end will be a section of aluminum C channel (for weight) with 8 xlr holes. I have 8 snake to mic cables, and just got the colored heatshrinks to code them and the mics.

Did a reception talk with 7 speakers, and during the Q and A, it would have been great to see the mic colors from the mixer, as the speakers were not used to public discussions so I had to drop all mics except the person answering the question.

jn

ps..those were printed at lowest resolution, if I use 120 micron slicing, it gets much better print quality just takes longer.

ps.. I have an 8 input mixing panel, a color coded snake 25 feet long..I recently purchased 1000 feet of belden (sumptin) and will make a 125 foot snake, the stage end will be a section of aluminum C channel (for weight) with 8 xlr holes. I have 8 snake to mic cables, and just got the colored heatshrinks to code them and the mics.

Did a reception talk with 7 speakers, and during the Q and A, it would have been great to see the mic colors from the mixer, as the speakers were not used to public discussions so I had to drop all mics except the person answering the question.

jn

Attachments

Last edited by a moderator:

Ed, I understand on the hole punches and related. But doesn't explain all the woodworking stuff if you are buying in speakers, other than your super precise picket fence!

(and you know I am only ribbing you).

(and you know I am only ribbing you).

Denon Lemon the sequel

So as I can't return my CD player that won't play CDs until lockdown is over I have been using it. Over the last 6 weeks the damn thing has gotten better such that now, all the CDs it wouldn't play it now will. Some still take 10 seconds to find track one but eventually all is good.

This is curious and I can only assume that the cheesy plastic in the servo arm has had enough cycles to rub off the rough spots and work reliably.

Wife in kitchen happy again.

So as I can't return my CD player that won't play CDs until lockdown is over I have been using it. Over the last 6 weeks the damn thing has gotten better such that now, all the CDs it wouldn't play it now will. Some still take 10 seconds to find track one but eventually all is good.

This is curious and I can only assume that the cheesy plastic in the servo arm has had enough cycles to rub off the rough spots and work reliably.

Wife in kitchen happy again.

Ed, I understand on the hole punches and related. But doesn't explain all the woodworking stuff if you are buying in speakers, other than your super precise picket fence!

(and you know I am only ribbing you).

Sometimes stock loudspeakers are not quite right, but more often we will make the control room furniture. Architects often design counters for mixing consoles that have no wiring access or are high enough to block the view.

If you ever price the difference between having the jobsite crew of either the general contractor or furnishing folks vs just bringing the right desk you just might be surprised to see which is more cost effective.

Worst case I had was when my desk was white oak and the architect had accepted birch as a substitute for the other counters. Of course ince the console covered most of the surface and the cost adder came in white oak was fine.

BTW white oak here is different than where you are! Packing crates I used to get from British manufacturers were Polish pine. Turned one into a nice looking table.

Side benefit of the woodshop is pieces like a front door, carved panels etc. for my house and others who work for me.

Also when we give tours of the place the woodshop is the place that most impresses some. They know what w woodshop is! No idea how many of my other tools actually cost more than the entire wood shop!

Personally I'll be impressed when you also have a pick and place machine and IR reflow oven setup for your microphones 🙂

I get it, but anyone with a recent MBA walking into your shop would blow a fuse as they would not be able to get their head around it.

And as you note, if as well as earning you the money the staff get to use the odd bit of down time for a homer then you get much happier staff.

What makes me smile is how there are some who furrow their brows if you say you have a machine shop, but think rapid prototyping printers are the greatest. They've never seen how rapid a good NC mill is in the right hands.

I get it, but anyone with a recent MBA walking into your shop would blow a fuse as they would not be able to get their head around it.

And as you note, if as well as earning you the money the staff get to use the odd bit of down time for a homer then you get much happier staff.

What makes me smile is how there are some who furrow their brows if you say you have a machine shop, but think rapid prototyping printers are the greatest. They've never seen how rapid a good NC mill is in the right hands.

Bill,

I looked at the cost and can't see getting my money out of it. As I pay about $15 for the fully populated and assembled PCB it doesn't fly. The other issue is my sub contractor does get a better price on the parts.

I was surprised to find out runs of 1,000 pieces makes me appear on the radar of the component manufacturers! Seems what I consider real quantities are mostly made offshore. So far I have three products that get done in runs of 1,000 units at a time.

Biggest issue is parts availibility. I tried placing an order for two reels of the single sourced part. One email and two phone calls not returned.

As to CNC mill you need to see a turret press in action. Need 1,000 small cases? Under an easy day.

I looked at the cost and can't see getting my money out of it. As I pay about $15 for the fully populated and assembled PCB it doesn't fly. The other issue is my sub contractor does get a better price on the parts.

I was surprised to find out runs of 1,000 pieces makes me appear on the radar of the component manufacturers! Seems what I consider real quantities are mostly made offshore. So far I have three products that get done in runs of 1,000 units at a time.

Biggest issue is parts availibility. I tried placing an order for two reels of the single sourced part. One email and two phone calls not returned.

As to CNC mill you need to see a turret press in action. Need 1,000 small cases? Under an easy day.

Yeah there is always one component on 26 week lead time.

back in the last century we were using about 400 cabinets a week on the production line. Custom jobs for outside GSM basestation installation. I went to a couple of cabinet makers and was mightily impressed by the speed they were punching and bending metal in the big machines on the production floor.

A sizable pick and place line is differently impressive. But still fun to watch it.

back in the last century we were using about 400 cabinets a week on the production line. Custom jobs for outside GSM basestation installation. I went to a couple of cabinet makers and was mightily impressed by the speed they were punching and bending metal in the big machines on the production floor.

A sizable pick and place line is differently impressive. But still fun to watch it.

Punching of course can have very loud impulse noise. The kind that damages hearing because it is so short you don't realize how loud it can be. Who knew moving an effective piston of 6 square inches with 50,000 pounds of pressure a quarter of an inch displacement in 150 milliseconds would create very high sound pressure levels!

- Home

- Member Areas

- The Lounge

- The Black Hole......