loninappleton said:

some people swear by the Voigt pipe...........

I do have a pair of 8" that have whizzers and were on deal as remainders from Roland electronic keyboard mfg.

And some folks swear at them. 😉

These specs fit your decription, though no way to know for sure without actually measuring yours of course.

Thanks to Zene:

Paper cone Roland 8" is/are: (Used Peak Inst. for test, only broke-in 12 hrs.)

Fs = 78.76 hz

Vas = 24.5 L/0.8652 cu ft

Re = 7.309

Le = .2462 mh

Qms = 5.772

Qes = 1.977

Qts = 1.473

Sd = 214 sq cm/33.17 sq in

BL = 4.4456 N/A (calc'd)

Spl 89.65 1w/1m

Pe = 30W

Get out the ceiling speaker hole saw or open baffle.

GM

Just curious,

but which are your favourite binding posts?

I'm building my BIBs and I can't decide what binding posts to buy.

And one more question, is it a good idea to use magnet wire instead of CAT5 wire for the inside connections? And why not from amp to BIBs, too?

but which are your favourite binding posts?

I'm building my BIBs and I can't decide what binding posts to buy.

And one more question, is it a good idea to use magnet wire instead of CAT5 wire for the inside connections? And why not from amp to BIBs, too?

resident said:Just curious,

but which are your favourite binding posts?

I'm building my BIBs and I can't decide what binding posts to buy.

And one more question, is it a good idea to use magnet wire instead of CAT5 wire for the inside connections? And why not from amp to BIBs, too?

I say no binding post is always the best way to go, hook straight to the driver and leave enough wire for your speaker position and application.. I have 12 feet of Cat5 per speaker for my BIB's, and it's all good😎 Dave🙂

What DaveCan said WRT binding posts, though be sure and use identical length wire runs and fold any excess in a lazy back and forth pattern since coiled creates an inductor.......

If posts must be used, then either make them copper studs with the appropriate split lock washer, nut or a fine threaded machine screw insert with the appropriate split lock washer and machine screw with ring tongue connector wire terminations, preferably cold welded, i.e. properly crimped using dies designed for the connector. The latter is typically too expensive for the casual DIYer though, so a soldered so-so crimp is recommended.

WRT actual wire used, single strand solid core has the lowest voltage drop for a given wire gage, so magnetic coil winding wire is a 'no-brainer' choice and assuming you're not using it as a contour filter (as $boutique$ wire is designed to do) it needs to be large enough to keep voltage drop acceptably low.

CAT 5, etc., is boutique on-the-cheap, so you can 'roll' your own to find which effective gage/braiding pattern sounds best to you if you'd rather insert any R/L/C into the speaker path without adding components.

GM

If posts must be used, then either make them copper studs with the appropriate split lock washer, nut or a fine threaded machine screw insert with the appropriate split lock washer and machine screw with ring tongue connector wire terminations, preferably cold welded, i.e. properly crimped using dies designed for the connector. The latter is typically too expensive for the casual DIYer though, so a soldered so-so crimp is recommended.

WRT actual wire used, single strand solid core has the lowest voltage drop for a given wire gage, so magnetic coil winding wire is a 'no-brainer' choice and assuming you're not using it as a contour filter (as $boutique$ wire is designed to do) it needs to be large enough to keep voltage drop acceptably low.

CAT 5, etc., is boutique on-the-cheap, so you can 'roll' your own to find which effective gage/braiding pattern sounds best to you if you'd rather insert any R/L/C into the speaker path without adding components.

GM

Thanks for the replies.

Dave, from where did you take off the wire from the cabinet? Just from a hole from the back?

GM,

Sorry for my newbiness but what does WRT, means?

I thought that a CAT5 wire is two solid core wires twisted together. So, thought that I could use two copper solid core wires instead of the CAT5... isn't the same?

I haven't seen from close a CAT5...

Dave, from where did you take off the wire from the cabinet? Just from a hole from the back?

GM,

Sorry for my newbiness but what does WRT, means?

I thought that a CAT5 wire is two solid core wires twisted together. So, thought that I could use two copper solid core wires instead of the CAT5... isn't the same?

I haven't seen from close a CAT5...

resident said:Thanks for the replies.

Dave, from where did you take off the wire from the cabinet? Just from a hole from the back?

GM,

Sorry for my newbiness but what does WRT, means?

I thought that a CAT5 wire is two solid core wires twisted together. So, thought that I could use two copper solid core wires instead of the CAT5... isn't the same?

I haven't seen from close a CAT5...

My BIB's are inverted and I'm using fe108es drivers.. I drilled a hole through the internal baffle right behind the driver and ran the wire to the driver then caulked the wire in the hole shut. Then ran the wire down through the mouth... Used one full 12' length of cat5 outdoor rated wire per driver, twisted two wires together for neg and two for pos.. Sound great to me, and not using binding posts takes all that metal out of the equation for the signal to pass through.. If you go down to the bottom of the page to the thread called 4.5 and 6.5 driver comparisons, I posted pics of my BIB there... Dave🙂

thanks!!

Always had problems with acronyms and text messages....

WRT CAT5 wire ;-) the copper wires in the cable are solid or branded?

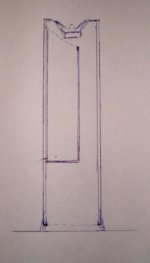

working on a new pennant

Last pennant I made was tacked with nails onto a board.

This time around I'm using 2 pieces of thin masonite with the new wider pennant (had to redo the BIB) sandwiched between. I think this will be better for flush mounting.

To keep the width of the pennant hanger down, I thought of coat hanger but did not pursue it.

Pennant wrapped around some dowel might work too.

Last pennant I made was tacked with nails onto a board.

This time around I'm using 2 pieces of thin masonite with the new wider pennant (had to redo the BIB) sandwiched between. I think this will be better for flush mounting.

To keep the width of the pennant hanger down, I thought of coat hanger but did not pursue it.

Pennant wrapped around some dowel might work too.

Ok, I'm doing my homework and just read some more info about CAT5 wire.... and of course anyone has, somewhere, in their house... and it's branded... and really interesting...

A little bit late in the CAT5 world, but better too late than never! 😉

A little bit late in the CAT5 world, but better too late than never! 😉

The Cool thing about Cat wire ,is it's cheap and works really well.. I cabled both my speakers for under $3.00, and at prices like that if it were to suck then no big deal changing them out to something new..

And the reason I direct wired to my drivers is I like to keep with the keep it simple method, why bother putting all that binding post material in the way of the signal when it's not really required.. If a person never had to move their amp and system much it would probably also be better to direct wire the speaker wire to the amp and bypass those posts too... I'm not quite ready for that though at this time... Dave🙂

And the reason I direct wired to my drivers is I like to keep with the keep it simple method, why bother putting all that binding post material in the way of the signal when it's not really required.. If a person never had to move their amp and system much it would probably also be better to direct wire the speaker wire to the amp and bypass those posts too... I'm not quite ready for that though at this time... Dave🙂

GM said:

And some folks swear at them. 😉

These specs fit your decription, though no way to know for sure without actually measuring yours of course.

Thanks to Zene:

Paper cone Roland 8" is/are: (Used Peak Inst. for test, only broke-in 12 hrs.)

Fs = 78.76 hz

Vas = 24.5 L/0.8652 cu ft

Re = 7.309

Le = .2462 mh

Qms = 5.772

Qes = 1.977

Qts = 1.473

Sd = 214 sq cm/33.17 sq in

BL = 4.4456 N/A (calc'd)

Spl 89.65 1w/1m

Pe = 30W

Get out the ceiling speaker hole saw or open baffle.

GM

GM you always have the info handy and know where to look. I had an open baffle mount of sorts but it was temporary and at the time had no cutter to make decent baffles. They may just never work.

But from the T/S would they work in some sort of subwoofer config?

I can start a new thread but these prob'ly are not used much and would have little interest. Other thing I tried but didn't have much luck with the build was isobarik. So if in a box with push pull wiring

(opposite polarization) could I get a sub made out of them?

If no, just say no.

cheers

loninappleton said:

GM you always have the info handy and know where to look. I had an open baffle mount of sorts but it was temporary and at the time had no cutter to make decent baffles. They may just never work.

But from the T/S would they work in some sort of subwoofer config?

I can start a new thread but these prob'ly are not used much and would have little interest. Other thing I tried but didn't have much luck with the build was isobarik. So if in a box with push pull wiring

(opposite polarization) could I get a sub made out of them?

If no, just say no.

cheers

Hi loninappleton!

If you want to make a quick, cheap'n'dirty box, try this,

Outer pipe, 110 cm long sonotube, 25 cm diameter

inner pipe, 63 cm long sonotube, 15 cm diameter

Inner pipe measured from center point of cutaway.

Adjust opening with height over floor.

I saw this in a Swedish forum and this guy used Philips AD9710 with good result. It may be to high qts in your drivers but that would maybe GM be able to answer.

How's it going with your "curtains" in your BIB's, I'm curious as I haven't been able to test it fully yet. I had too short pieces of felt and it didn't make a difference. I have maybe a another idea but have to sit on it for a while.

Cheers,

Peter

Attachments

peterbrorsson said:

Hi loninappleton!

If you want to make a quick, cheap'n'dirty box, try this,

Outer pipe, 110 cm long sonotube, 25 cm diameter

inner pipe, 63 cm long sonotube, 15 cm diameter

Inner pipe measured from center point of cutaway.

Adjust opening with height over floor.

I saw this in a Swedish forum and this guy used Philips AD9710 with good result. It may be to high qts in your drivers but that would maybe GM be able to answer.

How's it going with your "curtains" in your BIB's, I'm curious as I haven't been able to test it fully yet. I had too short pieces of felt and it didn't make a difference. I have maybe a another idea but have to sit on it for a while.

Cheers,

Peter

Yes I've seen the sonotubes in AudioXpress and they looked fascinating. There's also a sub technique using an old water heater

but maybe more trouble than it's worth.

CSS has a kit that uses sonotube with the parts precut for assembly (using a Shiva I think.)

Back to BIBS: I just completed wrapping the magnet on my 127e with some old blanket stuff similar to that used in another thread discussion. Also finished the pennant (not really a curtain. ) No news until I get some listening tests.

I also want to try that thing that Scottmoose has that looks like Jiminy Cricket walking around the edge of the cone.

There's also a sub technique using an old water heater

If one want warm bass🙂

I also want to try that thing that Scottmoose has that looks like Jiminy Cricket walking around the edge of the cone.

I guess that it is enable then?

It would be nice to see some pictures of the pennant you made!

Cheers

If one want warm bass🙂

I also want to try that thing that Scottmoose has that looks like Jiminy Cricket walking around the edge of the cone.

I guess that it is enable then?

It would be nice to see some pictures of the pennant you made!

Cheers

peterbrorsson said:There's also a sub technique using an old water heater

If one want warm bass🙂

I also want to try that thing that Scottmoose has that looks like Jiminy Cricket walking around the edge of the cone.

I guess that it is enable then?

It would be nice to see some pictures of the pennant you made!

Cheers

No CAM here but it's pretty easy to describe. Choice of materials may vary but GM, the designer, said that lighter is better rather than thick and dense. The pennant is a right angle at the wide corner and matching angle of the internal divider down to the a-b-c bend. The bottom is the measurement used at a-b-c like the How To Build a BIB drawing shows at zillapeak. Use the internal diagonal of the

terminus (horn mouth) to get the width. Mounting can be like a wall hanging with a piece of dowel or sandwiched between two strips of thin material (I used some masonite left over from a cabinet back) and suspended over the top.

Alternatively, using a narrower measurement than the diagonal will allow for a variety of placements.

Big measuring tools help with this. A drywall framing square is a t-square 48" long. The big box home stores have them for $11 US.

Lay out with a chalk line or some tailor's chalk. Don't cut through the carpet.

Roll ends at the drapery store would likely find some ideal material.

I went into a pool table supply place and the guy gave me a piece of remnant billiard felt. The remnant has some holes in odd places but I trimmed around most of them.

Hi...

I built a pair of Monacor SPH-60X - BIBs a couple of months ago.

They sound amazing, especially for the 25 € I paid for the drivers!

BUT....of course, like anybody else I want to improve. The problem is, that I'm really lazy. That's why I want to use the SPH-60-X BIBs with new drivers...I think about the FX 120.

Monacor SPH-60-X:

L = (Line length) 128"

So = Driver 25.5" down from sealed end of cabinet

Sm = 55"^2

Fostex FX120:

L = (Line length) 120"

Zdriver = Driver 24" down from sealed end of cabinet

Sm = 50"^2

I guess it should work, but will it be an improvement?

I built a pair of Monacor SPH-60X - BIBs a couple of months ago.

They sound amazing, especially for the 25 € I paid for the drivers!

BUT....of course, like anybody else I want to improve. The problem is, that I'm really lazy. That's why I want to use the SPH-60-X BIBs with new drivers...I think about the FX 120.

Monacor SPH-60-X:

L = (Line length) 128"

So = Driver 25.5" down from sealed end of cabinet

Sm = 55"^2

Fostex FX120:

L = (Line length) 120"

Zdriver = Driver 24" down from sealed end of cabinet

Sm = 50"^2

I guess it should work, but will it be an improvement?

- Home

- Loudspeakers

- Full Range

- Terry Cain's BIB -why does it work and does anyone have those Fostex Craft Handbooks?