Hi

interesting new ideas coming up...

moray, you can use imageshack to upload big images and then post the link here, it's free 'n easy.

best, LC

interesting new ideas coming up...

moray, you can use imageshack to upload big images and then post the link here, it's free 'n easy.

best, LC

Oh Zilla, you slay me with this.

Okay, first off, putting the piezos on the back means you'd need to pull these monoliths out from wall, right? And even if you did, its likely that you've got enough of the wall blocked off with cabinets and source gear (and display, perhaps?) that you would have a hard time getting any reflections from the piezos at the listening position. Please correct me if I'm wrong, though as I've never rear mounted a tweeter (actually been "dipole or bust" for me so far in my DIY experience ;-p).

Anyway, assuming that doing this with the monoliths is kosher, what's up with the short line of piezos? What are we accomplishing here? Am I reading this correctly in that you're wanting the B20 toward the inside and the piezos toward the outside? If you were to put in a line of 4 piezos like this, how would you wire them and what components might you use with them? How about instead of a line of drivers, you use one of those with the 4"x10" horn turn vertically?

I'm thinking this monolith concept is strangely high WAF. I need to measure to be sure, but I've got 2'-2.5' of space on either side of the entertainment center, which is 6' tall, so I could just match that going to the side. The center is 18" deep, though, and I dont' want to get anywhere near that depth (more like 6"-8"), so up against the wall its going to be 10"-12" further back than the front edge of the center. So, I'm figuring I would be better off with my drivers set toward the outside, right?

Kensai

Okay, first off, putting the piezos on the back means you'd need to pull these monoliths out from wall, right? And even if you did, its likely that you've got enough of the wall blocked off with cabinets and source gear (and display, perhaps?) that you would have a hard time getting any reflections from the piezos at the listening position. Please correct me if I'm wrong, though as I've never rear mounted a tweeter (actually been "dipole or bust" for me so far in my DIY experience ;-p).

Anyway, assuming that doing this with the monoliths is kosher, what's up with the short line of piezos? What are we accomplishing here? Am I reading this correctly in that you're wanting the B20 toward the inside and the piezos toward the outside? If you were to put in a line of 4 piezos like this, how would you wire them and what components might you use with them? How about instead of a line of drivers, you use one of those with the 4"x10" horn turn vertically?

I'm thinking this monolith concept is strangely high WAF. I need to measure to be sure, but I've got 2'-2.5' of space on either side of the entertainment center, which is 6' tall, so I could just match that going to the side. The center is 18" deep, though, and I dont' want to get anywhere near that depth (more like 6"-8"), so up against the wall its going to be 10"-12" further back than the front edge of the center. So, I'm figuring I would be better off with my drivers set toward the outside, right?

Kensai

Kensai said:Oh Zilla, you slay me with this.

What did you expect from a giant lizard??? He likes to crush and destroy. Nothing elegant here. 😀

FWIW, that line of piezos on the back freaked me out, too. Maybe it's a lizard back thing?

I'm thinking this monolith concept is strangely high WAF.

You are thinking right. When I asked my wife about them, I got immediate approval. " Flat to the wall? Only 8 to 12" deep? I can make them whatever color/finish I want? Build 'em!"

You can sell the idea as ...."elegant Jacobean panelling"

Let the games begin. Mr Mardis, good luck, and we look forward to the eye candy.

Let the games begin. Mr Mardis, good luck, and we look forward to the eye candy.

removable glue

Somebody a while back mentioned that glue that's

on product and particularly mailers which comes

completely off.

What is that called and where is it found?

Previously I've used bathtub caulk to stick my

boxes together in case I want to take them

apart to change the front baffle/speaker cutout.

Because it's rubberized. I think the seal is pretty good

and also inert/sound neutral. No problems with the

cabs in any case far as resonances.

I'm finally making progress on my bib.

Somebody a while back mentioned that glue that's

on product and particularly mailers which comes

completely off.

What is that called and where is it found?

Previously I've used bathtub caulk to stick my

boxes together in case I want to take them

apart to change the front baffle/speaker cutout.

Because it's rubberized. I think the seal is pretty good

and also inert/sound neutral. No problems with the

cabs in any case far as resonances.

I'm finally making progress on my bib.

panomaniac said:You are thinking right. When I asked my wife about them, I got immediate approval. " Flat to the wall? Only 8 to 12" deep? I can make them whatever color/finish I want? Build 'em!"

I'd think you'll have to be out from the rear wall a small bit in order for this to work, no? Maybe 18" or so? Perhaps I'm wrong, but I would think that would help disperse the rear treble much more evenly.

Tis a fun idea. Curious to hear thoughts.

glue

Loni, i'd try removable weatherstripping sold at Menards. Don't use too much, it holds very well.

I like to use it for semipermanent speaker gasket, too.

Loni, i'd try removable weatherstripping sold at Menards. Don't use too much, it holds very well.

I like to use it for semipermanent speaker gasket, too.

Re: glue

That's Lon, as in Lon in Appleton. ;-)

Anyways I use the weather strip for mounting speakers too.

But I want the glue which should retain it's flexibility

but also it's adhesion so I can stand 'em up after

clamping. It's the glue that resembles rubber cement but

remains shiny and transparent and flexible forever. It's the

stuff that easily pulls away from the surface to which it had

adhered. The guy that talk about this never mentioned the

name of the product.

If it's way expensive there's no point, but if it's available at

retail I'd like to see how it is sold.

pekar said:Loni, i'd try removable weatherstripping sold at Menards. Don't use too much, it holds very well.

I like to use it for semipermanent speaker gasket, too.

That's Lon, as in Lon in Appleton. ;-)

Anyways I use the weather strip for mounting speakers too.

But I want the glue which should retain it's flexibility

but also it's adhesion so I can stand 'em up after

clamping. It's the glue that resembles rubber cement but

remains shiny and transparent and flexible forever. It's the

stuff that easily pulls away from the surface to which it had

adhered. The guy that talk about this never mentioned the

name of the product.

If it's way expensive there's no point, but if it's available at

retail I'd like to see how it is sold.

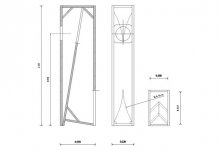

Just to repeat guys: you might need an extra baffle to allow the magnet to clear the sloping internal baffle with some drivers. Nor is it the ideal expansion rate, sacrificed to provide the 1 x 4 x 9 ratio necessary for a Monolith. Should still sound pretty good though. Best constructed out of clear perspex, or painted gloss black, sanded with 600 grit, and then polished, obviously. 😉

goo

Lon,

Again, try the caulk aisle, it's called Seasonseal Removable Weather Stripping in a green and white tube.

...and while you're at it, get a tube of PL Premium Construction Adhesive, in the yellow tube. It's a great, no-fumes, mildly expanding polyurethane adhesive. Very permanent.

Cheers,

Pekar

Lon,

Again, try the caulk aisle, it's called Seasonseal Removable Weather Stripping in a green and white tube.

...and while you're at it, get a tube of PL Premium Construction Adhesive, in the yellow tube. It's a great, no-fumes, mildly expanding polyurethane adhesive. Very permanent.

Cheers,

Pekar

Scottmoose said:Nor is it the ideal expansion rate

Do you think the expansion is too fast? Because the cabinet is wider than it should be?

I was thinking of a little deeper box - 12", and somewhat narrower. Like 28-30" outside. That should give the terminus closer to the 1.414:1 ratio. Going to be a tight squeeze to get an 8" driver in there.

Of course HAL would not approve.

I know not everyone agrees but I like piezos splashing off the back wall. Not for my main system but certainly for the ‘fun’ second system in the basement or office. I even like the sound of my Pioneer B20’s too… even if they only cost $25. Not as detailed and fast as Fostex but certainly in the same category as my TB’s that cost even more.

Keeping the price down + having fun + good sound = exactly what I want to be doing! The kiddies will love helping me build these monsters!

This is all for fun and I bet it will sound good too. Multiple piezos on the back bring up the overall efficiency to match the added efficiency the B20 gains by being in the BIB.

I see 95db on the chart and just wanted to make sure the tweeters on back have enough sparkle without having to strain themselves. That’s also why I put the Lpad there… to lower and raise treble output to my taste. At $1.50 each per tweeter I figured it’s better to be safe and have more than enough output than too little… tho maybe just one or two tweeters will work I also figured on four because my basement is pretty large (maybe 20 x 25 foot… or more). One rear facing piezo alone didn’t fill the basement with enough ‘tweet’ in the past so I just wanted MORE just in case.

I don’t expect this system to be the most accurate but as a basement system where kids are playing… and for me to show my buddies what sound I can get from a feather light SI amp + portable cd player… well, I think this will be a most impressive sounding second system!

If I ever build it that is… and I may play with the dims just to gain WAF too… who cares if it’s not perfect! I bet they’ll have personality! Maybe I can mount a Spiderman poster on one and Superman on the other and they can flank the air hockey table.

Keeping the price down + having fun + good sound = exactly what I want to be doing! The kiddies will love helping me build these monsters!

This is all for fun and I bet it will sound good too. Multiple piezos on the back bring up the overall efficiency to match the added efficiency the B20 gains by being in the BIB.

I see 95db on the chart and just wanted to make sure the tweeters on back have enough sparkle without having to strain themselves. That’s also why I put the Lpad there… to lower and raise treble output to my taste. At $1.50 each per tweeter I figured it’s better to be safe and have more than enough output than too little… tho maybe just one or two tweeters will work I also figured on four because my basement is pretty large (maybe 20 x 25 foot… or more). One rear facing piezo alone didn’t fill the basement with enough ‘tweet’ in the past so I just wanted MORE just in case.

I don’t expect this system to be the most accurate but as a basement system where kids are playing… and for me to show my buddies what sound I can get from a feather light SI amp + portable cd player… well, I think this will be a most impressive sounding second system!

If I ever build it that is… and I may play with the dims just to gain WAF too… who cares if it’s not perfect! I bet they’ll have personality! Maybe I can mount a Spiderman poster on one and Superman on the other and they can flank the air hockey table.

Godzilla said:

Keeping the price down + having fun + good sound = exactly what I want to be doing! The kiddies will love helping me build these monsters!

with t-amp + portable cd player… well, I think this will be a most impressive sounding second system!

who cares if it’s not perfect! I bet they’ll have personality! Maybe I can mount a Spiderman poster on one and Superman on the other and they can flank the air hockey table.

I agree, is there a small cabinet (bookshelf) that is "price down + having fun + good sound = what I want"

any votes out there?, should be a new thread...

gychang

Hello fellow BIBer's,

I built the BIB's for my fe108's awhile back and just love them, they were the one's that I made the front and sides 60'' so that they fire down into the floor and a round baffle mount for the speaker etc. Anyhow I've been getting curious about the fe206esr as a project to do sometime down the road, and wondered if anyone has heard them in a BIB? Or has anyone heard both the 108's and 206esr to compare? I'd hate to loose the beautiful sound of the 108 just to have more bass and way more efficiency... Dave🙂

I built the BIB's for my fe108's awhile back and just love them, they were the one's that I made the front and sides 60'' so that they fire down into the floor and a round baffle mount for the speaker etc. Anyhow I've been getting curious about the fe206esr as a project to do sometime down the road, and wondered if anyone has heard them in a BIB? Or has anyone heard both the 108's and 206esr to compare? I'd hate to loose the beautiful sound of the 108 just to have more bass and way more efficiency... Dave🙂

I've been around this thread since the beginning, and today I finally started my Hemp BIB's. I'm using all Baltic Birch ply, with a double thick front Baffle.

Does anybody have advice on how to laminate the two pieces for the baffle? I'm planning to use PL premium construction adhesive to glue the cabs. It seems a little thick, but I could spread it thinly. Would a few cement blocks be enough weight, or should I use a bunch of srews? I don't have enough clamps.

Paul

Does anybody have advice on how to laminate the two pieces for the baffle? I'm planning to use PL premium construction adhesive to glue the cabs. It seems a little thick, but I could spread it thinly. Would a few cement blocks be enough weight, or should I use a bunch of srews? I don't have enough clamps.

Paul

pjanda1 said:I've been around this thread since the beginning, and today I finally started my Hemp BIB's. I'm using all Baltic Birch ply, with a double thick front Baffle.

Does anybody have advice on how to laminate the two pieces for the baffle? I'm planning to use PL premium construction adhesive to glue the cabs. It seems a little thick, but I could spread it thinly. Would a few cement blocks be enough weight, or should I use a bunch of srews? I don't have enough clamps.

Paul

Where can you find Baltic Birch in pieces big enough for a Hemp-sized BIB? All I have found here is 60" x 60" sheets.

2001 monolith ratio

So from my extremely limited understanding of design, and given that the 8" depth of the monolith concept seems to be too shallow, and someone mentioned the 32" width being a little too wide, would a modification of, say, 12" depth and 28" width still "react" the same?

Also, my only reference for the project is at the zillaspeak site, but I had a little trouble deciphering what "Baffle terminates 14.875in from base & internal left & right side walls." meant, as I'm a first-time cabinet builder.

I'd like to know if anyone has completed a build of these. Should these be stuffed? Did the MK MathCad sim show how much stuffing to use?

I'm gonna search this forum for general building practices, as I don't know what are the best joints to use, and how to build the "fake baffles". I also need to determine whether I want to go with a circular saw and some steady handwork or save up for a nice tablesaw.

Anyway, those hemp drivers seem like a great driver to use, for sure! I'm excited as the driver height is about my height when sitting in my chair and I have plenty of ceiling space and room area for the speakers to really shine.

So from my extremely limited understanding of design, and given that the 8" depth of the monolith concept seems to be too shallow, and someone mentioned the 32" width being a little too wide, would a modification of, say, 12" depth and 28" width still "react" the same?

Also, my only reference for the project is at the zillaspeak site, but I had a little trouble deciphering what "Baffle terminates 14.875in from base & internal left & right side walls." meant, as I'm a first-time cabinet builder.

I'd like to know if anyone has completed a build of these. Should these be stuffed? Did the MK MathCad sim show how much stuffing to use?

I'm gonna search this forum for general building practices, as I don't know what are the best joints to use, and how to build the "fake baffles". I also need to determine whether I want to go with a circular saw and some steady handwork or save up for a nice tablesaw.

Anyway, those hemp drivers seem like a great driver to use, for sure! I'm excited as the driver height is about my height when sitting in my chair and I have plenty of ceiling space and room area for the speakers to really shine.

Re: 2001 monolith ratio

[snip

I'm gonna search this forum for general building practices, as I don't know what are the best joints to use, and how to build the "fake baffles". I also need to determine whether I want to go with a circular saw and some steady handwork or save up for a nice tablesaw.

Anyway, those hemp drivers seem like a great driver to use, for sure! I'm excited as the driver height is about my height when sitting in my chair and I have plenty of ceiling space and room area for the speakers to really shine. [/B][/QUOTE]

A circular saw with a guide board can get around the tablesaw dilemma.

There should be some visuals if you google > guide board

Setting up for long cuts is the biggest problem. Also a chalk line for

marking will be helpful.

[snip

I'm gonna search this forum for general building practices, as I don't know what are the best joints to use, and how to build the "fake baffles". I also need to determine whether I want to go with a circular saw and some steady handwork or save up for a nice tablesaw.

Anyway, those hemp drivers seem like a great driver to use, for sure! I'm excited as the driver height is about my height when sitting in my chair and I have plenty of ceiling space and room area for the speakers to really shine. [/B][/QUOTE]

A circular saw with a guide board can get around the tablesaw dilemma.

There should be some visuals if you google > guide board

Setting up for long cuts is the biggest problem. Also a chalk line for

marking will be helpful.

Re: 2001 monolith ratio

Greets!

There's probably some subtle differences in its upper harmonics, but I wouldn't worry about it.

If you look at the standard BIB drawing, it shows that the bottom of the internal baffle board is equidistant from the front, rear, and bottom panels. The difference with the Monolith is that one of the sides becomes the front, ergo the baffle board runs from one side to the middle rather than top front to in between the front and back.

Not me. Doesn't look like the sim has any stuffing, but for sure none I've done used any. How much stuffing, if any, is required will be based on what you determine once you get them set up in-room and experiment a bit. I do recommend that the area behind the driver and on the sidewall nearest it be covered to quell early reflections back to the driver.

Fancy joints are nice, but plain ol' butt joints are fine, though with the Monolith, mitered joints on at least the two sides and front panel is preferred if you're going to do the 'piano black' finish.

Fake baffles aren't required if the cab's deep enough to hold the driver.

Tablesaws are nice, but the vast majority of speakers I built were with either a hand or circular saw using a cutting board and even after I got one, I still ripped large pieces with the board: http://members.aol.com/woodmiser1/sawbd.htm

GM

mrbubbs said:.......would a modification of, say, 12" depth and 28" width still "react" the same?

......."Baffle terminates 14.875in from base & internal left & right side walls." meant........

I'd like to know if anyone has completed a build of these. Should these be stuffed? Did the MK MathCad sim show how much stuffing to use?

.......what are the best joints to use, and how to build the "fake baffles". I also need to determine whether I want to go with a circular saw and some steady handwork or save up for a nice tablesaw.

Greets!

There's probably some subtle differences in its upper harmonics, but I wouldn't worry about it.

If you look at the standard BIB drawing, it shows that the bottom of the internal baffle board is equidistant from the front, rear, and bottom panels. The difference with the Monolith is that one of the sides becomes the front, ergo the baffle board runs from one side to the middle rather than top front to in between the front and back.

Not me. Doesn't look like the sim has any stuffing, but for sure none I've done used any. How much stuffing, if any, is required will be based on what you determine once you get them set up in-room and experiment a bit. I do recommend that the area behind the driver and on the sidewall nearest it be covered to quell early reflections back to the driver.

Fancy joints are nice, but plain ol' butt joints are fine, though with the Monolith, mitered joints on at least the two sides and front panel is preferred if you're going to do the 'piano black' finish.

Fake baffles aren't required if the cab's deep enough to hold the driver.

Tablesaws are nice, but the vast majority of speakers I built were with either a hand or circular saw using a cutting board and even after I got one, I still ripped large pieces with the board: http://members.aol.com/woodmiser1/sawbd.htm

GM

- Home

- Loudspeakers

- Full Range

- Terry Cain's BIB -why does it work and does anyone have those Fostex Craft Handbooks?