A couple of pics of the build:

You can see the last issue. The post is now too short to center the disc. The machinist is making a new post longer by the thickness of the copper platen. Shouldn't take long.

An externally hosted image should be here but it was not working when we last tested it.

You can see the last issue. The post is now too short to center the disc. The machinist is making a new post longer by the thickness of the copper platen. Shouldn't take long.

He did a beautiful job. Is the copper bolted or bonded to the aluminum? Are you going to try the album right on the copper or use a mat? Now the fun begins.

Enjoy the ride

Tom

Enjoy the ride

Tom

It will be bonded with Loctite after I add the lead shot. Pretty certain that i will use a mat. Thoughts?

On the mat it gets to a fine tuning of your system. I like PVC and PVC lead sandwich in my system right now. But all the rest seem to play a different sonic role. The good news is you have a large heavy platter, your 90 % home now.

Tom

Tom

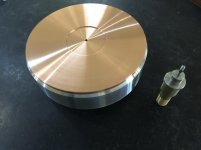

The platter and platen arrived today. The pics don’t do it justice. Nine and a half years to get to this point. The Teres Bearing instruction sheet is dated March ‘09.

Now to locate some #11 lead shot. May have to compromise here. That stuff is very hard to source.

Now to locate some #11 lead shot. May have to compromise here. That stuff is very hard to source.

Seth

I think I used #8. Not sure if anyone did listening test with different shot. I also did it dry. I know redpoint played with oil mixed in. You should be able to get shot at gun places and sportsman warehouse etc... Have fun!!!

Tom

I think I used #8. Not sure if anyone did listening test with different shot. I also did it dry. I know redpoint played with oil mixed in. You should be able to get shot at gun places and sportsman warehouse etc... Have fun!!!

Tom

Yeah. I can get #9. Anything smaller is unobtainium. Of course, the smaller the sphere, the more you can pack into a given cylinder. The greatest density involves a mix of sphere sizes. Some Russian geometer made a formula for that but the brain cells that retained that info died a while back.

Weight wise small is better. The fun begins with the vibration control. Small, large, combo, how much surface contact etc.etc.etc... And the bottom line when you get to the end of the math, is how does it sound? You should be between 30-40 lbs loaded, that seems to be a sweet spot.

Enjoy the ride

Tom

Enjoy the ride

Tom

That last bit is making me think. I’m estimating somewhere around 60 lbs loaded if the holes are filled to the top.

Last edited:

Doing the math, (dont have a capable scale) I’m very close to 35 lbs right now with no shot. The copper platen alone is 11.235 lbs

You do have the copper top. How thick is the platter? The outside is most important. Not sure hole size, how many, and how deep. How much does weigh now?

You should be able to do the math for a close total weight. Subtract the removed aluminum weight then add the lead weight and your home.

Tom

You should be able to do the math for a close total weight. Subtract the removed aluminum weight then add the lead weight and your home.

Tom

Not sure about the proper english word or name, but there used to be something we locally call "lead sand" - used in chem labs for ballast weighting... ??

Hey Seth are the holes already drilled? If they are you could put lead shot in plastic bag and fill hole. Then pull it out and weight it, then multiply. This would save you the time of figuring volume. Forgot how much Chris said the bearing/ ball pad can take.

Tom

Tom

Oh yes. The holes are machined. I’d post pics but its such a pain on this platform. We used to have a gallery one could link to but apparently that’s gone. I in fact did the maths on the weight. How i got to 35 lbs +- a couple of ounces

For pictures hit advanced post at bottom then hit attachments. Then hit top one should bring up camera Docs etc.

Wow. Looks excellent. Remember to lift with your knees when picking up the platter. 🙂

Any avenues on surface finish? I take it the copper will tarnish over time?

Any avenues on surface finish? I take it the copper will tarnish over time?

I was advised to use latex gloves when handling the copper platen. Once it is bonded to the aluminum it will be lacquered it I think. Per TomWh I will be using a mat.

Interesting.

I have been struggling with finishing options - my approach uses a combination of POM (Delrin) and Aluminium. Delrin is relatively easy to clean using isopropyl, but the aluminium platter, even when anodized, can sometimes "stain".

It turns out that the bearing oil I've found most success with (in my approach) is slightly alkaline, and that dissolves the oxide layer causing the "staining". Apparently I have trouble wiping the oil from my fingers before handling the platter. 🙂

Lacquering would be an interesting approach, but won't that chip?

I have been struggling with finishing options - my approach uses a combination of POM (Delrin) and Aluminium. Delrin is relatively easy to clean using isopropyl, but the aluminium platter, even when anodized, can sometimes "stain".

It turns out that the bearing oil I've found most success with (in my approach) is slightly alkaline, and that dissolves the oxide layer causing the "staining". Apparently I have trouble wiping the oil from my fingers before handling the platter. 🙂

Lacquering would be an interesting approach, but won't that chip?

There are several protective finishes available for copper e.g. Copperfield, Everbright. Caswell sells a coating for raw aluminum called “Sharkhide”. They’re all insanely expensive.

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- Teres platter options