Hi,

Yes, that may well be.

To me it seems like this is due to a lot of people talking about DD without knowing about how the servos function.

I've written someting on that theme on my website under projects/phono/directdrive.

It seems that people think, that with a DD the platter receives multiple discrete, short pushes with the full torque.

This is not the case. The motor supplies a constant small amount of torque to account for friction losses from the bearing, needle drag and maybe a brush.

If a disturbance occurs the system reacts in a sliding way, increasing or decreasing torque softly.

The difference to full possible torque doesn't increase regulation speed or precision, but only allows for a larger load range.

Now if You slow down platter speed intentionally and regularly high torque is of use.

For typical home useage it is not.

The 'green coil' is representative for the 3phase iron-cored motor Technics used from the beginning on.

From about the early-90s on Technics and most other manufacturers simplified to 2-phase coreless motors with lower numbers of coils.

The motor became an integral part of a subassembly, containing the electronics (FG-and PLL-servos only) and bearing at the same .... easy and cheap to manufacture and used rather in the lowcost entry range.

Typically the assemblies reduced building height also.

Combined with ever lower platter- and overall turntable weight and ever more use of plastic the players looked and felt cheap.

The magnet used in these assemblies is a flat disc with the coils mounted on a PCB immediately below the rotating magnet disc.

So the difference in the drive systems between the good old drives and the younger cheapies is obvious as soon as You lift the platter off of the spindle.

jauu

Calvin

Dear Calvin

I own Technics SP 15 as well as Denon DP 80 and DP 7000. In addition I had SL 110 and several other DDs in the past.

For me and my hearing experiances Torque matters. The high torque drives sound better, stiffer, they perform with more patience and power. The lower torque drives are more or less comparable to good string drives, the more powerfull ones with exeptional good idler wheel drives. But at the end of the day that‘s an individual thing.

I think one thing that is important is to grab one now if you want a DD. If you look at 'classic' turntables prices are rising. Garrards are all silly money now, lencos have doubled in the last 12 months. Given the sheer volume of SL1200s out there will be interesting to see how quickly they rise.

I quick check on ebay for some of the models Calvin mentions and they seem to currently be going in the UK for around £75 vs £300ish for an SL1200/1210. Will be interesting to see if DIY projects around them start to appear. With over 3Million SL1200s out there may remain cheap for a while!

I quick check on ebay for some of the models Calvin mentions and they seem to currently be going in the UK for around £75 vs £300ish for an SL1200/1210. Will be interesting to see if DIY projects around them start to appear. With over 3Million SL1200s out there may remain cheap for a while!

There's a world of difference between the 1210 and sp10 drive electronics. I don't imagine that 1210 prices will skyrocket soon for anything other than NOS boxed examples.

Technics SL-1500MK2 replinth.

Technics SL-1500MK2 Replinth Project [Archive] - The Art of Sound Forum

Biff

Technics SL-1500MK2 Replinth Project [Archive] - The Art of Sound Forum

Biff

There was a petition started by gentleman called Moni Daniel to reintroduce sl-1200. Here is the link. If they start manufacturing again, it would be wonderful if it comes with option of buying it without Tonearm and make new design without sliding pitch control and light. Or probably just a motor unit like SP-10 would be great.

35 years ago I had Technics Q2 which I sold because everybody at that time said that DD is bad for the sound. I bought Thorens TD 160 S MK4 BC with Linn Basic+ tonearm. But frankly when I first played the Thorens I was surprised that it sounded just a little bit differnt, but not better than Technics. I asked myself was that change really necessary? I think that older Technics DD are great sounding turntables with excellent specs even with Technics arms and pick-ups.

There is one Technics D2 for low price here on offer. Is it good turntable?

One other thing that I would like to know is what kind of bearing oil can be substitute for original Technics SFWO oil?

There is one Technics D2 for low price here on offer. Is it good turntable?

One other thing that I would like to know is what kind of bearing oil can be substitute for original Technics SFWO oil?

There's a world of difference between the 1210 and sp10 drive electronics. I don't imagine that 1210 prices will skyrocket soon for anything other than NOS boxed examples.

I am not sure there is that much difference based on what I know. But happy to be proved wrong. You may be right on prices, and supply is high, but given how rarely SP10s come up for sale and even basket cases are £350 (no PSU, wont run) and how easily a fad can start amongst the great unwashed who knows.

My projections are always wrong, which is why I am not rich!

I am not sure there is that much difference based on what I know.

... well, let´s have a look at some Technics Service Manuals and extract a list of which motor and (if stated) power units were used in which of those famous and praised Technics:

SL-1200 MKI = MJL-9A

SL-110 = MJL-9A oder MJL-12A

This are very low torque units; their platter can be stopped with very little finger pressure. With later models Technics increased the torque of those motor units.

SP-10 MKI = MPL-10A - that´s the version without external power supply

SP-10 MK II: Power Unit SH-10E, Motor SFMZ102-01E

SP-10 MK 2a: Power Unit SH-10EA, Motor SFMZ102-01E

SP-10 MK3: Motor SFOP109M11A

SP-15 = SFMZ015-02Z

SP-25 = SFMG520-31A

SL-1210 MKII = SFMG520-31A

SL-1710 MKII = SFMG520-31A

SL-M1 = SFMG520-31A

SL-M2 = SFMG520-31A

SL-M3 = SFMG520-31A

Conclusion: Neither SP-15 nor SP-10 were identical or related to other Technics. They were individual designs but not identically or related to each other.

Only SL-1210 MKII, SL-1710 MKII, SP-25, SL-M1, SL-M2 and SL-M3 are related to each other and very similar by technical design and performance perspective. In addition early SL-1200 are technically identical to the SL-110.

Following what´s mentioned in old papers the SP-10 MK3 was the most powerfull motor unit in combination with the most advanced power unit and speed regulation. From a technical perspective it was followed by SP-10 MK-2a and SP-15. From a torque perspective the SP-15 provides a bit more torque then the SP-10 MK 2 but the SP-10 MK2 offers the more advanced speed regulation circuit.

But at the end of the day you will get something like half broken fingers trying to stop those platters by finger pressure. If you try that with Denon DP-80 or DP-7000 your fingers won´t be even heated up. Their available torque is much lower.

May be some of you might remember those rumors back in the eighties that direct drives were supposed to fall into a systematic staggering of it´s speed and torque. That happend when low torque was paired with high platter mass and a speedy regulation that regulated with most of the available torque and power.

Last edited:

@Rolf: both are not Quarz locked direct drive? Where then is the 'world of difference between the electronics I was questioning?

You‘re right; with the perspective both beeing quartz locked DD drives there‘s at least no ‘world‘ of a difference between a SP-10 and a SP-15.

Hi,

If it sounds different, it is not due to higher possible torque.

As I said before the motor supplies only for so much torque as to keep the platter speed constant.

The high torque motor dosn´t supply a jota more torque to the platter than the low torque motor if running undisturbed.

It is only capable to cope with larger disturbances, like breaking the platter with a finger.

The high-torque motor simply can keep the speed up and PLL-locked over a largerer load range.

Nothing else.

Any sonic differences are solely due to constructional differences, like a different plinth, etc, and maybe due to the design of the feedback loop.

High-Torque or low-torque as single parameter is not sonically detectable.

jauu

Calvin

For me and my hearing experiances Torque matters. The high torque drives sound better, stiffer, they perform with more patience and power

If it sounds different, it is not due to higher possible torque.

As I said before the motor supplies only for so much torque as to keep the platter speed constant.

The high torque motor dosn´t supply a jota more torque to the platter than the low torque motor if running undisturbed.

It is only capable to cope with larger disturbances, like breaking the platter with a finger.

The high-torque motor simply can keep the speed up and PLL-locked over a largerer load range.

Nothing else.

Any sonic differences are solely due to constructional differences, like a different plinth, etc, and maybe due to the design of the feedback loop.

High-Torque or low-torque as single parameter is not sonically detectable.

jauu

Calvin

@ billshurv

I was playing with a SP-10 MKIIa with it´s original obsidian plinth and EPA-100 back then at the end of the 90´s. Since then I heard the SP-10 only at friends but it was always sounding a bit shiny up to pale with a lack of emotions.

An SP-15 on other hand seems to sound a bit more harmonic, not that bit to much brightness, tonal consistent, rocking, intoxicating; but with buying a SP-10 today I will be lucky to compare the sonical performance of SP-10 and SP-15 in some weeks in my music system.

From a technical perspective and even if both are a quartz locked DD drive they differ a bit. The SP-15 comes with a highly effective platter damping resulting in -5 dB better rumble and a pulsed power supply that´s not that enhanced as the SP-10s power supply; thus and even with same performance at wow and flutter results in a slightly higher speed drift (0,002% vs. 0% within 5kg-cm).

Conclusion: For my point of view they differ, but we aren´t talking about worlds or a universe ... but they differ.

@ Calvin

Sorry that I do not agree. Within all of the tests I did in the past 20 years torque matters. But I´m pointing at the sonical performance of a turntable not at the technical aspects.

I agree that in any undisturbed situation the motor supplies only for so much torque as to keep the platter speed constant. But you won´t find many undisturbed situations while spinning vinyl. In all undisturbed situations the high torque motor will be capable of providing a much stiffer drive and to correct any speed variation faster, with more perfection and not only with or for a larger load range.

If you try to disturb the platter you will be able to recognize that besides a change in tonality the spatiality will change as well. I´ve done tests that sketched about 3 m smaller scenes than without disturbing the platter. In addition the bass gets swampy, bloated and messy.

But those effects might be estimated by some people as `wow, great tweeking, bass performance was increased´

I was playing with a SP-10 MKIIa with it´s original obsidian plinth and EPA-100 back then at the end of the 90´s. Since then I heard the SP-10 only at friends but it was always sounding a bit shiny up to pale with a lack of emotions.

An SP-15 on other hand seems to sound a bit more harmonic, not that bit to much brightness, tonal consistent, rocking, intoxicating; but with buying a SP-10 today I will be lucky to compare the sonical performance of SP-10 and SP-15 in some weeks in my music system.

From a technical perspective and even if both are a quartz locked DD drive they differ a bit. The SP-15 comes with a highly effective platter damping resulting in -5 dB better rumble and a pulsed power supply that´s not that enhanced as the SP-10s power supply; thus and even with same performance at wow and flutter results in a slightly higher speed drift (0,002% vs. 0% within 5kg-cm).

Conclusion: For my point of view they differ, but we aren´t talking about worlds or a universe ... but they differ.

@ Calvin

Sorry that I do not agree. Within all of the tests I did in the past 20 years torque matters. But I´m pointing at the sonical performance of a turntable not at the technical aspects.

I agree that in any undisturbed situation the motor supplies only for so much torque as to keep the platter speed constant. But you won´t find many undisturbed situations while spinning vinyl. In all undisturbed situations the high torque motor will be capable of providing a much stiffer drive and to correct any speed variation faster, with more perfection and not only with or for a larger load range.

If you try to disturb the platter you will be able to recognize that besides a change in tonality the spatiality will change as well. I´ve done tests that sketched about 3 m smaller scenes than without disturbing the platter. In addition the bass gets swampy, bloated and messy.

But those effects might be estimated by some people as `wow, great tweeking, bass performance was increased´

Last edited:

sl5300 replinth

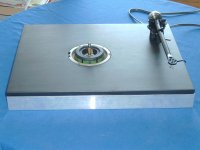

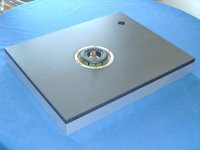

This is my technics dd turntable project.

The motor is mounted on a 5mm steel plate and it has of board ac power supply.

I am using a 1210 tone arm.

I hope to have it running in a few days now.

This is my technics dd turntable project.

The motor is mounted on a 5mm steel plate and it has of board ac power supply.

I am using a 1210 tone arm.

I hope to have it running in a few days now.

Attachments

If a turntable bearing is turning smoothly it doesn't matter if it is being driven by high or low torque. Mostly the motor does little but add a touch of GO to keep things turning, they do bugger all. I'd love to see how many watts are consumed by a turning platter. I bet 90%+ of the consumed energy are system loss related.

Free spinning platters aren't good for speed stability, a motor needs load to work 'efficiently' a bit of drag is a good thing depending on how it is created, especially if it puts the motor In the middle it's load/torque curve.

Free spinning platters aren't good for speed stability, a motor needs load to work 'efficiently' a bit of drag is a good thing depending on how it is created, especially if it puts the motor In the middle it's load/torque curve.

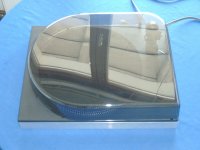

Hi,

same theme, similar solution 😉

This time with a sandwiched multilayer-plinth.

See also on MyTechnics

jauu

Calvin

same theme, similar solution 😉

This time with a sandwiched multilayer-plinth.

See also on MyTechnics

jauu

Calvin

Attachments

-

MyTechnics 024 small.jpg481.1 KB · Views: 194

MyTechnics 024 small.jpg481.1 KB · Views: 194 -

MyTechnics 020 small.jpg491.4 KB · Views: 162

MyTechnics 020 small.jpg491.4 KB · Views: 162 -

MyTechnics 017 small.jpg482.3 KB · Views: 194

MyTechnics 017 small.jpg482.3 KB · Views: 194 -

MyTechnics 015 small.jpg209.6 KB · Views: 213

MyTechnics 015 small.jpg209.6 KB · Views: 213 -

MyTechnics 011 small.jpg460.3 KB · Views: 142

MyTechnics 011 small.jpg460.3 KB · Views: 142 -

MyTechnics 009 small.jpg502.7 KB · Views: 122

MyTechnics 009 small.jpg502.7 KB · Views: 122 -

MyTechnics 006 small.jpg481.6 KB · Views: 122

MyTechnics 006 small.jpg481.6 KB · Views: 122 -

MyTechnics 005 small.jpg465.5 KB · Views: 125

MyTechnics 005 small.jpg465.5 KB · Views: 125 -

MyTechnics 004 small.jpg494 KB · Views: 176

MyTechnics 004 small.jpg494 KB · Views: 176 -

MyTechnics 027 small.jpg457.2 KB · Views: 180

MyTechnics 027 small.jpg457.2 KB · Views: 180

Here is the 4 page article I wrote on Technics Direct Drive Turntables

http://www.soundhifi.com/FOURUMIMAGES/DC.pdf

BTW, the jury is out on the performance of the MKIII, I have one here...............

Regards

Dave

http://www.soundhifi.com/FOURUMIMAGES/DC.pdf

BTW, the jury is out on the performance of the MKIII, I have one here...............

Regards

Dave

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- Technics SP-10/SL-1200 alternatives