I built the Volvotreter 38hz folded tapped horn mini subwoofer. Tried the original Tang Band driver and also a Wavecor driver.

I built the double fold version:

https://volvotreter.de/downloads/TangBand_W6-1139SC_38Hz_TH_Rev_1.pdf

The Tangband 38Hz Tapped Horn – Volvotreter Homepage

The mouth of this tapped horn makes way too much chuffing noise. Using it 35-75hz.

It's a pity and I'd like to ask for help identifying the problem. Is it a bad design?

Can I increase the mouth opening, or modify it in some way to not scrap all the wood?

Any advice and thoughts on making this design work for me would be very appreciated.

I built the double fold version:

https://volvotreter.de/downloads/TangBand_W6-1139SC_38Hz_TH_Rev_1.pdf

The Tangband 38Hz Tapped Horn – Volvotreter Homepage

The mouth of this tapped horn makes way too much chuffing noise. Using it 35-75hz.

It's a pity and I'd like to ask for help identifying the problem. Is it a bad design?

Can I increase the mouth opening, or modify it in some way to not scrap all the wood?

Any advice and thoughts on making this design work for me would be very appreciated.

If you have a laptop, phone or mixer and headphones, you can move the mic around the exit while listening to determine the source of the chuffing. That said, the mic may clip at the SPL levels around the exit, the clipping sound could obscure the problem. A hose or tube used like a stethoscope won't clip..The mouth of this tapped horn makes way too much chuffing noise. Using it 35-75hz.

It's a pity and I'd like to ask for help identifying the problem. Is it a bad design?

Can I increase the mouth opening, or modify it in some way to not scrap all the wood?

The chuffing is more likely to be from the magnet vent than the mouth exit, though rounding the mouth corners certainly would not hurt.

Some felt or polyfill in a sock could acoustically filter vent noise out.

Art

Last edited:

High pass is 24db/oct at 75hz.

Anything wrong with those plans?

For one, I just saw that the mouth opening is less that 2x drivers Sd(surface area). If the output from front and rear of driver sums at the moth opening, it needs to be at leas 2(Sd). It's not, it's less.

Is round over going to help or is there a need for a flare to slow down the air velocity? What are the rules for tapped horn proportions in relation to the driver's Sd?

Anything wrong with those plans?

For one, I just saw that the mouth opening is less that 2x drivers Sd(surface area). If the output from front and rear of driver sums at the moth opening, it needs to be at leas 2(Sd). It's not, it's less.

Is round over going to help or is there a need for a flare to slow down the air velocity? What are the rules for tapped horn proportions in relation to the driver's Sd?

Add a waveguide to the existing mouth as a temporary easy experiment to look for non chuffing and easy to add not deconstruct possibilities?

High pass is 24db/oct at 75hz.

Are you not high passing the tapped horn around 35Hz ? (The volvotreter site calls it a 38Hz horn so I'm assuming it will unload below that? )

Yes, high pass 24db/oct at 35hz. Just way too much turbulence noise below 55hz. Should I model it in HornResp and look for a problem?

Could be worth modelling in HR (including your 35Hz high pass and seeing what power it takes to drive the sub to xmax. Output might be lower than expected due to the size of the driver ?

I'm following this thread as this horn looks promising for a multi sub setup.

Cheers,

Rob.

I'm following this thread as this horn looks promising for a multi sub setup.

Cheers,

Rob.

The mouth of this tapped horn makes way too much chuffing noise.

HR calcs plenty low vent mach @ 200 W, the practical transient peak limit, so not a bad design per se other than using a driver with such a closed off back, pretty much only leaving 'whistling'/'turbulence' around/through the driver basket as the main source. Can't have too open a basket design for TH or similar.

'Critically' damping the basket's vents and/or the horn's terminus should in theory solve the problem [and Art's], though will roll off the bass somewhat and may still need at least a 50 Hz hi-pass or higher if > 100 W is used.

If just 'stuffing' the terminus to 'taste', then from sad experience, highly recommend loosely covering the back of the basket with cheesecloth and putting the stuffing in a bag made from it.

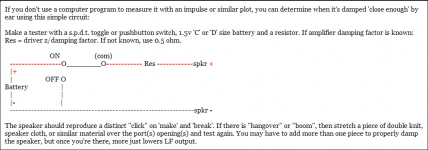

'Click' [impulse] tester:

GM

Attachments

HR calcs plenty low vent mach @ 200 W, the practical transient peak limit, so not a bad design per se other than using a driver with such a closed off back, pretty much only leaving 'whistling'/'turbulence' around/through the driver basket as the main source. Can't have too open a basket design for TH or similar.

'Critically' damping the basket's vents and/or the horn's terminus should in theory solve the problem [and Art's], though will roll off the bass somewhat and may still need at least a 50 Hz hi-pass or higher if > 100 W is used.

If just 'stuffing' the terminus to 'taste', then from sad experience, highly recommend loosely covering the back of the basket with cheesecloth and putting the stuffing in a bag made from it.

'Click' [impulse] tester:

GM

Wow,Thanks for this! Very nice.

GM,

>> "HR calcs plenty low vent mach"

I will model this project in HR, play with the last horn section flare. What air speed one needs to have to eliminate the "chuffing" noise? Is that possible to model the air speed in HR?

High passing a sub at 50hz is a bit pointless so I better work on this design to get it to perform like a real sub but no chuffing.

I will try flipping the driver around, so the magnet is inside the folded horn. Two reasons:

1. open up the mouth area for less restriction

2. point the turbulent noisy basket into the box

May have to make a riser ring so the magnet will clear the inside wall of the horn. Currently using this driver:

SW178WA01

>> "HR calcs plenty low vent mach"

I will model this project in HR, play with the last horn section flare. What air speed one needs to have to eliminate the "chuffing" noise? Is that possible to model the air speed in HR?

High passing a sub at 50hz is a bit pointless so I better work on this design to get it to perform like a real sub but no chuffing.

I will try flipping the driver around, so the magnet is inside the folded horn. Two reasons:

1. open up the mouth area for less restriction

2. point the turbulent noisy basket into the box

May have to make a riser ring so the magnet will clear the inside wall of the horn. Currently using this driver:

SW178WA01

Last edited:

Sorry about the generic picture, but it shows a pinchpoint between the drivers that’s not simmed or can be if creative use of driver volume is removed from CSA in a Length. It’s not a big deal usually, but at the end of a tapped pipe it might matter a little or even significantly.

Attachments

Depends on who you ask as it varies from ~3.5 - 5% vent mach [~12-17.2 m/s], though most folks use ~5% for HIFI/HT and some as high as ~30% depending on the [prosound] app.

Well, complete enough for me. 😉

For HIFI/HT, no; prosound, yes in many [most, all nowadays?] apps.

Started to mention this option, but the picture convinced me it was not an option since the TB would likely need a spacer thick enough to potentially create enough of a tunnel to impair performance, though a super open basket such as the LABhorn woofer should work OK.

No clue about the Wavecor or other 'traditional' small driver basket designs, just know that Altec, etc., switched to more n' more open frames as soon as manufacturing cost dropped enough for a given size, performance criteria, so 'caveat emptor'.

GM

Some modeling

I modeled the 38hz tapped horn. I think I got it right...

Need some help here:

My guess is that if I want to reduce the chuffing at the horn mouth I can increase the mouth opening by cutting down the last wall of the horn segment. Will that work? Or do I need to flare out the last segment? The second option is more difficult because I will have to change the entire box.

I can feel with my hand that there is very high air velocity along the last wall, right before the mouth opening.

BTW, is there someone in Chicago I can consult with, who can help me with this project?

I modeled the 38hz tapped horn. I think I got it right...

Need some help here:

My guess is that if I want to reduce the chuffing at the horn mouth I can increase the mouth opening by cutting down the last wall of the horn segment. Will that work? Or do I need to flare out the last segment? The second option is more difficult because I will have to change the entire box.

I can feel with my hand that there is very high air velocity along the last wall, right before the mouth opening.

BTW, is there someone in Chicago I can consult with, who can help me with this project?

"caveat emptor" -- yes I discovered that despite the high xmax of the TangBand woofer, it is not suitable for a tapped horn because of high noise from the stamped basket. The Wavecor is better in that regard, although 50 bucks more expensive and much less xmax.

If you calc the max power, then in [Tools/Particle Velocity/Horn Mouth] you'll see the calc'd velocity, then right click/[capture [current results], then go double the S4 area and redo the calc, [compare] to see that it's near enough cut in half and hopefully will be low enough not to 'choke' the driver basket vents.

Well, if it was an offset driver TH [DTS concept] I doubt it would audibly 'chuff' due to pipe duct acoustic damping.

GM

Well, if it was an offset driver TH [DTS concept] I doubt it would audibly 'chuff' due to pipe duct acoustic damping.

GM

In HR, why is it when I increase the last segment S3, the horn mouth peak velocity increases and not decreases? This is counter intuitive to me because I am flaring out the last section of the horn. This means it expands out faster, get's larger towards the exit. Would not the velocity decrease?

- Home

- Loudspeakers

- Subwoofers

- Tapped horn sub chuffing too much