When I am modeling the particle air velocity, The result is not making any sense to me. As I increase the volume of the last segment (flare it out more) the air velocity also increases. Am I doing something wrong or is that what really happens?

At which frequency ? From how much to how much ?

Near S2, surface is small, it can chuff. A old trick was to add stuffing L12 and 1/3 of L23 trying if you can, to orient damping fiber in the same orientation as the segment. One other thing, is to avoid homs generated by slot kind segment L23, simply splitting it in two with a separator. All this was advices taken here from master Bjorno (RIP).

Near S2, surface is small, it can chuff. A old trick was to add stuffing L12 and 1/3 of L23 trying if you can, to orient damping fiber in the same orientation as the segment. One other thing, is to avoid homs generated by slot kind segment L23, simply splitting it in two with a separator. All this was advices taken here from master Bjorno (RIP).

Since driver is really near output, Weltersys is probably right about motor noise. It's a bit more work, bit still cheap if you can get some fireplace insulating 3-5cm sheet . If you can suspend a sheet with rubber strings in front of output mouth to cover 50-70%, it can make a really useful acoustical low pass that nearly won't affect at all sub-range frequencies. And it will low pass higher range distortion. Not a costly mod.The chuffing is more likely to be from the magnet vent than the mouth exit, though rounding the mouth corners certainly would not hurt.

Some felt or polyfill in a sock could acoustically filter vent noise out.

Art

Last edited:

Modeling an increase in S3

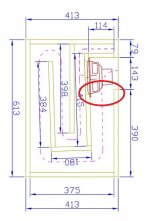

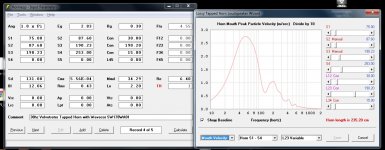

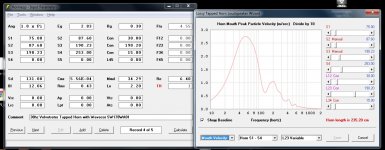

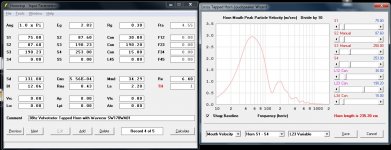

Here is the original model, all original dimentions.

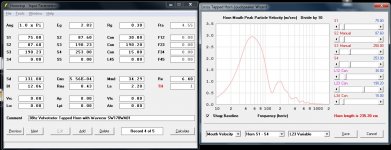

Now I increase S3 to about the same as mouth opening area. From 190 sq. cm to 250 sq. cm. This is the cross section area of the last horn.

Why is mouth particle velocity increasing and not reducing like I need it? I am trying to reduce the airflow velocity so that the "chuffing" is reduced.

😕

Also, if you look at the area of S3, it is 190 sq.cm. But 2(Sd) is a lot more, 260 sq.cm. So is the exit of the tapped horn pinching the air and creating the intense chuffing?

Here is the original model, all original dimentions.

Now I increase S3 to about the same as mouth opening area. From 190 sq. cm to 250 sq. cm. This is the cross section area of the last horn.

Why is mouth particle velocity increasing and not reducing like I need it? I am trying to reduce the airflow velocity so that the "chuffing" is reduced.

😕

Also, if you look at the area of S3, it is 190 sq.cm. But 2(Sd) is a lot more, 260 sq.cm. So is the exit of the tapped horn pinching the air and creating the intense chuffing?

Last edited:

In HR, why is it when I increase the last segment S3, the horn mouth peak velocity increases and not decreases?

Hmm, looking at your charts, your descriptions don't mirror them, so rather confused ATM.

Regardless, the last segment is S4, so if S3 is increased, you've created a higher acoustic power alignment [it's bigger], hence will have a higher vent mach, but if you double S4 [its mouth], vent mach sims a ~50% drop.

GM

Possibly pinching the air and causing strong chuffing?

Correct, so vent mach is probably higher than simmed, but open up S4 as I just posted seems to 'kill two birds with one stone' 😉 with no [simmed] audible change to the frequency response.

GM

edit: This still may not solve the [potentially] 'whistling' basket issue at high power.

Last edited:

GM,

I see what you are saying but my point was the pinching is occurring at S3, the part that I circled. S4 is already much larger so that will not be the pinching area.

But I'll try something. I'll flip the driver so that the cone faces the horn mouth. The good thing is that the Wavecor driver has a shallow basket and the magnet clears the internal wall. Nice! I'll post my findings.

It would be nice to make this design usable, so that it beats the output of other subs of this compact size 40-80hz. Will it, being a tapped hon?

I see what you are saying but my point was the pinching is occurring at S3, the part that I circled. S4 is already much larger so that will not be the pinching area.

But I'll try something. I'll flip the driver so that the cone faces the horn mouth. The good thing is that the Wavecor driver has a shallow basket and the magnet clears the internal wall. Nice! I'll post my findings.

It would be nice to make this design usable, so that it beats the output of other subs of this compact size 40-80hz. Will it, being a tapped hon?

??? To make S4 [mouth] bigger, you're cutting away a section of the panel, exposing the driver more, so it IS opening up this 'pinch' area, which BTW is not accounted for in the sim.

GM

GM

I built the Volvotreter 38hz folded tapped horn mini subwoofer. Tried the original Tang Band driver and also a Wavecor driver.

I built the double fold version:

https://volvotreter.de/downloads/TangBand_W6-1139SC_38Hz_TH_Rev_1.pdf

The Tangband 38Hz Tapped Horn – Volvotreter Homepage

The mouth of this tapped horn makes way too much chuffing noise. Using it 35-75hz.

It's a pity and I'd like to ask for help identifying the problem. Is it a bad design?

Can I increase the mouth opening, or modify it in some way to not scrap all the wood?

Any advice and thoughts on making this design work for me would be very appreciated.

Did you resolve the chuffing issue yet?

I’ve built 3 of these 38Hz tapped horns recently and have not experienced the chuffing problem. I’m powering mine with class D amplifiers @ 100 watts maximum at the moment so perhaps I am not generating air movement you are. How much power are you running? For my purposes 100 watts is plenty of power. I’ve got a pair of them in my open plan living room/kitchen/dining area ~500 sq ft and I’ve got one in my small TV room which is about 170 sq ft.

As far as content is concerned, I’ve listened to everything from classical to techno EDM to RB and the bass is very smooth and musical.

It’s been my experience that chuffing can be caused by leakage in the box or the speaker. since Tang Band don’t ship with gaskets, I made cork gaskets using auto gasket material. It’s about 3/16” thick and seals up nicely.

I hope you get it sorted out. I’m pretty pleased with how they turned out.

On a related note, have you looked at the Reed Exodus Anarchy 25hz Tapped Horn over at AVS? It’s a much more complex build and slightly larger outside dimensions but apparently the design will work with the Tang Band driver without mods and pull down much lower than the Volvotreter design. I’ll be building a pair for my office where I spend most of my time and have a decent audio setup.

Cheers,

Andrew

Last edited:

Tangband w5. Trial and error. Later trimmed down the mouth and throat chambers and it flattened nicely into a response which was tuned in the low 30s at xmax and 100 watts. now i have 2 more to build.

Attachments

- Home

- Loudspeakers

- Subwoofers

- Tapped horn sub chuffing too much