Hi,

Which plans are your speakers based on? I want to build a pair with the W5-2143. Could you please share if you don't mind?

Best,

Selim

Yes no problem so here the original sim for W5-2143 and my own plan....all the best

Attachments

Many thanks - yes I looked at your build - it was what got me thinking of options for a curved cabinet build!

I will look through the other thread in detail - thank you for providing the link.

Just a few questions if I may?

1) From your experience, would it be best to use thicker sheets or build up a curve using a laminate of thin sheets?

2) What glue/adhesive did you use?

3) Would adding ‘mass’ to panels be advisable acoustics wise?

4) Once built, is it relatively straightforward to finish these well? Will the material take a vinyl wrap of some sort?

Alex

A laminate of two sheets using a pliable adhesive like latex caulking will form a constrained layer damping (CLD) that greatly reduces sound transmission and resonances through the walls. I have also added sheets of mass loaded butyl with foil face (auto sound dampening sheets) to the inside walls. That works really well too.

Hot melt glue for quick joints and PVA (white glue) when instant bonding is not needed.

Yes, it takes a vinyl wrap well. Also look into fabric or upholstery covering. PVA glue can be used to apply covering like wall paper. Thin wood veneer can be used too. Be careful not to use VOC based adhesive or paints as that will dissolve the foam.

Curved wall can also be made using “bendy” plywood/MDF.

Here are some ideas for finishes on foamcore as done by folks on the mini Karlsonator thread (a folded mass loaded tapered quarter wave TL speaker project):

Fabric covered:

Paint and wood veneer:

Attachments

Last edited:

Design for center channel using (6) Tang Band W3-526S plus tweeter...

Howdy all!

First time here on the forum. I used to build speakers but have been out of it for years. Recently picked up a garage sale find of a homemade center channel with six Tang Band W30526S full-range, plus a tweeter in the middle. Haven't listened to it yet but I understand it's a proven design. The problem? It's a flat, deep box - to sit on a TV stand or whatever. I want to re-make it as a 'soundbar' type, long and skinny to mount on the wall below the TV. The Tang Bands are discontinued but had a lot of favorable reviews.

The box is vented, with no baffles inside, just the crossover. It has four ports, each around 1.5"(?). No stuffing either, which surprised me.

Anybody know anything about this design? It could be a one-off.

Thanks everyone, great site!

Howdy all!

First time here on the forum. I used to build speakers but have been out of it for years. Recently picked up a garage sale find of a homemade center channel with six Tang Band W30526S full-range, plus a tweeter in the middle. Haven't listened to it yet but I understand it's a proven design. The problem? It's a flat, deep box - to sit on a TV stand or whatever. I want to re-make it as a 'soundbar' type, long and skinny to mount on the wall below the TV. The Tang Bands are discontinued but had a lot of favorable reviews.

The box is vented, with no baffles inside, just the crossover. It has four ports, each around 1.5"(?). No stuffing either, which surprised me.

Anybody know anything about this design? It could be a one-off.

Thanks everyone, great site!

Attachments

xrk971 many thanks for the info.

A CLD made in the way you suggest is what I was thinking. I also have experience of using Dynamat Extreme in my MGB + other applications and it is very effective if applied intelligently.

I have looked up paper backed foam and have found some 5mm sheets in A1 size in black or white. They are paper fronted and backed with the foam in the middle - does that sound like the correct material?

I was thinking that even if I made the sides out layered plywood I could use the foam material for the cabinet top, internal brace, rear support bar port assembly/base and possibly parts of the baffle. It seems that, with the limited tools I have available, this will be an easier material than MDF to shape into curves etc.

A CLD made in the way you suggest is what I was thinking. I also have experience of using Dynamat Extreme in my MGB + other applications and it is very effective if applied intelligently.

I have looked up paper backed foam and have found some 5mm sheets in A1 size in black or white. They are paper fronted and backed with the foam in the middle - does that sound like the correct material?

I was thinking that even if I made the sides out layered plywood I could use the foam material for the cabinet top, internal brace, rear support bar port assembly/base and possibly parts of the baffle. It seems that, with the limited tools I have available, this will be an easier material than MDF to shape into curves etc.

Ccrider147, this is the TABAQ design thread.

If you want people to comment, start your own thread, and probably in the multiway section too.

If you want people to comment, start your own thread, and probably in the multiway section too.

Stuffing!

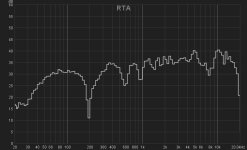

When I measured my Tectonic drivers in the 36' Pipes the other day, I hauled out my TABAQ W5-2143 build to see what it did in open air. Below is what I measured - a huge comb at ~200.

I only had the top portion stuffed, with a little blanket directly behind the river.

So I realized I had to stuff them the rest of the way; 2/3 the line length. To do so, I had to build a basket to hold up the stuffing from falling down. That was a chore to get in place reaching through the speaker cutout, but I did it. I've now got ~1/2b stuffing behind the driver and the rest of the way down to the basket.

I havent measured the result yet, but I believe the combing is going to happen unless you stuff it. I thought I read someone liked it better w/o the stuffing, which, if it does that, seems odd. My question is, the 0.5 lb of polyfil - is that in the ballpark, to tight? What's the art of stuffing these MLTLs? I only have so many driver mounting cycles, before the screw holes strip out of the the MDF. Thanks,

When I measured my Tectonic drivers in the 36' Pipes the other day, I hauled out my TABAQ W5-2143 build to see what it did in open air. Below is what I measured - a huge comb at ~200.

I only had the top portion stuffed, with a little blanket directly behind the river.

So I realized I had to stuff them the rest of the way; 2/3 the line length. To do so, I had to build a basket to hold up the stuffing from falling down. That was a chore to get in place reaching through the speaker cutout, but I did it. I've now got ~1/2b stuffing behind the driver and the rest of the way down to the basket.

I havent measured the result yet, but I believe the combing is going to happen unless you stuff it. I thought I read someone liked it better w/o the stuffing, which, if it does that, seems odd. My question is, the 0.5 lb of polyfil - is that in the ballpark, to tight? What's the art of stuffing these MLTLs? I only have so many driver mounting cycles, before the screw holes strip out of the the MDF. Thanks,

Attachments

I think that is floor bounce dip and not because you did not stuff it enough. It also looks like you need some serious BSC.

Set your speaker on a stand so that the driver is at least 40in off the floor. Put mike at 19in (0.5m) from the driver, and use REW with 6 cycle freq dependent window. This will remove floor bounce and give you a much more accurate response without the floor bounce.

You have a rising response, so that means the treble neede to be shelved with a BSC circuit. I think use a 1mH inductor and about a 6.8ohm to 8.2ohm to even 10ohm 10W crossover resistor in parallel. Adjust to taste but the RTA should show a flat or slightly right leaning response.

Set your speaker on a stand so that the driver is at least 40in off the floor. Put mike at 19in (0.5m) from the driver, and use REW with 6 cycle freq dependent window. This will remove floor bounce and give you a much more accurate response without the floor bounce.

You have a rising response, so that means the treble neede to be shelved with a BSC circuit. I think use a 1mH inductor and about a 6.8ohm to 8.2ohm to even 10ohm 10W crossover resistor in parallel. Adjust to taste but the RTA should show a flat or slightly right leaning response.

... and welcome to the forum. 😉Ccrider147, this is the TABAQ design thread.

If you want people to comment, start your own thread, and probably in the multiway section too.

A laminate of two sheets using a pliable adhesive like latex caulking will form a constrained layer damping (CLD) that greatly reduces sound transmission and resonances through the walls. I have also added sheets of mass loaded butyl with foil face (auto sound dampening sheets) to the inside walls. That works really well too.

Hot melt glue for quick joints and PVA (white glue) when instant bonding is not needed.

Yes, it takes a vinyl wrap well. Also look into fabric or upholstery covering. PVA glue can be used to apply covering like wall paper. Thin wood veneer can be used too. Be careful not to use VOC based adhesive or paints as that will dissolve the foam.

Curved wall can also be made using “bendy” plywood/MDF.

:

I think I’m getting there with the choice of materials - I have discovered flexible MDF/Plywood which is available pre-kerfed. I am thinking that this could be used on the curved cabinet sides either as two thinner sheets laminated together or one thicker sheet.

The front baffle could be made in a dual layer of MDF/plywood/solid wood like oak. The top, port assembly and foot area could be made from the same. Natural wood elements (probably oak) could be finished with oil and the curved sides could be painted or covered in a vinyl wrap in some colour or other. Internal surfaces would have some bitumen panels applied and an appropriate amount of ‘stuffing’ put in for the 3 inch driver I choose. The Peerlless or Faital options seem favourite.

I would use a supplementary box for any BSC that may been needed (would make the speaker easier to make/seal).

Now all I need to do is work out what effect that choosing a curved cabinet has on the important maths involved. If I keep the same height and width dimensions as the Bjorn’s original designs then at least I would only have to work in the depth ‘domain’ to workout any changes in volume. Am I correct that, as well as the vertical positioning of the driver on the front baffle, and assuming that the internal height and width of the speaker remain the same, it is the internal volume that is most critical to get right?

Apologies...

My apologies. This was the only thread that Tang Band hit on. I don't want to be that guy who asks a question before searching.

Thanks!

c.

Ccrider147, this is the TABAQ design thread.

If you want people to comment, start your own thread, and probably in the multiway section too.

My apologies. This was the only thread that Tang Band hit on. I don't want to be that guy who asks a question before searching.

Thanks!

c.

XRK, thanks. The measurement was done outdoors over grass / lawn. Whenever I do a measure like this, I always bring my handy-dandy reference speaker (some little Polk HT job) that I know the FR of. Just to sort out that I'm not going crazy over heights, distances, equipment blindsiding me.

At appx the same height and distance to the mike, with the same signal source and measurement equipment, same location, day etc the little Polk did not exhibit a gigantic comb at 200 Hz!

Rain has been pretty fierce over the past 24 hours, but I'll plan a second measurement of my TABAQs with the basket-held 0.5lb of Polyfil as soon as the weather turns nice again. Which of course I'll post the result here.

At appx the same height and distance to the mike, with the same signal source and measurement equipment, same location, day etc the little Polk did not exhibit a gigantic comb at 200 Hz!

Rain has been pretty fierce over the past 24 hours, but I'll plan a second measurement of my TABAQs with the basket-held 0.5lb of Polyfil as soon as the weather turns nice again. Which of course I'll post the result here.

Last edited:

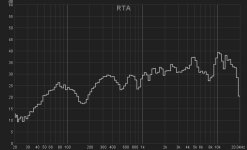

Well, with stuffing (~0.5lb) down to 2/3 length, I'm getting the following, which is different than w/o it, but still got a hole at ~200. Albeit different shape - not as deep.

Is the measurement facility anechoic enough for this? Any reflection from ground plane is off lawn. Do I need to go to .75lb, 1 lb of polyfil? How does one rid their MLTL from the lowest frequency comb?

At least I'm headed in the right direction. Thanks.

Is the measurement facility anechoic enough for this? Any reflection from ground plane is off lawn. Do I need to go to .75lb, 1 lb of polyfil? How does one rid their MLTL from the lowest frequency comb?

At least I'm headed in the right direction. Thanks.

Attachments

Did you measure the driver while not in the TABAQ?

Maybe that dip is driver related, that's why it's so hard to get rid of?

Maybe that dip is driver related, that's why it's so hard to get rid of?

Well, with stuffing (~0.5lb) down to 2/3 length, I'm getting the following, which is different than w/o it, but still got a hole at ~200. Albeit different shape - not as deep.

Could you try different measuring distances to see how the frequency of the ~200Hz dip depends on the measuring distance? I am wondering whether it is the sum of the outputs of the driver and the port (delayed by 1/4 wavelength plus additional distance of travel) that is giving you the dip at the mic measuring point. This might also explain why you did not see a dip with the Polk speaker.

Also, could you try plugging the port to see if the dip goes away? If it does, it would (1) strongly suggest that the problem comes from the port, and (2) reduce the likelihood of a frequency response anomaly of the driver itself. I am less inclined to think that the driver is the culprit. At 200Hz, the wavelength is ~172cm, and it is hard to think about a mechanism for the 5" driver to have a response dip at such a long wavelength.

Kurt

I think KCHANG is right, I have the same Tabaq with W5-2143, I make lots of measurement with filling, without filling, close to driver, different distances and always there is this deep peak at 200Hz so is clear to me now is a problem of the driver itself , I always thought was a problem of the room, anyway sometimes I will try to measure it in different space....all the best

If it is possible, you could try elevating the speaker and the mic up off the ground? 200Hz is about where the floor/ground bounce cancellation would be.

I agree with xrk971:

It is floor / ground reflection. MJKs software can simulate the loudspeaker in the listening room, and i always get a dip at 2-300 Hz.

As xrk971 already mentioned: You need BSC to balance the sound. The treble is dominating.

Regards

Bjørn

It is floor / ground reflection. MJKs software can simulate the loudspeaker in the listening room, and i always get a dip at 2-300 Hz.

As xrk971 already mentioned: You need BSC to balance the sound. The treble is dominating.

Regards

Bjørn

Last edited:

Yes no problem so here the original sim for W5-2143 and my own plan....all the best

Thank you. I built it according to the sim but with a right angle cabinet. I'll post the plans soon as well.

Best,

Selim

I agree with xrk971:

It is floor / ground reflection. MJKs software can simulate the loudspeaker in the listening room, and i always get a dip at 2-300 Hz.

Floor/ground reflection of course is there, but jjasniew's own statement seems to suggest that something else is at play:

At appx the same height and distance to the mike, with the same signal source and measurement equipment, same location, day etc the little Polk did not exhibit a gigantic comb at 200 Hz!

It is of course possible that his "approximating" the height and distance (or using the Polk speaker to approximate the TB speaker) was not good enough, and such deviations somehow significantly changed the magnitude of the cancellation. 😉

The easiest thing to do to solve the mystery is for jjasniew to plug the port, and see what happens. If the same deep cancellation is still there, then the problem is the floor/ground reflection. If the cancellation is significantly reduced, then it is the port. Of course, he has to measure the speaker with the port open in situ again as a reference (i.e., cannot reuse the old measurement for comparison).

Kurt

@perceval, KCHANG, kissabout2002, NeilBlanchard, Bjohannesen -

I really appreciate your helping my out with this. It looks like I dont know how to measure this type of speaker. I'm pretty lost; I was always under the impression that this type of cabinet "combs" until properly stuffed, upon which it goes flat.

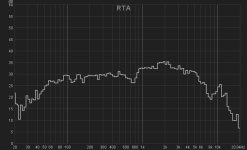

There's a back deck where I live. It's pretty high up off the ground, so I arranged my TABAQ sideways on the safety railing and setup the mic on a ladder. It was a one shot quick pink noise test (didnt have time to horse the ladders into perfect position for the mic) to see if the ground bounce could be eliminated.

Here's a couple picture of the setup and the FR I got. (Next time I'll build something that clips onto the deck rails and holds a mic out 1M beyond) Disregarding the HF response - as I'm sure I wasnt precisely on axis - the ~200 Hz dip is gone.

TL;DR - when I raise the speaker and mic well above the ground, the dip goes away. So does my understanding of "how it works"...

I really appreciate your helping my out with this. It looks like I dont know how to measure this type of speaker. I'm pretty lost; I was always under the impression that this type of cabinet "combs" until properly stuffed, upon which it goes flat.

There's a back deck where I live. It's pretty high up off the ground, so I arranged my TABAQ sideways on the safety railing and setup the mic on a ladder. It was a one shot quick pink noise test (didnt have time to horse the ladders into perfect position for the mic) to see if the ground bounce could be eliminated.

Here's a couple picture of the setup and the FR I got. (Next time I'll build something that clips onto the deck rails and holds a mic out 1M beyond) Disregarding the HF response - as I'm sure I wasnt precisely on axis - the ~200 Hz dip is gone.

TL;DR - when I raise the speaker and mic well above the ground, the dip goes away. So does my understanding of "how it works"...

Attachments

Last edited:

- Home

- Loudspeakers

- Full Range

- TABAQ TL for Tangband