Thanks Art.

Wow those ports are big.

I am currently in discussion with a friend about 3D printing the entire box in one go.

Wow those ports are big.

I am currently in discussion with a friend about 3D printing the entire box in one go.

Printing in smaller sections and glueing together is safer because printing problems (filament running out, jams, etc.) may occur part way thru and you don't want to risk ruining the whole thing. I would print in quadrants or in major assemblies.

Good news! I have a qualified furniture maker with a mind boggling woodworking factory on board to head up the build.

There are no less than three different sized saw benches on hand to get the cuts of all sizes and angles to perfection.

We are continuing the 3D modelling this week, and I hope to be able to get Art to verify the models dimensions are as specified.

After the 3D model has been verified as correct, it then gets exploded into cut sheets...and we fire up the saws!

There are no less than three different sized saw benches on hand to get the cuts of all sizes and angles to perfection.

We are continuing the 3D modelling this week, and I hope to be able to get Art to verify the models dimensions are as specified.

After the 3D model has been verified as correct, it then gets exploded into cut sheets...and we fire up the saws!

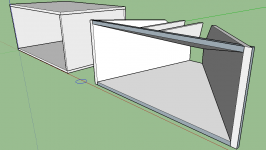

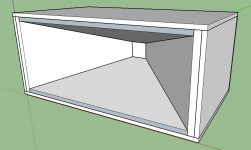

3D model coming along.

There were a few expected discrepancies due to exact inch increments being quoted where angles are involved.

However the horn itself should be exactly to spec with respect to angles and sizes.

This initial sketchup model is intended to communicate to the fabricator what the end result should be, and he will recreate it from scratch in solidworks.

A few deceiving looking angles on the screen grab, but its actually all square and measuring up to spec!

There were a few expected discrepancies due to exact inch increments being quoted where angles are involved.

However the horn itself should be exactly to spec with respect to angles and sizes.

This initial sketchup model is intended to communicate to the fabricator what the end result should be, and he will recreate it from scratch in solidworks.

A few deceiving looking angles on the screen grab, but its actually all square and measuring up to spec!

Attachments

Last edited:

A few more pics.

Nice work! The throat looks visually to be larger than a 1in or even 1.4in dia CD throat. Are you planning on adding an adapter plate still to bring it down smaller? Can you share the sketchup model?

Fin,However the horn itself should be exactly to spec with respect to angles and sizes.

A few deceiving looking angles on the screen grab, but its actually all square and measuring up to spec!

The throat of the SynTripP is not square, so a bit more respect to angles and sizes will be required ;^).

Also, the front of the horn is not flush with the front of the box, unless you intend to eliminate the grill frame that fits in, which is an intermediate angle between the initial and secondary horn expansion, and contributes to better polar performance when the secondary horn is not used, and smoother response when it is.

Art

Attachments

Last edited:

Yes, the horn is not square.Is there a reason why the throat is not square?

I think the Synergy calculator by Bwaslo will calculate cut panels for you with square throat and rectangular mouth. That would be preferable as the transition from the round CD throat to horn throat would not have the sudden expansion in 1 dimension.

To avoid a "sudden expansion" with a square throat would require the 1/2" horn walls to be reduced to almost nothing at the transition, not preferable from a construction standpoint.I think the Synergy calculator by Bwaslo will calculate cut panels for you with square throat and rectangular mouth. That would be preferable as the transition from the round CD throat to horn throat would not have the sudden expansion in 1 dimension.

The driver mounting plate contains most of the horn throat round to rectangular transition, hence the rectangular shape of the horn throat.

The 90 degree horizontal and 40 degree vertical dispersion at 16 kHz demonstrates the throat transition works well.

Attachments

Fin,

The throat of the SynTripP is not square, so a bit more respect to angles and sizes will be required ;^).

Also, the front of the horn is not flush with the front of the box, unless you intend to eliminate the grill frame that fits in, which is an intermediate angle between the initial and secondary horn expansion, and contributes to better polar performance when the secondary horn is not used, and smoother response when it is.

Art

Understood, thanks Art.

Although I do like the visual appeal of seeing into the horn!

I expect there will be a few things to fine tune in the model before it gets turned into cut sheets.

We can also include any mods you might wish to introduce that would be beneficial.

(getting excited!)

Art,

Apologies if I have missed an included instruction, however I am not identifying the location of the centre points for the 1/2 and 1 inch injection port hole drill point locations.

May we reiterate the location of them here?

(hope that makes sense)

Apologies if I have missed an included instruction, however I am not identifying the location of the centre points for the 1/2 and 1 inch injection port hole drill point locations.

May we reiterate the location of them here?

(hope that makes sense)

I was looking for the measurements of the center of each drill point.

Perhaps squared off from the center line would be comprehensive.

I appreciate the location and volume of the ports are vitally important.

Perhaps squared off from the center line would be comprehensive.

I appreciate the location and volume of the ports are vitally important.

Fin,

The locations and size of the ports are important, but not to the point of splitting hairs. The distance between the throat from the inside of the horn and the center of the 1/2" port center line is 1 7/8".

Art

The locations and size of the ports are important, but not to the point of splitting hairs. The distance between the throat from the inside of the horn and the center of the 1/2" port center line is 1 7/8".

Art

Cheers Art!

THROAT:

I missed the non-square throat size because I made the assumption it was square and took the dimensions from part D, as 2.3125.

Ill reverse engineer the size from the angles and sizes of D and E.

ON DIMENTIONS:

At this stage I am assuming that the dimensions of E specifically state the horns INSIDE dimensions.

As E is rotated to 18.175 degrees, the faces that touch D are slightly angled, and so the join is not square. Thus they need a slight angle cut, but which side becomes the stated measurement? Thus I have currently assumed the dimensions state the INSIDE of the horn.

THROAT:

I missed the non-square throat size because I made the assumption it was square and took the dimensions from part D, as 2.3125.

Ill reverse engineer the size from the angles and sizes of D and E.

ON DIMENTIONS:

At this stage I am assuming that the dimensions of E specifically state the horns INSIDE dimensions.

As E is rotated to 18.175 degrees, the faces that touch D are slightly angled, and so the join is not square. Thus they need a slight angle cut, but which side becomes the stated measurement? Thus I have currently assumed the dimensions state the INSIDE of the horn.

Correct, the dimensions are the largest dimension, which is the inside of the horn, but also include the length from front to back which is longer than the inside dimension.

- Home

- Loudspeakers

- Multi-Way

- SynTripP: 2-way 2-part Virtual Single Point Source Horn