That looks scary! I work for a transport company and have seen the horror stories first hand. I realize these will be in transport racks but I'd be worried about parts being damaged in shipping! I may be over cautious but I think anything with substantial mass needs to be adequately suspended when near a source of vibration.

Interesting, as Meyer has a lot of experience with the powered loudspeakers. They manufacturing them since decades...

Sajti

Interesting, as Meyer has a lot of experience with the powered loudspeakers. They manufacturing them since decades...

Sajti

As I said, I'm likely over cautious. My experience with electronics and vibration is from heavy trucks going millions of kilometers. Possibly the severity of vibration is different but ultimately it shouldn't be as the objective of the subwoofer is to actually make vibration.

Meyersound use 2250W classH MOSFET amplifier in 700HP.

Sajti

And I thought what I was building was complicated 😱 .

Looks like a whole computer system in there along with the PS !

I slept on it -

For ease of service (tinkering , too) , the slewmaster OPS will be raised 2.25"

above the plate ... "floating" on "C" channels. The wolverine will be by it's

side , connected with wires. Still4given does this on all his slews.

The control board and any input circuitry can also be near the IPS , wiring

will be far shorter will all The FR-4 in one place.

Behind the plate (inside) - relays , toroid , and main supply caps. I'll even

silicone between the caps to reduce any "macrophonics"😀

I've been looking at ebay "C" channels - that's how I know they exist. My

local hardware store wouldn't even know what I was talking about 😱 .

The channel will even stiffen the plate. 😎 Just AC/DC , speaker , and control

wires will have to "breach" the plate .... "goop them well" (like the Logitech's).

Best of all , all my electronics will be outside. What would happen if I tripped a

thermal alarm , take the whole plate off to reset .... screw that ! 😡

OS

And I thought what I was building was complicated 😱 .

Looks like a whole computer system in there along with the PS !

OS

That is the remote monitoring system. Even it looks quite complicated.

Sajti

As I said, I'm likely over cautious. My experience with electronics and vibration is from heavy trucks going millions of kilometers. Possibly the severity of vibration is different but ultimately it shouldn't be as the objective of the subwoofer is to actually make vibration.

Maybe the sub does not go "millions of miles" , but anything in the vicinity

of the port area will feel like it did VERY quickly.

The potting and plastic dishes are for consumer fools and warranties.

This is DIY.

I've seen a many a blown sub amp come up on the forum. BUT , the

cheap logitech's just have bad-broken connectors/controllers. Their amps and

power supplies are just about always functional.

OS

Last edited:

That is the remote monitoring system. Even it looks quite complicated.

Sajti

Like the pro amps , all networked with a PC.

Have a concert , know what units failed .... replace "modules".

OS

And I thought what I was building was complicated 😱 .

Looks like a whole computer system in there along with the PS !

I slept on it -

For ease of service (tinkering , too) , the slewmaster OPS will be raised 2.25"

above the plate ... "floating" on "C" channels. The wolverine will be by it's

side , connected with wires. Still4given does this on all his slews.

The control board and any input circuitry can also be near the IPS , wiring

will be far shorter will all The FR-4 in one place.

Behind the plate (inside) - relays , toroid , and main supply caps. I'll even

silicone between the caps to reduce any "macrophonics"😀

I've been looking at ebay "C" channels - that's how I know they exist. My

local hardware store wouldn't even know what I was talking about 😱 .

The channel will even stiffen the plate. 😎 Just AC/DC , speaker , and control

wires will have to "breach" the plate .... "goop them well" (like the Logitech's).

Best of all , all my electronics will be outside. What would happen if I tripped a

thermal alarm , take the whole plate off to reset .... screw that ! 😡

OS

You can get C-channel at any metal fabricator or cut length metal supplier. Not likely many of them around you though. I did a quick Google search. A place like Specialty Metals | | | Specialty Metals - Knoxville, TN in Knoxville is what you are looking for. Or I could just form something and send it to you.

Your thermal alarm will reset if you unhook mains power for a couple seconds. No need to open the amp to reset it.

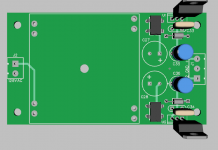

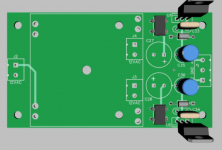

I've got a supply layed out to go with the crossover. 2.25 x 4" with the screw holes in from the edge of the board.

What timing !!!

I'm actually at that exact point in the project.

All my trafo's are in the sub enclosure , do you need the

trafo on the pcb ??

Typically , one would use a auxillary main trafo secondary or

a small toroid like those antek 10VA's.

Below -

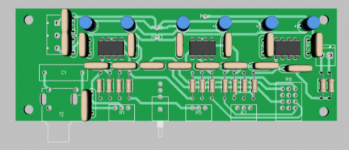

1/2 = amp on front , what's lay'ed out on the front will actually

be under (inside - on the left).

3= will be the IPS area in the front.

4= will be where I could fit an auxiliary supply.

5= control board area

6= where that thin EQ bord could mount vertically.

This layout is much more involved , as the environment is "hostile"

Trafo's and PS (hostile) and small signal area (safe, ventilated , "less hostile").

😱😱

Edit - I'm running both my control board and EQ off of my

25VA EI - it's 15-0-15Vac.

OS

Attachments

Last edited:

I can make the transformer optional and add a couple terminal blocks under it for AC. Just chop the board shorter. The supply could sit in the bottom of the speaker as is too. I'm trying to make everything in modules for mine to get rid of the wire mess.

Chopping the board is good.

You see zone 4 in the photo - reserved for any aux supply ... 😎

(It's 3 X 4")

I want to keep any component I can OUT of the enclosure.

I've seen trafo's , bridges and large caps in boxes before.

I wasn't sure on the caps , but I read electrolytic 's are the least

susceptible to micro-phonics. Heat is their major weakness 🙁

OS

You see zone 4 in the photo - reserved for any aux supply ... 😎

(It's 3 X 4")

I want to keep any component I can OUT of the enclosure.

I've seen trafo's , bridges and large caps in boxes before.

I wasn't sure on the caps , but I read electrolytic 's are the least

susceptible to micro-phonics. Heat is their major weakness 🙁

OS

Last edited:

This can be cut to 2 x 2 3/4".

That's cool software. Man , your quick ! 😱

Ideal ...

???? --- separate bridge for each aux regulator ??

OS

Last edited:

That's cool software. Man , your quick ! 😱

Ideal ...

???? --- separate bridge for each aux regulator ??

OS

That was just easier to do a star ground without screwing up current flow directions.

The EQ can be mounted with just the pot's and input jack , right ?

Just want to give enough clearance (and forethought) for any expected

future additions/"enhancements".

Edit - I'm about to drill/tap now....

OS

Just want to give enough clearance (and forethought) for any expected

future additions/"enhancements".

Edit - I'm about to drill/tap now....

OS

It could be mounted by the pots. It might eventually crack the solder joints. If you can leave a little room at the top and bottom I can form a gusset for it.

"gusset" I knew what a clothing gusset was ....

"gusset plate " ?? like an "L" bracket to hold the PCB ?

OS

"gusset plate " ?? like an "L" bracket to hold the PCB ?

OS

L brackets are actually bad for vibration. It will be constantly flexing the bend. A bracket kind of like the heat sink for your drivers is better. The triangular part doesn't need to be as wide.

- Status

- Not open for further replies.

- Home

- Amplifiers

- Solid State

- Subwoofer Class AB plate amp