kevinkr,

Just let know the diameter you need. The rods will be 12" long.

Hi hottattoo,

Best I can determine the rod is 122.9 mils in diameter. I think 125 mils is probably realistic with tolerances taken into consideration. It's quite consistent at several barely accessible measurement points. My thanks!

kevinkr,

So that means 1/8" which is .125"---just want to make sure before I put in the order. Send me an email to ( deleted by moderation) with your mailing information. I will let you know when the rods are on their way.

deleted by moderation) with your mailing information. I will let you know when the rods are on their way.

So that means 1/8" which is .125"---just want to make sure before I put in the order. Send me an email to (

deleted by moderation) with your mailing information. I will let you know when the rods are on their way.

deleted by moderation) with your mailing information. I will let you know when the rods are on their way.Reading this thread with interest. I owned a Souther SLA3 for many years. It also altered my thinking radically when it comes to tonearms.

Conclusions. Tracking distortion is a major detractor from high fidelity audio reproduction irrespective of what the measurements conclude.

9 inch arms suck. I loved the Souther but the constant tweaking, cleaning & tuning drove me quite insane. They best suit a non suspended high mass TT. Keeping the quartz running rails clean & dust free is essential. I sold the Souther and regressed to 12 inch arms for the sake of convenience as an acceptable compromise that still made the inner grooves of a record listenable. That is thanks to the Souther not even remotely possible with any 9inch arm anymore no matter how precisely built or what magic fairy dust is sprinkled on it.

Conclusions. Tracking distortion is a major detractor from high fidelity audio reproduction irrespective of what the measurements conclude.

9 inch arms suck. I loved the Souther but the constant tweaking, cleaning & tuning drove me quite insane. They best suit a non suspended high mass TT. Keeping the quartz running rails clean & dust free is essential. I sold the Souther and regressed to 12 inch arms for the sake of convenience as an acceptable compromise that still made the inner grooves of a record listenable. That is thanks to the Souther not even remotely possible with any 9inch arm anymore no matter how precisely built or what magic fairy dust is sprinkled on it.

I'm having the same problem with my 12 inch arms, the Tri-Quartz and SLA-3 have replaced both. The turntables are TD-124 which are inherently a PITA, so an arm that needs a lot of attention seems not at all out of character.

I attempted my first counter weight in tellurium copper tonight, things did not go according plan at all. I panicked our pet rabbits with machining noise, and to top it off the first weight was ruined by the bit breaking off due to my failure to clear the debris frequently enough when center drilling on the lathe. The second one was a success in that I drilled all the way through without breaking the bit, but this rank amateur machinist somehow drilled a hole that started at the center on one side and ended off center at the other - the hole is straight as an arrow, but I thought I had the work well centered in the chuck of the lathe. I am not sure how I did not break the second bit given the eccentricity.

The new weight is just a prototype, unlike the wand I don't consider this to be a quite good enough. I have not drilled it for a set screw as I figure this will result in another disaster.. LOL

It came in at 14.67gms which is within a reasonable distance of 14 - 15gms deemed reasonable. Total arm mass with cartridge and this counterweight is still around 43gms which seems to about the minimum the Windfeld will tolerate. I think there is some improvement over the stock collection of Souther weights, but it is subtle, I think a slight improvement in focus is how I would describe. The Windfeld remains extremely fussy, but is now sounding quite promising.

I attempted my first counter weight in tellurium copper tonight, things did not go according plan at all. I panicked our pet rabbits with machining noise, and to top it off the first weight was ruined by the bit breaking off due to my failure to clear the debris frequently enough when center drilling on the lathe. The second one was a success in that I drilled all the way through without breaking the bit, but this rank amateur machinist somehow drilled a hole that started at the center on one side and ended off center at the other - the hole is straight as an arrow, but I thought I had the work well centered in the chuck of the lathe. I am not sure how I did not break the second bit given the eccentricity.

The new weight is just a prototype, unlike the wand I don't consider this to be a quite good enough. I have not drilled it for a set screw as I figure this will result in another disaster.. LOL

It came in at 14.67gms which is within a reasonable distance of 14 - 15gms deemed reasonable. Total arm mass with cartridge and this counterweight is still around 43gms which seems to about the minimum the Windfeld will tolerate. I think there is some improvement over the stock collection of Souther weights, but it is subtle, I think a slight improvement in focus is how I would describe. The Windfeld remains extremely fussy, but is now sounding quite promising.

Attachments

If you don't want extra weight which will add to total mass, you may make counter weight same as my air bearing arm's counter weight. Each lead shot is .5 g. I have way enough lead shots. If you want some, just drop me a note. I will be traveling tomorrow and will send to you once I get back. I would suggest that counter weight should be slightly lower than the record surface.

Attachments

Something to bear in mind when I start to work on my own arm.. The counterweight spends most of its time over the record surface so although I have thought about placing the counter weight off center so that more of the mass is below the wand I have not attempted to make such a weight yet.

The total arm mass sans cartridge is under 15gms, the counter weights are 2, 4, 8 and 14 so far. I have determined that the ideal mass for the Windfeld is > 40gms and the heavier counter weight gets me into that range and also allows me to place it closer to the pivot to reduce inertia effects in the vertical plane.

The wand is about 6.25" long from forward end of shell to tail, most of the length is behind the vertical pivot, so completely backwards compared to pivoted arms and most air bearing and the newer CA LTA arms as well.

I made them because I have this compelling desire to make the Windfeld work on one of these arms.. 😱 I seem to be succeeding.

The total arm mass sans cartridge is under 15gms, the counter weights are 2, 4, 8 and 14 so far. I have determined that the ideal mass for the Windfeld is > 40gms and the heavier counter weight gets me into that range and also allows me to place it closer to the pivot to reduce inertia effects in the vertical plane.

The wand is about 6.25" long from forward end of shell to tail, most of the length is behind the vertical pivot, so completely backwards compared to pivoted arms and most air bearing and the newer CA LTA arms as well.

I made them because I have this compelling desire to make the Windfeld work on one of these arms.. 😱 I seem to be succeeding.

Hi Kevin.

I think I know why the hole you drilled went adrift and how to prevent it from doing so again. Did you use a centre drill before attempting to drill through the rod?

Without using one of these first the long drill bits tip will skate across the surface of the workpiece, flexing along its length, until it bites and starts drilling. The point where it starts drilling will not be perfectly centred causing the hole formed to slant. As you drill deeper the flexing becomes more severe which is why the first drill snapped. Just drill in a little way at a time then back of to clear the swarf. Use of a cutting lubricant also helps. One last thing to check, are the lathe chuck and tail stock chucks both perfectly aligned? If it's a budget minilathe you can be pretty sure that straight out of the box they won't be.

I hope this helps.

On the subject of where the counterweight should be relative to the record surface.

Ideally the vertical centre of mass of the whole arm, including cartridge and counterweight, should be about level with the vertical PIVOT, not the record surface. Locating the com here minimizes tracking force variations due to warps. The use of an underslung counterweight on a souther would pull the com way below the vertical pivot causing tracking force to increase whilst navigating a warps. Having the centre of mass just below the pivot can help arm stability. Looking at the souther it looks like the com will be about perfect with the counterweight you've made. Of course try an underslung counterweight as well and listen.

Ideally the vertical pivot should be level with the record surface in order to minimize warp wow.

The centre of mass should only be level with the record surface if the vertical pivot is also level with the record surface. Due to the shortness of the souther arm the pivot has to be above the record so the centre of mass has to be above the record also.

The sonic advantages of using a very short arm more than outweighs the disadvantage of not being able to have centre of mass, vertical pivot and record surface all on the same plane. These disadvantages can be reduced by the use of a well designed record clamp that flattens the record reducing warps and therefore reducing warp induced tracking force variations and warp wow.

Niffy

I think I know why the hole you drilled went adrift and how to prevent it from doing so again. Did you use a centre drill before attempting to drill through the rod?

Without using one of these first the long drill bits tip will skate across the surface of the workpiece, flexing along its length, until it bites and starts drilling. The point where it starts drilling will not be perfectly centred causing the hole formed to slant. As you drill deeper the flexing becomes more severe which is why the first drill snapped. Just drill in a little way at a time then back of to clear the swarf. Use of a cutting lubricant also helps. One last thing to check, are the lathe chuck and tail stock chucks both perfectly aligned? If it's a budget minilathe you can be pretty sure that straight out of the box they won't be.

I hope this helps.

On the subject of where the counterweight should be relative to the record surface.

Ideally the vertical centre of mass of the whole arm, including cartridge and counterweight, should be about level with the vertical PIVOT, not the record surface. Locating the com here minimizes tracking force variations due to warps. The use of an underslung counterweight on a souther would pull the com way below the vertical pivot causing tracking force to increase whilst navigating a warps. Having the centre of mass just below the pivot can help arm stability. Looking at the souther it looks like the com will be about perfect with the counterweight you've made. Of course try an underslung counterweight as well and listen.

Ideally the vertical pivot should be level with the record surface in order to minimize warp wow.

The centre of mass should only be level with the record surface if the vertical pivot is also level with the record surface. Due to the shortness of the souther arm the pivot has to be above the record so the centre of mass has to be above the record also.

The sonic advantages of using a very short arm more than outweighs the disadvantage of not being able to have centre of mass, vertical pivot and record surface all on the same plane. These disadvantages can be reduced by the use of a well designed record clamp that flattens the record reducing warps and therefore reducing warp induced tracking force variations and warp wow.

Niffy

Last edited:

Hi Niffy,

I didn't use a center drill, and will need to check to see if I have one in the right size range. (Didn't occur to me - the danger of being a newbie.. lol)

I did use cutting oil, and I quickly figured out to take my time and back the drill out and clear out the swarf every couple of seconds.

I was surprised how it started off quite well centered and ended up off center at the exit point on the work piece, but it works and reasonably well.

You've confirmed my suspicions about the location of the counter weight and filled in some gaps in my knowledge while doing it.. 😀 So thank you!

I use a clever clamp which while not the ultimate seems to work to some extent to flatten out my records, most are not very warped, the exceptions are not helped by that or any clamp or weight unfortunately. Those records cause problems with my remaining pivoted arm as well. They play, but with the cartridges I use I don't like seeing that sort of behavior.

I didn't use a center drill, and will need to check to see if I have one in the right size range. (Didn't occur to me - the danger of being a newbie.. lol)

I did use cutting oil, and I quickly figured out to take my time and back the drill out and clear out the swarf every couple of seconds.

I was surprised how it started off quite well centered and ended up off center at the exit point on the work piece, but it works and reasonably well.

You've confirmed my suspicions about the location of the counter weight and filled in some gaps in my knowledge while doing it.. 😀 So thank you!

I use a clever clamp which while not the ultimate seems to work to some extent to flatten out my records, most are not very warped, the exceptions are not helped by that or any clamp or weight unfortunately. Those records cause problems with my remaining pivoted arm as well. They play, but with the cartridges I use I don't like seeing that sort of behavior.

Counter Weight Success

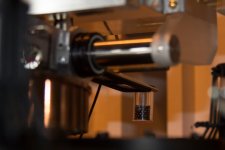

Thanks to the input of several friends I successfully completed my first decent counter weight this afternoon. I'm pretty stoked.. LOL

For the many guys here who are crackerjack machinists feel free to laugh! I took all of the advice about dubbing bits, dimpled the work piece, and took my time drilling the center hole, backing out the bit every time I took a tiny cut of material. It went without incident. I then jigged the part in my milling vise and used the mill to drill a hole for the set screw, and then finished by tapping it.

Perhaps the biggest surprise to me is that I seem to have sufficient patience. I guess getting old does have some compensations. I might even be good at this some day.

These skills will come in handy over time.

Thanks to the input of several friends I successfully completed my first decent counter weight this afternoon. I'm pretty stoked.. LOL

For the many guys here who are crackerjack machinists feel free to laugh! I took all of the advice about dubbing bits, dimpled the work piece, and took my time drilling the center hole, backing out the bit every time I took a tiny cut of material. It went without incident. I then jigged the part in my milling vise and used the mill to drill a hole for the set screw, and then finished by tapping it.

Perhaps the biggest surprise to me is that I seem to have sufficient patience. I guess getting old does have some compensations. I might even be good at this some day.

These skills will come in handy over time.

Attachments

I ordered 6" x 0.75" x 0.75" blanks of Cocobolo, African blackwood, Bubinga, and East Indian Rosewood to try for head shell blanks.

Hopefully my father in law can band saw them lengthwise in half and run the pieces through his planer to make a couple of thinner 6" pieces for me to turn into head shells.

Hopefully my father in law can band saw them lengthwise in half and run the pieces through his planer to make a couple of thinner 6" pieces for me to turn into head shells.

Hi Kevin,

I've just been reading through your thread of your rebuild and tweaking of a thorens td 124. Even though it is not a deck I am ever likely to own I am finding it fascinating and informative, only 150 pages to go. Well worth a read for anyone interested in refurbishing any type of deck.

I have fitted the pin bearings to my arm so the previously used hybrid ceramic are removed. I had thought that they were similar in performance to the full zirconium oxide ceramic bearings that I reported. I have now tested the hybrids and have say they do measure a lot better. The ZnO3 bearings had a mean coefficient of friction of about 0.01. The hybrids are a lot better at about 0.006. The hybrids did sound a bit better and this could be the reason. The hybrid bearings I was using are from Boca bearings. They use silicon nitride balls and 440 grade stainless for the races and retainer. If you plan on further experimentation with bearings I would highly recommend this manufacturer. They have a very wide range and will probably have the exact size you require. (no affiliation disclaimer)

Niffy

I've just been reading through your thread of your rebuild and tweaking of a thorens td 124. Even though it is not a deck I am ever likely to own I am finding it fascinating and informative, only 150 pages to go. Well worth a read for anyone interested in refurbishing any type of deck.

I have fitted the pin bearings to my arm so the previously used hybrid ceramic are removed. I had thought that they were similar in performance to the full zirconium oxide ceramic bearings that I reported. I have now tested the hybrids and have say they do measure a lot better. The ZnO3 bearings had a mean coefficient of friction of about 0.01. The hybrids are a lot better at about 0.006. The hybrids did sound a bit better and this could be the reason. The hybrid bearings I was using are from Boca bearings. They use silicon nitride balls and 440 grade stainless for the races and retainer. If you plan on further experimentation with bearings I would highly recommend this manufacturer. They have a very wide range and will probably have the exact size you require. (no affiliation disclaimer)

Niffy

Hi Niffy,

Much appreciated comments on the TD-124 thread, it has quieted down quite a bit recently. I have a love/hate with mine, but they are about nicest tables I have ever owned when it comes down to actually playing records. I have a 401 in the wings which should be very interesting.

Always interested in further potential improvement, so those bearings will be of interest if I can find ones that will interchange with the existing ones.

Hottatoo graciously sent me a set of carbide rods, and they look like serious business. I am hoping to build an arm around them at some point.

At the moment I have been experimenting with making arm wands and weights. I've had some success.

Much appreciated comments on the TD-124 thread, it has quieted down quite a bit recently. I have a love/hate with mine, but they are about nicest tables I have ever owned when it comes down to actually playing records. I have a 401 in the wings which should be very interesting.

Always interested in further potential improvement, so those bearings will be of interest if I can find ones that will interchange with the existing ones.

Hottatoo graciously sent me a set of carbide rods, and they look like serious business. I am hoping to build an arm around them at some point.

At the moment I have been experimenting with making arm wands and weights. I've had some success.

Never actually seen the innards of a Linear gizmo.

Fascinating contraption... Thanks for the views.

In truth tho it does remind me of the Nasa ; 'space pen' alegedly millions in development.

Whereas the Soviets used a pencil 😀

Fascinating contraption... Thanks for the views.

In truth tho it does remind me of the Nasa ; 'space pen' alegedly millions in development.

Whereas the Soviets used a pencil 😀

Urban myth alert

No one has used pencils in space. If the end breaks you have an electrically conductive shard free floating just looking for an electrical short to create. A normal biro works just fine in zero gee.

I am also in proud possession of a pair of tungsten carbide rods courtesy of hottattoo. I've extended my investigation into linear bearing design so I can make the best possible use of them.

Niffy

No one has used pencils in space. If the end breaks you have an electrically conductive shard free floating just looking for an electrical short to create. A normal biro works just fine in zero gee.

I am also in proud possession of a pair of tungsten carbide rods courtesy of hottattoo. I've extended my investigation into linear bearing design so I can make the best possible use of them.

Niffy

As far as I know Nasa paid very little money for its space pens. The company that made them (and still makes them) is here: Fisher Space Pen Co.

Here is a bit more on the space pen myth, and incidentally the U.S. and Russian space programs did in fact use pencils in space.

Fact or Fiction?: NASA Spent Millions to Develop a Pen that Would Write in Space, whereas the Soviet Cosmonauts Used a Pencil - Scientific American

Both the U.S. and Russian space programs used the Fisher space pen when it became available.

Here is a bit more on the space pen myth, and incidentally the U.S. and Russian space programs did in fact use pencils in space.

Fact or Fiction?: NASA Spent Millions to Develop a Pen that Would Write in Space, whereas the Soviet Cosmonauts Used a Pencil - Scientific American

Both the U.S. and Russian space programs used the Fisher space pen when it became available.

After this let's get back on topic.

Once I figure out how to deal with planing my wood blanks I'll be making more wands and will report back.

Once I figure out how to deal with planing my wood blanks I'll be making more wands and will report back.

Have mine on original Delphi Oracle

Not sure why you would want to do any modifications to a Souther arm. I tried a few cartridges over the years but I've keep a Koetsu Black in there for two retips (since 1981). It is a heavy cartridge with fairy high tracking force and it is just a magic wet your pants combination. Sure digital has better bass and treble and no pops but that Koetsu midrange and 3d focus can't be described to someone who grew up on digital. I've tried other arms on this table with a Koetsu but none had this synergy. I have it mounted on an original Delphi Oracle. I've tried other lighter cartridges but I think the extra mass helps. The Souther has yellowed with age a little as it is 36 years old. It is a pain to clean and can skip if dirty. I've been lucky and all parts are original. I fear those thin wires will break. I'm working on a diy phono preamp (Pearl 2) since my last preamp purchase sadly did not include a phono input. The Pearl inverts so will need to flip the cartridge wiring. Perhaps I will flip polarity on the Pearl input to leave those wires alone.

Not sure why you would want to do any modifications to a Souther arm. I tried a few cartridges over the years but I've keep a Koetsu Black in there for two retips (since 1981). It is a heavy cartridge with fairy high tracking force and it is just a magic wet your pants combination. Sure digital has better bass and treble and no pops but that Koetsu midrange and 3d focus can't be described to someone who grew up on digital. I've tried other arms on this table with a Koetsu but none had this synergy. I have it mounted on an original Delphi Oracle. I've tried other lighter cartridges but I think the extra mass helps. The Souther has yellowed with age a little as it is 36 years old. It is a pain to clean and can skip if dirty. I've been lucky and all parts are original. I fear those thin wires will break. I'm working on a diy phono preamp (Pearl 2) since my last preamp purchase sadly did not include a phono input. The Pearl inverts so will need to flip the cartridge wiring. Perhaps I will flip polarity on the Pearl input to leave those wires alone.

Souther spindle locator

Hello Souther SLA-3 Linear Tracking Tonearm fans,

This Souther tri-quartz just sold for $717. I noticed that the spindle locator is different. Instead of a plastic cap that rides on top of the spindle this one is pointed. Has anyone had any experience using this type of locator?

Regards,

David

PS Kevin, any updates on your Souther - Thorens 124 combo?

Hello Souther SLA-3 Linear Tracking Tonearm fans,

This Souther tri-quartz just sold for $717. I noticed that the spindle locator is different. Instead of a plastic cap that rides on top of the spindle this one is pointed. Has anyone had any experience using this type of locator?

Regards,

David

PS Kevin, any updates on your Souther - Thorens 124 combo?

Attachments

Souther spindle locator

Hello Souther SLA-3 Linear Tracking Tonearm fans,

This Souther tri-quartz just sold for $717. I noticed that the spindle locator is different. Instead of a plastic cap that rides on top of the spindle this one is pointed. Has anyone had any experience using this type of locator?

Regards,

David

PS Kevin, any updates on your Souther - Thorens 124 combo?

Hello Souther SLA-3 Linear Tracking Tonearm fans,

This Souther tri-quartz just sold for $717. I noticed that the spindle locator is different. Instead of a plastic cap that rides on top of the spindle this one is pointed. Has anyone had any experience using this type of locator?

Regards,

David

PS Kevin, any updates on your Souther - Thorens 124 combo?

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- Souther Linear Tonearm on A TD-124