Measure the speaker with the tweeter reversed in polarity. This will show you how the crossover really works.

This is no weird or exotic thing to do, but a must when building a crossover.

If you ask me, the driver combination could make a much better speaker with a good crossover. The woofer is running too high.

If your two cabinets show different bass output, the "screw on" rear panel may be the cause. These 6 screws are not enough, make it 10 or even better glue it on if you you are finished (in this case you sure will change something in the future, so maybe stick with screws).

The resonace you see in the impedance plot is quite usual for such a high cabinet. You may reduce it with some damping material in the top of the volume (as your port is on the lower end). Some diagonal bracing can help, too.

This is no weird or exotic thing to do, but a must when building a crossover.

If you ask me, the driver combination could make a much better speaker with a good crossover. The woofer is running too high.

If your two cabinets show different bass output, the "screw on" rear panel may be the cause. These 6 screws are not enough, make it 10 or even better glue it on if you you are finished (in this case you sure will change something in the future, so maybe stick with screws).

The resonace you see in the impedance plot is quite usual for such a high cabinet. You may reduce it with some damping material in the top of the volume (as your port is on the lower end). Some diagonal bracing can help, too.

Probably the speaker heigth resonance - it will be excited at wavelength of double heigth (heigth 85 cm?). But it is not very strong - I wouldn't loose any sleep over it.There's a ~200Hz resonance in both speakers.

The bass reflex / helmholtz resonator seems to be quite lossy. That may be caused by air leaks or "too much" dampening material.Also, the "port dip" is different in one speaker - same freequency but less deep - anyone know why that may be so?

Did you put any sealing strips when screwing on the back panel?

No problem at all and very normal at crossover frequency, as others have stated!Yes - that 33Ohm mountain will be in the "lessons learned".

Very nice speaker, I like the partial bevels!

Edit - just saw Turbowatch2 was quicker!

Thank you all for the wonderful advice. I need to consider my options.

I also thought about making a 3 way using these drivers along with Peerless 830992. Maybe I wait till spring and try making that speaker instead? How do you fellas keep from accumulating projects/stuff?

- Redoing the cabinet is not likely to happen, although I am very curious as to what would happen if I put the woofer above the tweeter - I suspect there wouldn't be too much to complain about. Winter is almost here and I need to vacate the woodworking garage in favour of the car, so woodworking will need to hibernate.

- I will make some stands that will raise the speaker a foot and give them a 5 degree tilt.

- I will add a bit more felt inside and rearrange the fill as per advice.

- Since the backs are screwed on - I can make a new X-over. Which means nearly all new parts and more $$ - for a speaker I tried to make as cheap as possible. I suppose I can keep the exiting parts and reuse them for other projects. Here's a new crossover idea. Crossover moves down to 1400Hz from 3300Hz. Better? Should I bother?

I also thought about making a 3 way using these drivers along with Peerless 830992. Maybe I wait till spring and try making that speaker instead? How do you fellas keep from accumulating projects/stuff?

In some respects its better, such as the much lower amount of overlap through the crossover region, as well as the more resistive impedance curve.Here's a new crossover idea. Crossover moves down to 1400Hz from 3300Hz. Better? Should I bother?

However, I'd caution against using such a low crossover frequency with a 20mm tweeter, as the tweeter's power handling capacity is likely to be exceeded if playing music at loud listening levels. You could drop it down to 2.8kHz or 3.0kHz, maybe even 2.5kHz, but 1.4kHz seems fraught with danger as far as long-term reliability goes.

If you can share your VituixCAD files, someone might be able to have a bit of a look at some options.

Isn't the Peerless 830992 a 4-inch mid/woofer driver?I also thought about making a 3 way using these drivers along with Peerless 830992.

Make suggestions for other people's projects and get them to build them? 🙂How do you fellas keep from accumulating projects/stuff?

Yup. I am aware that 1.4 is low - but I can't seem to get to 2K without everything else going askew. This is the best I got at 2K, by going to a 4th order on the tweeter.

Vertical directivity seems a bit worse, narrower. More parts. More $$ 🙁

Yes, I was going to try to bridge the 830667 to the tweeter with the 830992. 6.5" cone to 3.5" cone.

Vertical directivity seems a bit worse, narrower. More parts. More $$ 🙁

Yes, I was going to try to bridge the 830667 to the tweeter with the 830992. 6.5" cone to 3.5" cone.

If you build speaker, you get an always growing stock of crossover parts. That is a natural law 🙂

You can only get around it if you go active.

In most cases, if you do not stick to well documented projects, what is my usual advice for a beginner, you will collect drivers too. Not any tweeter works with any woofer or mid. Sometimes you get stuck and get another driver to finish your project. At least if you want to build high quality speaker.

If you just want "some noise", in most cases you can get away with a cap, a resistor and a coil, sometimes even without a coil. You will find such combination in many older low and not so low budget speakers and many, even quite expensive car audio combinations. In some rare cases this can even sound quite good, but usually this C, R, L crossover only protects the driver from instant destruction.

There are some rules you can explain over pages, or simply except. With a usual two way, the 25mm 1" dome tweeter should not be crossed lower than 2kHz, a 20mm 3/8" one should x higher than 2.8kHz, both using a 12dB / second order cut.

If you go by this rule, you will have low distortion and prevent the tweeter from burning through.

There are, as always, exceptions from the rule, with exotic, expensive drivers and special duty, but in general this is what the data sheet will tell you too.

Your new crossover is set way too low. Sound and voice coil will suffer. You had a crossover at post #3 that looked quite promising.

Try to do that with a second order configuration.

You can only get around it if you go active.

In most cases, if you do not stick to well documented projects, what is my usual advice for a beginner, you will collect drivers too. Not any tweeter works with any woofer or mid. Sometimes you get stuck and get another driver to finish your project. At least if you want to build high quality speaker.

If you just want "some noise", in most cases you can get away with a cap, a resistor and a coil, sometimes even without a coil. You will find such combination in many older low and not so low budget speakers and many, even quite expensive car audio combinations. In some rare cases this can even sound quite good, but usually this C, R, L crossover only protects the driver from instant destruction.

There are some rules you can explain over pages, or simply except. With a usual two way, the 25mm 1" dome tweeter should not be crossed lower than 2kHz, a 20mm 3/8" one should x higher than 2.8kHz, both using a 12dB / second order cut.

If you go by this rule, you will have low distortion and prevent the tweeter from burning through.

There are, as always, exceptions from the rule, with exotic, expensive drivers and special duty, but in general this is what the data sheet will tell you too.

Your new crossover is set way too low. Sound and voice coil will suffer. You had a crossover at post #3 that looked quite promising.

Try to do that with a second order configuration.

eddantes, witwald has made the suggestion that you share the save file and data files. It’s easier for us as we can assess the interactions for ourselves.

That is quite a good result. At least now your tweeter must cope with much-reduced levels at 1kHz. It's 29dB down at 1kHz, versus only 14dB down in the previous design, a benefit of 15dB. This translates to a reduction in input power of 96.8%.Yup. I am aware that 1.4 is low - but I can't seem to get to 2K without everything else going askew. This is the best I got at 2K, by going to a 4th order on the tweeter.

Unfortunately, a blown tweeter, 😢 , also means more (replacement) parts, more expense, and also added repair time.More parts. More $$ 🙁

The newer tweeter filter that you have produced should help the tweeter give its best in your loudspeaker system and do so in a reliable manner.

I understand now...thanks for clarifying. It would be interesting to see the results, especially directivity-wise.Yes, I was going to try to bridge the 830667 to the tweeter with the 830992. 6.5" cone to 3.5" cone.

Last edited:

Another small update:

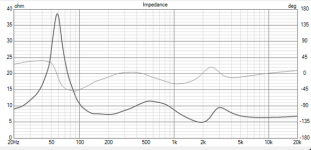

I installed the xover in post 46. I haven't had a chance to measure yet, but here is the new impedence curve:

Model:

And measurement:

The resonance near 200Hz is still there, as expected; but now there's a blip near 500Hz. Since I had them open, I moved the stiffing around and now the port dips are more aligned. Generally looks good to me, but if anyone can see something I need to improve on - please let me know.

BTW - I looked at my vertical (above tweeter) off-axis measurements again of the old xover, and compared to the model, they were close. So maybe my measurements were OKish. For your reference below:

Subjectively, the new crossover seems to sound more consistent as I walk around the room. Also, removing and respositioning some stuffing, seems to have made the midbass a bit more tame. Over all - subjectively - an improvement.

Will attempt to measure on Monday. Thanks again everyone for your input.

I installed the xover in post 46. I haven't had a chance to measure yet, but here is the new impedence curve:

Model:

And measurement:

The resonance near 200Hz is still there, as expected; but now there's a blip near 500Hz. Since I had them open, I moved the stiffing around and now the port dips are more aligned. Generally looks good to me, but if anyone can see something I need to improve on - please let me know.

BTW - I looked at my vertical (above tweeter) off-axis measurements again of the old xover, and compared to the model, they were close. So maybe my measurements were OKish. For your reference below:

Subjectively, the new crossover seems to sound more consistent as I walk around the room. Also, removing and respositioning some stuffing, seems to have made the midbass a bit more tame. Over all - subjectively - an improvement.

Will attempt to measure on Monday. Thanks again everyone for your input.

Attachments

Final update to the thread: I am call this project done.

As my first (non-kit) DIY I set out to see if I can make a speaker that sounds reasonably good to me. Low bar, I know; but it came with the caveat: that I was going to use the cheapest drivers I could buy ($10 tweeter and $15 woofer) and I would make every attempt to follow good design principles to arrive at a speaker that follows the science of Toole and Olive. I feel, accepting my limitations, I did that here.

HUGE thanks to this forum and ASR for teaching me all the things I need to (kinda) know to get here. It was a satisfyingly cathartic moment to say - I'm finished.

As my first (non-kit) DIY I set out to see if I can make a speaker that sounds reasonably good to me. Low bar, I know; but it came with the caveat: that I was going to use the cheapest drivers I could buy ($10 tweeter and $15 woofer) and I would make every attempt to follow good design principles to arrive at a speaker that follows the science of Toole and Olive. I feel, accepting my limitations, I did that here.

HUGE thanks to this forum and ASR for teaching me all the things I need to (kinda) know to get here. It was a satisfyingly cathartic moment to say - I'm finished.

- Home

- Loudspeakers

- Multi-Way

- Sorry, newb needs X-over input