Fusion360 is free to hobbyists. You can then find a trophy shop that has a laser cutter/engraver. Or, take the file to a sheet metal shop and they can use a laser or waterjet machine.

You're not going to pay $1.99 and you're not going to do it in a short period of time. But, that's why you're Doing It Yourself.

You're not going to pay $1.99 and you're not going to do it in a short period of time. But, that's why you're Doing It Yourself.

Member

Joined 2003

Inkscape is a great vector drawing tool. For CAD, FreeCAD is well...free. It's interface can be a bit daunting, and a bit of a learning curve but it's surprisingly powerful CAD software.

https://inkscape.org/

https://www.freecad.org/

If you're looking to have panels manufactured as well, this site might be of interest:

https://www.frontpanelexpress.com/

https://inkscape.org/

https://www.freecad.org/

If you're looking to have panels manufactured as well, this site might be of interest:

https://www.frontpanelexpress.com/

I've made good progress with Layout but there's a yearly fee

I've downloaded Inkscape and will try to figure out the tools

My neighbor has the etching machine so no issue on that end.

Thanks!

I've downloaded Inkscape and will try to figure out the tools

My neighbor has the etching machine so no issue on that end.

Thanks!

I use Corel Draw since 1990 or so (started with Corel 2!!!!! 😱 )

Before that it was Technical pens on vellum paper or Letraset, or ordering typographical "proof sheets" with text which could be cut and pasted (LITERALLY!!!) on a large sheet of drawing paper (Schöller architect paper preferred) and then photographed on a fridge sized Litho camera

This one takes a 24" by 36" negative!!!!

Back to computers, search for "Frontplate designer" or something very close to that.

Before that it was Technical pens on vellum paper or Letraset, or ordering typographical "proof sheets" with text which could be cut and pasted (LITERALLY!!!) on a large sheet of drawing paper (Schöller architect paper preferred) and then photographed on a fridge sized Litho camera

This one takes a 24" by 36" negative!!!!

Back to computers, search for "Frontplate designer" or something very close to that.

Here, Front Panel Designer.

Excellent dedicated software, and you can´t complain about price 😉

https://www.frontpanelexpress.com/front-panel-designer#

Excellent dedicated software, and you can´t complain about price 😉

https://www.frontpanelexpress.com/front-panel-designer#

For my labeling design and etching, it's essential that I have control over Letter spacing(kerning) and ability to download my Font into the program

I'm playing with Front Panel Designer and looks like there is no kerning and it has a prescribed font list - I'll see what I can do, maybe have to play some more

Inkscape appears to have everything I need and so much more. Makes for a steeper learning curve

I'm playing with Front Panel Designer and looks like there is no kerning and it has a prescribed font list - I'll see what I can do, maybe have to play some more

Inkscape appears to have everything I need and so much more. Makes for a steeper learning curve

I use designspark pcb(is free) generate gerberfiles so i can order at jlcpcb. Inclusive holes. 5 pieces onnly 2 euro.

Corel Draw definitely allows that and 1000 other font enhancements, such as:For my labeling design and etching, it's essential that I have control over Letter spacing(kerning) and ability to download my Font into the program

I'm playing with Front Panel Designer and looks like there is no kerning and it has a prescribed font list - I'll see what I can do, maybe have to play some more

Inkscape appears to have everything I need and so much more. Makes for a steeper learning curve

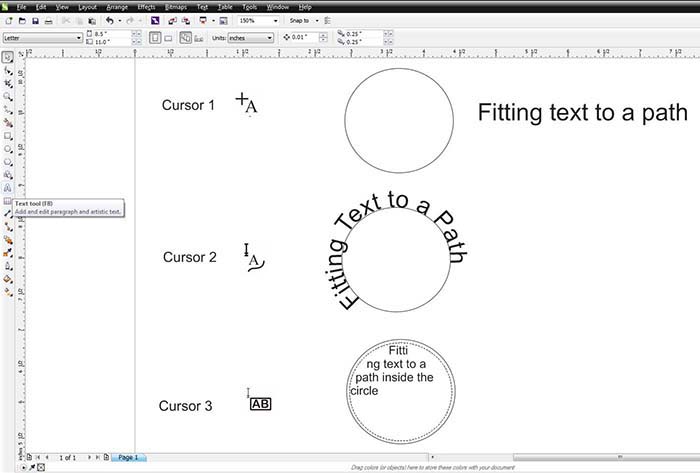

"fit text to path"

"extruding text"

and a lot more, but I suggest you start using it as if it were white paper and black ink, period, which is way more intuitive.

The rest comes bit by bit.

As of Fonts, not sure about Front Panel Designer but in principle Windows programs use whatever Fonts have been previpusly loaded into Windows Fonts directory itself.

Never used Inkscape but most Graphic Design packages include very similar features, also quite similar Menus so going from one to another is not difficult.

Loved it.I use designspark pcb(is free) generate gerberfiles so i can order at jlcpcb. Inclusive holes. 5 pieces onnly 2 euro.

Sort of steampunk using modern PCBs as panels for 40s 50s look Electronics products 😉

Microsoft Word, and Open Office as well, have many font choices.

And you can download font files.

Corel Draw uses vector files for storage, they take up less space, and is very good, many options.

You can do a lot of work in a CAD program, or make a print in a Word like program, and do the finals at the etching shop on their software, less issue if their software modifies files automatically.

If you like, get the face plate laser etched, looks good in my opinion.

And you can download font files.

Corel Draw uses vector files for storage, they take up less space, and is very good, many options.

You can do a lot of work in a CAD program, or make a print in a Word like program, and do the finals at the etching shop on their software, less issue if their software modifies files automatically.

If you like, get the face plate laser etched, looks good in my opinion.

Last edited:

Thanks for all the suggestions..

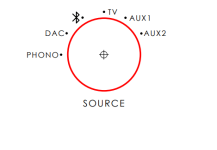

After many many hours of looking into the other software options, messing with inkscape and drawing with layout, I simply dove deeper into layout to get it done.. I have over a dozen faceplates do draw with only slight variations so this one serves as a template and the other should go much faster.

Hopefully the .dxf export will work out so my neighbor(not home until June 10) can perform the etching...

He already etched a few and they look great.. The original file was created by a friend. He couldn't find time anymore, hence, the reason I'm creating the drawings.. 🙂

After many many hours of looking into the other software options, messing with inkscape and drawing with layout, I simply dove deeper into layout to get it done.. I have over a dozen faceplates do draw with only slight variations so this one serves as a template and the other should go much faster.

Hopefully the .dxf export will work out so my neighbor(not home until June 10) can perform the etching...

He already etched a few and they look great.. The original file was created by a friend. He couldn't find time anymore, hence, the reason I'm creating the drawings.. 🙂

Attachments

Thanks for sharing. The CAD model can now be used on a laser cutter/etcher to create your faceplate.

If you get tired of waiting until June 10th, you can also take the file to a sheetmetal shop that has a water jet machine, or a laser cutter.

That's what DIY is all about.

If you get tired of waiting until June 10th, you can also take the file to a sheetmetal shop that has a water jet machine, or a laser cutter.

That's what DIY is all about.

I was under an assumption something to that but havent began a search. I need a stainless steel dash insert I cut, to be cut more to accept five circular gauges (to be specific). Besides a waterjet I'm not aware of something else that will cut this stuff cleanly and accurately. Anywhere in the gta would be great.Fusion360 is free to hobbyists. You can then find a trophy shop that has a laser cutter/engraver. Or, take the file to a sheet metal shop and they can use a laser or waterjet machine.

You're not going to pay $1.99 and you're not going to do it in a short period of time. But, that's why you're Doing It Yourself.

I’ve heard this gives the amp a more warm sound. 🤣and then photographed on a fridge sized Litho camera

Laser, up to 10 mm in steel are common here at this time.

Wire EDM will also work.

Many shops in GTA, and Brampton (I think part of GTA).

See in the USA otherwise, up to Ohio.

Most shops will insist on a drawing.

Your dash plate will be max. 3 mm, not much of an issue.

Wire EDM will also work.

Many shops in GTA, and Brampton (I think part of GTA).

See in the USA otherwise, up to Ohio.

Most shops will insist on a drawing.

Your dash plate will be max. 3 mm, not much of an issue.

"gta is Greater Toronto Area? If so, Toronto is near many auto manufacturing/parts business/machine shops/sheet metal shops.I was under an assumption something to that but havent began a search. I need a stainless steel dash insert I cut, to be cut more to accept five circular gauges (to be specific). Besides a waterjet I'm not aware of something else that will cut this stuff cleanly and accurately. Anywhere in the gta would be great.

I looked on Yelp Canada, there are dozens of sheet metal fabricators in the Toronto area. That part of the world, there shouldn't be any problem finding someone to fabricate a stainless steel dash, but as mentioned, you'll need a drawing with dimensions. On the Omax water jet cutter I used to have access to, a pencil and paper drawing can easily be drawn with the CAD software on the machine controller.

Here a drawing is sometimes the proof of order, some people try to weasel out of payment, if the job was not suitable, or liked, for whatever reason.

Particularly if it is a one off job for a non regular customer.

Wire EDM can be used to cut plates, most standard machines will go through 60 mm plates, but they need a start hole.

It is a simple job for laser or wire EDM, water jet may be cheaper.

Particularly if it is a one off job for a non regular customer.

Wire EDM can be used to cut plates, most standard machines will go through 60 mm plates, but they need a start hole.

It is a simple job for laser or wire EDM, water jet may be cheaper.

- Home

- Design & Build

- Software Tools

- Software for faceplate etching