academia50; Apparently in my case most of the mechanical energy generated by the driver ends up in the sound pressure it makes, while the reaction to the force it takes to do so is minimal due to the mass of the driver.

If I decouple that mass further from the cabinet, it's apparent that not much racket is added into the cabinet structure, compared to what the sound pressure inside the box does to it.

I really thought it was going to make a huge difference. Perhaps if the driver frame and magnet assembly had no mass at all...

Nothing like getting rid of doubts on our own, good try!

I think that if there would be a marked difference in favor of decoupling, it would have already been implemented by the vast majority of acoustic cabinet manufacturers.

Obviously, the advantages must be small in relation to the increase in costs .......

Can you be sure it’s not pleasing (but ultimately inaccurate) resonant modes in the cabinet contributing to the sound?

I can't be scientifically certain with out accelerometer experimentation, however, it wasn't more euphonically pleasant sounding, it rather exhibited greater subjective clarity, and so, was more pleasant for that reason.

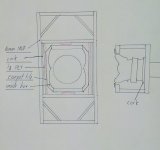

This is one way to softly mount full range drivers, two drivers mounted back to back to cancel out forces, and in their own boxes to try to stop sound transition through the enclosure; this is only partially effective as some vibration can be felt in the side panels. The drivers are coupled in parallel , 8 ohms each, and the rear has a 1.9mh choke. the internal boxes are supported on carpet tile and foam gaskets. For two 2 1/5 " drivers they have decent bass.

I can't be scientifically certain with out accelerometer experimentation, however, it wasn't more euphonically pleasant sounding, it rather exhibited greater subjective clarity, and so, was more pleasant for that reason.

Clarity is subjective. Especially voice band clarity sometimes comes at a price. Or rather voice clarity can be deceptive. Sometimes it’s real, sometimes it’s sugar coating deeper deficiencies.

Are the small boxes decoupled from the larger box?

Yes, it " Floats ", held in place by foam gaskets ( front and rear ) and small pieces of carpet tile on the sides, top and bottom. It's annoying that the side panels still vibrate, I'm considering either adding another 6mm layer of mdf to the outside to stiffen it, or possibly sanding the exterior 6mm mdf concave so there is an air gap in the centre but sealed ( glued ) around the periphery, or perhaps a layer of felt followed by mdf.

I think for how much two opposing drivers would move, a bit of foam/carpet tile is enough, I think that the vibration is coming from air pressure exciting the side panels at near their natural frequency. Remlab has suggested copper sheet as a possibility for extra side panels, heavy and dead so should work

When I tested them without the rear cover a slight vibration could be felt. With the rear cover on the air pressure should be more even resulting in less movement, however I don't really want to drill a hole in and stick a rod through to find out. I may make some more using ( 4" ) drivers without dust covers so I should be able to tell with them.

I think that the vibration is coming from air pressure exciting the side panels at near their natural frequency.

Great effort! I think the same thing. I thought I read somewhere Scott Moose saying that nothing will stop it. So I wonder if a designer could do a judo on that fact and make it work for you, in a musical way.

As I think I mentioned before, Gibson guitars makes tensioned hunks of wood (or wood boxes) come alive when tuned to concert pitch. If you cant beat 'em, join 'em, as long as it's musical and hopefully, subtle.

I dont know how to do this, nor do I know how they do, or did it. Maybe these guys that back in the late 50s / early 60s, could take a hunk of cherry or mahogany, shape it into an SG and have it do that are no longer with us.

Has melamine been mentioned? IMF offered their TL monitors with this option. It apparently drastically reduced cab resonance.

Adding a material that is stiff and “different” than the base material, especially if done both sides, stiffens a box considerably.

Before i discoverered proper plywood i laminated “arborite” both side sof ⅝” HDF to make it considerably stiffer (early 80s). For the same reason you will find some manufactures veneer both sides of their panel sbefore cutting. Veneer offers little but cosmetic…

Melamine is a low budget variation of that.

dave

Before i discoverered proper plywood i laminated “arborite” both side sof ⅝” HDF to make it considerably stiffer (early 80s). For the same reason you will find some manufactures veneer both sides of their panel sbefore cutting. Veneer offers little but cosmetic…

Melamine is a low budget variation of that.

dave

Great effort! I think the same thing. I thought I read somewhere Scott Moose saying that nothing will stop it. So I wonder if a designer could do a judo on that fact and make it work for you, in a musical way.

As I think I mentioned before, Gibson guitars makes tensioned hunks of wood (or wood boxes) come alive when tuned to concert pitch. If you cant beat 'em, join 'em, as long as it's musical and hopefully, subtle.

I dont know how to do this, nor do I know how they do, or did it. Maybe these guys that back in the late 50s / early 60s, could take a hunk of cherry or mahogany, shape it into an SG and have it do that are no longer with us.

Google ONKYO D-TK10

If I remember correctly, in a review they were described as sounding bigger than their size would suggest, but they were expensive.

Great topic!

Late to this very interesting topic!

In 2010 I decoupled an Audio Nirvana 10 inch full-range driver from its cabinet using EAR elastomer grommets and sorbothane gaskets. The cabinet was purpose-built from thick plywood, well braced and stiffened to lift panel resonances to high frequencies (worst case well above 15kHz), fitted with constrained layer damping effective to <150Hz and filled with polyether acoustic foam (Latimer Acoustics "Acoustop") and other materials to damp internal reflections and chamber resonances.

As reported by B&W (many thanks for that reference!) there was a very substantial reduction in the vibration transmitted to the cabinet. To arrive at this result, I used ... a stethoscope, plus FFT analysis of 3rd octave pink noise played through the speakers. The FFT showed textbook decoupling.

So far, so good 🙂 except ... the installation and construction was at the very limits of the mechanical capacity of the grommets and sorbothane to withstand sag and hold the driver in the vertical plane (I suspect that it would have failed within 12 months - the AN10 is a weighty item) and it all made little difference to listening. 🙁 My listening colleagues agreed that detail, air, bass, punch, faults and features were ... unchanged!

Bummer. I had hoped that reducing cabinet vibration would make an audible improvement that would correspond to improvements indicated by the stethoscope and the FFT. Nope. Not to my ears or to anyone else's. I had even hoped to tame some of the AN10's propensity to rip the ears off listeners when playing poorly recorded material but it was not to be.

What did I learn? Well, decoupling works but doing it for a big driver is a significant challenge to available materials (thanks, B&W) for which decoupling better suits low-mass drivers.

Did I conclude that decoupling is a dud idea? No, though it might best be applied to solving specific cabinet vibrations. Put another way, it might make an audible difference only after other problematic effects have been dealt with.

Fun 🙂

Late to this very interesting topic!

In 2010 I decoupled an Audio Nirvana 10 inch full-range driver from its cabinet using EAR elastomer grommets and sorbothane gaskets. The cabinet was purpose-built from thick plywood, well braced and stiffened to lift panel resonances to high frequencies (worst case well above 15kHz), fitted with constrained layer damping effective to <150Hz and filled with polyether acoustic foam (Latimer Acoustics "Acoustop") and other materials to damp internal reflections and chamber resonances.

As reported by B&W (many thanks for that reference!) there was a very substantial reduction in the vibration transmitted to the cabinet. To arrive at this result, I used ... a stethoscope, plus FFT analysis of 3rd octave pink noise played through the speakers. The FFT showed textbook decoupling.

So far, so good 🙂 except ... the installation and construction was at the very limits of the mechanical capacity of the grommets and sorbothane to withstand sag and hold the driver in the vertical plane (I suspect that it would have failed within 12 months - the AN10 is a weighty item) and it all made little difference to listening. 🙁 My listening colleagues agreed that detail, air, bass, punch, faults and features were ... unchanged!

Bummer. I had hoped that reducing cabinet vibration would make an audible improvement that would correspond to improvements indicated by the stethoscope and the FFT. Nope. Not to my ears or to anyone else's. I had even hoped to tame some of the AN10's propensity to rip the ears off listeners when playing poorly recorded material but it was not to be.

What did I learn? Well, decoupling works but doing it for a big driver is a significant challenge to available materials (thanks, B&W) for which decoupling better suits low-mass drivers.

Did I conclude that decoupling is a dud idea? No, though it might best be applied to solving specific cabinet vibrations. Put another way, it might make an audible difference only after other problematic effects have been dealt with.

Fun 🙂

That seems to be a lovely bit of work bondini, and although you did not get a +ve result in the sense of providing a solution to a known problem, it is a very good evaluation.

Yes, very impressive. It seems your cabinet was so well made and designed that any improvement due to decoupling would be very small. You didn't hear any degradation though which is as expected, contrary to what some would have you believe.

The cabinet was purpose-built from thick plywood, well braced and stiffened to lift panel resonances to high frequencies (worst case well above 15kHz), fitted with constrained layer damping effective to <150Hz and filled with polyether acoustic foam (Latimer Acoustics "Acoustop") and other materials to damp internal reflections and chamber resonances.

Panel resonances as high as you suggest is likely not the case, just getting them to near 1 k is an issue. And the constrained layer damping, how was that done. Foam is not a great damping material.

AN’s suggest cabinet or a properly designed one?

In the end as lomg as you enjoy the music.

dave

I think it's much better to mass dampen the panel that holds the driver and brace enough. Mass dampen can be done with bitumen sheets like is used in cars and construction to dampen vibrations. Constrain layers also works but is a lot of hustle for a little effect, as far as i can see in the cases discussed here.

I should have written guesstimated fundamental resonant frequencies >15kHz. I used classical formulae for panels with clamped edges🙂 published data on the mechanical properties of plywoodPanel resonances as high as you suggest is likely not the case, just getting them to near 1 k is an issue.

and a fudge factor or two

and a fudge factor or two  In practice, my experience of predicting the resonant frequencies of structural panels showed that actual resonant behaviour is complex and probably best measured as it happens ... we used to count ourselves lucky if we recorded a resonance close to our calculated fundamental.

In practice, my experience of predicting the resonant frequencies of structural panels showed that actual resonant behaviour is complex and probably best measured as it happens ... we used to count ourselves lucky if we recorded a resonance close to our calculated fundamental. I applied Dynamat Extreme to the enclosure panels. The stethoscope and FFT showed damping above 150Hz.And the constrained layer damping, how was that done.

I agree that it's not good for damping panels. However, it can be effective when used for its intended purpose which is to reduce sound pressure levels in an excited mass of air mass. Latimer Acoustics published test data showing that its 60mm thick foam was capable of >95% attenuation of SPL at frequencies >80Hz. The testing was independent and conducted for certification of the foam as a noise suppressant in environments where fire was a critical risk - polyether foams are preferred!Foam is not a great damping material.

My own design based on measurements taken with a WooferTester.AN’s suggest cabinet or a properly designed one?

- Home

- Loudspeakers

- Full Range

- Softly coupling a driver to the cabinet