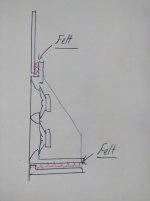

Here was my idea to magnet mount with soft couple to the front baffle from behind.

I used dowels inset into the bottom of the cabinet a little under the magnet to give room for a gasket seal in between. I was planning on using an elastic band around the top of the magnet and pulled downward into the dowel.

Then using butyl rubber or gasket material on the baffle front with brackets i made to press the frame into the front. Ill have to take more pictures of them when i get them back.

The dowels shouldn’t change how air is flowed on the back wave of the driver they are pretty small and rounded.

Has nobody tried using dowels under the magnet for mounting/support? It was one of my first ideas when i saw the linkwitz magnet mounting technique. I didn’t want to use a metal clamp like they showed in their diagram.

I used dowels inset into the bottom of the cabinet a little under the magnet to give room for a gasket seal in between. I was planning on using an elastic band around the top of the magnet and pulled downward into the dowel.

Then using butyl rubber or gasket material on the baffle front with brackets i made to press the frame into the front. Ill have to take more pictures of them when i get them back.

The dowels shouldn’t change how air is flowed on the back wave of the driver they are pretty small and rounded.

Has nobody tried using dowels under the magnet for mounting/support? It was one of my first ideas when i saw the linkwitz magnet mounting technique. I didn’t want to use a metal clamp like they showed in their diagram.

Attachments

Here's my current experiment in isolating the driver, it's mounted to the upper black chamber that will be isolated from the main chamber ( ply wood ) by being supported on coil springs with a foam gasket seal. There is currently a foam spacer as a " temporary " substitute to the coil springs, however it's quite effective.

You guys have got me thinkin' again on how to eliminate vibrations in an "L" shaped standing Open Baffle board. Being "pinned" at just the bottom edge, the 20" X 20" board rings freely - and it doesnt seem to matter what I mass load it with from behind; only helps some.

Since the baffle mostly shields the backwave from wrapping around to the front and cancelling, I believe the driver could "hang" in its current position, as long as there's at least an airtight seal between it and the baffle.

Equivalent mass of the hard baffle connection could be added to the driver's magnet, to give it something to push against above its own mass.

Depending on fabrication skills (which I am far from optimal) a butyl driver-to-baffle suspension could be fit, with a trapeze structure behind to hold up the magnet/added mass so it doesnt twist.

Smart money would put the suspension material as a laminate component in a baffle sandwich, perhaps further deadening the panel ring from the driver vibrations it's no longer getting; all in one fell swoop. Done thoughtfully, it'd also serve to flush mount the driver and get more of the driver backside unencumbered by the panel thickness.

Wife asks "When are you going to be done with the speaker projects". Honest answer - "Never!". OK, maybe someday...

Since the baffle mostly shields the backwave from wrapping around to the front and cancelling, I believe the driver could "hang" in its current position, as long as there's at least an airtight seal between it and the baffle.

Equivalent mass of the hard baffle connection could be added to the driver's magnet, to give it something to push against above its own mass.

Depending on fabrication skills (which I am far from optimal) a butyl driver-to-baffle suspension could be fit, with a trapeze structure behind to hold up the magnet/added mass so it doesnt twist.

Smart money would put the suspension material as a laminate component in a baffle sandwich, perhaps further deadening the panel ring from the driver vibrations it's no longer getting; all in one fell swoop. Done thoughtfully, it'd also serve to flush mount the driver and get more of the driver backside unencumbered by the panel thickness.

Wife asks "When are you going to be done with the speaker projects". Honest answer - "Never!". OK, maybe someday...

Last edited:

I routed out a 7 X 1/2" deep cutout into my OB panels. Into this I glued a 7" circular piece of 1/4" thick rubber stall mat (picked up from the local farm supply store for another project) using a polymer construction adhesive.

Cutting the mounting hole into this "suspension", I was able to place my Pluvis 7 HDs onto the rubber trampoline sealed - and without sag. I believe its an effective driver induced vibration isolation - by ear against the baffle, I'm still hearing something, but not like when hard mounted.

Pictures if anyone's interested here in FR - I already posted in "construction tips", but I feel more appropriate to this "softly coupling" thread topic. Apologies if I violated anything.

Cutting the mounting hole into this "suspension", I was able to place my Pluvis 7 HDs onto the rubber trampoline sealed - and without sag. I believe its an effective driver induced vibration isolation - by ear against the baffle, I'm still hearing something, but not like when hard mounted.

Pictures if anyone's interested here in FR - I already posted in "construction tips", but I feel more appropriate to this "softly coupling" thread topic. Apologies if I violated anything.

Attachments

- Home

- Loudspeakers

- Full Range

- Softly coupling a driver to the cabinet