I got oppanol which is PIB with low viscosity and this thing doesn't dry at all even after a week. Its gel like stickiness doesn't go off. Any way to dry this at least to an extent if not completely? Or does it really dry?

Hi. What did you use for recoating the tweeters please? I have a pair of Acoustic Research 132 and the coating on the tweeters was cracked. I cleaned them with alcohol and now they sound dull.I recently had to recoat a pair of silk(?) dome tweeters whose sound level output had dropped considerably, the weave of the silk was quite open and the doping compound had almost disappeared, once recoated, the sound level was back to an acceptable level, the tweeters looked like they were an early Morel type (no model number)

cheers, Arthur

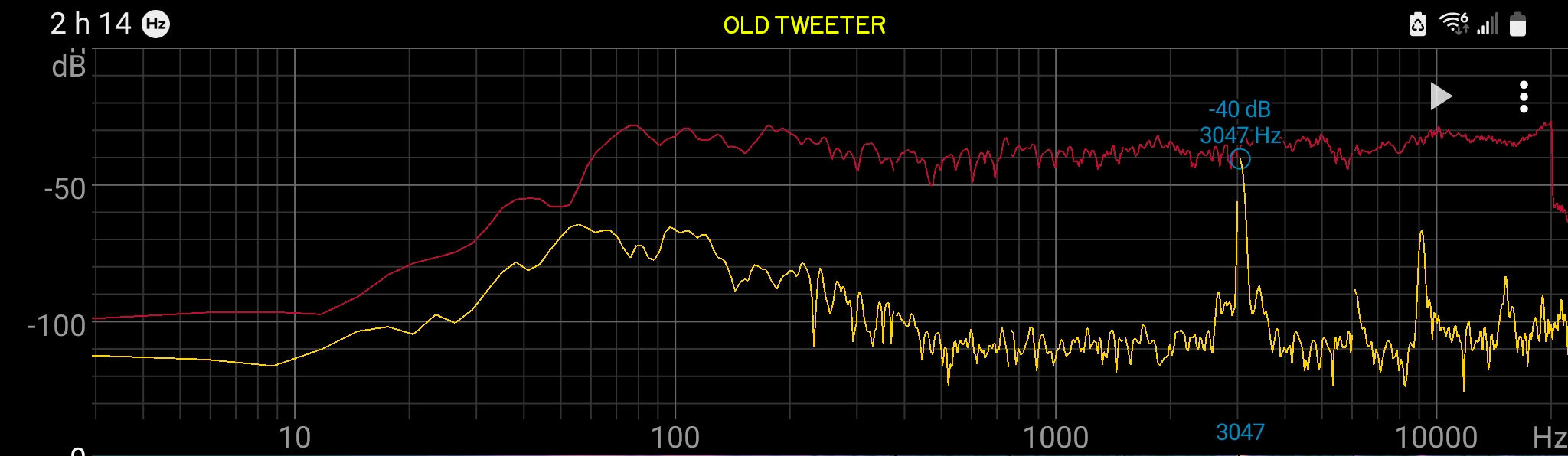

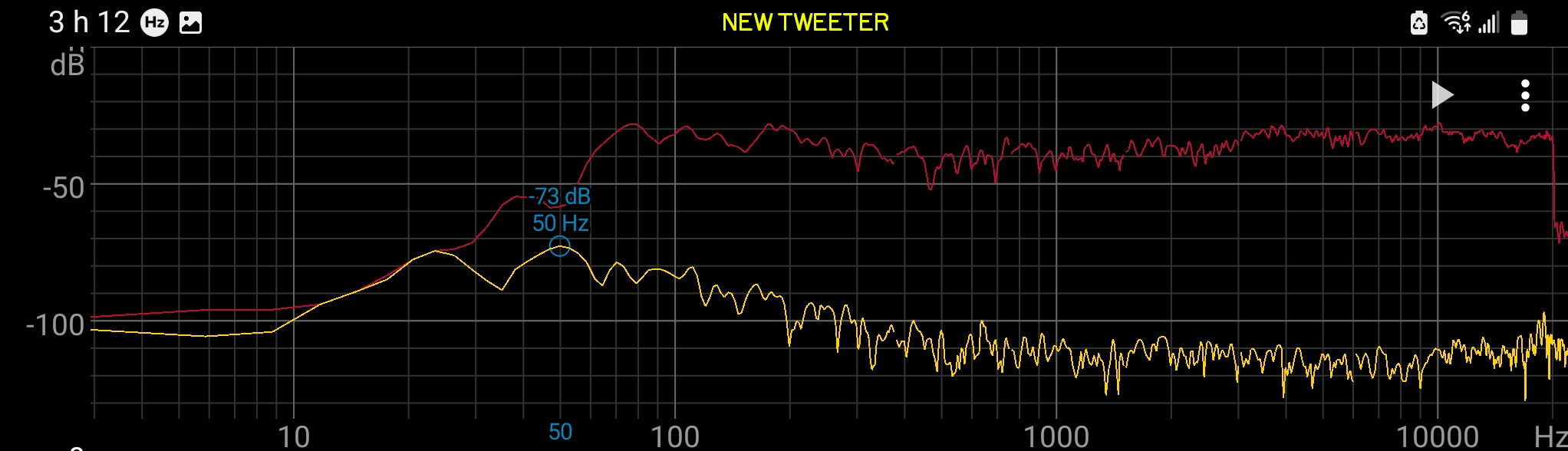

I have a question related indirectly to this topic. I recently replaced the silk dome diaphragm of a Celestion Ditton 22 tweeter. The one I used came from China and the fabric is very soft compared to the original that seems coated with some kind of varnish. I'm wondering if every tweeter needs coating?

It sounds definitely more "fatiguing" however it shows a more linear response than the original on the other speaker.

Would coating dimple the sound a bit and help with the fatigue or stiffing it would make it worst?

It sounds definitely more "fatiguing" however it shows a more linear response than the original on the other speaker.

Would coating dimple the sound a bit and help with the fatigue or stiffing it would make it worst?

-most of your problem is linearity.

You currently have about a 5db rise in response above the average starting at around 2.6 kHz with the new tweeter.

Don’t get me wrong though, the old tweeter isn’t good.

Also (generally) you should replace both tweeters at the same time and should do so with a tweeter that is almost the same sensitivity with extremely similar Impedances (to integrate properly into the existing crossover).

What is the old tweeter’s nominal impedance? Also, can you sweep just the old tweeter’s response at 2.83v at 1 meter? (to get an idea of eff..)

You currently have about a 5db rise in response above the average starting at around 2.6 kHz with the new tweeter.

Don’t get me wrong though, the old tweeter isn’t good.

Also (generally) you should replace both tweeters at the same time and should do so with a tweeter that is almost the same sensitivity with extremely similar Impedances (to integrate properly into the existing crossover).

What is the old tweeter’s nominal impedance? Also, can you sweep just the old tweeter’s response at 2.83v at 1 meter? (to get an idea of eff..)

Last edited:

Thank you ScottG. Yes, I wanted to change both but before destroying the old working one I needed to know if my replacement was valid. My question was about coating and stiffness but you responded to it indirectly. The twitter nominal impedance is 4 Ohms. And DC resistance of old is 4.1 ohms while the one with new diaphragm is 3.9 ohms. If you don't think the coating will change much the result, I will be glad to open another thread to discuss this as I don't want to hijack this thread.

It won’t change the response much at all unless you apply (many) multiple coats, and it will likely end-up worse.

-the thread is ancient - I wouldn’t worry about it.

-the thread is ancient - I wouldn’t worry about it.

Not sure if this thread is the right/correct place but I have a set of speakers with Coral open back cone tweeters and the dope on the silk surround has melted and flowed onto the paper cone.

Guidance sought on the best compound to re-coat the silk surround.

What did Coral [ and also Foster/Fostex ] use as dope when these were assembled back in the 60s and 70s??

Guidance sought on the best compound to re-coat the silk surround.

What did Coral [ and also Foster/Fostex ] use as dope when these were assembled back in the 60s and 70s??

TTBOMK; way back when, Airflex 5100 was what everyone spec'd (no clue about Europe) made by Air Products and Chemicals, Inc. - Manufacturer of industrial gases and specialty chemicals until EPA forced them to switch to the water based PVA currently sold ~universally (spec sheet).

- Home

- Loudspeakers

- Multi-Way

- Soft Dome Tweeter Coatings