Initially i had not planed to use veener in my case building but sseing all that nice stuff make me doubt...i have have some mapple laying around plus some other brand.....

Marc

Marc

I know we are off topic but it is a part of the build to make an enclosure for the finished amplifier. I don't know that a wooden case is the most practical or the best solution over a metallic enclosure, but if you are going to use MDF you do need to finish the outside at some point. I would say a nice paint job could be even more work than putting a nice veneer finish on the outside. Making a painted finish look really nice takes a lot of work, you have to seal the MDF on both the inside and outside so the wood doesn't change with the humidity and then if you want a really nice paint finish you have to spray and sand and polish and that can be a big job. I've done piano black on MDF enclosures and that is a major job. If you don't go after a high gloss clear finish on the veneer that can be the easiest way to finish MDF.

Just my two cents on that. I like the look of a nice wood finish.

Just my two cents on that. I like the look of a nice wood finish.

I know we are off topic but it is a part of the build to make an enclosure for the finished amplifier. I don't know that a wooden case is the most practical or the best solution over a metallic enclosure, but if you are going to use MDF you do need to finish the outside at some point. I would say a nice paint job could be even more work than putting a nice veneer finish on the outside. Making a painted finish look really nice takes a lot of work, you have to seal the MDF on both the inside and outside so the wood doesn't change with the humidity and then if you want a really nice paint finish you have to spray and sand and polish and that can be a big job. I've done piano black on MDF enclosures and that is a major job. If you don't go after a high gloss clear finish on the veneer that can be the easiest way to finish MDF.

Just my two cents on that. I like the look of a nice wood finish.

I have some pratice in these job and can confirm all the steps you mention. I seal MDF with 2 parts epoxy resin and than after priming i apply with sraygun the finals coating. I have a 3CV air compressor and automotiv spraygun

Attachments

I have some pratice in these job and can confirm all the steps you mention. I seal MDF with 2 parts epoxy resin and than after priming i apply with sraygun the finals coating. I have a 3CV air compressor and automotiv spraygun

I've actually had problems lately with MDF swelling when I tried to seal it with epoxy. All the MDF I've been able to find in my are is much lighter weight and not as tough as it used to be(not enough glue in it). Possibly this is why.

I've actually had problems lately with MDF swelling when I tried to seal it with epoxy. All the MDF I've been able to find in my are is much lighter weight and not as tough as it used to be(not enough glue in it). Possibly this is why.

Possibly. I bougth for a while a piece of MDF in a big DIY Store....Poor quality product in fact. It was visibly ligther the quality mdf i bought usualy. It was in winter and when i goes to basement with the mdf i touch a little bit the snow near the door....the mdf immediatly show a swelling at the place it touch snow...

Marc

Possibly. I bougth for a while a piece of MDF in a big DIY Store....Poor quality product in fact. It was visibly ligther the quality mdf i bought usualy. It was in winter and when i goes to basement with the mdf i touch a little bit the snow near the door....the mdf immediatly show a swelling at the place it touch snow...

Marc

All the Big Box store drove our lumber suppliers out of business in my area. That's likely the issue. I remember MDF being much heavier 20 years ago. Now I can split chunks of it off with my thumbnail.

Firstly Those cases are ALL Seriously Good workmanship imo.

Wood is lovely indeed.

But note that it ain't so good a shielding. Mild steel is the best choice for that.

Consider lining those lovely boxes with thin gauge mild steel? Fairly simple and inexpensive If shielding is a concern

Wood is lovely indeed.

But note that it ain't so good a shielding. Mild steel is the best choice for that.

Consider lining those lovely boxes with thin gauge mild steel? Fairly simple and inexpensive If shielding is a concern

Firstly Those cases are ALL Seriously Good workmanship imo.

Wood is lovely indeed.

But note that it ain't so good a shielding. Mild steel is the best choice for that.

Consider lining those lovely boxes with thin gauge mild steel? Fairly simple and inexpensive If shielding is a concern

Yes and that's why the minimum for my case is a 1.5mm steel sheet that spread PSU area (front of the case) and amplifier area (rear of the case).

Marc

All the Big Box store drove our lumber suppliers out of business in my area. That's likely the issue. I remember MDF being much heavier 20 years ago. Now I can split chunks of it off with my thumbnail.

I live in france where big bos store deliver poor quality MDF, but where i live in france is 30mn away from germany and their bix box store sell good quality one.

Marc

Idefixes,

Yes I have been a car painter at one time for custom cars and still have my old spray guns, now illegal to use in my state if I was a commercial shop, they all have to be HVLP guns today. The other problem is they keep reformulating the paint to lower the VOC's and you have to keep changing your technique for the newer paints. I still like to paint with two component urethane color coats. I also use Epoxy or polyester primer coats.

I imagine the MDF is changing for the same reasons. One of the common binder resins has always been a phenol based resin and those are now considered toxic, so perhaps a reformulation of the binder resins has happened here also? In my fancy cabinet I showed I used 1" (25.4mm), the front face was double thickness 2" MDF and those sheets were really heavy, not much fun to move around. I still have a panel saw that I use when making straight cuts but used a precision straight edge and a good worm driver Skill saw to cut the angles. I always used aliphatic glues made for outdoor useage and also used screws and counterbored and covered those with plastic body filler so they wouldn't show. I think we all seem to be on the same level working on these finishes, it is not for the amateur to do, this is true quality paint work. Besides the fact that the two component urethane finishes are highly toxic. I have an air feed hood for that, much better than a standard respirator but I've done plenty of that also.

Yes I have been a car painter at one time for custom cars and still have my old spray guns, now illegal to use in my state if I was a commercial shop, they all have to be HVLP guns today. The other problem is they keep reformulating the paint to lower the VOC's and you have to keep changing your technique for the newer paints. I still like to paint with two component urethane color coats. I also use Epoxy or polyester primer coats.

I imagine the MDF is changing for the same reasons. One of the common binder resins has always been a phenol based resin and those are now considered toxic, so perhaps a reformulation of the binder resins has happened here also? In my fancy cabinet I showed I used 1" (25.4mm), the front face was double thickness 2" MDF and those sheets were really heavy, not much fun to move around. I still have a panel saw that I use when making straight cuts but used a precision straight edge and a good worm driver Skill saw to cut the angles. I always used aliphatic glues made for outdoor useage and also used screws and counterbored and covered those with plastic body filler so they wouldn't show. I think we all seem to be on the same level working on these finishes, it is not for the amateur to do, this is true quality paint work. Besides the fact that the two component urethane finishes are highly toxic. I have an air feed hood for that, much better than a standard respirator but I've done plenty of that also.

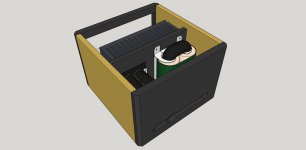

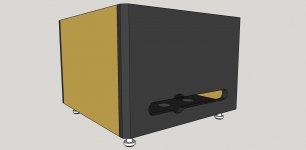

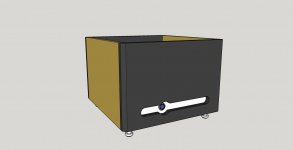

Last night i play a little bit with sketchup to achieve a monobloc 3D modelisation...

In fact i want to have easy acces from behind to be able to swap IPS without unbuilt whole monobloc. I will close rear front with a acrylique sheet...Soft start and 12Vdc secondary PSU will be located on a separated plate mounted in front of Rcore trafo

In fact i want to have easy acces from behind to be able to swap IPS without unbuilt whole monobloc. I will close rear front with a acrylique sheet...Soft start and 12Vdc secondary PSU will be located on a separated plate mounted in front of Rcore trafo

Attachments

How long did it take to create the R transformer? Outstanding... along with the heat sink...

10mn....just scaling as you have "3Dwarehouse" where people share their sketch. Speakon/powecon/RCA/large capacitor are comming from...Sketchup+3Dwarehouse is a quite nice tool for rapid 3D modelisation. I like to do it to evaluate 3D internal distribution and external proportions.

Under a new piction with push button on front face

Attachments

That is a lot easier than having to do a drawing from just a sketch. I do that in Solidworks and it does take some time to do a 3D surface model from nothing. I've only used pre-made sketches for some connectors and bolts and such.

Interesting,can you share your pcb?

i'm far from home,out of my town.. i'll send you went I got home. i'm using old OPS v1.2 with little mod. so i don't have to mount small heatsink to it. driver and final all stick to main heatsink. all 2 vbe, 1 screw on top of driver and other on top of final transistor.

That is a lot easier than having to do a drawing from just a sketch. I do that in Solidworks and it does take some time to do a 3D surface model from nothing. I've only used pre-made sketches for some connectors and bolts and such.

I was using solidworks by the past to but Sketchup is free and there is the 3Dwarehouse....even if i like more some feature from solidworks....

Marc

- Home

- Amplifiers

- Solid State

- SlewMaster Builds