keeping “port” open results in a dip in frequency response and a severe peak in distortion at helmholtz resonance. Generally high distortion.

keeping the port open but dampened results in a flat roll-off but in a peak of distortion at helmholtz resonance and below.

does this apply to all helmholtz-speakers?

Hi celef, no, as far as i understand the output at helmholtz is mainly the port and as this is at the back of the tweeter behind the baffle the port output is just masked. I will do a measurement at back of the tweeter to prove it ...

thanks watchal!

very interesting, I did some tests very similar to your pictures.

the most promising until now seems to be extending the pole drilling hole with a dampened tube, kind of a "aperiodic box", avoiding the helmholtz resonator effect.

measurement results will follow!

does this apply to all helmholtz-speakers?

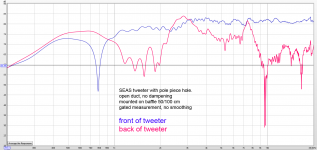

attached the front and back frequency response measurement, just the plain tweeter with hole, no dampening.

there are obviously lots of resonance peaks exiting the rear pole piece vent.

I also suppose the response looks ugly and distortion is high because

- the tweeter is not optimized for large displacements and the helmholtz resonance is way below normal operating area of the tweeter

- rear volume is not dampened

- duct is absolutely not optimized for air flow (sharp edges!)

Attachments

Your findings with the open pole piece are predictable. The resonances create acoustic impedance fluctuations that affect mechanical dampening and cause reflections behind the dome and in the undampened pole piece. All that will wreak havoc with THD and linearity.

Tapering the pole piece cavity fixes some of the resonance issues by breaking up the parallel walls in the cavity, improves are flow and lowers the primary resonance from the increase in volume.

I've done a bit of testing with my TW034. The best compromise overall for THD and FR was a tapered cavity. If I opened the pole piece all the way and added a chamber, it elevated the VC gap chamber resonance around 2k and made the FR wiggle in that are worse. Moving the two resonances closer together improved mechanical dampening and linearized the 1-2k response, further decreasing THD as well.

Tapering the pole piece cavity fixes some of the resonance issues by breaking up the parallel walls in the cavity, improves are flow and lowers the primary resonance from the increase in volume.

I've done a bit of testing with my TW034. The best compromise overall for THD and FR was a tapered cavity. If I opened the pole piece all the way and added a chamber, it elevated the VC gap chamber resonance around 2k and made the FR wiggle in that are worse. Moving the two resonances closer together improved mechanical dampening and linearized the 1-2k response, further decreasing THD as well.

thanks profiguy for you input - it's higly appreciated!

I am considering another modification and make the holes wider and tapered, as you suggested.

there are still some measurements that I will post here and probably some more will come - unfortunately I cannot spend as much time as i would like with my tweeters 😀.

I am considering another modification and make the holes wider and tapered, as you suggested.

there are still some measurements that I will post here and probably some more will come - unfortunately I cannot spend as much time as i would like with my tweeters 😀.

an update from my drilled seas tweeters:

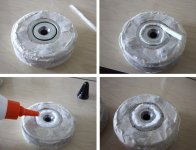

I was not able to make tapered holes, as suggested by profiguy. however i did enlarge the polepiece holes: 10 mm all through and 12 mm to about half of the polepiece lenght. this gives a "stepped-tapered" volume.

you can see on the photos that it makes sense to mark the exact center of the pole piece before covering the magnet gap ...

I tried out a new technique to protect the magnet gap from iron particles, by filling it with a thin strip of paper towel, covered with PVA wood glue. this protects the magnet gap perfectly and the dry glue can easily be removed, as long as paper and glue do not enter the cavity below the magnet gap. it is still necessary to inspect and clean the magnet gap after PVA removal.

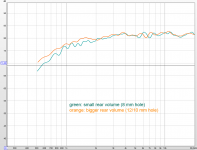

enlarging the rear air volume (+ dampening and closing at the rear) lead to a even lower resonance frequency and a higher impedance peak, as to be expected. the small resonance around 2,7 kHz that seemed to be a magnet gap resonance nearly disappeared. freqency response is now slightly extended towards lower end. note the slightly lowered response wiggles between 5 and 8 kHz, obviously resonances in the rear volume.

I will stop producing iron particles now - too much troubles with that!

anyone experimented with removing of the "phase plug"? i suppose this might expose upper frequency range break-up of the dome.

I was not able to make tapered holes, as suggested by profiguy. however i did enlarge the polepiece holes: 10 mm all through and 12 mm to about half of the polepiece lenght. this gives a "stepped-tapered" volume.

you can see on the photos that it makes sense to mark the exact center of the pole piece before covering the magnet gap ...

I tried out a new technique to protect the magnet gap from iron particles, by filling it with a thin strip of paper towel, covered with PVA wood glue. this protects the magnet gap perfectly and the dry glue can easily be removed, as long as paper and glue do not enter the cavity below the magnet gap. it is still necessary to inspect and clean the magnet gap after PVA removal.

enlarging the rear air volume (+ dampening and closing at the rear) lead to a even lower resonance frequency and a higher impedance peak, as to be expected. the small resonance around 2,7 kHz that seemed to be a magnet gap resonance nearly disappeared. freqency response is now slightly extended towards lower end. note the slightly lowered response wiggles between 5 and 8 kHz, obviously resonances in the rear volume.

I will stop producing iron particles now - too much troubles with that!

anyone experimented with removing of the "phase plug"? i suppose this might expose upper frequency range break-up of the dome.

Attachments

Last edited:

Does the taper degree angle and its depth matter? I drilled a couple factory Polk tweeters and made custom back-chambers. I'm contemplating making 1-off pole pieces on the CNC to interface with alloy housings that have heat-dissipation fins.an update from my drilled seas tweeters:

I was not able to make tapered holes, as suggested by profiguy. however i did enlarge the polepiece holes: 10 mm all through and 12 mm to about half of the polepiece lenght. this gives a "stepped-tapered" volume.

you can see on the photos that it makes sense to mark the exact center of the pole piece before covering the magnet gap ...

I tried out a new technique to protect the magnet gap from iron particles, by filling it with a thin strip of paper towel, covered with PVA wood glue. this protects the magnet gap perfectly and the dry glue can easily be removed, as long as paper and glue do not enter the cavity below the magnet gap. it is still necessary to inspect and clean the magnet gap after PVA removal.

enlarging the rear air volume (+ dampening and closing at the rear) lead to a even lower resonance frequency and a higher impedance peak, as to be expected. the small resonance around 2,7 kHz that seemed to be a magnet gap resonance nearly disappeared. freqency response is now slightly extended towards lower end. note the slightly lowered response wiggles between 5 and 8 kHz, obviously resonances in the rear volume.

I will stop producing iron particles now - too much troubles with that!

anyone experimented with removing of the "phase plug"? i suppose this might expose upper frequency range break-up of the dome.

hi xschop,Does the taper degree angle and its depth matter?

it may have some influence, see profiguy's post:

in his previous messages he stated it may not make much sense to hugely increase the air volume behind the dome, this will create several other issues.Tapering the pole piece cavity fixes some of the resonance issues by breaking up the parallel walls in the cavity, improves are flow and lowers the primary resonance from the increase in volume.

also note that if you have a small duct and a big volume behind it, this will act as a helmholtz resonator - you don't really want that! see my findings on page 1.

Ok. Thank you

for replying. That would be good news not needing an actual back-chamber. I'm also in discussion with an

for replying. That would be good news not needing an actual back-chamber. I'm also in discussion with an

engineer friend of the modification mentioned here about stuffing the void/chamber between pole-piece and magnet underneath top plate, since I break them and reassemble anyway, when drilling pole-pieces.

engineer friend of the modification mentioned here about stuffing the void/chamber between pole-piece and magnet underneath top plate, since I break them and reassemble anyway, when drilling pole-pieces.

I would suggest not to add a back-chamber.That would be good news not needing an actual back-chamber.

but you should probably verify that with measurements of your tweeters.

my tweeter showed a massive increase of H3 distorsion at helmholtz frequency around 1kHz - however that was with a completely open back.

see the "helmholtz" graphs in my post #18!

Some tweeters don't benefit from a larger back cavity, as is with the case of smaller Seas and Peerless domes with dampened pole piece surfaces (back cavity formed by only air volume behind dome itself).. The main benefits of enlarging the rear volume by drilling the pole piece is to lower the driver Qts and shift the primary resonance lower down for easier crossover design and cleaner lower midrange output. Some tweeters sound more lively and engaging with small undampened chambers, mainly due to the small resonances in the upper HF that would get lost with better dampening. Such is the case with ferrofluid, as it swallows some fine details. Its a delicate balance and requires judicial application, especially with higher end tweeters which have already been refined to an extent. Its easy to go backwards with these modifications. In the case of the Audax TW034, it needs more room behind the dome to lower the system Q and clean up the 2 k wiggle (phase shift). This makes the tweeter sound much cleaner with lower crossover points. Other tweeters, especially those which already come with back chambers may just need better dampening material (wool instead of synthetic foam) or more of it and may actually respond worse to further dampening. A tweeter with a Qts of higher than .7 will almost always benefit from a lower Qts, given it has the overall potential to sound better by means of posessing decent build quality to start with.hi xschop,

it may have some influence, see profiguy's post:

in his previous messages he stated it may not make much sense to hugely increase the air volume behind the dome, this will create several other issues.

also note that if you have a small duct and a big volume behind it, this will act as a helmholtz resonator - you don't really want that! see my findings on page 1.

I too am interested in this idea of filling the resonant cavity beneath the voice coil. I wonder if anyone has tried this and the theory should be sound since any resonant cavity could be responsible for distortion, ie. disturbing the response of the transducer to the musical signal and only the musical signal.I'm also in discussion with an engineer friend of the modification mentioned here about stuffing the void/chamber between pole-piece and magnet underneath top plate, since I break them and reassemble anyway, when drilling pole-pieces.

After dissecting the Q1R tweeters, I'll mimick their pole piece profile and stuff the tunnel and the void between pole piece and magnet....

I too am interested in this idea of filling the resonant cavity beneath the voice coil. I wonder if anyone has tried this and the theory should be sound since any resonant cavity could be responsible for distortion, ie. disturbing the response of the transducer to the musical signal and only the musical signal.

That's a lot of work to go through for this kind of thing on a pair of dome tweeters.

How are you pulling the pole pieces apart and keeping the magnets from fragmenting while prying them apart?

Its hard enough to dissolve the glue that holds it all together. Do you have some ability to demagnetize the whole thing before and remagnetize it?

Curious to see the benefit of filling the magnet gap cavity as well.

How are you pulling the pole pieces apart and keeping the magnets from fragmenting while prying them apart?

Its hard enough to dissolve the glue that holds it all together. Do you have some ability to demagnetize the whole thing before and remagnetize it?

Curious to see the benefit of filling the magnet gap cavity as well.

I opened a failed dome tweeter from my JBL LSR32 studio monitors and found the pole piece was drilled and filled with what seemed to be a plug of memory foam that seems to fully contact the back of the dome. Those 035TI tweeters have a very flat response and very low distortion.

I machined custom non-magnetic punch and magnet seats to either dead blow with a hammer or shop press.

The jig in the pic there, I designed to recenter Polk's Midwoofers and their tweeters since they all have 0.600" thick magnets but different diameters.

If this mod does the same for the inexpensive"wuhans" and smooths them at high volume without distorting, then it's a win/win and I'll offer a turn-around service to the uber-modders.

The jig in the pic there, I designed to recenter Polk's Midwoofers and their tweeters since they all have 0.600" thick magnets but different diameters.

If this mod does the same for the inexpensive"wuhans" and smooths them at high volume without distorting, then it's a win/win and I'll offer a turn-around service to the uber-modders.

Last edited:

- Home

- Loudspeakers

- Multi-Way

- SEAS tweeter pole piece drilling