The Klippel graph demonstrates a very non-symmetrical BL curve.

But how to cope with that as a manufacturer without having to tune each voicecoil individually before glueing the vc-spider-cone assembly? Or is the Satori motor above inherently asymmetric beacause of design flaws?

But how to cope with that as a manufacturer without having to tune each voicecoil individually before glueing the vc-spider-cone assembly? Or is the Satori motor above inherently asymmetric beacause of design flaws?

There are two main things to note there. One is the X-centering. This is just a question of tuning the production line assembly tools. They can be adjusted down to maybe 0,1mm quite reliably, depending on the size of the parts. Very wide suspensions and large, heavy parts are not nearly as precise, while a tweeter can easily be tuned to better than 0,1mm if one bothers to make good quality. A driver the size of the Satori 6 should be possible to tune at least near that range.

Secondly, the tilt in the curve towards one side is a design issue. This is something that is most effectively sorted in a relatively simple FEM-simulation before one even starts building prototypes.

There are some old standards, or more like habits in the industry that commonly uses -18% for woofers and -30% for subwoofers as limit for Bl loss.

Using THD is not a great idea as the driver may seem to cancel out distortion in the suspension, while at the same time producing masses of IMD.

Since the opposing force that the motor has to work against is determined by mass, compliance (including cabinet) and frequency we typically see that in such a test one works against the suspension as the dominating force, while in determining the amount of IMD, all secondary tones of interest will stay far above the system fundamental resonant frequency, thus making the moving mass the dominating opposing force and therefore taking suspension out of the equation. This is simply not covered by measuring THD, and we therefore rarely get any valuable information about this.

A motor design can and should be judged both by its ability to keep Bl constant with motion, its ability to keep Le constant, and by its ability to keep Bl constant under different currents and frequencies. Those last bits are typically very much overlooked, meaning we have numerous expensive designs out there that performs excellently right up until things start to go a bit more complex. Since all we see related to Le is measured at 1kHz, the information we get from this regarding the motors stability is very limited as well.

Secondly, the tilt in the curve towards one side is a design issue. This is something that is most effectively sorted in a relatively simple FEM-simulation before one even starts building prototypes.

There are some old standards, or more like habits in the industry that commonly uses -18% for woofers and -30% for subwoofers as limit for Bl loss.

Using THD is not a great idea as the driver may seem to cancel out distortion in the suspension, while at the same time producing masses of IMD.

Since the opposing force that the motor has to work against is determined by mass, compliance (including cabinet) and frequency we typically see that in such a test one works against the suspension as the dominating force, while in determining the amount of IMD, all secondary tones of interest will stay far above the system fundamental resonant frequency, thus making the moving mass the dominating opposing force and therefore taking suspension out of the equation. This is simply not covered by measuring THD, and we therefore rarely get any valuable information about this.

A motor design can and should be judged both by its ability to keep Bl constant with motion, its ability to keep Le constant, and by its ability to keep Bl constant under different currents and frequencies. Those last bits are typically very much overlooked, meaning we have numerous expensive designs out there that performs excellently right up until things start to go a bit more complex. Since all we see related to Le is measured at 1kHz, the information we get from this regarding the motors stability is very limited as well.

Most of the time this is the so called surround dip.Are you asking what is causing it? A lot of times it's a self-flexing of the cone where the membrane has a self resonance. A lot of woven cones are not completely pistonic to breakup, and can have an issue. I've noticed it more on Curv, carbon fiber, and glass fiber cones in particular.

Basically it's a acoustic mechanical impedance mismatch of the materials.

John Eargle describes this pretty well in his book, but I think there is also a Klippel paper out there that very briefly explains it.

Stiffer materials seems to be less prone to this.

A very quick, easy but very well performing fix, is just to put some extra material (often some kind of glue or so) on the edge of the cone/surround. This is that little line you see with some speakers.

It totally beats me why they don't do this by default, since it's even very easy and simple to implement in production.

I have also seen this with some strategically placed rubber "pads" as well.

Last edited:

No, this is not the surround dip. For example, the U18 has an issue around 850Hz, which would be closer to 1.1-1.5k if it was the surround due to the nominal diameter.

@wolf_teeth

I guess to be very fair, the term "surround dip" can be rather vague in general.

A secondary resonance caused by the interaction between the cone stiffness/construction and surround would be more adequate.

This does not always depend on the cone diameter per se, but is more like a property of the cone construction and stiffness.

Obviously the two are somewhat related.

A pure surround dip is a property of the surround itself, that's true.

As far as I know, this is also not always related to the diameter.

A bigger fatter surround wil result in a dip that is lower in frequency with the same diameter.

(the same more mass = lower frequency also applies to resonances in materials)

Which can typically seen by subwoofers for example.

In other words; a woofer from the same size, same motor construction, and cone material but with a fatter surround, will have a significantly lower surround resonance.

This woofer is more close to the L16 family btw, not U18.

In fact, the T/S are extremely close to the L16RNX3.

These woofers have a rather (unusual) fat surround with a low stiffness.

So I don't think it's unreasonable to say it's a surround issue.

Actually, there are also not many other properties that will cause a similar issues and can been seen in the impedance graph.

So even by deductive reasoning we can come to the same conclusion.

It's just one of those compromises that one has to make when a low Fs is needed in combination with a reasonable cone excursion. They are doing a pretty good job at that tbh.

Unless it's some weird resonance in the motor design (which does happen), but I find that hard to believe for such a high quality woofer.

I guess to be very fair, the term "surround dip" can be rather vague in general.

A secondary resonance caused by the interaction between the cone stiffness/construction and surround would be more adequate.

This does not always depend on the cone diameter per se, but is more like a property of the cone construction and stiffness.

Obviously the two are somewhat related.

A pure surround dip is a property of the surround itself, that's true.

As far as I know, this is also not always related to the diameter.

A bigger fatter surround wil result in a dip that is lower in frequency with the same diameter.

(the same more mass = lower frequency also applies to resonances in materials)

Which can typically seen by subwoofers for example.

In other words; a woofer from the same size, same motor construction, and cone material but with a fatter surround, will have a significantly lower surround resonance.

This woofer is more close to the L16 family btw, not U18.

In fact, the T/S are extremely close to the L16RNX3.

These woofers have a rather (unusual) fat surround with a low stiffness.

So I don't think it's unreasonable to say it's a surround issue.

Actually, there are also not many other properties that will cause a similar issues and can been seen in the impedance graph.

So even by deductive reasoning we can come to the same conclusion.

It's just one of those compromises that one has to make when a low Fs is needed in combination with a reasonable cone excursion. They are doing a pretty good job at that tbh.

Unless it's some weird resonance in the motor design (which does happen), but I find that hard to believe for such a high quality woofer.

Last edited:

There is a difference between a static offset and a dynamic offset.The Klippel graph demonstrates a very non-symmetrical BL curve.

But how to cope with that as a manufacturer without having to tune each voicecoil individually before glueing the vc-spider-cone assembly? Or is the Satori motor above inherently asymmetric beacause of design flaws?

The first one is a matter of having your production methods right.

The second one is having your design "right".

Which in some cases is not always easy, since there are other parameters besides distortion that are (more) important.

(distortion feels a bit like pixel peeping these days, as if it's the only important parameter).

Since most speakers are mounted in a box with a certain volume, some manufactures actually even compensate for the asymmetry of the compliance that is created by this volume.

Also, an asymmetry results mostly in even order distortion which isn't as harmful.

In fact, most people find this even pleasing.

Especially for lower frequencies, I would much rather prefer some higher 2nd order but an absence of odd order vs lower overal distortion with higher odd order.

So purely looking at this the BL or Cms graph doesn't show the whole picture.

It only shows us some information how a driver behaves around the Fs.

It even assumes that this Fs doesn't drift (which can be measured with a Klippel system, but no one seems to show that)

Last edited:

I beg to differ in case BL is measured with DC: in that case Fs is not relevant i.m.o.It only shows us some information how a driver behaves around the Fs.

It even assumes that this Fs doesn't drift (which can be measured with a Klippel system, but no one seems to show that)

For @Boden @Snickers-is and @b_force -

What is an acceptable level of IMD in a midwoofer?

From hificompass measurements, he describes MW16TX IMD at -18dB as high, but MW19TX IMD at -25dB as amongst the best in the class.

But the BL plots on audioexpress reviews of both MW16 and MW19 show the asymmetric/tilted BL curve - so is the BL curve the main predictor of IMD, and what are the other factors that might make the MW19 'better' in this regard?

Also is IMD/BL curve relevant if you're operating well above Fs? In such a situation cone excursion will be minimum and BL asymmetry won't affect it, correct? eg if one were to use the MW16TX as a pure midrange, operating above 250Hz.

Forgive me if these are basic or already answered in this thread, I'm very new to understanding driver measurements 🙂

Thanks!

Edit: These are the links I'm looking at:

https://audioxpress.com/article/voi...-home-audio-tpcd-textreme-cone-midbass-driver

https://audioxpress.com/article/test-bench-sb-acoustics-satori-mw16tx-8-textreme-woofer

https://hificompass.com/en/reviews/satori-mw16tx-4

https://hificompass.com/en/reviews/satori-mw19tx-4

https://hificompass.com/en/reviews/purifi-ptt65x04-naa-08-65-alu-midwoofer - for comparison, at -33.5dB

What is an acceptable level of IMD in a midwoofer?

From hificompass measurements, he describes MW16TX IMD at -18dB as high, but MW19TX IMD at -25dB as amongst the best in the class.

But the BL plots on audioexpress reviews of both MW16 and MW19 show the asymmetric/tilted BL curve - so is the BL curve the main predictor of IMD, and what are the other factors that might make the MW19 'better' in this regard?

Also is IMD/BL curve relevant if you're operating well above Fs? In such a situation cone excursion will be minimum and BL asymmetry won't affect it, correct? eg if one were to use the MW16TX as a pure midrange, operating above 250Hz.

Forgive me if these are basic or already answered in this thread, I'm very new to understanding driver measurements 🙂

Thanks!

Edit: These are the links I'm looking at:

https://audioxpress.com/article/voi...-home-audio-tpcd-textreme-cone-midbass-driver

https://audioxpress.com/article/test-bench-sb-acoustics-satori-mw16tx-8-textreme-woofer

https://hificompass.com/en/reviews/satori-mw16tx-4

https://hificompass.com/en/reviews/satori-mw19tx-4

https://hificompass.com/en/reviews/purifi-ptt65x04-naa-08-65-alu-midwoofer - for comparison, at -33.5dB

I am not sure those statements regarding the Satori drivers are correct. But what values you get from a single type of test is off limited value as it represents such a small piece of what would be a complete data set. As you say, IMD for a driver used way above its Fs will not be based on Bl(x), but it will be based on Bl(i).

We need something very different than a percentage or a single curve to describe the properties of a driver.

We need something very different than a percentage or a single curve to describe the properties of a driver.

That's true, but I thought that was kinda obvious sorry 🙂I beg to differ in case BL is measured with DC: in that case Fs is not relevant i.m.o.

Although difference in DC doesn't happen that often anymore these days, plus it's mostly even harmonics.

So a lot less harmful.

@Snickers-is

Above about roughly 2 x Fs, Le(X) takes over, and Kms(x) and BL(x) are not of any significance anymore.

Additionally there are other issues like cone resonances, and non-linearities in the magnet (or magnetic field rather).

The main reason why demodulation rings work so well.

Above about roughly 2 x Fs, Le(X) takes over, and Kms(x) and BL(x) are not of any significance anymore.

Additionally there are other issues like cone resonances, and non-linearities in the magnet (or magnetic field rather).

The main reason why demodulation rings work so well.

The answer is; yes.

Long answer, describe "acceptable" and context.

The even longer answer, the correlation between IMD and audibility is poor.

The short answer, I think there are an awful lot of other parameters besides (IMD) distortion that are a lot more significant.

In general, I also think a much better approach is to minimize problematic areas to begin with.

That way we don't even have to quantify such numbers (and spend so much money)

Suppose you would be able to start with a clean sheet; where would you start to focus on? I certainly have my own views, but out of curiosity would like to know what you would start with.

@Boden My main focus is just to avoid things.

For example, instead of focusing on what IMD or THD levels are "important", just try to avoid them as much as possible.

Practically speaking, these days we are REALLY blessed with drivers that perform absolutely great in certain regions.

Like many miles better than 15-20 years before.

So use certain drivers in their best region on a smart way.

The beauty of it, is that is actually practically and financially very doable.

In a much much general since, I focus on what certain people/customers find important.

For example, instead of focusing on what IMD or THD levels are "important", just try to avoid them as much as possible.

Practically speaking, these days we are REALLY blessed with drivers that perform absolutely great in certain regions.

Like many miles better than 15-20 years before.

So use certain drivers in their best region on a smart way.

The beauty of it, is that is actually practically and financially very doable.

In a much much general since, I focus on what certain people/customers find important.

1) Motor optimization (many ways to skin a cat here)

2) avoidance of sharp breakup in passband (idem)

3) proper cone-surround matching/cone termination

4) resonance free,stable and ventilated chassis, allowing for large mech X

5) progressive spider characteristics, not working against the surround (but how?)

what is next?

2) avoidance of sharp breakup in passband (idem)

3) proper cone-surround matching/cone termination

4) resonance free,stable and ventilated chassis, allowing for large mech X

5) progressive spider characteristics, not working against the surround (but how?)

what is next?

@Snickers-is

Above about roughly 2 x Fs, Le(X) takes over, and Kms(x) and BL(x) are not of any significance anymore.

Additionally there are other issues like cone resonances, and non-linearities in the magnet (or magnetic field rather).

The main reason why demodulation rings work so well.

If we include passive crossover Le(x) may be a factor, but not at 2*Fs. But it is a good indicator for the level of magnetic coupling between the voice coil and the steel parts. However, since it is measured at 1k it is ofte dominated by the shorting rings. If we measured it at very low frequencies, we would get an idea how far the Bl(i) may go in a real life situation.

I am not sure we should include the soft parts here, but I see you point towards non linearities in the magnet and the magnetic field.

For the latter, Bl(x) will normally cover all that is of interest, and since we mainly see over hung drivers, these non linearities inside the gap are not an issue.

But the first one is of more interest. Not that non linearities in the actual magnet will cause any problems, but the paramagnetic materials, normally steel, do have some properties that can cause both HD, IMD and non harmonic distortion. The large part of this would best be described with a plot that shows Bl as a function of both x, i and frequency in order to include as many as the combined non linearities as possible into one plot. That would at least be very useful for an engineer with limited experience with driver design when selecting the correct driver for a task.

That would be great for anyone to have, but unfortunately loudspeaker datasheets are still so bad (understatement) it's embarrassing.The large part of this would best be described with a plot that shows Bl as a function of both x, i and frequency in order to include as many as the combined non linearities as possible into one plot.

Especially given the fact that about 85% of all manufactures use the same Klippel measurement system te begin with.

Le(x) is always a factor, also without a passive filter.

2 x fs only describes when Le(X) becomes dominant over BL(x) and Cms(x) (and vice versa)

Le(x) does not become a factor anymore when there is no or very little cone excursion.

Although like you said, in general it's a decent indication of the performance of a driver in general.

The 500hz issue is almost definitely caused by using dust cap instead of a phase plug. Basically, all hard cone Seas drivers with dust cup(L16s, L19s) has similar issues. It's cavity resonance behind dust cup through the hole on the pole piece on the back of the driver magnet.

Many early SB driver has this issue too, including my MW16p, and SB1xNACs. Later SB drivers(MR16p, SB1xNBACs) simply solved the issue with venting in the voice coil bobbin. But I guess it would lower power rating, since a non-vented voice coil bobbin should has some kind of "forced air cooling" effects by forcing more air flow through the gap with excursion.

Many early SB driver has this issue too, including my MW16p, and SB1xNACs. Later SB drivers(MR16p, SB1xNBACs) simply solved the issue with venting in the voice coil bobbin. But I guess it would lower power rating, since a non-vented voice coil bobbin should has some kind of "forced air cooling" effects by forcing more air flow through the gap with excursion.

That would be great for anyone to have, but unfortunately loudspeaker datasheets are still so bad (understatement) it's embarrassing.

Especially given the fact that about 85% of all manufactures use the same Klippel measurement system te begin with.

Le(x) is always a factor, also without a passive filter.

2 x fs only describes when Le(X) becomes dominant over BL(x) and Cms(x) (and vice versa)

Le(x) does not become a factor anymore when there is no or very little cone excursion.

Although like you said, in general it's a decent indication of the performance of a driver in general.

After all this time, I finally got to make a simulation showing Force factor, current, position and frequency in the same diagram. I am going to develop it further with DC offset, but this is what I have at this point:

PS: THIS IS JUST FOR ILLUSTRATION, IT DOES NOT SHOW ANY OF THE DRIVERS IN THIS THREAD!

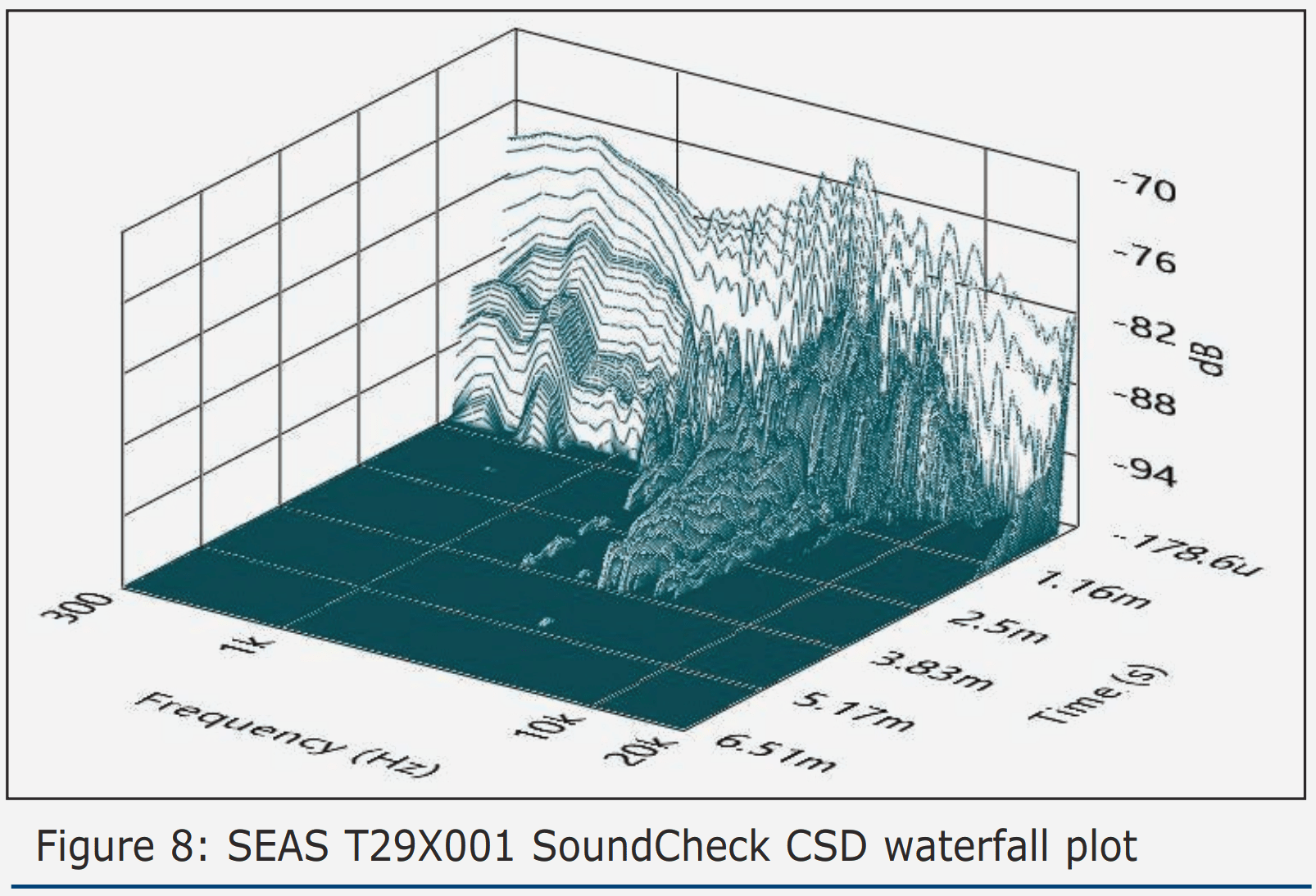

On the topic of Seas TPCD, Vance Dickason at AudioXpress has tested the T29X001 now. I do not think they have published it open to everyone yet, but hopefully I will be forgiven for showing a teaser:

- Home

- Loudspeakers

- Multi-Way

- SEAS "textreme" launching soon