On the whole the SB Acoustics Textreme cones do what was advertised - giving rigid cone performance but also being well damped. The Textreme Satori's do indeed do away with the cone edge/surround resonances that plague every soft cone SB driver. But they don't have the ugly HD3 peaks that typically come with metal cones.

Obviously SBs ribbed metal cones go a long way to solving this issue too.

I had high hopes for the SEAS Textreme coaxial in the Ex Machina speaker but that was a big let down. The midrange performance has that awful issue in the third harmonic distortion at around the crossover frequency. From what I can see this comes from the midrange and not the tweeter, just like the metal cone version of this driver. So much for Textreme should have just kept the metal version.

Clearly Textreme has potential, such as with SBs implementation, but it's application seems important too.

The world doesn't need any more fancy, for fancies sake, cone materials and nor does it need it attached only to stupid expensive drivers. Funny thing is Textreme is made of carbon fibre, dirt cheap, at it's base. Woven and impregnated and laminated. Another dirt cheap industrial process.

Alnico? No thanks. I'll use the upcoming iron nitride magnets.

Obviously SBs ribbed metal cones go a long way to solving this issue too.

I had high hopes for the SEAS Textreme coaxial in the Ex Machina speaker but that was a big let down. The midrange performance has that awful issue in the third harmonic distortion at around the crossover frequency. From what I can see this comes from the midrange and not the tweeter, just like the metal cone version of this driver. So much for Textreme should have just kept the metal version.

Clearly Textreme has potential, such as with SBs implementation, but it's application seems important too.

The world doesn't need any more fancy, for fancies sake, cone materials and nor does it need it attached only to stupid expensive drivers. Funny thing is Textreme is made of carbon fibre, dirt cheap, at it's base. Woven and impregnated and laminated. Another dirt cheap industrial process.

Alnico? No thanks. I'll use the upcoming iron nitride magnets.

In the 1970's JBL discovered that they were able to improve performance in a ferrite driver, past the current performance of an alnico driver. That was before anyone had access to FEM-tools.

Today we know that the best performance is achieved through a thorough design process, and not through selecting the most expensive and rare unobtainable material out there. A near perfect ferrite motor will typically not be improved by using a different magnet material. The same goes for diaphragms and suspensions. The shape and coating details of a paper cone is what makes our breaks its performance. By thinking in 3D and observing how materials behave one can achieve huge improvements in sound quality that are simply not there just by swapping materials.

Today we know that the best performance is achieved through a thorough design process, and not through selecting the most expensive and rare unobtainable material out there. A near perfect ferrite motor will typically not be improved by using a different magnet material. The same goes for diaphragms and suspensions. The shape and coating details of a paper cone is what makes our breaks its performance. By thinking in 3D and observing how materials behave one can achieve huge improvements in sound quality that are simply not there just by swapping materials.

Alright, I was there at AXPONA Saturday, and spoke with the rep/designer from Seas. He said they took 2 years to develop the cone, applying it piece by piece, to address response and sound, issue by issue empirically. Sometimes it was too much damping in one place, and then fixed one problem, but also made them sound dead subjectively. It is not random placement, but placement of each piece is on purpose and has a distinct job to do in terms of objective and subjective performance. That said, it is not actually textreme product because it is not the even weave pattern.

They had the 16mm driver on hand, in a sealed cabinet with the respective carbon fiber tweeter, in about 8 ltrs if I had to guess. The bass was very nice with some real kick, and the mids were open and clean. The tweeter did its job and was never harsh. Of course this is with their yet unrevealed xover for the design, but it did its job well.

Apparently Seas is very surprised and elated with this new driver, as it's only been in house for the 2 weeks they developed this little speaker. They could not wait to show it off.

They had the 16mm driver on hand, in a sealed cabinet with the respective carbon fiber tweeter, in about 8 ltrs if I had to guess. The bass was very nice with some real kick, and the mids were open and clean. The tweeter did its job and was never harsh. Of course this is with their yet unrevealed xover for the design, but it did its job well.

Apparently Seas is very surprised and elated with this new driver, as it's only been in house for the 2 weeks they developed this little speaker. They could not wait to show it off.

As well as a horrible taste, lolLooks like the “high-end” crowd really fancy new materials.

2 drivers. Probably 500€ ea.

But jeeze, they aren't the prettiest are they? 😀 😀

Anyway, whatever floats your boat I guess.

It kinda feels 80-90s all over again, going into fancy materials.

As long as the cone resonances are well controlled, the motor design is well made, there is plenty of demodulation going on, there isn't much else besides paper (plus some small additives) or aluminium.

It's totally fine to go for certain looks obviously.

As for Seas; I am hoping they will find their niche better.

They produce excellent speakers, but it heavily feels they hang more on their brand name than anything else.

There are so many other competitors that simply offer a better price-performance ratio.

Which is even more true for OEM prices and quantities.

I can't remember when I advised Seas drivers to any OEM clients, except for the exception here and there.

That was mostly for the looks than anything else.

Which is a shame, because their quality and performance is excellent.

Here are the preliminary datasheets as provided by Seas on the Axpona show:

https://www.dropbox.com/s/zxibt58ou83bfcl/E0115-08_W16NX_temp_datasheet_(230330).pdf?dl=0

https://www.dropbox.com/s/njh1ym6n5zulfax/E0110-04_T29X_temp_datasheet_230330.pdf?dl=0

https://www.dropbox.com/s/zxibt58ou83bfcl/E0115-08_W16NX_temp_datasheet_(230330).pdf?dl=0

https://www.dropbox.com/s/njh1ym6n5zulfax/E0110-04_T29X_temp_datasheet_230330.pdf?dl=0

Interesting, this seas W16 TPCD has different motor than W16NX003.

This new TPCD cone version has 20 ohm impedance at 10khz, but W16NX003 graphene have only little over 10 ohm at 10khz.

But TPCD cone is very, very nice. Breakup at 9khz. Very far from crossover region.

This new TPCD cone version has 20 ohm impedance at 10khz, but W16NX003 graphene have only little over 10 ohm at 10khz.

But TPCD cone is very, very nice. Breakup at 9khz. Very far from crossover region.

I noticed the same. The inductance is also a fair bit higher. I believe this could be due to some more turns in the voicecoil.

The breakup might still need a notch unless crossing rather low or using a higher order filter.

Also, the response is a bit ragged with 2db dips and peaks here and there.

I would have expected better linearity for a new Excel driver.

The tweeter datasheet looks good.

Hopefully these are not priced stupidly vs the competition.

Also, the response is a bit ragged with 2db dips and peaks here and there.

I would have expected better linearity for a new Excel driver.

The tweeter datasheet looks good.

Hopefully these are not priced stupidly vs the competition.

the seas cone look a bit messy, they should coat them with nextel to hide the mess. or they should try harder to get the patchwork easy on the eye, because we hears and eats in part with our eyes

The Z curve shows an issue at 500 Hz. Cone-surround issues once again for a brandnew multi Euro/Dollah driver? Could not agree more with 5th element in his statement below..The loudspeaker industry is rapidly becoming a marketing industry, turning commodity items into pure jewellery.

The world doesn't need any more fancy, for fancies sake, cone materials and nor does it need it attached only to stupid expensive drivers. Funny thing is Textreme is made of carbon fibre, dirt cheap, at it's base. Woven and impregnated and laminated. Another dirt cheap industrial process.

And then cover it with an aluminium skin, in turn coated by an ultra thin layer of polypropylene..the seas cone look a bit messy, they should coat them with nextel to hide the mess. or they should try harder to get the patchwork easy on the eye, because we hears and eats in part with our eyes

Most of your woven fiber drivers exhibit a distortion spike and corresponding dip in response between 500 and 900Hz. I would not expect the new CF W16 to be any different.

Are you asking what is causing it? A lot of times it's a self-flexing of the cone where the membrane has a self resonance. A lot of woven cones are not completely pistonic to breakup, and can have an issue. I've noticed it more on Curv, carbon fiber, and glass fiber cones in particular.

Exactly, even Sb acoustics satori textreme has little wrinkle in the impedance response near 500hz and also wrinkles in the distortion response at those frequencies. Buy those are very small differences and makes no harm to sound.

I bet this makes more harm to the sound of the Satori than the cone does...

Yes, satori have very low harmonic distortion.

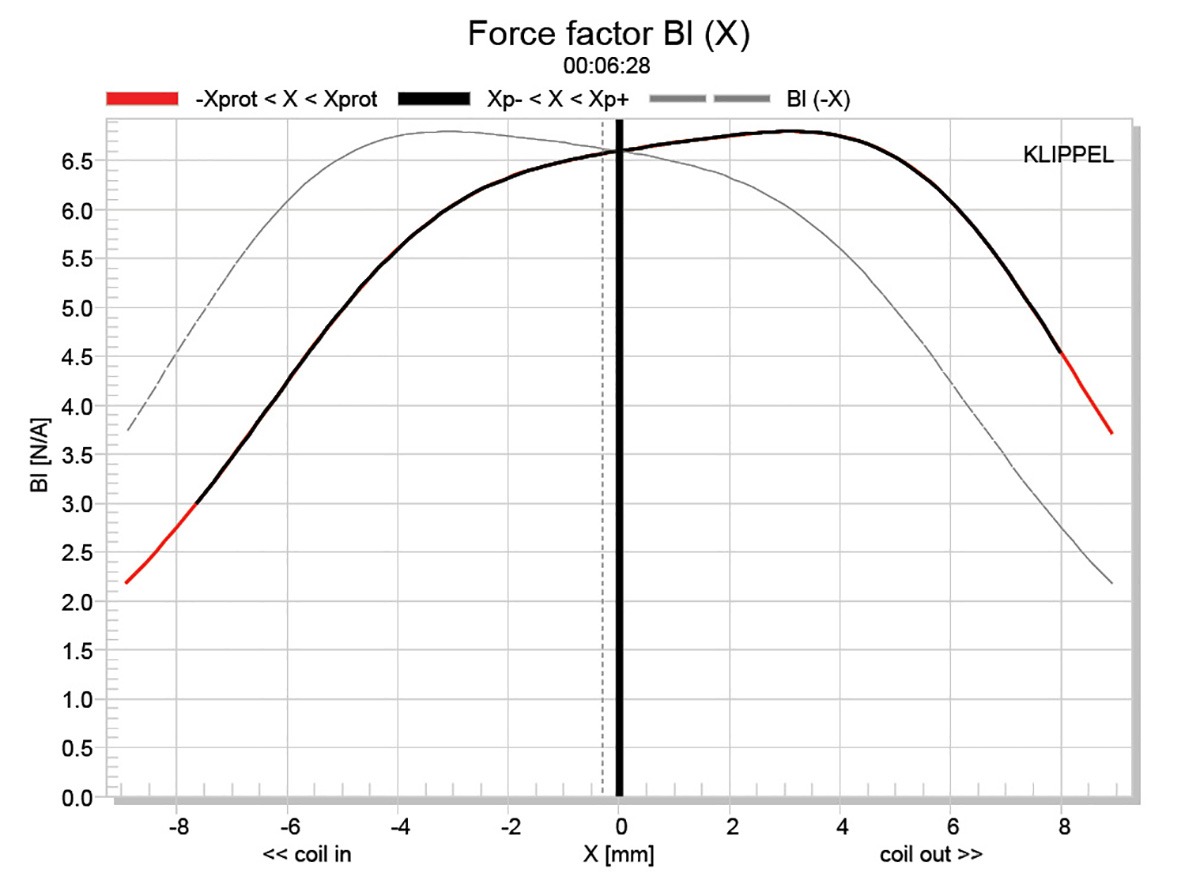

But satori motor has bad design flaw its motor for a high end speaker, like you see from klippel picture. Satori has very high IMD distortion. Even cheaper SB17 -series is much better. I'm 100% sure that seas TPCD beat satori at this point.

But satori motor has bad design flaw its motor for a high end speaker, like you see from klippel picture. Satori has very high IMD distortion. Even cheaper SB17 -series is much better. I'm 100% sure that seas TPCD beat satori at this point.

- Home

- Loudspeakers

- Multi-Way

- SEAS "textreme" launching soon