Patrick, can you provide details (specs., supplier) and photos of the magnet you added to the A26RE4?May it help:

I bulid a O96? clone AR26(magnet add+ DIY phase plug) + Morel378

The XOver is relative simple, the sound is comparable my AN E Silver Hemp

View attachment 1007523View attachment 1007524

1m distance in room (REW)

View attachment 1007525

1cm in the reflex portView attachment 1007528

1cm from the bass port

View attachment 1007526

bought from:Patrick, can you provide details (specs., supplier) and photos of the magnet you added to the A26RE4?

https://europe-audio.com/Product.asp?mfr=Scan-Speak&part=107004&Product_ID=8156

Thanks, Patrick.

Have you measured the resulting change in woofer Qtc and sensitivity?

out of frustration with another project i dusted off some old drivers; seas 25fewx and altec 806/511b, wow this combo sounds so good, why do i even bother building something else i wonder...

What cabinet did you use for the SEAS? Do you have a picture? I also have a few 25few's that I should do something with. I was thinkog of using a good sized sealed squat tower (60~70 liters) but.... what did you do?out of frustration with another project i dusted off some old drivers; seas 25fewx and altec 806/511b, wow this combo sounds so good, why do i even bother building something else i wonder...

it is really not much to see but here you go 😎

the cabs are recycled from an old subwoofer project, 45 liter closed and fully stuffed with dacron fill

25fewx has stronger magnets then 25few so smaller cabs are fine, 70 liters sounds fine for your drivers but even bigger is better for lower Q

compared to what i am used to, this setup releases "tsunamis" of soundwaves, it sounds big and clean, i like it a lot

now i would like to try modern drivers in a similar setup

the cabs are recycled from an old subwoofer project, 45 liter closed and fully stuffed with dacron fill

25fewx has stronger magnets then 25few so smaller cabs are fine, 70 liters sounds fine for your drivers but even bigger is better for lower Q

compared to what i am used to, this setup releases "tsunamis" of soundwaves, it sounds big and clean, i like it a lot

now i would like to try modern drivers in a similar setup

spot on times three 🙂Boredom, curiosity, wondering if the grass is greener on the other side of the fence.....lll

it is really not much to see but here you go 😎

the cabs are recycled from an old subwoofer project, 45 liter closed and fully stuffed with dacron fill

25fewx has stronger magnets then 25few so smaller cabs are fine, 70 liters sounds fine for your drivers but even bigger is better for lower Q

compared to what i am used to, this setup releases "tsunamis" of soundwaves, it sounds big and clean, i like it a lot

now i would like to try modern drivers in a similar setup

Thanks for posting that picture, celef.

Hi Dave,No pictures.

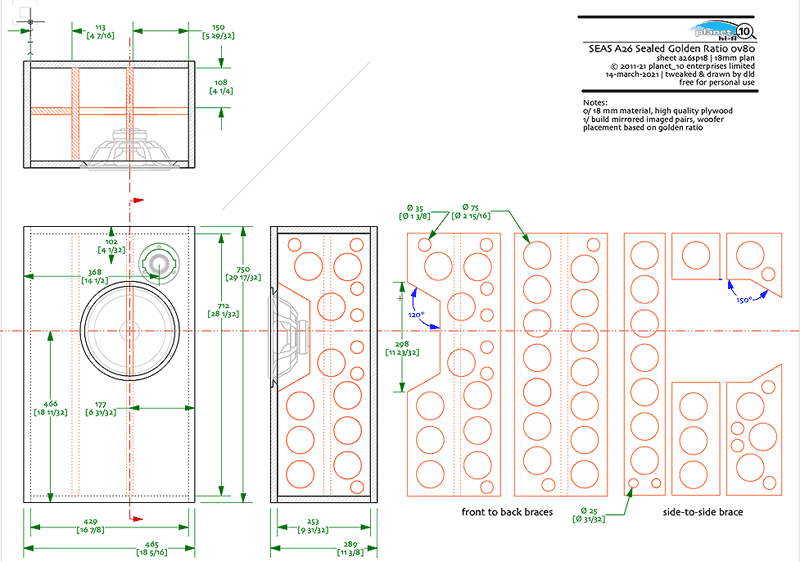

Do measure your plywood thickness before cutting. It is unlikely to be ¾”/19.05 mm.

If you cut assuming that, you could be in trouble,

dave

Working through the larger sealed cabinet (pg 22) of your file. I wanted to thank you for the plans, and mention that it might be helpful to add a measurement for the depth of the woofer basket cutout in the vertical brace (I approximated it when doing mine) as well as adding the dimension for the top/bottom depth on the cut sheet. LMK if I'm just missing it somewhere!

The depth of the holey brace cutout is purposely left out. This forces you to do measurements to get the right depth. Thta will ensure you take into account the details of material thickness and other details that i can onl guess at. Getting the fit just right is not all that easy.

Top/bottom depth is the same as the inside depth of the box.

dave

Top/bottom depth is the same as the inside depth of the box.

dave

Ahh that makes good sense! Should that brace be tight on the magnet back? or should there be some air between the two?

Getting the brace to just support the basket while not stressing it is not easy. The brace can then distribute the reactive energy of the driver across the baffle, the back, and the top/bottom. Not only is this considerably more material to share the energy, and the iBeam-like structure gretly enhances rigidity.

dave

dave

Excellent! thank you for explaining. I'll dry fit everything, and measure that gap live leaving 1-2mm or so of the magnet to squish onto the brace. just checking that this was the intent of your plan.Getting the brace to just support the basket while not stressing it is not easy. The brace can then distribute the reactive energy of the driver across the baffle, the back, and the top/bottom. Not only is this considerably more material to share the energy, and the iBeam-like structure gretly enhances rigidity.

dave

I've used the ScanSpeak Aperiodic Vent to good effect. Love the A35!

In the A35 there was only a bit of “cloth” covering the slit that is the aperiodic vent.

Same technique used in some NAIM speakers.

dave

Very nice!built a clone of O/96 a couple of years ago and still hasn’t disappoint. amp on the photo is F5, I am now using Tubelab SSE in triode mode and I can say it plays clean and loud.

View attachment 1008514View attachment 1008515

I love this design!70 litres. Mostly finished this AM. Sealed. Aperidic is so you can tame the bass of a too small an enclosure.

Here is a teaser:

dave

- Home

- Loudspeakers

- Multi-Way

- SEAS A26 Devore Style Build