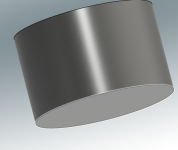

So after a long delay,, here are the files for the D7608 chamber. They're still in basic format for people to adjust scaling as needed. The design is close enough to print unmodified as long as the infill ratios are high enough. 50 - 60% is probably more than enough for adequately stiff walls. Most D7608 mids are fairly consistent to exact diameter for the chamber to fit using contact adhesive or hot melt glue. Lower infill ratios under 50% may end up being a little resonant for standard PLA filament depending on the quality or grade.

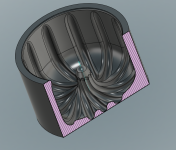

Printing it inverted (open side up) is likely the orientation that will yield the lowest print time. You will need to tweak the inside ID to fit exactly on the D7608 motor. I don’t recommend extending the inner center post of the back toroidal shape so that it touches the motor. I'd use a good quality contact adhesive to attach the chamber around the inner ID to motor edge so it can be removed later. You can also attach the chamber to the enclosure opening for the mid. Id personally do the later, as its a bit simpler to make dampening changes on the fly, not needing to be constantly re-glued.

People can post questions here or in my dome midrange thread, but its probably more organized and logical to have it in this specific D7608 thread.

The lowest cutoff for the D7608 with a basic LR2 or BW2 filter is 600 hz for acceptable lower mid output / THD ie. 100 dB max in room SPL for the stereo pair. It will also depend on the mid's distance to floor, walls, speaker baffle width, crest factor and overall EQ the music was treated with. I can't overemphasize how much a wide baffle will reinforce the lower mid output.

Anyone who uses the design, please dont share or host the files outside of these forums. You're welcome to augment or adapt the design for your own personal needs but please don't repost a changed file without asking me first. This is to avoid any confusion.

Please feel free to post all measurements and other details of your build using the D7608 on here if you so wish. I just ask that the chamber model files aren't used commercially for profit.

Again, I'd like to thank @stv for his time and efforts in getting this done for us.

Printing it inverted (open side up) is likely the orientation that will yield the lowest print time. You will need to tweak the inside ID to fit exactly on the D7608 motor. I don’t recommend extending the inner center post of the back toroidal shape so that it touches the motor. I'd use a good quality contact adhesive to attach the chamber around the inner ID to motor edge so it can be removed later. You can also attach the chamber to the enclosure opening for the mid. Id personally do the later, as its a bit simpler to make dampening changes on the fly, not needing to be constantly re-glued.

People can post questions here or in my dome midrange thread, but its probably more organized and logical to have it in this specific D7608 thread.

The lowest cutoff for the D7608 with a basic LR2 or BW2 filter is 600 hz for acceptable lower mid output / THD ie. 100 dB max in room SPL for the stereo pair. It will also depend on the mid's distance to floor, walls, speaker baffle width, crest factor and overall EQ the music was treated with. I can't overemphasize how much a wide baffle will reinforce the lower mid output.

Anyone who uses the design, please dont share or host the files outside of these forums. You're welcome to augment or adapt the design for your own personal needs but please don't repost a changed file without asking me first. This is to avoid any confusion.

Please feel free to post all measurements and other details of your build using the D7608 on here if you so wish. I just ask that the chamber model files aren't used commercially for profit.

Again, I'd like to thank @stv for his time and efforts in getting this done for us.

Attachments

I modified the bottom so it can be printed flat. This should make it way easier to print. I can post this if you want.Anyone who uses the design, please dont share or host the files outside of these forums. You're welcome to augment or adapt the design for your own personal needs but please don't repost a changed file without asking me first. This is to avoid any confusion.

Also, STEP files are the only types of files that actually print with proper curves. STL, OBJ, etc are basically a series of straight lines and you will always end up with artifacts rather than a perfectly curved object.

What is the mounting method? You just glue it on?

Attachments

Does anyone have off axis measurements of the D7608 along with the distortion measurements? I am choosing a woofer for my D7608 project and need to base that choice off of the distortion rise of the low end off the dome mid.

@Bmsluite Attachment method is via hot glue or other adhesive with the chamber opening sitting around the magnet yoke OD. This is to make it more flexible and versatile. You can of course add a flange, etc. for surface mounting inside baffle, etc.

Yes, feel free to please post the other files if you like, as long as they're titled clearly to reflect any changes. Good idea to make the bottom flat. It would have been waste material anyways if that was a big standoff support.

Yes, feel free to please post the other files if you like, as long as they're titled clearly to reflect any changes. Good idea to make the bottom flat. It would have been waste material anyways if that was a big standoff support.

Does anyone have off axis measurements of the D7608 along with the distortion measurements? I am choosing a woofer for my D7608 project and need to base that choice off of the distortion rise of the low end off the dome mid.

Have you checked out the measurements at Hificompass.com ?

Great resource.

I always forget about that site. It has it on there. ThanksHave you checked out the measurements at Hificompass.com ?

Great resource.

It's interesting that HFC's measurements show H3 and H2 distortion below 1kHz to be at the same level till 8V drive level, at which point the H2 is clearly dominant. But distortion rises steadily and steeply from a bit >1kHz to a peak at around 500Hz. Based on those curves, I'd probably cross the D7608 no lower than 600Hz, even with steep filter slopes.Does anyone have off axis measurements of the D7608 along with the distortion measurements? I am choosing a woofer for my D7608 project and need to base that choice off of the distortion rise of the low end off the dome mid.

I wonder what the SPL is at 8V input level? If the rated 80W is accepted, along with the 92 dB/2.8v/1m sensitivity, that would calculate to be around 108-110 dB max SPL. Which seems optimistic for <1kHz.

Mike,

Please click on the Axial response-

Btw, if anyone finds @HiFiCompass resource useful, please consider donating to his cause.

I cannot begin to imagine how is able to continue his work during wartime.

Please click on the Axial response-

Btw, if anyone finds @HiFiCompass resource useful, please consider donating to his cause.

I cannot begin to imagine how is able to continue his work during wartime.

Got it.The upper mid portion of the D7608 Hifi Compass measurements is pretty close to the mid's actual upper rolloff with the chamber.

Did you ever try breaking the nodes up further on the inside using the chamber? I found this type of thing extremely beneficial when designing the back cup for the GRS planar mid. With equal length walls you end up with nodes. With designs like this you can disperse the sound waves further. You also cause the waves to take longer paths around the cup which, if you fill it with dampening material, gives your dampening material more time to dissipate energies.

Also doubles as an orange juicer.

Attachments

@Bmsluite I was tempted, but dismissed it due to not having seen much promise from other similar experiences. The torroid shape actually breaks up similar radius high pressure modes.

Jeez, I didn't even think to look at the vertical scale! 🙄😵Please click on the Axial response-

- Home

- Loudspeakers

- Multi-Way

- Scanspeak D7608-9200 mid dome disassembly tips and other info