Thank you, Wrinex.very nice 🙂 i made this kind of thing a while ago. im not sure what made me dispose of it (might be my not so perfect folds) looking forward to you result ! looks great so far !

I hope that I in a day or two will have some measurements made.

I'm using a Hypertherm 45XP.damned i want a plasma cutter to 🙁 looking for an affordable one i can strap to the cnc 🙂 may i ask what one you used ? if it is a hypertherm.... i must save some more i gues haha

As I value my time a lot, I couldn't afford anything less.

First membrane mounted in a speaker:

There might be need of an extra support at the middle of the membrane.

It'll be 11 mm in height between active membranes.

There might be need of an extra support at the middle of the membrane.

It'll be 11 mm in height between active membranes.

damned a hypertherm 🙂 haha i was afraid you would own one 🙁 well if it is your work for instance !! i understand 🙂

maybe i should see if i can find a used one. i mean 1500 is allot of money 🙂

By the way i like the more simple design you build now, with the 3d printed bracket holding the steel in place. they also seem to work to not interfere 🙂 (diffraction and such)

maybe i should see if i can find a used one. i mean 1500 is allot of money 🙂

By the way i like the more simple design you build now, with the 3d printed bracket holding the steel in place. they also seem to work to not interfere 🙂 (diffraction and such)

Last edited:

I think I paid almost double that amount, with some extra consumables though.damned a hypertherm 🙂 haha i was afraid you would own one 🙁 well if it is your work for instance !! i understand 🙂

maybe i should see if i can find a used one. i mean 1500 is allot of money 🙂

Yes, when I made SLAM!, 3D printing was new for me.By the way i like the more simple design you build now, with the 3d printed bracket holding the steel in place. they also seem to work to not interfere 🙂 (diffraction and such)

I actually bought the printer after I started that project.

And I had ordered the pole pieces from a shop, they were €1.50 each.

Now I can make them for "free" with my own plasma cutter.

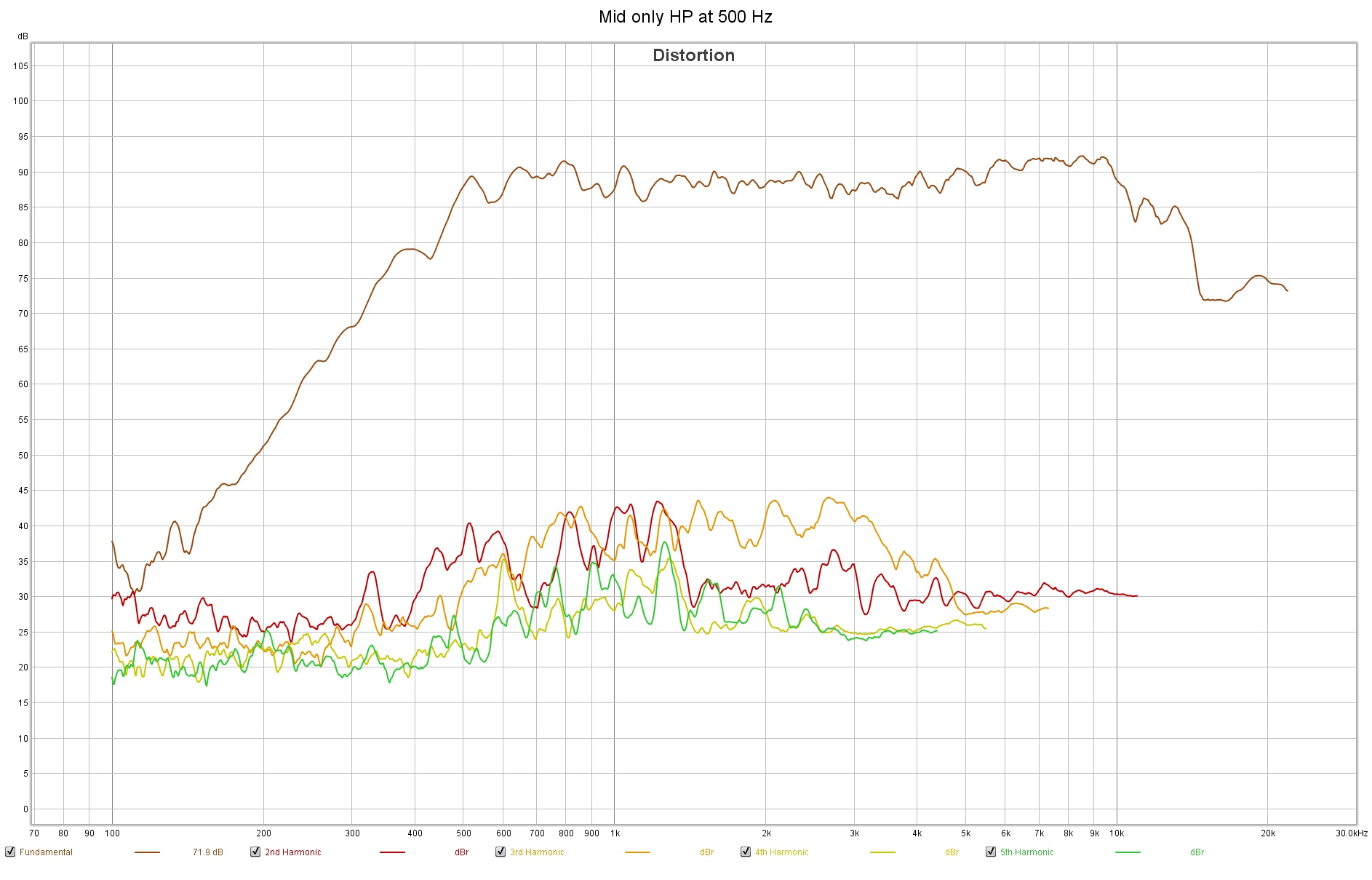

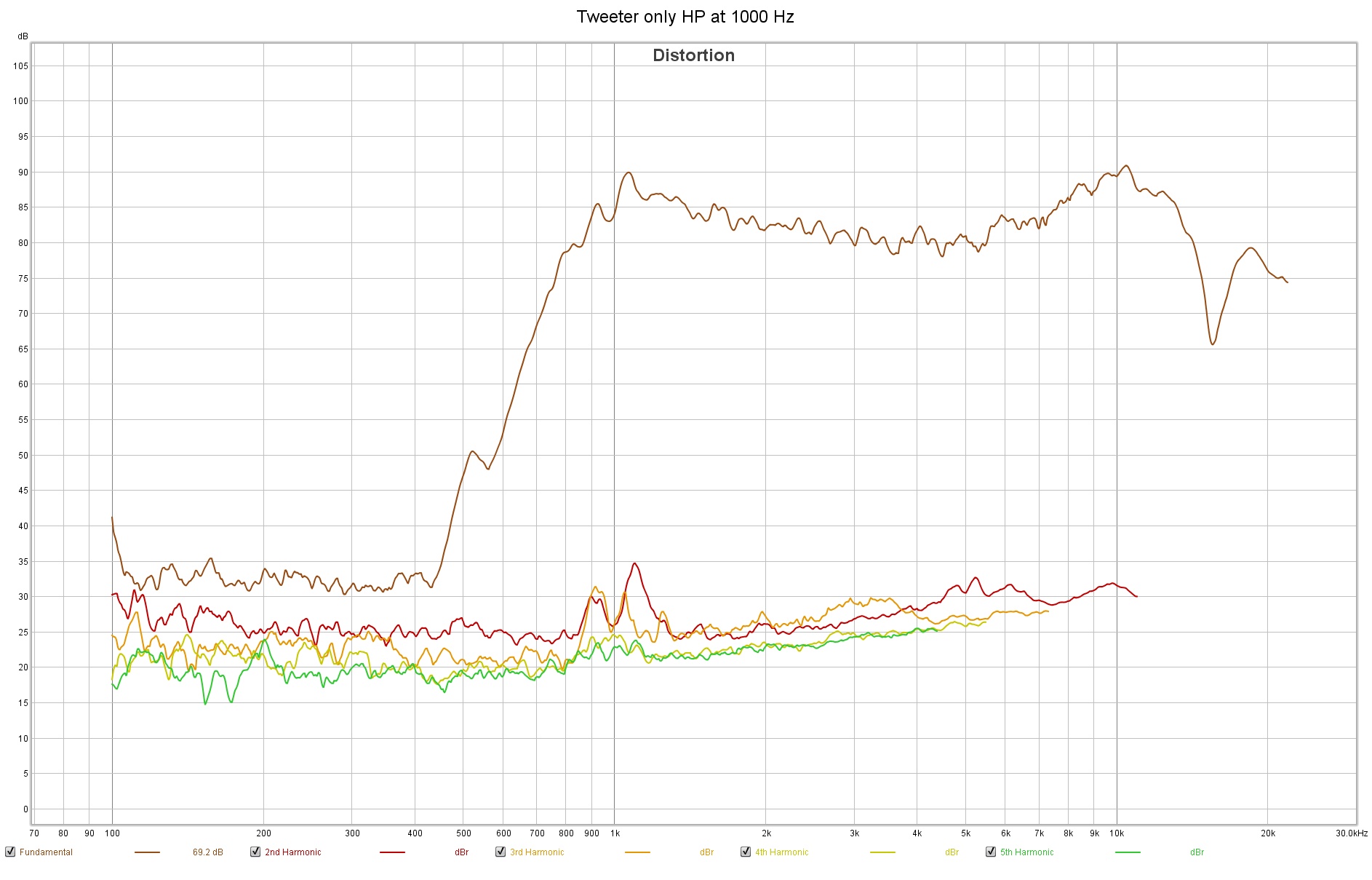

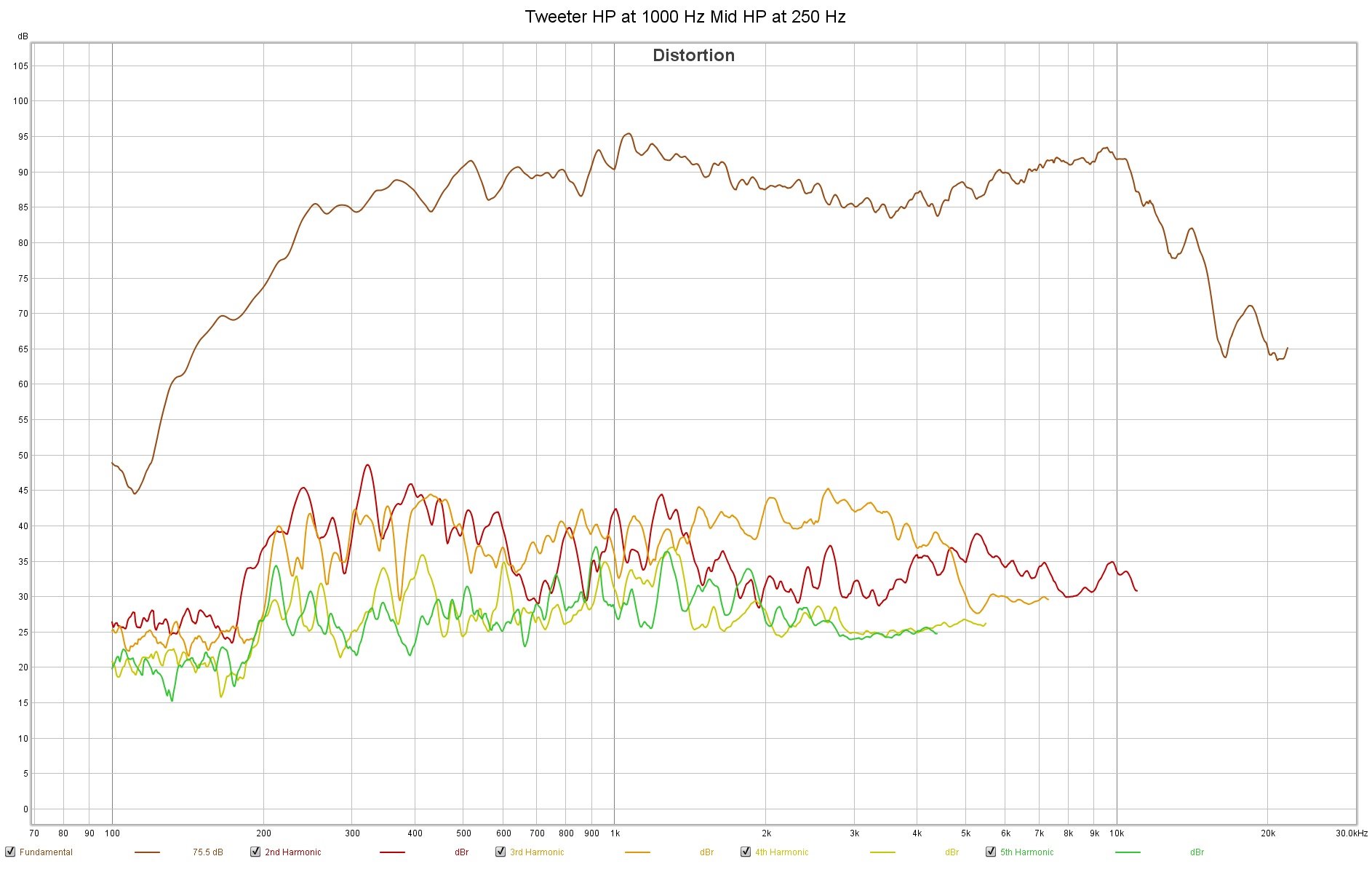

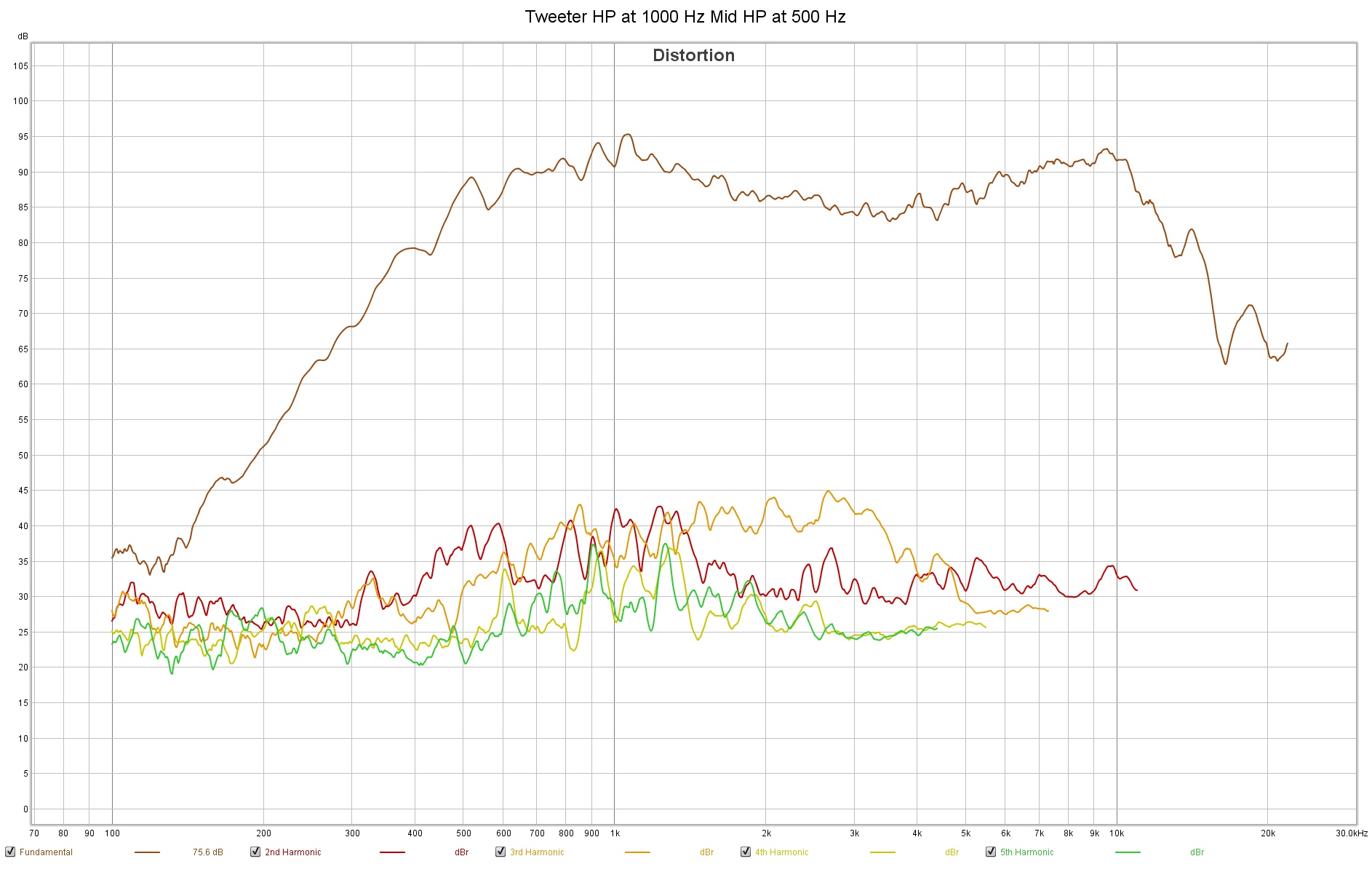

Some first measurements then at approximately 1 W.

Only two membranes and no back pole pieces.

So the SPL at 1W 1 meter is a little bit low and the distortion is a little bit high.

But I reckon that the back pole pieces will add 3 to 6 dB and they will also lower the distortion levels.

Doubling the amount of membranes twice will also add at least 6 dB.

So I guess it'll be above 95 dB in sensitivity at 1 meter for the full SALS?A!

Frequency response slopes down above 15 kHz and are more or less the same for both mid and tweeter.

I don't know how much the narrower back pole piece for the tweeter section will help.

But the tweeter section is not only about high frequency response, it will also have a muck better dispersion being only ten millimeters wide.

Only two membranes and no back pole pieces.

So the SPL at 1W 1 meter is a little bit low and the distortion is a little bit high.

But I reckon that the back pole pieces will add 3 to 6 dB and they will also lower the distortion levels.

Doubling the amount of membranes twice will also add at least 6 dB.

So I guess it'll be above 95 dB in sensitivity at 1 meter for the full SALS?A!

Frequency response slopes down above 15 kHz and are more or less the same for both mid and tweeter.

I don't know how much the narrower back pole piece for the tweeter section will help.

But the tweeter section is not only about high frequency response, it will also have a muck better dispersion being only ten millimeters wide.

Attachments

-

Mid only HP at 500 Hz.jpg327.8 KB · Views: 395

Mid only HP at 500 Hz.jpg327.8 KB · Views: 395 -

Tweeter only HP at 1000 Hz.jpg312 KB · Views: 383

Tweeter only HP at 1000 Hz.jpg312 KB · Views: 383 -

Tweeter HP at 1000 Hz Mid HP at 250 Hz.jpg343.9 KB · Views: 402

Tweeter HP at 1000 Hz Mid HP at 250 Hz.jpg343.9 KB · Views: 402 -

Tweeter HP at 1000 Hz Mid HP at 500 Hz.jpg332.8 KB · Views: 389

Tweeter HP at 1000 Hz Mid HP at 500 Hz.jpg332.8 KB · Views: 389 -

Tweeter HP at 1000 Hz Mid HP at 500 Hz At 1 m.jpg329.7 KB · Views: 382

Tweeter HP at 1000 Hz Mid HP at 500 Hz At 1 m.jpg329.7 KB · Views: 382

Last edited:

I'm thinking of adding supports for the tweeter part of the membrane.

If I replace an ordinary 3 mm back pole piece with a 1 mm tweeter support:

together with a 2 mm back pole piece:

I'll get four 65 mm sub-sections and the HF response should get better.

The rest of the back pole pieces are still 3 mm thick.

If I replace an ordinary 3 mm back pole piece with a 1 mm tweeter support:

together with a 2 mm back pole piece:

I'll get four 65 mm sub-sections and the HF response should get better.

The rest of the back pole pieces are still 3 mm thick.

I did four supports, so there's five sub sections in a membrane

The support also helps keeping the mid in the middle of the gap deepth.

Now I got to make 66 3 mm back pole pieces and then I can redo the measurements above.

The support also helps keeping the mid in the middle of the gap deepth.

Now I got to make 66 3 mm back pole pieces and then I can redo the measurements above.

Measurements on the same two membranes but now with the back pole pieces.

No HP filtering and still with 1 W input power:

So SPL went up overall by 6 dB!

One can see that the tweeter needs a HP filter at 2 kHz or so but the mid HP filter can be lower than the current 500 Hz.

Lets see how it all plays later in the complete system.

With some FIR filtering this is going to be good.

So now I have to produce the rest; this was only an eight.

No HP filtering and still with 1 W input power:

So SPL went up overall by 6 dB!

One can see that the tweeter needs a HP filter at 2 kHz or so but the mid HP filter can be lower than the current 500 Hz.

Lets see how it all plays later in the complete system.

With some FIR filtering this is going to be good.

So now I have to produce the rest; this was only an eight.

Horizontal dispersion; -45° to 45°. The order is given by the colors given at vertical cursor at 10.29kHz.

Measured at 1 W and 60 cm distance.

It is hard to read because of the reflections from the room and furniture, but I think it looks as expected.

An externally hosted image should be here but it was not working when we last tested it.

Measured at 1 W and 60 cm distance.

It is hard to read because of the reflections from the room and furniture, but I think it looks as expected.

I decided to try to get rid of the Helmholtz dips.

So I made a diffuser for the front pole piece so that the distance to the open fold is less and thus should result in higher cutoff frequencies.

They are to be glued with cyanoacrylate glue:

So I made a diffuser for the front pole piece so that the distance to the open fold is less and thus should result in higher cutoff frequencies.

They are to be glued with cyanoacrylate glue:

Measurements with diffusers on all front pole pieces for one membrane.

Noise:

Sweep:

The dips for the tweeter at 14 kHz and for the mid at 11 kHz are now not that distinct, so with EQ on the tweeter between 4 and 10 kHz should do it.

I doubt that I will LP filter the mid over 10 kHz, it rolls off nicely by it self.

One alternative is to have a LP filter at 18 kHz. But on the sweep nothing is visible over 18 kHz, only on the noise measurement.

Future listening test will decide.

Noise:

Sweep:

The dips for the tweeter at 14 kHz and for the mid at 11 kHz are now not that distinct, so with EQ on the tweeter between 4 and 10 kHz should do it.

I doubt that I will LP filter the mid over 10 kHz, it rolls off nicely by it self.

One alternative is to have a LP filter at 18 kHz. But on the sweep nothing is visible over 18 kHz, only on the noise measurement.

Future listening test will decide.

I checked the magnetic flux that was simulated in this post using a hand held Digital Gauss meter TD8620.

And the simulations was very accurate, even with not having a solid pole piece but rather sparse 3 mm pole pieces with 4 mm space in between.

The magnetic flux in mid gap had 200 mT and the tweeter 400 mT.

The flux didn't change in the void between the pole pieces.

And the simulations was very accurate, even with not having a solid pole piece but rather sparse 3 mm pole pieces with 4 mm space in between.

The magnetic flux in mid gap had 200 mT and the tweeter 400 mT.

The flux didn't change in the void between the pole pieces.

Thats looking really nice ! by not using a HP you will get the 2khz distortion for the tweeter.. but in the whole realm of things that might not be a huge problem. i mean they are playing LOUUUD !

i bought myself another plasma cutter to 🙂 not as fancy as your hyperterm. but usefull for my cnc in any case, since it has a CNC port with all the controlls i need 🙂

Love your build ! a really out of the box design with all kinds of interesting ways of fabricating !

i bought myself another plasma cutter to 🙂 not as fancy as your hyperterm. but usefull for my cnc in any case, since it has a CNC port with all the controlls i need 🙂

Love your build ! a really out of the box design with all kinds of interesting ways of fabricating !

But I will have an HP at 2 kHz for the tweeter.

Yes, I have seen your success with the new plasma cutter on your Youtube channel.

Yes, it's a real use of the Silhouette, 3D printer and plasma cutter.

Yes, I have seen your success with the new plasma cutter on your Youtube channel.

Yes, it's a real use of the Silhouette, 3D printer and plasma cutter.

All membranes and back pole pieces are now mounted.

The total weight of a SALS?A! is then:

One of the eight membranes weigh:

The only thing that is left is the internal cabling:

The total weight of a SALS?A! is then:

One of the eight membranes weigh:

The only thing that is left is the internal cabling:

After a couple of hours work.

It wasn't that hard as I first thought.

I will glue the loose cables to the frame.

It wasn't that hard as I first thought.

I will glue the loose cables to the frame.

I reckon the tweeter part is only 1 gram out of those.3.2 grams... thaaaats light !

Yes, but it looks okay in the end:endless amount of pigtails 🙂

After the first LP, HP and EQ settings I can say that SALS?A! really puts the music into the room and not only in the sweet spot like SLAM! did:

It's unbelievable what 8 grams tweeter membrane and 16 grams mid membrane a side can do.

Giving music to the whole room means that the increase in SPL that I anticipated didn't happen. Removing the attenuation I had on the bases and sub bases fixed that.

So the sound stage is totally different; the horizontal dispersion due to the only 10 mm wide tweeters and the vertical dispersion due to the line source makes the

pronounced stereo separation had before gone.

The sound stage is now "whole" and the stately speakers vanishes.

I'm very pleased with the result this far.

I can still work on the membranes though when it comes to SPL, frequency response and distortion levels, but I can experiment using the now old (?) SLAM! motors.

The SALS?A! membranes have had only one iteration, so there are for sure more work to be done.

It's unbelievable what 8 grams tweeter membrane and 16 grams mid membrane a side can do.

Giving music to the whole room means that the increase in SPL that I anticipated didn't happen. Removing the attenuation I had on the bases and sub bases fixed that.

So the sound stage is totally different; the horizontal dispersion due to the only 10 mm wide tweeters and the vertical dispersion due to the line source makes the

pronounced stereo separation had before gone.

The sound stage is now "whole" and the stately speakers vanishes.

I'm very pleased with the result this far.

I can still work on the membranes though when it comes to SPL, frequency response and distortion levels, but I can experiment using the now old (?) SLAM! motors.

The SALS?A! membranes have had only one iteration, so there are for sure more work to be done.

- Home

- Loudspeakers

- Planars & Exotics

- SALS?A! - a very long story