That's a big sink for 100mA bias, it will stay rather cool.

Sink either too big or too small. Can't get it right, can I.. 🙂 Anyways, it was quite cheap and I wanted to mount whole board on the it.

Good to have something cool in the box because the four UBiBs gonna tax the ambient temperature anyway

Struggling still....so it plays music so that is something.

Still have a hiss issue and then some horrible noises further up the volume range.

I hope some of you could maybe find the time to have a quick watch of this video I made to help diagnose?

Thanks

YouTube

Just had a look at your video - the way those woofers are moving when you're changing the volume looks like you've got significant DC offset. I'd suggest disconecting the DCG3 from the rest of your system and re-doing the DC offset procedure - remember to let it warm up before tweaking the trim pots. If the offset is too high could the squealing be oscilation in the servo circuit? Once you've got the figures down to low mV at worst try listening to it before putting the servo chip back in - won't hurt for a short time and could tell you where the high frequency noise is coming from - good luck

Thanks for that. When doing the DC offset test ...with the OP amp removed.....I can get down to 2mv or so....but without shorting the inputs. If I do short them then it jumps up to several hundred mV.

Whilst this was playing last night I measured for DC at the speaker output terminals on the power amp and only saw a max of 30mv one channel and about 10mv the other.

Shall try the test you mention also thankyou. Could it prove a fried opamp ....maybe static blasted?

IDM asked me to check thevoltage on each of the BF256B drains relative to 0V, by measuring outer pins of upa68h to ground.

For this I got 13v.

Regards

James

Whilst this was playing last night I measured for DC at the speaker output terminals on the power amp and only saw a max of 30mv one channel and about 10mv the other.

Shall try the test you mention also thankyou. Could it prove a fried opamp ....maybe static blasted?

IDM asked me to check thevoltage on each of the BF256B drains relative to 0V, by measuring outer pins of upa68h to ground.

For this I got 13v.

Regards

James

From our offline discussion I recall that your BF256B CCS is producing approx 4.5mA (from memory) so appears fine, as does the DN2540 CCS.

I didn't realise your offset still jumped on shorted input. To me this does not sound right and maybe points to a damaged UPA68H. If that is so its a pain as they are hard to get out.

Cheers

Ian

I didn't realise your offset still jumped on shorted input. To me this does not sound right and maybe points to a damaged UPA68H. If that is so its a pain as they are hard to get out.

Cheers

Ian

Another question, is the noise on both channels? It would be odd to damage a transistor on both channels at the same time.

Ian

Ian

Make sure the insulation is good for each one by using the DMM's continuity buzzer anyway.

OK, got 4 out of 8 mosfet insulation failures on ultra-bibs. Worse on DCG3, only 2 out of 6 were fine. How useless are these shoulder washers.. Gonna have to go for nylon screws.

OK, got 4 out of 8 mosfet insulation failures on ultra-bibs. Worse on DCG3, only 2 out of 6 were fine. How useless are these shoulder washers.. Gonna have to go for nylon screws.

If you're drilling/tapping the heatsink, be sure to carefully countersink/debur the hole afterwards. The soft aluminum can form a raised ridge that can pierce the flexible insulator, if that's what your're using. Also never hurts to gently run the mosfet over some flat sandpaper to ensure there are no sharp parts.

BK

If you're drilling/tapping the heatsink, be sure to carefully countersink/debur the hole afterwards. The soft aluminum can form a raised ridge that can pierce the flexible insulator, if that's what your're using. Also never hurts to gently run the mosfet over some flat sandpaper to ensure there are no sharp parts.

BK

I did tap the holes, but was sure that the surface was quite clean afterwards. The insulator is regular mica pad. The main issue I think is that screws end up slightly tilted because of my "great" drilling skills 🙂 Anyways, the plastic screws should do the trick.

Thanks.

I did tap the holes, but was sure that the surface was quite clean afterwards. The insulator is regular mica pad. The main issue I think is that screws end up slightly tilted because of my "great" drilling skills 🙂 Anyways, the plastic screws should do the trick.

Thanks.

Disconnect the in and out wire connections to the DCG3 and Ubib and check again.

nash

Disconnect the in and out wire connections to the DCG3 and Ubib and check again.

nash

How does wire connections affect continuity test between mosfet and sink?

Also - if I use nylon screws, what temperature should I be worried when it will start to melt or change it's properties to hold the mosfet properly attached? Anyone had any issues with nylon screws before?

I had the same problem during my DCG3 build. I used nylon screws without issues. But being a OCD, I decided to drill and tap new holes and this time, I used the nylon washers with the metal screws without issues.

Remove the ground cable off the DCG3 and disconnect the power cables between the UBiB and DCG3 when you check for continuity. Double check and triple check, doesn't hurt.

Remove the ground cable off the DCG3 and disconnect the power cables between the UBiB and DCG3 when you check for continuity. Double check and triple check, doesn't hurt.

Could you link what nylon washers did you use? I feel like mine didn't really protect much from mosfet hole edges.I used the nylon washers with the metal screws without issues.

Remove the ground cable off the DCG3 and disconnect the power cables between the UBiB and DCG3 when you check for continuity. Double check and triple check, doesn't hurt.

Sure thing, will do once I get a chance. Thanks !

Could you link what nylon washers did you use?

For typical openings on TO-220 and even TO-247 case sizes I use these:

https://www.digikey.ca/product-detail/en/keystone-electronics/3049/36-3049-ND/40010

They are made for #4 hardware, but I use them with M3 fasteners without problem.

For typical openings on TO-220 and even TO-247 case sizes I use these:

3049 Keystone Electronics | Hardware, Fasteners, Accessories | DigiKey

They are made for #4 hardware, but I use them with M3 fasteners without problem.

I believe these are the ones I have right now. Thanks.

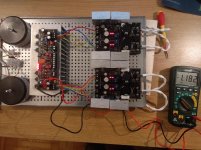

Apparently bk856er was right - I left some uneven surface after drilling that's how I got the sink touching the mosfets. After re-attaching all of the mosfets I finally got the DCG3 connected!

With R10 12R I am getting 98mA bias that is I guess close enough to 100.

UltraBiB sinks are warm after the test while DCG3 big sink has barely heated. Guess this is OK as well.

Will continue to check the DC offset with shorted inputs and later finishing up the build. So far - so good.

Attachments

Last edited:

Thanks Salas.

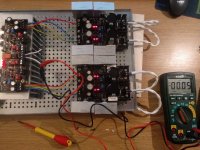

Quick update on DC offset. Without op-amp I managed easily to contain within 1mV range. Got same results with op-amp - maybe slightly more stable. One channel -0.25-0mV, other -0.50-0mV. Should be OK.

Bad news - the UltraBiB sink temperature got up during the measurement. I don't have anything right now to measure it but sink was quite hot when i touched. Will check when I get proper thermometer.

Quick update on DC offset. Without op-amp I managed easily to contain within 1mV range. Got same results with op-amp - maybe slightly more stable. One channel -0.25-0mV, other -0.50-0mV. Should be OK.

Bad news - the UltraBiB sink temperature got up during the measurement. I don't have anything right now to measure it but sink was quite hot when i touched. Will check when I get proper thermometer.

Attachments

I am quite sure all of them were quite hot after the test. Will double check though.

As you mentioned before, the sinks are quite small for it. I did flipped them over so that fat part of the sink would be closer to the center of the mosfet for better distribution.

As you mentioned before, the sinks are quite small for it. I did flipped them over so that fat part of the sink would be closer to the center of the mosfet for better distribution.

- Home

- Source & Line

- Analog Line Level

- Salas DCG3 preamp (line & headphone)