That is an interesting project. Fo you have the link for it. I have a pair of B&G neo 8 which I have not used. What frequency did you cross it at?Yes, I would like to try those but none on hand. I have used 6FE120 with B&G Neo8 in a Pro style monitor.

Oon

Check out the LS3/5A inspired speaker Tubemax made using the RTS28A and Visaton W130S:

Introduction to designing crossovers without measurement

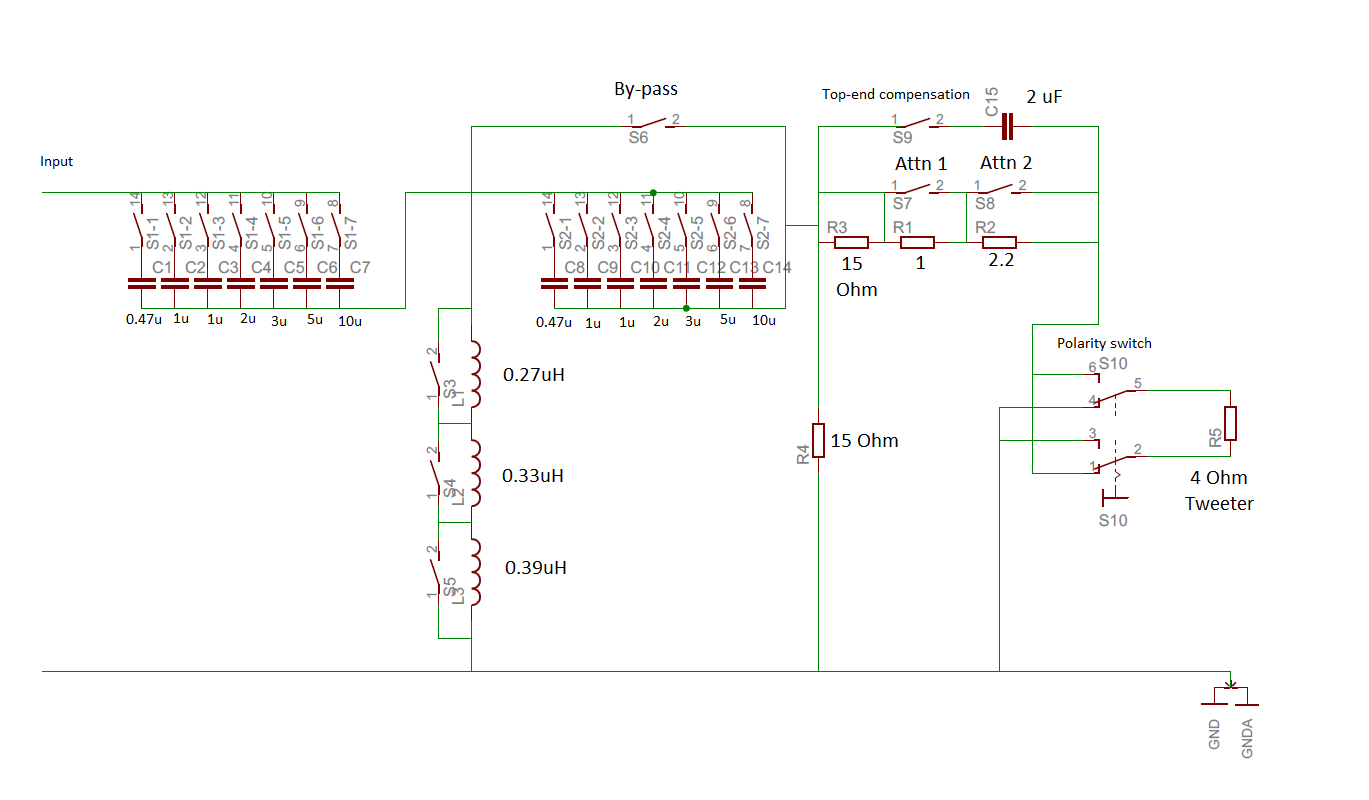

Check out his real-time crossover switch box:

Introduction to designing crossovers without measurement

Check out his real-time crossover switch box:

In Stereo at Last!

I finally had some time to finish up the second speaker and made a permanent crossover using P2P construction on a plank of wood. I even installed a real spring loaded binding post terminal cup in the back. Almost identical construction, except things go a bit faster the second time as the bracing and damping pads are all figured out.

Lots of butyl autosound damping sheets and bracing:

Melamine and eggcrate foam combo:

Driver cutouts:

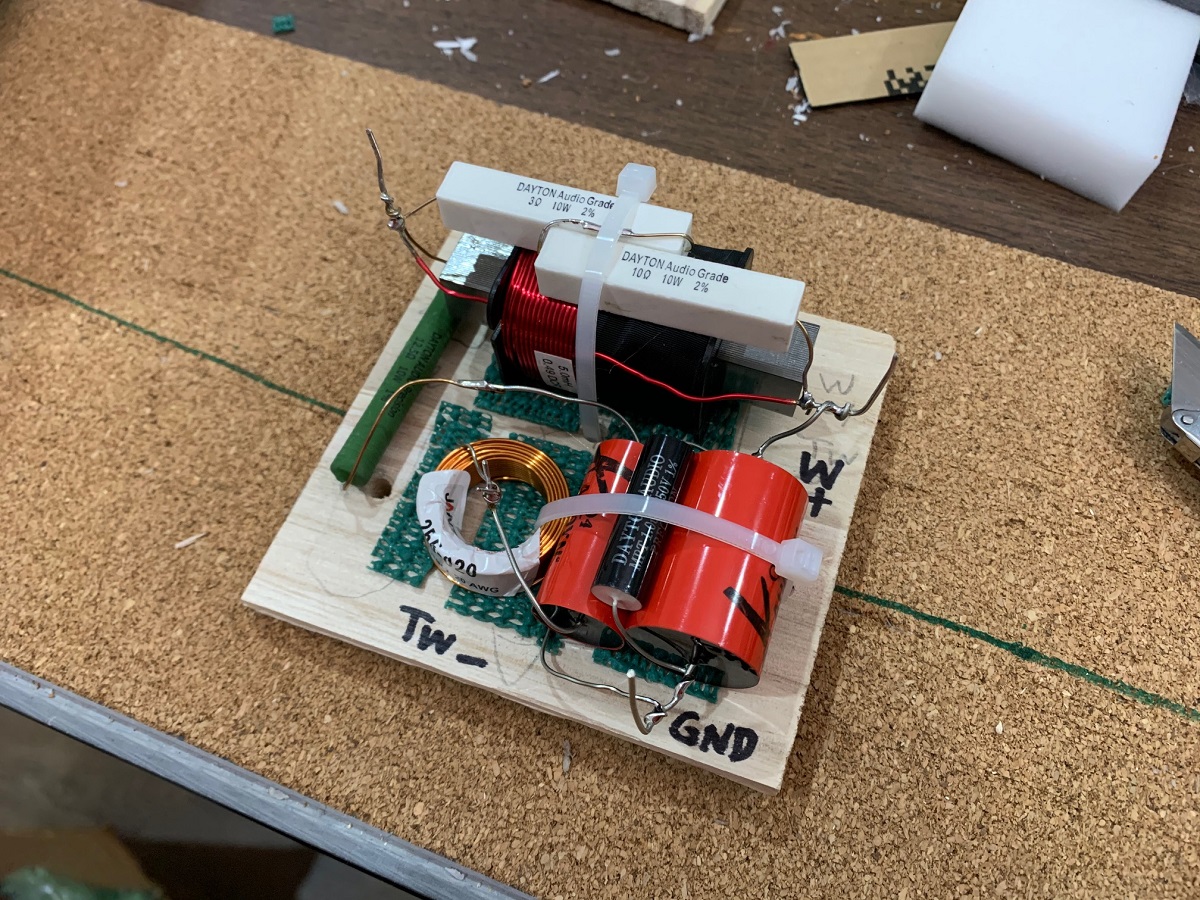

P2P XO board:

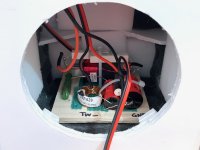

Compact little XO board stuffed inside:

Real terminal cups:

In stereo at last:

Listening to a few songs and it sounds great. Very neutral and renders vocals very well. I am surprised that I can hear bass on it, especially on stands.

I finally had some time to finish up the second speaker and made a permanent crossover using P2P construction on a plank of wood. I even installed a real spring loaded binding post terminal cup in the back. Almost identical construction, except things go a bit faster the second time as the bracing and damping pads are all figured out.

Lots of butyl autosound damping sheets and bracing:

Melamine and eggcrate foam combo:

Driver cutouts:

P2P XO board:

Compact little XO board stuffed inside:

Real terminal cups:

In stereo at last:

Listening to a few songs and it sounds great. Very neutral and renders vocals very well. I am surprised that I can hear bass on it, especially on stands.

Attachments

-

LS3-5A-Homage-Stereo-build-01.jpg351 KB · Views: 1,440

LS3-5A-Homage-Stereo-build-01.jpg351 KB · Views: 1,440 -

LS3-5A-Homage-Stereo-build-08.jpg251.6 KB · Views: 1,391

LS3-5A-Homage-Stereo-build-08.jpg251.6 KB · Views: 1,391 -

LS3-5A-Homage-Stereo-build-07.jpg280.5 KB · Views: 2,352

LS3-5A-Homage-Stereo-build-07.jpg280.5 KB · Views: 2,352 -

LS3-5A-Homage-Stereo-build-06.jpg262.4 KB · Views: 1,393

LS3-5A-Homage-Stereo-build-06.jpg262.4 KB · Views: 1,393 -

LS3-5A-Homage-Stereo-build-05.jpg278.3 KB · Views: 2,321

LS3-5A-Homage-Stereo-build-05.jpg278.3 KB · Views: 2,321 -

LS3-5A-Homage-Stereo-build-04.jpg485.8 KB · Views: 1,426

LS3-5A-Homage-Stereo-build-04.jpg485.8 KB · Views: 1,426 -

LS3-5A-Homage-Stereo-build-03.jpg310.4 KB · Views: 1,422

LS3-5A-Homage-Stereo-build-03.jpg310.4 KB · Views: 1,422 -

LS3-5A-Homage-Stereo-build-02.jpg299.3 KB · Views: 1,429

LS3-5A-Homage-Stereo-build-02.jpg299.3 KB · Views: 1,429

Hey X what do you think of the egg crate foam? I see some manufacturers using it extensively but some here think it's not really useful at all?

I ask because I have bags of the stuff free from work.

I ask because I have bags of the stuff free from work.

It’s better than nothing - you can see and hear an improvement when it’s used but melamine is superior and I use it for critical places like direct line of sight from back membrane of driver. Polyurethane foam is not as fine pore so is not as effective and it will rot in 20 years. But if you have tons of it, use it.

Yeah I've done a few little experiments with it and was surprised at how much was needed for attenuation but that said when you have bags of the stuff it becomes viable.

xrk971> watch my Box Construction Methods thread over the next two weeks. I'm using the pink Foamular foam insulation sheets. One box is foam only constructed of 1" sheet. The other will be 1/2" foam sandwiched between 1/4" MDF. I'll be using Loctite PL300 adhesive for that.

Augerpro,

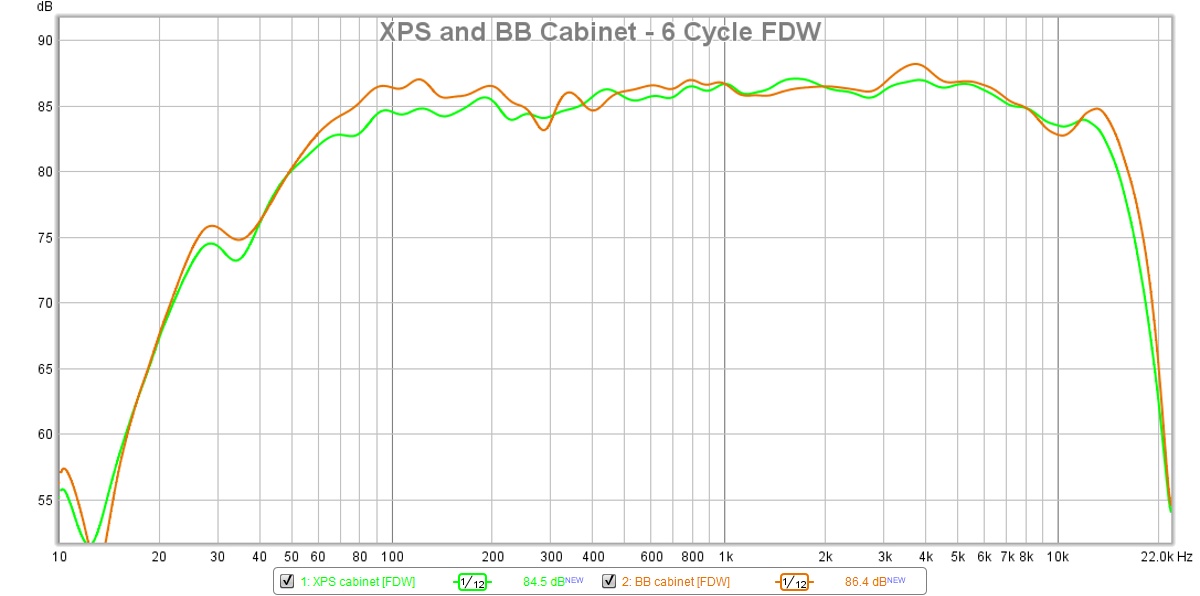

Ok - will do. XPS and thin plywood is excellent. It performs better than plain BB ply and much much lighter weight. I think you may have seen my measurements of XPS/ply vs all 3/4in BB with butyl and eggcrate foam.

10F/8424 & RS225-8 FAST / WAW Ref Monitor

It seems the BB is perhaps stiffer and for a sealed cabinet, produced a bit higher deep bass SPL. But that could purely be a function of bracing. I only had thin 3/16in plywood on the baffle. The other 5 walls was pure 1in XPS. I think your 1/4in ply and 1/2in XPS might be a magic combo.

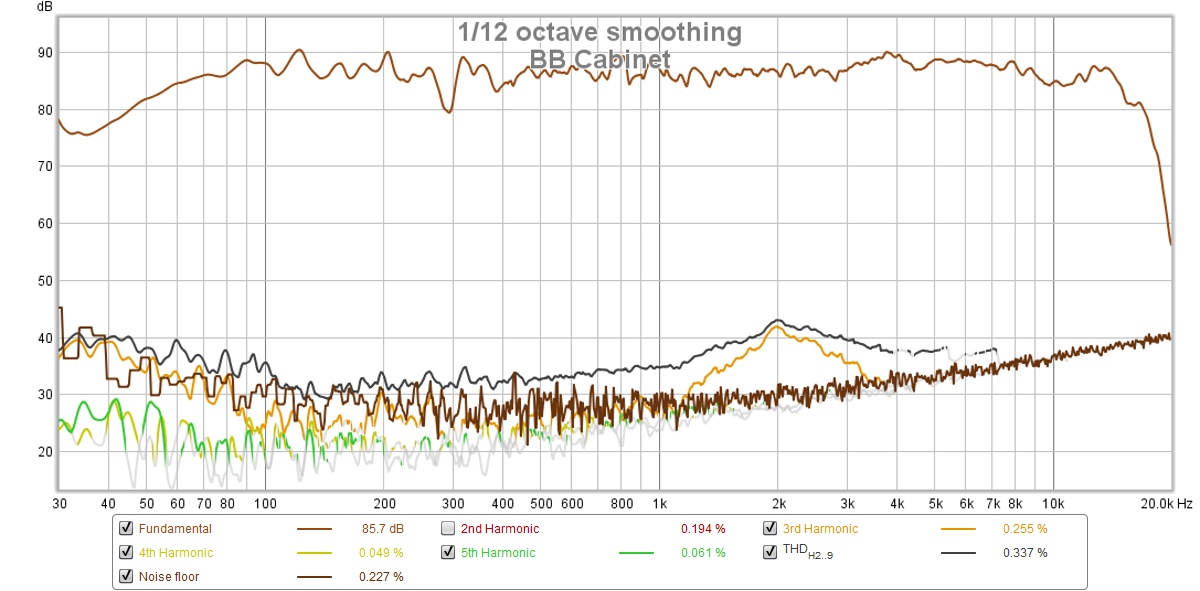

XPS:

BB:

Overlay FR:

Ok - will do. XPS and thin plywood is excellent. It performs better than plain BB ply and much much lighter weight. I think you may have seen my measurements of XPS/ply vs all 3/4in BB with butyl and eggcrate foam.

10F/8424 & RS225-8 FAST / WAW Ref Monitor

It seems the BB is perhaps stiffer and for a sealed cabinet, produced a bit higher deep bass SPL. But that could purely be a function of bracing. I only had thin 3/16in plywood on the baffle. The other 5 walls was pure 1in XPS. I think your 1/4in ply and 1/2in XPS might be a magic combo.

XPS:

BB:

Overlay FR:

I moved the FoamClone* LS3/5A speakers to the bedroom and placed on proper stands. Used a proper preamp (Aksa Lender) and proper 65w Class AB (Aspen Deltic) and wow - the sound is incredible. Never had such nice sound upstairs before in the bedroom. These speakers are small enough to fit anywhere.

*FoamClone - I’m going to have to trademark this name. 🙂

*FoamClone - I’m going to have to trademark this name. 🙂

It’s such a good sounding speaker, I am going to have a few sets of boxes made up in 1/2in BB plywood. My cabinet maker is going to make a set for himself as well. The cost of parts and hardware is about $180 so the value is really good.

Hi X,

Looking good in the neighborhood. 🙂

Pls. attach cabinet drawing for the 1/2" BB plywood build, when you get time.

I must try to build a pair of these! 😀

Thanks.

Looking good in the neighborhood. 🙂

Pls. attach cabinet drawing for the 1/2" BB plywood build, when you get time.

I must try to build a pair of these! 😀

Thanks.

Last edited:

It might be 9mm BB ply - looking at my 0.53x Karlsonator build and not sure if this small speaker even needs 12mm.

Hey X,

I just had a thought, what if you used a noico on top of another noico.That will improve on the vibration control of the cabinet.

Another thought, did you consider putting in a passive radiator? Dayton Audio has a lot of cheap passive radiators.

Oon

I just had a thought, what if you used a noico on top of another noico.That will improve on the vibration control of the cabinet.

Another thought, did you consider putting in a passive radiator? Dayton Audio has a lot of cheap passive radiators.

Oon

I have not tried two layers of butyl damping pads yet. One always seems to do the trick pretty well. I just ordered another box. I actually have some of the cheap 6.5in passive radiators. It might fit on the back but then you are changing this drastically to a vented alignment and it’s really deviating from the acoustic suspension box. It might give it some incredible bass though.

These are the ones I tried out with the Purifi:

These are the ones I tried out with the Purifi:

CAD drawing of speaker in 9mm and 12mm BB ply. I ended up making a few design choices like extending the depth from the usual 6.5in to 8in in order to get a little more bass extension. I also decided to make all the panels out of 9mm ply except for the front baffle which is 12mm since the drivers are front mounted and need extra room for a rebate. The 9mm ply was based on reading that the original in-house BBC test speakers were all 9mm wall construction. I plan to use 1/2in square beech battens all around and have the front baffle screwed in and all other panels glued together.

3D Render:

Exploded View:

2D Assembly Plan:

3D Render:

Exploded View:

2D Assembly Plan:

Attachments

Last edited:

Hi xrk971,

I have also used 9mm BB for front & back baffle, but 12mm BB for the top, bottom & sides.

Damping was done more or less as per BBC instructions - 1 layer of bitumen for sides and 2 Layers for top&bottom.

As I was assembling empty box - I noticed that back baffle wants to vibrate a lot more than predicted - so I put 1 layer of bitumen as well, together with heavy crossover was dead quiet.

I have also used 9mm BB for front & back baffle, but 12mm BB for the top, bottom & sides.

Damping was done more or less as per BBC instructions - 1 layer of bitumen for sides and 2 Layers for top&bottom.

As I was assembling empty box - I noticed that back baffle wants to vibrate a lot more than predicted - so I put 1 layer of bitumen as well, together with heavy crossover was dead quiet.

Attachments

Hi Tubemax,

What size square battens did you use? I was going to use 1/2in (12mm) bit yours seem larger maybe 18mm? Also, I’m having a hard time sourcing square beech wood stock. Might have to go with white oak or maple. I think oak is closer as it is heavier and dense.

What size square battens did you use? I was going to use 1/2in (12mm) bit yours seem larger maybe 18mm? Also, I’m having a hard time sourcing square beech wood stock. Might have to go with white oak or maple. I think oak is closer as it is heavier and dense.

- Home

- Loudspeakers

- Multi-Way

- RST28F and DC130A Foamcore Homage to LS3/5A