I currently own three tables, two are TD-124s, and one is an early Garrard 401. I've also owned a multitude of AR-XA, a TD-125 MKI, a TD-166 MKII, and had a long term loaner SME 20/2. The 401 is a work in progress so I have not yet been able to set it up and play it. The TD-125 MKI and the SME 20/2 were the tables in use at the time my first TD-124, a MKII was acquired. Once some fairly significant work was complete it completely clobbered the 125, and the SME 20 which I could have owned at considerable expense went back to its owner.

The second one a mid series original version was given to me in pieces and was missing most of what made it a 124, my best guess being that many of its parts went on an upgrade to a 121. After years of careful eBay shopping I have only the top platter left to get.. (Given what they go for I don't feel too compelled to rush out and get one.)

I've experimented with a lot of belts, and the ones that work best are those that like the original (I have two) are skinny and compliant. Stiffer belts result in a substantial increase in drive train noise.. The best I have found are either lightly used or unused vintage OEM belts (very rare) and the Schopper replacement, followed by a belt sold by a fellow in FLA which IMLE is almost, but not quite as quiet running as the Schopper. A number of initially promising belts shed some sort of petro-chemical goo that resulted in a rapidly rising level of noise. Cleaning the belt and pulley running surfaces regularly seems to be a part of necessary maintenance. (I find about once every 3 months or so is generally OK) I can't imagine that this was commonly done in the table's heyday, and indeed the OEM belt I am using on table 2 needs less attention than the Schopper on table 1..

The second one a mid series original version was given to me in pieces and was missing most of what made it a 124, my best guess being that many of its parts went on an upgrade to a 121. After years of careful eBay shopping I have only the top platter left to get.. (Given what they go for I don't feel too compelled to rush out and get one.)

I've experimented with a lot of belts, and the ones that work best are those that like the original (I have two) are skinny and compliant. Stiffer belts result in a substantial increase in drive train noise.. The best I have found are either lightly used or unused vintage OEM belts (very rare) and the Schopper replacement, followed by a belt sold by a fellow in FLA which IMLE is almost, but not quite as quiet running as the Schopper. A number of initially promising belts shed some sort of petro-chemical goo that resulted in a rapidly rising level of noise. Cleaning the belt and pulley running surfaces regularly seems to be a part of necessary maintenance. (I find about once every 3 months or so is generally OK) I can't imagine that this was commonly done in the table's heyday, and indeed the OEM belt I am using on table 2 needs less attention than the Schopper on table 1..

. In my opinion the belt exists for one reason in TD124 . To have a cheaper motor, it looks engineered also. That's what I call tinsel engineering.

If you look closely at the patent from Adrien Zahner 1957 then it is clear that they have not made the effort to use a cheap motor !

Volken

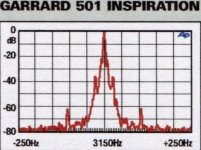

The Garrard 501 has a world record for idler drive rumble ( over most belts also ) at - 79 dB weighted. This shows it can be done.

This is indeed impressiv if I look at the speed spectrum from the 501 I see two sidebands at about 25 hz and 100hz .

I assume these are from the motor vibration ?

Volken

I wold say the TD124 has exactly the same qualities as an LP12 and more so. The metronome quality where everything sounds right. My TD124 was in Sunshine Records Oxford. Recused by a friend when it closed. Despite having an ancient system the sounds in the shop were real when playing ECM jazz that I had at home. It was too far gone so I gave it to Terry at Loricraft to fix. The motor was shot and needed new everything . Terry made the parts. It is now his wife's turntable and has been in Hi Fi World and still in the back pages.

<snip>

Someone said something about the eddy current brake. This not only sets speed it also damps the system. Much like oil would although the graph looks different. The thing to note is the graph at that point and not that magnetic damping differs from oil. Thicker oil in the bearing can help. If it results in a drastic speed change suspect it has gone too far. SAE 30 is about as thick as I would go.

If a stiffer belt could be found of good quality that might improve things. In the old days video belts might have offered a cheap solution. I doubt these exist now.

My preferred plinth is two pieces of 25 mm MDF separated by squash balls. This helps PRAT. PRAT is a quality of real music so not a bad choice. Plywood I have doubts about. Keep the plinth as minimal as possible. If stone, bottom plinth section only. Polished concrete with as many things in it as possible should work. Derby Limestone is nice. Certainly try thicker boards. You might find too thick sounds lifeless. The reason can be found with contact microphones and a spectrum analyzer going to - 80 dB. . Do not dismiss MDF as it works. This is not a loudspeaker. Metal will cause you to really need measuring tools. As Rega do on P6 seems to work.

<snip>

What might amuse you is I was asked by Thorens could I make the TD124 ? For a start if I could I would do a Garrard 301 first and secondly the TD 214 would cost >£5000 even is some of it was made in China or Vietnam. Even at that price a minimum £250 000 up front tooling costs. A lot of turntables have to be sold to do that. As long as the money was in place the TD124 is easy to do as the vital parts are still made. The motor would be easy and to be frank it is not the best they could do.

I would have built a 301 TD124 hybrid motor. I think I would have made it 6 pole and have a larger pulley to help torque. 6 pole hysteresis still exist in ducted ventilators. At least the skills to build these motors still exist ( just ). The hysteresis is a better motor type over synchronous and is almost synchronous. In my opinion the belt exists for one reason in TD124 . To have a cheaper motor, it looks engineered also. That's what I call tinsel engineering. The Garrard 501 has a world record for idler drive rumble ( over most belts also ) at - 79 dB weighted. This shows it can be done.

Hi Nigel.

Thanks for chiming in. I did some checking....you're the chief designer of the recent Garrard 501. I, for one, am very interested in what you would do as a redesign for the TD124.

After a few years of somewhat obsessive tinkering I have come to the conclusion that "almost all" of the faults of the TD124 lie with its motor, the E50. It requires a rock steady line voltage and requires a rock steady line frequency for it to operate as it was originally intended. Neither of those requirements are as well met, I suspect, as those conditions might have been back when these turntables were new.

I also think that the E50, particularly early samples, is somewhat low on power output. Perhaps this was a design intent. First version TD124 reported a weighted rumble value in the range of -40db. Second version reported better at -50db. IIRC. On this list we are familiar with the differences between the mk1 and mk2 versions and can account for the difference in rumble reduction. Motor mounting grommets.... mostly.

btw, I'm not saying that Thorens chose a cheap motor. Although costs of production had to have been a factor. It always is.

So my thoughts are that an updated motor could be a real game changer for this chassis. Some hopes rest with using the 3-phase Aussenlaufer motors from Papst....but a true 3-phase PS is required to reach that goal.

I'd be interested in further fleshing out your thoughts on a 6-pole hysterisis (301-Thorens) hybrid motor.

We notice that the motor isolation design in the 301 and 401 is quite elaborate with the motor suspended entirely by springs. And the Thorens method is quite a lot simpler hanging by studs from rubber grommets.

And now Volken at Hanze Hi-Fi is showing us a spring kit that replaces the grommets of the TD124 mounting with conical coil springs. All who have tried this claim improvements heard.

This leads me to think that another look at motor mounting on the TD124 chassis is time well spent. But how about an entirely new motor! What shape would it be?

re: eddy brake and the belt. We know that drag induced force will slow the motor somewhat. And we know that the electromagnetic eddy currents generated within the eddy brake is effective at speed pitch control on motor rpm. But there is reason to suspect that higher loadings from the eddy brake result in a somewhat higher overall drive train noise level. And the belt, which is purposefully elastic, does stretch under the combined loads of motor torque, the eddy brake and the interaction of forces betwixt idler wheel, step pulley (as capstan) and the driven platter rim.

Is a firmer belt a good idea? I speculate that it might so long as we can find one of the correct length. These days it is typical to find firmer belts that are either too short or too long and will not provide an optimal link between the motor and driven stepped pulley. Too much belt tension results in excessive drag to the motor and increased wear to motor axle bushings as well as, probably , an increase in motor vibrations.

-Steve

PS: re: LP12 talk. Probably best kept to a minimum. Only as a reference. Discussion on this thread is described in the thread title: "Restoring and Improving a Thorens TD-124 MKII".

We want to optimize these old players as best we can. And, fwiw, many of us are presently enjoying a high level of playback quality from one or more of these. We just want to see how far we can take the old design. And....might be willing to go to considerable efforts (if not expense) to achieve it.

Something strange has happened: The sound of the TD124 has gone from bad to reasonable good. I played little vinyl with the first cartridge the Denon 103 because of the sound. Later I read about the mismatch with the 3009 II i so I sold it. The same began with the Benz Gold but the last week I played several records without sound because I thought about a burn-inn period. Yesterday I listened for the first time again and the the treble sounds like it has to and the mid (tenorsax, trombone) seems to sound every time better. Wow, is there really a burn-inn periode?

This week I'm going to visit a few hifi shops. I decided now to buy nothing before having heared it here at home. I hope I can borrow a burned-inn cartridge.

A friend reviewer has tryed hundreds of turntable combinations advised me a Denon DL301. It's al about the combination according to him. One of the best is: TD124 & SME3009IIimpr & Denon 301. This will give the most realistic sound you can get. For him this SME is one of the best arms you can buy the rest is only marketing!?

So I really need some help because I am a little confused. Did I sell the Denon 103 to early? Will become the Gold very good? I don't now.

This week I'm going to visit a few hifi shops. I decided now to buy nothing before having heared it here at home. I hope I can borrow a burned-inn cartridge.

A friend reviewer has tryed hundreds of turntable combinations advised me a Denon DL301. It's al about the combination according to him. One of the best is: TD124 & SME3009IIimpr & Denon 301. This will give the most realistic sound you can get. For him this SME is one of the best arms you can buy the rest is only marketing!?

So I really need some help because I am a little confused. Did I sell the Denon 103 to early? Will become the Gold very good? I don't now.

We got the 501 to be - 79 dB with a larger mountain to climb in that no belt to help us. It is a bit of a mystery that Thorens did so much work and didn't really get the rumble they should. Thorens were very interested in the 501 and and asked could we do them a 124. I said impossible without the money to do it. I was very flattered and was told they couldn't do it also. The thing to take away from this is if Thorens can do a AR clone or whatever why can't they do a 124 ? Simple answer is too costly in the numbers that could be sold even if some of it done in China. The metal still has a world market price as one reason. The other thing to take away is if they want to do it they think it is better.

The LP12 debate made me wonder if I had entered a war zone. All I was trying to get across as an obvious fan of the LP12 I think TD124 is considerably better. And it is possibly in the top 10 at any price. The Lenco also.

The little tweaks people do wouldn't have interested Thorens. I think it sort of says to me if cheap why not otherwise be careful. If I had done the Thorens project I think the belt would have been one thing to change. It could be an upgrade for existing 124's. The Motor would be Garrard / Thorens universal. A soft toothed belt ideal like EAR use.

Keeping the motor board mass low and suspended is usually a good idea. 25 mm MDF is cheap and will say if the next move is right. That will keep rumble down as the last thing you want is a piano frame.

I have been using a TD145 recently ( TP16 DL110 ). It's my sons and I have enjoyed it. The Glasgow clown came out of the loft and it was a little better. I have 5 x TD124 at Loricratft and my 401 in pieces. I would give a lot to be using a 124 right now. As made would be fine for me with a bit of oil in the motor and new belt. Often idlers work fine even 50 years on.

The TD124 has an annoying tinkle noise in the sound. It could be the belt drive mechanism. People sell cheap cork+neoprene mats. These seem ideal and are actually superior to expensive mats in the technical sense as they are not high Q absorbers.

I think those rumble figures of the past were unreliable. When the Thorens rumble coupler was used it showed considerable differences. Mostly test disks couldn't measure it if better than - 57 dB. That says perhaps it isn't the last word in performance as the record usually will be worse.The mystery is how they could fit a belt and not get to - 60 dB? Rumble can be many things. That would be a book so best say this. Simple 50/60/100/120/25/30 Hz sinusoidal components if low enough are mostly harmless. Anything that is other than that is dreadful. If you like spike noise.

One thing you could try which I never got around to is additional drive. Find a belt from somewhere and add a motor to the exterior. The strobe will say if the arrangement works. Very cheaply it might solve the problems. It is the fact you can't exactly synchronize the speed that would work. Tape decks did this to keep the tape under tension. Same here.

In a dash. Hope not too many typo's.

The LP12 debate made me wonder if I had entered a war zone. All I was trying to get across as an obvious fan of the LP12 I think TD124 is considerably better. And it is possibly in the top 10 at any price. The Lenco also.

The little tweaks people do wouldn't have interested Thorens. I think it sort of says to me if cheap why not otherwise be careful. If I had done the Thorens project I think the belt would have been one thing to change. It could be an upgrade for existing 124's. The Motor would be Garrard / Thorens universal. A soft toothed belt ideal like EAR use.

Keeping the motor board mass low and suspended is usually a good idea. 25 mm MDF is cheap and will say if the next move is right. That will keep rumble down as the last thing you want is a piano frame.

I have been using a TD145 recently ( TP16 DL110 ). It's my sons and I have enjoyed it. The Glasgow clown came out of the loft and it was a little better. I have 5 x TD124 at Loricratft and my 401 in pieces. I would give a lot to be using a 124 right now. As made would be fine for me with a bit of oil in the motor and new belt. Often idlers work fine even 50 years on.

The TD124 has an annoying tinkle noise in the sound. It could be the belt drive mechanism. People sell cheap cork+neoprene mats. These seem ideal and are actually superior to expensive mats in the technical sense as they are not high Q absorbers.

I think those rumble figures of the past were unreliable. When the Thorens rumble coupler was used it showed considerable differences. Mostly test disks couldn't measure it if better than - 57 dB. That says perhaps it isn't the last word in performance as the record usually will be worse.The mystery is how they could fit a belt and not get to - 60 dB? Rumble can be many things. That would be a book so best say this. Simple 50/60/100/120/25/30 Hz sinusoidal components if low enough are mostly harmless. Anything that is other than that is dreadful. If you like spike noise.

One thing you could try which I never got around to is additional drive. Find a belt from somewhere and add a motor to the exterior. The strobe will say if the arrangement works. Very cheaply it might solve the problems. It is the fact you can't exactly synchronize the speed that would work. Tape decks did this to keep the tape under tension. Same here.

In a dash. Hope not too many typo's.

Something strange has happened: The sound of the TD124 has gone from bad to reasonable good. I played little vinyl with the first cartridge the Denon 103 because of the sound. Later I read about the mismatch with the 3009 II i so I sold it. The same began with the Benz Gold but the last week I played several records without sound because I thought about a burn-inn period. Yesterday I listened for the first time again and the the treble sounds like it has to and the mid (tenorsax, trombone) seems to sound every time better. Wow, is there really a burn-inn periode?

This week I'm going to visit a few hifi shops. I decided now to buy nothing before having heared it here at home. I hope I can borrow a burned-inn cartridge.

A friend reviewer has tryed hundreds of turntable combinations advised me a Denon DL301. It's al about the combination according to him. One of the best is: TD124 & SME3009IIimpr & Denon 301. This will give the most realistic sound you can get. For him this SME is one of the best arms you can buy the rest is only marketing!?

So I really need some help because I am a little confused. Did I sell the Denon 103 to early? Will become the Gold very good? I don't now.

That's correct. DL110 also. I am trying to build a bespoke pre amp for DL110. It needs a gain of about 300 to 500 at a guess. PCL 86 or all transistor. Trying for once not to use op amps. DL110 needs mass also to be ideal > 15 g inc DL110 I would say. Fo = 10 Hz would be ideal. Mostly arm differences if a good arm are only mass. Sorry to say most people have it badly wrong. If a motor car it would fail it's test certificate.

This is indeed impressiv if I look at the speed spectrum from the 501 I see two sidebands at about 25 hz and 100hz .

I assume these are from the motor vibration ?

Volken

View attachment 444258

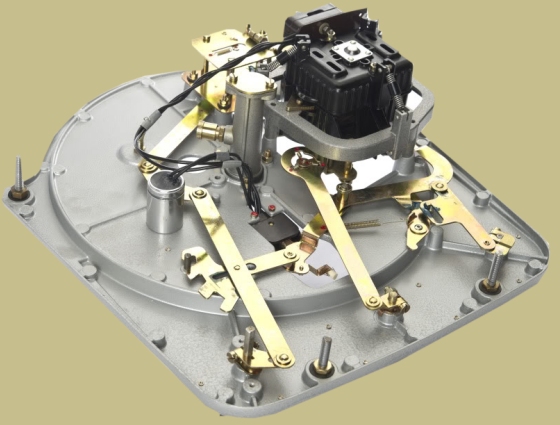

It's many small things. The motor is very good. Built in the Black Forset would you believe by a gentleman called Martin who is ill health retired. Matin is the engineer I like best. After a Fomular one supplier messed up about 10 motors Martin was asked by my engineer Martina ( ex Thorens) to fix the problem. Martin said the reason they failed is they were rushing the job. He took a gamble that despite the way the rotor is made it can be dynamically made stable if very accurately centred . He took days to set up the work and minutes to do it. The result was no need for any balancing. What I found is balancing should only be on a 99% perfect motor. As 99% can not be achieved quickly that's the problem. Rega have this problem with the main bearing . It takes a week to get things ready. After that is is very quick.

The motor is on an air suspension thrust bearing . This also finds the magnetic centre of the motor. Almost certainly all other motors do not. This means there is no chaotic noise in the spectrum. In fact the noise looks like an AM transmitter as drawn for text books. The better the bearings work the lower the amplitude of that noise. The motor is a rotating transformer if the hysteresis type as both TD124 and Garrard have. The two are very similar with Garrard using a bit more metal. To my mind the hysteresis motor is the better type we have. It does not pulsate or distort the AC waveform as much as synchronous. A lightly loaded hysteresis is almost synchronous.

Some noise was reduced by diamond lapping the bearings. Linn taught me that. Doesn't need special tools even. Finest grade surface needed. Can not say more alas.

Low distortion PSU also. Alas pointless on TD124 I found. The belt both is good and bad. The bad is the PSU that must help doesn't. That means the belt is too effective.

The 501 main bearing is 95% a 401. Crazy thing is people modify 401 bearings as they " know " the Garrard is rubbish. It's not rubbish. It is different. How could we get - 79 dB if it were? My guess is the bearing is good for - 85 dB as we know we cannot make a silent motor. Transrotor is - 90 dB so it is possible.

WI think those rumble figures of the past were unreliable. When the Thorens rumble coupler was used it showed considerable differences. Mostly test disks couldn't measure it if better than - 57 dB. That says perhaps it isn't the last word in performance as the record usually will be worse.The mystery is how they could fit a belt and not get to - 60 dB? Rumble can be many things. That would be a book so best say this. Simple 50/60/100/120/25/30 Hz sinusoidal components if low enough are mostly harmless. Anything that is other than that is dreadful. If you like spike noise.

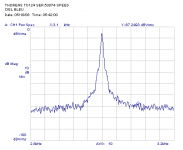

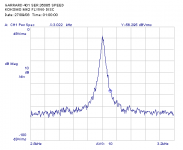

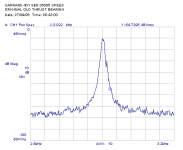

Here are a couple off measurements to concerning speed stability and other ,,rumbling,,components it is not a 1:1 compare because I don"t no the testrecord from the German test they used a 500 Hz span mine is 400 Hz measurements which is more critical .

The motor vibration at 24 Hz can be critical in combination with tonearm resonance freq. The noisefloor from the Garrard 401 is somewhat lower but don"t forget that the tonearm at the 124 is mounted on the chassis and the Garrard on the console !

Volken

The Garrard 501

Thorens TD124 after revision

Garrard 401 after revision with new bearing

Garrard 401 after revision with original bearing

tre of the motor. Almost certainly all other motors do not. This means there is no chaotic noise in the spectrum. In fact the noise looks like an AM transmitter as drawn for text books.

Are these the 25/100Hz sidebands in the speed spectrum ?

The better the bearings work the lower the amplitude of that noise. The motor is a rotating transformer if the hysteresis type as both TD124 and Garrard have.

Thorens TD124 has a 4 pole asynchr.motor same as Garrard later they used short the Papst Hyst.motor !

The two are very similar with Garrard using a bit more metal. To my mind the hysteresis motor is the better type we have.

But has also problems with vibration see in measurents I made in previous post !

Low distortion PSU also. Alas pointless on TD124 I found. The belt both is good and bad. The bad is the PSU that must help doesn't. That means the belt is too effective.

My findings and listening are opposite there is a huge improvement soundwise with a good clean 50 hz or 60hz powersupply on all turntable motors !

Not so strange if you measure the heavy distorted mains supply and read about the infuence on motor vibrations !

And the vibrations from the motor transferred to the chassis !

The 501 main bearing is 95% a 401. Crazy thing is people modify 401 bearings as they " know " the Garrard is rubbish. It's not rubbish. It is different. How could we get - 79 dB if it were?

See the measurement with the old trustbearing and new one !

Volken

Instead of placing E-50 motor on rubber grommets, why not make a two tier plinth and rest it firmly on bottom plinth ? This would isolate it from main chassis.

Regards.

Regards.

... also would like to know. If we make a hollow cavity filled with sand or ball bearings which could be fitted on center bearing shaft on bottom, will the noise/vibrations dissipate in to it ?

thanks.

thanks.

I suppose without allowing myself to believe it we did improve the 401 bearing. Well done me and I may have undersold my own work. All that was done was logical improvements. Concept the same.

As you say rotation and transformer effect in the graphs. We used 52 Hz so it should be 104 Hz.

I never came across the other motor for 124's. I would have like to see how it worked.

I made a number of PSU that people have that were on sale or return. Garrard people never returned them and TD124 nearly always did . It is very simple. If the motor is direct coupled any sine-wave distortion is accurately transmitted to the platter as if it were a loudspeaker. This is simple and logical and one of the easiest things to prove technically. The motor itself imposes a distortion limit of about -52 dB. This is more like -26 dB in a LP12 motor. The LP12 shows no obvious effect from this except to link voltage with torque and in turn sound difference. I would say LP12 has two sounds which are bad in different ways. You can not find a ideal version with that motor. TD124 is more like LP12 than Garrard with a PSU. Many PSU's have a voltage control, for a 124 I feel this is the PSU and not the distortion. Mains distortion is about 3 to 6 % THD with spectrum to 1 kHz. I doubt and in fact have proof that this is not usually caused by users. It is how the regulation works. I have the output reading of a 100KVA diesel generator doing the same with minimal load. It could be the diesel vibration. Strange it should look the same as a steam turbine alternator if so.

Some people have used a ceramic balls for 401. The Garrard bearing is very soft ( 55 Rockwell C, LP12 64 ) compared to typical . We found the life was short when used this way. Loricraft have some spacial bearings made that are harder. These will cost a fortune. Guess where they come from.

One of Thorens staff tested bearings. He concluded that the noise spectrum of Garrard or TD124 would peak about 1.5 kHz in the way we both did it. Perhaps Garrard better as it is a bronze contact point. Ceramic about 6 kHz. His solution would be to use a cracked glass shaft to stop the resonance build up. I liked that idea ( concept as he said he wanted metal like it. A coke like structure might work. It would hold oil very well. The ideal resonance would be > 40 kHz. His work was part of the - 90 dB turntable I spoke about. My friend felt 6 kHz was more of a problem than a solution.

As you say rotation and transformer effect in the graphs. We used 52 Hz so it should be 104 Hz.

I never came across the other motor for 124's. I would have like to see how it worked.

I made a number of PSU that people have that were on sale or return. Garrard people never returned them and TD124 nearly always did . It is very simple. If the motor is direct coupled any sine-wave distortion is accurately transmitted to the platter as if it were a loudspeaker. This is simple and logical and one of the easiest things to prove technically. The motor itself imposes a distortion limit of about -52 dB. This is more like -26 dB in a LP12 motor. The LP12 shows no obvious effect from this except to link voltage with torque and in turn sound difference. I would say LP12 has two sounds which are bad in different ways. You can not find a ideal version with that motor. TD124 is more like LP12 than Garrard with a PSU. Many PSU's have a voltage control, for a 124 I feel this is the PSU and not the distortion. Mains distortion is about 3 to 6 % THD with spectrum to 1 kHz. I doubt and in fact have proof that this is not usually caused by users. It is how the regulation works. I have the output reading of a 100KVA diesel generator doing the same with minimal load. It could be the diesel vibration. Strange it should look the same as a steam turbine alternator if so.

Some people have used a ceramic balls for 401. The Garrard bearing is very soft ( 55 Rockwell C, LP12 64 ) compared to typical . We found the life was short when used this way. Loricraft have some spacial bearings made that are harder. These will cost a fortune. Guess where they come from.

One of Thorens staff tested bearings. He concluded that the noise spectrum of Garrard or TD124 would peak about 1.5 kHz in the way we both did it. Perhaps Garrard better as it is a bronze contact point. Ceramic about 6 kHz. His solution would be to use a cracked glass shaft to stop the resonance build up. I liked that idea ( concept as he said he wanted metal like it. A coke like structure might work. It would hold oil very well. The ideal resonance would be > 40 kHz. His work was part of the - 90 dB turntable I spoke about. My friend felt 6 kHz was more of a problem than a solution.

Instead of placing E-50 motor on rubber grommets, why not make a two tier plinth and rest it firmly on bottom plinth ? This would isolate it from main chassis.

Regards.

Mr.J-C Verdier did this in 1980 , I tried it to with mixed results the vibration couples with the console for best results the motor must also decoupled from the bottom console.

But it goes to far from the original design and complicated a set off springs is easier with almost the same results .

Volken

It does seem Thorens didn't think clearly. Rubber is not really good enough to isolate the motor. To then fit a belt whislst leaving the back door open to vibration is daft. I am going to be a bit arrogant now and I don't intend to be. Could it be Thorens hastily came to market with something to beat Garrard 301? 301 obviously had rumble although not really with a mono pick ups. Something tells me this was done in a rush. The motor is a little bit cheaply made. The money is then given to the beautiful drive gear. Something is a little bit wrong here and I would loved to be told why. The haste might have been to win when Stereo was in full production. Garrard revised the 301 which helped when stereo ( about S No 50 000) . 401 is a less good 301 . The late numbered 401 gets it right. 401 is still very good and it is what I use. In my heart 301 is better. I think the world accepts the 501 is a good turntable. If someone said to me 301 is better I would have to agree as it is the one that taught everybody. The difference is not enough to get excited about between 301 and 501. If someone says 301 rumbles I will say CD players don't.

Some of the story is to be found in Joachim Bung's book "Swiss Precision" on the TD-124, I have it.

The TD-124 came to market primarily because the U.S. importer Elpa was impressed with the prototype and of course the 301 preceded it by a couple of years so time probably was of the essence.

Compromises were made to keep it within a certain budget range, it was expensive even for the U.S. market when it was introduced in the 1956/57 time frame.

The owners of Thorens (Thorens family) stipulated at the time that Louis Thevenaz the designer of the TD-124 try and reuse some components from predecessor table CBA83. I think the motor might have been one of these. The prototype table also used the tone arm from this table, but I don't think made it into production with this as an option. Thorens for example was aware of non-magnetic iron for the platter as Schopper currently produces, but this was too expensive at the time for consideration. (The later zamac platter abomination fitted more or less as standard to U.S. bound TD-124 MKII was undoubtedly more about cost reduction than improving compatibility with LOMC then becoming popular. I use cast iron platters on both tables now equipped with modern Ortofon SPUs and also have two ugh zamac platters which ring like a proverbial bell - you can hear it quite clearly even with cork/rubber mats.)

Given the fact that the table is variable speed I am not sure that anything other than the shaded pole induction motor was going to be a practical choice. Fairchild did make a TT with electronic speed control and a synchronous motor, but it was extremely expensive by the standards of the day.

I've actually worked on a table from the very first year of production, serial number <1100.

I think in the context of the time, cost and materials technology somewhat constrained the choices of materials used. The 124 is certainly much simpler than the early 401 I own, and probably outperforms it as well. (I'll know soon enough)

The TD-124 was not an inexpensive table to purchase during its lifetime. My dad's entire stereo system purchased in 1961 cost about as much as just a TD-124 with an SME 3009 series arm (no cartridge or plinth) just to give you a little perspective.

The TD-124 does have a lot of flaws, I live with two of them, and it is a rare week where I am not reminded of their imperfections. The motor and clever drive train are both a strength and weakness, depending on how willing/fussy you are about maintenance. I own a 3 phase Papst I acquired from user510 and a Mark Kelly controller I am slowly assembling to run it. This will eventually makes its way into one of the two tables - which I have not decided yet. I may borrow a note from Win Tinnon and modify the Papst to reduce the wind noise at some point.

I am running one of these tables on a precision power source (50/60Hz xtal controlled low distortion sine source, 100 - 120V, 200 - 240V output, 40VA) of my devising, I will say the differences in performance are not earth shattering. It makes me feel better, but other than that I am not sure. The voltage stability is perhaps the major benefit. It was built to run the 401 on 50Hz but since that table is not ready it got repurposed....

All of these comments aside, I can't think of another table I would rather own, and I have had a few options. A 501 would be very nice! 😀 However well beyond my reach..

The TD-124 came to market primarily because the U.S. importer Elpa was impressed with the prototype and of course the 301 preceded it by a couple of years so time probably was of the essence.

Compromises were made to keep it within a certain budget range, it was expensive even for the U.S. market when it was introduced in the 1956/57 time frame.

The owners of Thorens (Thorens family) stipulated at the time that Louis Thevenaz the designer of the TD-124 try and reuse some components from predecessor table CBA83. I think the motor might have been one of these. The prototype table also used the tone arm from this table, but I don't think made it into production with this as an option. Thorens for example was aware of non-magnetic iron for the platter as Schopper currently produces, but this was too expensive at the time for consideration. (The later zamac platter abomination fitted more or less as standard to U.S. bound TD-124 MKII was undoubtedly more about cost reduction than improving compatibility with LOMC then becoming popular. I use cast iron platters on both tables now equipped with modern Ortofon SPUs and also have two ugh zamac platters which ring like a proverbial bell - you can hear it quite clearly even with cork/rubber mats.)

Given the fact that the table is variable speed I am not sure that anything other than the shaded pole induction motor was going to be a practical choice. Fairchild did make a TT with electronic speed control and a synchronous motor, but it was extremely expensive by the standards of the day.

I've actually worked on a table from the very first year of production, serial number <1100.

I think in the context of the time, cost and materials technology somewhat constrained the choices of materials used. The 124 is certainly much simpler than the early 401 I own, and probably outperforms it as well. (I'll know soon enough)

The TD-124 was not an inexpensive table to purchase during its lifetime. My dad's entire stereo system purchased in 1961 cost about as much as just a TD-124 with an SME 3009 series arm (no cartridge or plinth) just to give you a little perspective.

The TD-124 does have a lot of flaws, I live with two of them, and it is a rare week where I am not reminded of their imperfections. The motor and clever drive train are both a strength and weakness, depending on how willing/fussy you are about maintenance. I own a 3 phase Papst I acquired from user510 and a Mark Kelly controller I am slowly assembling to run it. This will eventually makes its way into one of the two tables - which I have not decided yet. I may borrow a note from Win Tinnon and modify the Papst to reduce the wind noise at some point.

I am running one of these tables on a precision power source (50/60Hz xtal controlled low distortion sine source, 100 - 120V, 200 - 240V output, 40VA) of my devising, I will say the differences in performance are not earth shattering. It makes me feel better, but other than that I am not sure. The voltage stability is perhaps the major benefit. It was built to run the 401 on 50Hz but since that table is not ready it got repurposed....

All of these comments aside, I can't think of another table I would rather own, and I have had a few options. A 501 would be very nice! 😀 However well beyond my reach..

I met those people I believe with the old Thorens director Mr Leitner ( spelling ). The gentleman was importer for Thorens before WW2 and also sold Garrard, He in his later 90's I would guess? Mr L I was told was a pianist of some talent who would not play in public. His father was the conductor of the same name. CBA83 is interesting. Don't take anything I say as criticism of TD124. All I am saying is maybe with care it can be even better.

Hysteresis and speed control is a good point. So obvious that it is easily forgotten. Not least when TD125 and 501 use a variable oscillator. TD 125 is the turntable that most interested me when young. Garrard claimed the eddy current brake was to suit 190 to 270 V where frequency was usually not too bad. The old Empire, Belgium sometimes went down to 190 V. The speed control wasn't really meant for people with perfect pitch, just a way of making it work anywhere. In UK usually 2 marks into minus would be about right when 240 V. 220/110 would be centre more or less. The hysteresis motor seems to produce the most torque for least vibration. The elastic way the rotor can follow the rotating stator field is the reason it works so well. A synchronous will fight.The Garrard using 16 watts has less vibration than the Linn using circa 1/2 watt.

I too would love to own a 501. I took the prototype home at Christmas with it's stainless steel chassis.Time had overtaken us. It was to go to CES and Terry had left it very late. Now for something I had forgotten. The only arm that would fit was a slightly broken series 2 SME. Looking in the workshop I found a a Shure M44/7. This I know to be a marriage made in heaven and possibly my favourite modern Shure. People never use them in high end so have no idea how good it is. Try > 68 K loading and build it a special pre amp. Decca London meets DL103 . It is the dynamic range which if Douglas Self is right is mildly superior to anything. It was also chosen as I couldn't find a bias weight. It was in a skeletal plinth. Dark side of the Moon was played and after thinking it sounded OK I corrected myself and said the best I ever heard it. Then the thing I only play if my mood is right. Messiaen The Quartet For The End Of Time. Stunning, I played it 1 1/2 times. I didn't go to bed that night.

Hysteresis and speed control is a good point. So obvious that it is easily forgotten. Not least when TD125 and 501 use a variable oscillator. TD 125 is the turntable that most interested me when young. Garrard claimed the eddy current brake was to suit 190 to 270 V where frequency was usually not too bad. The old Empire, Belgium sometimes went down to 190 V. The speed control wasn't really meant for people with perfect pitch, just a way of making it work anywhere. In UK usually 2 marks into minus would be about right when 240 V. 220/110 would be centre more or less. The hysteresis motor seems to produce the most torque for least vibration. The elastic way the rotor can follow the rotating stator field is the reason it works so well. A synchronous will fight.The Garrard using 16 watts has less vibration than the Linn using circa 1/2 watt.

I too would love to own a 501. I took the prototype home at Christmas with it's stainless steel chassis.Time had overtaken us. It was to go to CES and Terry had left it very late. Now for something I had forgotten. The only arm that would fit was a slightly broken series 2 SME. Looking in the workshop I found a a Shure M44/7. This I know to be a marriage made in heaven and possibly my favourite modern Shure. People never use them in high end so have no idea how good it is. Try > 68 K loading and build it a special pre amp. Decca London meets DL103 . It is the dynamic range which if Douglas Self is right is mildly superior to anything. It was also chosen as I couldn't find a bias weight. It was in a skeletal plinth. Dark side of the Moon was played and after thinking it sounded OK I corrected myself and said the best I ever heard it. Then the thing I only play if my mood is right. Messiaen The Quartet For The End Of Time. Stunning, I played it 1 1/2 times. I didn't go to bed that night.

Schopper AG - Restoration of Thorens TD 135 MK I

I only had one chance to try a TD135. I liked it both for sound and size. Smaller than nearly any other transcription turntable. I suspect the arm to be very good. Sound was soft and less detailed compared with TD124.

I only had one chance to try a TD135. I liked it both for sound and size. Smaller than nearly any other transcription turntable. I suspect the arm to be very good. Sound was soft and less detailed compared with TD124.

... also would like to know. If we make a hollow cavity filled with sand or ball bearings which could be fitted on center bearing shaft on bottom, will the noise/vibrations dissipate in to it ?

thanks.

I tried a graphite thrust, it was very different sounding. Thinking about it, it is perfection in some ways. The one I fitted to a 301 came out perfect months later, took me an hour to make. I fitted on the 301 shaft a Pyrometer window ( 10 mm ) made of Pyrex. The glass bonded to the shaft using a lathe to make it true. Use a dial gauge to check ( as best you can, I used the end stock to push it flat, worked well ). The TD124 might suit even better. Graphite can be worked with simple tools. I use electrical grade for motor brushes. It would both damp and offer minimal displacement due to imperfections on the graphite surface. TD124 might need the glass thrust also. If so a slight dome shaped thrust works well or flat. I think I would put the graphite on the TD124 shaft as a dome and have a recess for the ball bearing in the graphite. The glass on the bottom set in Blu Tack, just enough to get it flat. The big deal is all of it is reversible if not the answer. I think Thorens saw that the centred ball is never that. The plastic thrust helps it work properly. The last Garrard bearing for the experimental 501 had a massive flat thrust and flat bottomed shaft. About 2 cm. The turntable rode on oil. It had a grey pattern of a different metal looking something like a milling too on the flat part. My 501 is a 301 with slightly better bits, I choose not to follow the Garrard Swindon 501 ideas, it was a belt drive.

- Home

- Source & Line

- Analogue Source

- Restoring and Improving A Thorens TD-124 MKII