Thank you both the gentlemen.

Saw some nice mods of oil well for idler shaft at schopper. Noise reduction kit Dont know how well it will retain the oil a felt washer inside inside the well and at the rubber washer at bottom would hold the oil well I think. Not sure.

Regards

Saw some nice mods of oil well for idler shaft at schopper. Noise reduction kit Dont know how well it will retain the oil a felt washer inside inside the well and at the rubber washer at bottom would hold the oil well I think. Not sure.

Regards

...just remembered. I also did the oil well mod to a garrard turntable. Details are here. Garrard 6 400.

Hiten. I never understood the bearing of cheaper Garrard turntables. Terry just did two turntables for one of the worlds most famous bass guitarists. Can not say who. Lab 80 and 401. Used with Harmon Kardon Citation amp and speakers based on JBL all from Abbey Road Studios. The Lab 80 was fitted with a nearly new Shure M3D. It has the bad idea bearing. Sounds very good.

On the 501 we used a 301 motor at first. It had it's thrust bear ground flat. Withing two weeks it was unusable. The problem is the 501 is much more strongly coupled motor to chassis even if using similar springs. Replacing the thrust with an air suspension bearing cured it. I can only conclude that TD 124 and 301/401 are subtly worn out two weeks after purchase if 501 tells us anything. Instead of bring new problems it cured one we didn't suspect. That is most motor never centre the rotors in the field.

On the 501 we used a 301 motor at first. It had it's thrust bear ground flat. Withing two weeks it was unusable. The problem is the 501 is much more strongly coupled motor to chassis even if using similar springs. Replacing the thrust with an air suspension bearing cured it. I can only conclude that TD 124 and 301/401 are subtly worn out two weeks after purchase if 501 tells us anything. Instead of bring new problems it cured one we didn't suspect. That is most motor never centre the rotors in the field.

Hiten.

On the 501 we used a 301 motor at first. It had it's thrust bear ground flat. Withing two weeks it was unusable. The problem is the 501 is much more strongly coupled motor to chassis even if using similar springs. Replacing the thrust with an air suspension bearing cured it. .

Can you tell us more about this floathing bearing as I undertand it goes ,,floathing ,,after startup I assume the magn.field pulls the rotor up or something ?

like poles repel.

I think that applies between the stator and the rotor.

I think that applies between the stator and the rotor.

seems to support this contention.That is most motor never centre the rotors in the field.

Still it is amazing that a 40/50 year old cheaper model still functions smoothly. I like the old style of making things.Hiten. I never understood the bearing of cheaper Garrard turntables.

This bridge was built by British Co. Richardson & Cruddas in 1914 in my city. Interesting bit is the Co. sent letter to authorities that the bridge has served its life and should no longer be used. Great engineering and dedication to a product. No wonder TD-124, 301/401 are still much sought after.

How does the air suspension bearing works ?Replacing the thrust with an air suspension bearing cured it.

Regards

like poles repel.

I think that applies between the stator and the rotor.seems to support this contention.

Andrew. The effect was found on the experimental motor. I suddenly realized most motors are not able to do this very accurately as the bearings dictate the motor alignment ( clamped by them ). The effect as viewed is once raised a little bit the rotor jumps up . If raised above centre it jumps down. It is a small thing but nice to have. Linn used to have a spring and cup on the Airpax motor bottom shaft exiting the phosphor bronze. The engineer who deigned the Lingo told them it was not ideal for the same reason. As I said not something we thought about, it just came gratis. It even means it doesn't have to be critically set. It just happens or doesn't happen. The rotor prefers to be in the exact field centre given half a chance.

Nothing about the 501 is not seen in the 301 except an electronic PSU. The motor is a very large clone of the 401 motor with air thrust bearing. Nothing about it was out of this world difficult. I knew if we started to reinvent things it would not be a genuine Garrard. I did exactly what many do and make small improvements. It is a mystery to me why Garrard and Thorens never got our rumble figures.

If you are wondering how Garrard was gifted to Terry and myself . The last managing director who asks not to be named described us as " a safe pair of hands " to the Brazilian owners. Terry had visited Garrard for years selling machine tools and had said to the MD he would love to have Garrard. He was taken seriously. Living in nearby Lambourn helped. Biggest help was people who worked at Garrard. Alas many now passed on. Brian Mortimer is still alive ( Head of quality control ), His father designed the 301. Brian has restored his fathers Ford Capri Classic and drives around in it as an every day car ( 1960 ? ). Brain asked when we started 501 I will quote Brian " OMG dad was still alive, he would have stayed alive longer to help you if he had known "!

Can you tell us more about this floathing bearing as I undertand it goes ,,floathing ,,after startup I assume the magn.field pulls the rotor up or something ?

I can't but it isn't hard to invent something. Verdier says how. I was supposed to go for patent. I didn't bother.

Dear music friends,

Yesterday I went to the leading analoge shop in Holland and bought a Goldring Legacy.

After taking a lot of measures the TD124 seemed perfect and also the 3009 arm.

I am very happy with the Thorens now. Maybe next year an upgrade of the phono amp is possible.

With kind regards,

Wil

Yesterday I went to the leading analoge shop in Holland and bought a Goldring Legacy.

After taking a lot of measures the TD124 seemed perfect and also the 3009 arm.

I am very happy with the Thorens now. Maybe next year an upgrade of the phono amp is possible.

With kind regards,

Wil

Build a phono amp. It is such fun.

Out of respect to my friend Terry of Loricraft I can't say how we improved the Garrard 501 motor. What I can say is from a poor start it exceed the 301/401/TD124 on rumble.

If you remove the ball bearing from TD124 motor and lay it horizontal it will when powered find it's own centre. Tilting it slightly shouldn't change it. A marker pen on the rotating shaft to give a reference. Then construct a glass and graphite thrust. It should equal the 501 bearing. This will take some ingenuity. It might mean replacing the shaft. Then it becomes serious engineering.

As I was just going to sleep last night when I realized that not only does the bearing point cause the random or chaotic vibration it is also the transmitter of hum + rotational vibration. As said earlier the shaft bearings help control that. If this was not true we never would have reached - 79 dB as my guess is we had a 10 dB disadvantage by not having the rubber both Thorens and Garrard used.

If a new motor bottom plate was machined out of a plastic material on TD124 it might help reduce this noisy. Garrard used cast iron when 401. I think this helps. The TD124 uses the cheapest steel pressing, one grade up from baked bean can. As I don't see the top steel pressing as the real problem I suspect that can be ignored. The bottom plate could be made by hand or 3 D printer.

Out of respect to my friend Terry of Loricraft I can't say how we improved the Garrard 501 motor. What I can say is from a poor start it exceed the 301/401/TD124 on rumble.

If you remove the ball bearing from TD124 motor and lay it horizontal it will when powered find it's own centre. Tilting it slightly shouldn't change it. A marker pen on the rotating shaft to give a reference. Then construct a glass and graphite thrust. It should equal the 501 bearing. This will take some ingenuity. It might mean replacing the shaft. Then it becomes serious engineering.

As I was just going to sleep last night when I realized that not only does the bearing point cause the random or chaotic vibration it is also the transmitter of hum + rotational vibration. As said earlier the shaft bearings help control that. If this was not true we never would have reached - 79 dB as my guess is we had a 10 dB disadvantage by not having the rubber both Thorens and Garrard used.

If a new motor bottom plate was machined out of a plastic material on TD124 it might help reduce this noisy. Garrard used cast iron when 401. I think this helps. The TD124 uses the cheapest steel pressing, one grade up from baked bean can. As I don't see the top steel pressing as the real problem I suspect that can be ignored. The bottom plate could be made by hand or 3 D printer.

Build a phono amp. It is such fun.

Out of respect to my friend Terry of Loricraft I can't say how we improved the Garrard 501 motor. What I can say is from a poor start it exceed the 301/401/TD124 on rumble.

If you remove the ball bearing from TD124 motor and lay it horizontal it will when powered find it's own centre. Tilting it slightly shouldn't change it. A marker pen on the rotating shaft to give a reference. Then construct a glass and graphite thrust. It should equal the 501 bearing. This will take some ingenuity. It might mean replacing the shaft. Then it becomes serious engineering.

As I was just going to sleep last night when I realized that not only does the bearing point cause the random or chaotic vibration it is also the transmitter of hum + rotational vibration. As said earlier the shaft bearings help control that. If this was not true we never would have reached - 79 dB as my guess is we had a 10 dB disadvantage by not having the rubber both Thorens and Garrard used.

If a new motor bottom plate was machined out of a plastic material on TD124 it might help reduce this noisy. Garrard used cast iron when 401. I think this helps. The TD124 uses the cheapest steel pressing, one grade up from baked bean can. As I don't see the top steel pressing as the real problem I suspect that can be ignored. The bottom plate could be made by hand or 3 D printer.

Ok thank you I think I know how it works with the floathing bearing .

Your idea about the trustbearing in the E50 motor is interresting .

Rotor adjustment in the field is very important for min.vibration thats why all the people are messing arround with loosening bolts etc on the motor.

First thing is replace worn motor bearings if you speak about steady rotor placement.

I give it a try in a next motor E 50 revision and make some mesurements before an after.

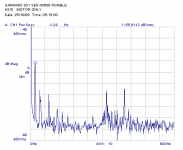

On the moment working on a old301 nice to see the vibration levels from the motor 24-100 hz and the harmonics only motor turning.

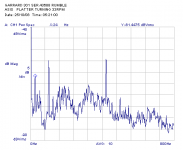

Second picture with platter turning and the extra rumble component from the idlerwheel .

Volken, I would be very interested in any 124 motor bearing improvement you came up with. I'm sold on the springs already obviously.. 😀

This seems to be real progress. Good to see someone walk the same road and enjoy the same results.

would it be useful to extract the posts and start a new Thread:

History of UK turntables 1950 to 1970?

History of UK turntables 1950 to 1970?

Andrew I think it would. The Connoisseur Craftsman should be one. The Garrard 201 also as it is a direct drive from before 1939 if I get my facts right. It might be wise to say 1970 as the ones after that are still with us.

Although highly unlikely I can find it in a hurry I might find the minutes of Mr Mortimer's early 1950's of how Garrard 201 needed to be replaced. Much of the 501 is based on going the extra mile from his report. He uses glass as a reference material when calibrating surface finish reading equipment. Simple and logical to do that. So much of what Linn shouted is in this report. I suspect it's not just Terry and I who read it?

I hope someone does BSR. I don't know much about them myself. The HT70 was my favourite and I suspect it was overlooked by everyone.

I don't think anyone should turn their noses up at the very cheap turntables. They had many good engineering ideas albeit very cheaply done.

Although highly unlikely I can find it in a hurry I might find the minutes of Mr Mortimer's early 1950's of how Garrard 201 needed to be replaced. Much of the 501 is based on going the extra mile from his report. He uses glass as a reference material when calibrating surface finish reading equipment. Simple and logical to do that. So much of what Linn shouted is in this report. I suspect it's not just Terry and I who read it?

I hope someone does BSR. I don't know much about them myself. The HT70 was my favourite and I suspect it was overlooked by everyone.

I don't think anyone should turn their noses up at the very cheap turntables. They had many good engineering ideas albeit very cheaply done.

You are right. Here is the new thread.would it be useful to extract the posts and start a new Thread:

History of UK turntables 1950 to 1970?

Interesting Turntables.

I did try consciously to post some thing related to TD-124 here. Anyway, sorry about that.

Regards.

Build a phono amp. It is such fun.

As I was just going to sleep last night when I realized that not only does the bearing point cause the random or chaotic vibration it is also the transmitter of hum + rotational vibration. As said earlier the shaft bearings help control that. If this was not true we never would have reached - 79 dB as my guess is we had a 10 dB disadvantage by not having the rubber both Thorens and Garrard used.

The hand-made Mørch GS6a with a Papst Aussenläufer motor (which is now no longer made) managed a very respectable -76dB by balancing the rotor with bits of tape!

The slightly difficult problem of TD124 is that the shaft is ground on centres. Linn and Garrard had solutions for the problem. Garrard a flat bottom correct to 0.0001" of 90 degrees and Linn concentric to 0.0001". As so much of Linns publicity reads like the 1952 paper of Mr Mortimer of Garrard I suspect Linn used his thinking. The important thing is to set a running clearence of 0.001". If any less drag will result. The oil does an excellent job of sorting out the wobble. TD124 doubles it's wobble as the ball is not perfect. The nylon thrust is a reasonable solution. I would try motor brush grade graphite. The indentation it will make is no problem as long as the ball is slightly clearing the graphite. It should fix the centre nicely. Come back 6 months later to be sure. Graphite is an ideal polution for the oil to have so no worries there. Use simple oil if possible. The later TD 160 follows Linn practice, they upped their game ( Hard to say who did it first, that wasn't the point if I am allowed an unintended pun ? Linn explained why mainly) . Rega do it best in engineering terms as they also do it very cheaply. They get it down to just the ball concentricity. Rega's whole bearing is worth replacing every 10 years. Just inspect for large contact patch. It should be a pin prick size.

Graphite choosen as it's lubricity is a bonus. 99% not that reason it was choosen. I have tried this with a 301. I found the sound very different. Not sure why ( damping with high Q ? ) . I should have tried the 401 as it would have been telling me more. 301 has too much motor rumble to say for sure better or worse. 301 is still the better turntable I know of so don't take the rumble as a problem. A CD player is the better thing if rumble matters that much. Beaing noise is a nasty version of white noise.

401 inverted the 301 flat thrust. I think Garrard realsied that the the 301 was a bit optimistic in how it worked. Who ever made that choice I think was wrong as 301 works and 401 mildly less so. It was to have less rejects. For all that my best guess is the 401 bearing > -80dB if it was possible to say. Not bad for a bearing that all the shed engineers think they can better.

Going back to the the graphite. A hardwood cup with a 7 mm graphite insert seems an idea. The wood as a universal absorber to reduce the Q a little. Wood and oil usually is OK.

TD124 reminds me of older cars. Big engineering is excellent, details not so good. That's exactly the best way as the little things can be solved. Best analogy is disc brakes. How is it drums were used so late in the day ? They even look harder to make. I saw a very recent car with upgraded wheels with drums at the rear! The little things can be wrong. Don't tell me drums are cheaper. I don't beleive it.

Graphite choosen as it's lubricity is a bonus. 99% not that reason it was choosen. I have tried this with a 301. I found the sound very different. Not sure why ( damping with high Q ? ) . I should have tried the 401 as it would have been telling me more. 301 has too much motor rumble to say for sure better or worse. 301 is still the better turntable I know of so don't take the rumble as a problem. A CD player is the better thing if rumble matters that much. Beaing noise is a nasty version of white noise.

401 inverted the 301 flat thrust. I think Garrard realsied that the the 301 was a bit optimistic in how it worked. Who ever made that choice I think was wrong as 301 works and 401 mildly less so. It was to have less rejects. For all that my best guess is the 401 bearing > -80dB if it was possible to say. Not bad for a bearing that all the shed engineers think they can better.

Going back to the the graphite. A hardwood cup with a 7 mm graphite insert seems an idea. The wood as a universal absorber to reduce the Q a little. Wood and oil usually is OK.

TD124 reminds me of older cars. Big engineering is excellent, details not so good. That's exactly the best way as the little things can be solved. Best analogy is disc brakes. How is it drums were used so late in the day ? They even look harder to make. I saw a very recent car with upgraded wheels with drums at the rear! The little things can be wrong. Don't tell me drums are cheaper. I don't beleive it.

The slightly difficult problem of TD124 is that the shaft is ground on centres. Linn and Garrard had solutions for the problem. Garrard a flat bottom correct to 0.0001" of 90 degrees and Linn concentric to 0.0001". As so much of Linns publicity reads like the 1952 paper of Mr Mortimer of Garrard I suspect Linn used his thinking. The important thing is to set a running clearence of 0.001". If any less drag will result. The oil does an excellent job of sorting out the wobble. TD124 doubles it's wobble as the ball is not perfect. The nylon thrust is a reasonable solution. I would try motor brush grade graphite. The indentation it will make is no problem as long as the ball is slightly clearing the graphite. It should fix the centre nicely. Come back 6 months later to be sure. Graphite is an ideal polution for the oil to have so no worries there. Use simple oil if possible. The later TD 160 follows Linn practice, they upped their game ( Hard to say who did it first, that wasn't the point if I am allowed an unintended pun ? Linn explained why mainly) . Rega do it best in engineering terms as they also do it very cheaply. They get it down to just the ball concentricity. Rega's whole bearing is worth replacing every 10 years. Just inspect for large contact patch. It should be a pin prick size.

Try to understand the effect on this concerning rumble levels and speedstabilty not only listening but also measurements

Can you tell how Garrard ground the shaft without using the center ?

-80 db how did they measured this ref.level ?

EMT 930 has a trustbearing were the ball is running on a hardsteel plate and a lot off oil your opinion ?

Interesting Nigel. Not intuitive though, can you touch a bit more on this shaft configuration issue wrt to bearing induced rumble? I own a 401 which I have yet to get running, but would have thought the flat ground shaft noisier than a ball bearing as found in the 124...

FWIW I am currently running mild steel thrust plates in at least one of my TD-124 main bearings and I do believe the steel thrust plate results in very slightly more noise. (I've no means to reliably measure it, but subjectively it seemed a bit noisier.)

FWIW I am currently running mild steel thrust plates in at least one of my TD-124 main bearings and I do believe the steel thrust plate results in very slightly more noise. (I've no means to reliably measure it, but subjectively it seemed a bit noisier.)

- Home

- Source & Line

- Analogue Source

- Restoring and Improving A Thorens TD-124 MKII