Measured the motor temperature of my older TD-124 which has a motor having the original bearings and felts.

This unit is a mid/late original TD-124 with cast iron platter and rebuilt main bearing. (everything on this table pretty has been rebuilt)

After an hour of operation I measured the motor temperature at the mid point between the coils and got a balmy 55 degrees C. Line voltage here is 119V 60Hz, and is supplied by an isolation transformer so there is no lurking DC present on the motor windings.

This motor is a bit noisy, truth be told, but comes up to speed quickly and is quite stable.

This unit is a mid/late original TD-124 with cast iron platter and rebuilt main bearing. (everything on this table pretty has been rebuilt)

After an hour of operation I measured the motor temperature at the mid point between the coils and got a balmy 55 degrees C. Line voltage here is 119V 60Hz, and is supplied by an isolation transformer so there is no lurking DC present on the motor windings.

This motor is a bit noisy, truth be told, but comes up to speed quickly and is quite stable.

Thanks for the reply.

For heat, will light weight aluminum heatsink attached to iron plate core be beneficial ? Or a peltier plates if voltages in this link (Peltier plate output ) can be achieved per degree temperature increase, we can light a LED so heat is transformed in light energy and gives visual indication ?

Also some kind of voltage/speed/frequency regulator so motor runs effeciently and heats less. Like Voltage decrease due to fluctuations will not increase current, DC blocking etc. ?

Regards.

Measured the motor temperature of my older TD-124 which has a motor having the original bearings and felts.

This unit is a mid/late original TD-124 with cast iron platter and rebuilt main bearing. (everything on this table pretty has been rebuilt)

After an hour of operation I measured the motor temperature at the mid point between the coils and got a balmy 55 degrees C. Line voltage here is 119V 60Hz, and is supplied by an isolation transformer so there is no lurking DC present on the motor windings.

This motor is a bit noisy, truth be told, but comes up to speed quickly and is quite stable.

How many seconds runs these motor from cold start power on /off without belt ?

Thanks for the reply.

For heat, will light weight aluminum heatsink attached to iron plate core be beneficial ? Or a peltier plates if voltages in this link (Peltier plate output ) can be achieved per degree temperature increase, we can light a LED so heat is transformed in light energy and gives visual indication ?

Also some kind of voltage/speed/frequency regulator so motor runs effeciently and heats less. Like Voltage decrease due to fluctuations will not increase current, DC blocking etc. ?

Regards.

If you read the posts you will see that you need to rebuild the motor first.

and that the mains voltage does influence the heat.

The motor must be able to work well without external cooling.

Ah! OK.

Sorry, I was thinking of motor under load and running for good amount of time.

Regards.

Sorry, I was thinking of motor under load and running for good amount of time.

Regards.

How many seconds runs these motor from cold start power on /off without belt ?

I will carefully check in the next couple of days, but with power removed it does coast for a significant amount of time, perhaps 5 seconds or so. Bearings seem good, but perhaps could stand to be replaced.

The other motor (a MKII) is rebuilt, and I installed new bearings and felts when I did it. This one runs extremely quietly, but I recall it ran just as hot. I am now running this one on 110V which makes a pretty big difference in terms of heat and the amount of eddy current brake that needs to be applied. (Which since the load is reduced probably helps further)

I should note since it seems to have been missed that both of my tables run on isolated power, and that there is no DC present.

The line voltage around here is what could be best termed distorted (clipped) sine wave as it comes into the house, typical for North America.

I am in fact in the process of designing, building and debugging some sine wave sources for powering several of my turntables, since output voltage will be adjustable I will probably run these at between 110 - 115V as opposed to the standard 120V line voltage now in force. See my sine source thread if you are curious here: http://www.diyaudio.com/forums/anal...ource-induction-motor-powered-turntables.html The source and filter end of things are pretty well sorted out, the power amplifier may be an issue based on dialog I have had with Mark K about chip amps.

The line voltage around here is what could be best termed distorted (clipped) sine wave as it comes into the house, typical for North America.

I am in fact in the process of designing, building and debugging some sine wave sources for powering several of my turntables, since output voltage will be adjustable I will probably run these at between 110 - 115V as opposed to the standard 120V line voltage now in force. See my sine source thread if you are curious here: http://www.diyaudio.com/forums/anal...ource-induction-motor-powered-turntables.html The source and filter end of things are pretty well sorted out, the power amplifier may be an issue based on dialog I have had with Mark K about chip amps.

Volken, I measured the motor coast down time with the belt removed on my older (original series) TD-124 at approximately 7 seconds. (This is the one that runs 55 degrees once fully warmed up)

Edit: I have since discovered that I had a minor motor bearing alignment issue which I addressed. Motor got quite noisy as it warmed up - this is no longer occurring. I am not sure that this would effect the coast down time, but at some point I will recheck it.

Edit: I have since discovered that I had a minor motor bearing alignment issue which I addressed. Motor got quite noisy as it warmed up - this is no longer occurring. I am not sure that this would effect the coast down time, but at some point I will recheck it.

Volken, I measured the motor coast down time with the belt removed on my older (original series) TD-124 at approximately 7 seconds. (This is the one that runs 55 degrees once fully warmed up)

Edit: I have since discovered that I had a minor motor bearing alignment issue which I addressed. Motor got quite noisy as it warmed up - this is no longer occurring. I am not sure that this would effect the coast down time, but at some point I will recheck it.

Kevin the min.coast down time with new bearings etc. must be 15 seconds otherwise the aligment or bearing friction is not ok.

The bearings in this motor are the original ones, and I have not rebuilt the motor. (I did disassemble it and clean and relubricate the bearings) At some point the Papst motor will go in this table at least temporarily, so I am not sure when this motor will get rebuilt.

I will recheck the coast time since I realigned the bearings next time I pull the platter off.

I like the gauges you show in your pictures.

I will recheck the coast time since I realigned the bearings next time I pull the platter off.

I like the gauges you show in your pictures.

Volken, what weight of lube do you use in the.....

...motor bushings. Most of us have been following the service manual and use 20 wt turbine oil.

-Steve

...motor bushings. Most of us have been following the service manual and use 20 wt turbine oil.

-Steve

Volken, to echo Steve I'm using SAE 20wt electric motor (non-detergent) oil to lubricate the oilite bushings in my motors. It's about the closest thing we have around here to the original oil used.

Volken, to echo Steve I'm using SAE 20wt electric motor (non-detergent) oil to lubricate the oilite bushings in my motors. It's about the closest thing we have around here to the original oil used.

I use Schopper oil for the new bushings they are no sinterbushings and need other oil. .

The viscosity is for me unknown but it is thinner then SAE20 but as you know the viscosity must match with the bushing tolerance !

Here's the latest update on the motor in the older of my two TD-124s.

Belt removed spin down time is 17 seconds, motor temperature is 52 degrees C after an hour of operation.

With mains of 120V the eddy current brake has to be adjusted such that the magnet is <3mm from the intermediate pulley to get a reasonable adjustment range. This is closer to the pulley than was the case with the original factory settings on the TD-124 MKII which after restoration ran far too fast. (It ran not at all prior to this)

Main bearings on both my tables are oilite bushings, the manufacturer recommends 30wt oil in these bushings which is what I am now using. I am still running them "wet" based on discussions about oilite bushings running at low speed where metal to metal contact can occur due a lack of oil film caused specifically by low speeds.

Belt removed spin down time is 17 seconds, motor temperature is 52 degrees C after an hour of operation.

With mains of 120V the eddy current brake has to be adjusted such that the magnet is <3mm from the intermediate pulley to get a reasonable adjustment range. This is closer to the pulley than was the case with the original factory settings on the TD-124 MKII which after restoration ran far too fast. (It ran not at all prior to this)

Main bearings on both my tables are oilite bushings, the manufacturer recommends 30wt oil in these bushings which is what I am now using. I am still running them "wet" based on discussions about oilite bushings running at low speed where metal to metal contact can occur due a lack of oil film caused specifically by low speeds.

OK, here is weird problem that I hope one of you can find a solution to.

I bought a second-hand White Noise TT power supply. it is a fairly simple concept: The turntable power supply is composed of two major modules. The crystal oscillator module produces a 50 (33.3rpm ) or 67.5Hz (45rpm ) sinewave from the square wave output of a crystal oscillator chip which is divided down and then low pass filtered to give low distortion sinewaves. The oscillator module is powered by 15V ac supplied from a small 15VA toroidal transformer.

The power amplifier module is an off-the-shelf, encapsulated, ILP 2003 60W unit with an integral dc power supply and heatsink. The dc power supply is fed from an encapsulated, toroidal, mains transformer producing 25V-0-25V ac at 80VA. The low distortion 50/67.5Hz sinewave from the oscillator module is input to the power amplifier module and amplified up to a suitable voltage and current for driving a step-up transformer. The step-up transformer is an encapsulated, 15V ac, 30VA, toroidal, mains transformer used in reverse. In other words, the power amplifier drives the 15V ac winding, which is normally the secondary, but is now used as the primary. The 230V ac winding, which is normally the primary, now becomes the secondary and produces the crystal controlled 50/67.5Hz power at 230V ac to drive the turntable motor

I had one of these before when I had a Garrard 401 and that worked fine. I am currently testing it on my Mørch GS6 (with a 24 V Papst außenläufer motor) where it seems to work fine. But on on the Thorens, it locks down because of overheating after 1½ hours. Why?

I bought a second-hand White Noise TT power supply. it is a fairly simple concept: The turntable power supply is composed of two major modules. The crystal oscillator module produces a 50 (33.3rpm ) or 67.5Hz (45rpm ) sinewave from the square wave output of a crystal oscillator chip which is divided down and then low pass filtered to give low distortion sinewaves. The oscillator module is powered by 15V ac supplied from a small 15VA toroidal transformer.

The power amplifier module is an off-the-shelf, encapsulated, ILP 2003 60W unit with an integral dc power supply and heatsink. The dc power supply is fed from an encapsulated, toroidal, mains transformer producing 25V-0-25V ac at 80VA. The low distortion 50/67.5Hz sinewave from the oscillator module is input to the power amplifier module and amplified up to a suitable voltage and current for driving a step-up transformer. The step-up transformer is an encapsulated, 15V ac, 30VA, toroidal, mains transformer used in reverse. In other words, the power amplifier drives the 15V ac winding, which is normally the secondary, but is now used as the primary. The 230V ac winding, which is normally the primary, now becomes the secondary and produces the crystal controlled 50/67.5Hz power at 230V ac to drive the turntable motor

I had one of these before when I had a Garrard 401 and that worked fine. I am currently testing it on my Mørch GS6 (with a 24 V Papst außenläufer motor) where it seems to work fine. But on on the Thorens, it locks down because of overheating after 1½ hours. Why?

The TD-124 uses slightly more power than the Garrard 401 which came as a surprise to me.. The Garrard motor uses 12W and the Thorens 15W, the Garrard motor is much larger and runs cooler - perhaps it is just more efficient and you are overloading your source? Perhaps measuring the power factor of the individual motors might provide a clue as to what is going on.. I'm actually working on a source for my tables - I'm using two inexpensive Chinese kit LM3886 50W amplifier boards in parallel and a 50VA EI transformer for step up - intended to run one table. (I have a 401 and two TD-124) Not yet fully tested, hoping it does not blow up.. Here: http://www.diyaudio.com/forums/anal...ource-induction-motor-powered-turntables.html

The Blurb/instructions that came with the White noise thing says it 'will produce up to 30W of 230V ac power', but that seems not to be true....Unless of course that there is something else that causes it to oscillate or something?

I am thinking that it might be worthwhile to use one of my ICEpower modules (125W) instead of the ILP module?

I am thinking that it might be worthwhile to use one of my ICEpower modules (125W) instead of the ILP module?

I suspect the transformer is a bit small. I am using a 50VA transformer for a device I don't expect to deliver more than 30W.. I am doing a 3 phase source for a Papst Aussenlaufer using a Mark Kelly designed source and 50W amplifiers and 50VA transformers to provide about 15W of 3 phase power..

I'd try a larger transformer first before using a bigger amp.

I'd try a larger transformer first before using a bigger amp.

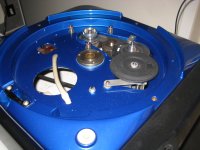

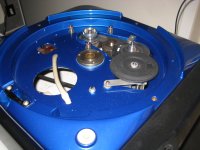

Thorens TD124 Ciel Bleu

Just finished the restauration on a TD124 because the chassis was in a very bad shape I deside to change the color in Ciel Bleu !

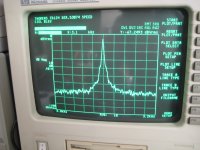

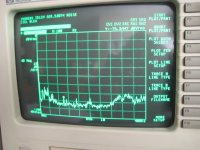

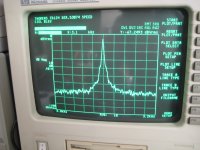

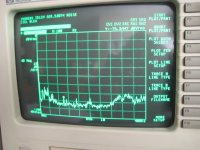

The speed and noise measurement are made after the restauration speed stability is excellent with a very sharp peak !

Motorvibration at 100hz is also very weak as result from the spring motor decoupling .

Volken

Just finished the restauration on a TD124 because the chassis was in a very bad shape I deside to change the color in Ciel Bleu !

The speed and noise measurement are made after the restauration speed stability is excellent with a very sharp peak !

Motorvibration at 100hz is also very weak as result from the spring motor decoupling .

Volken

- Home

- Source & Line

- Analogue Source

- Restoring and Improving A Thorens TD-124 MKII