I have a Marantz TT-15s1 that has a stand-alone AC motor that powers the platter via a belt. I've recently moved to the UK so I'm trying to find some way to make this work with the 220-240v here (my current motor is 120v). I've contacted Marantz suppliers and they're looking into it, but it doesn't look hopefull. Does anyone have any suggestions for a kit or another standalone motor that I could jerry-rig to work in this setup?

Thanks, yeah, I've been looking at things like this. The issue is they don't transform the frequency, so the 230v / 50 hz input ends up being 120v / 50 hz output (instead of 60 hz). And since it's an AC motor, that (should) will make it run 20% off speed. But this comes from my somewhat limited knowledge of AC circuits, so perhaps I'm misunderstanding things?

If at all possible get the European 50Hz pulley, if this is not available there are two options, swap out the motor for a DC type

or source a variable frequency drive in order to feed the existing motor with a 60 Hz supply.

My choice would be for the latter; as a diy project either the https://www.diyaudio.com/community/...tor-for-synchronous-motor-drive.365849/unread,

or the https://www.diyaudio.com/community/...rator-for-turntable-motor-drive.298018/latest

or source a variable frequency drive in order to feed the existing motor with a 60 Hz supply.

My choice would be for the latter; as a diy project either the https://www.diyaudio.com/community/...tor-for-synchronous-motor-drive.365849/unread,

or the https://www.diyaudio.com/community/...rator-for-turntable-motor-drive.298018/latest

Check for two sets of pulleys...50 and 60 Hz.

And a voltage switch.

And you might find another table.

The difficult way is to obtain a drive like IGBT / triac / Mosfet to give 120V / 60 Hz, try and search for such a circuit.

And a voltage switch.

And you might find another table.

The difficult way is to obtain a drive like IGBT / triac / Mosfet to give 120V / 60 Hz, try and search for such a circuit.

Hi, Just a suggestion. Change the motor to DC, lower noise, speed control, smoother running. You will end up with a better T/T which can handle any country voltage.

Cheers

Cheers

I don't agree, DC motors are OK but are themselves prone to speed variation and long term drift. Good ones are also not cheap. The motor in this TT is a high quality unit and is a multi pole unit. it would be better to build or otherwise obtain a variable frequency drive.

Another option is to have a replacement pulley made; this is a bit tricky as the sizes have to include the belt thickness. It can be done if accurate measurements of the pulley and belt are made.

Another option is to have a replacement pulley made; this is a bit tricky as the sizes have to include the belt thickness. It can be done if accurate measurements of the pulley and belt are made.

Last edited:

Can these be used? Charge with a step-down transformer. Since the turntable consumes so little wattage, it can last for many hours on a single charge.

JACKERY400 Watt Peak Output Explorer 290Wh Portable Power Station

JACKERY400 Watt Peak Output Explorer 290Wh Portable Power Station

Many portable power station provide Pure Sine Wave AC Power.

Energizer Portable Power Station PPS320, 320Wh LiFePO4 Battery 110V/300W Pure Sine Wave AC Outlet PD100W

Energizer Portable Power Station PPS320, 320Wh LiFePO4 Battery 110V/300W Pure Sine Wave AC Outlet PD100W

I think a replacement table may be a better choice in terms of cash spent.

You do get drives for motors, the smallest will be around rated 500W, and that will be stepping down the voltage, and multiplying the frequency, and will cost quite a lot of money, if it is extreme quality medical grade, $1000 will be an approximate figure...$200 for a good quality industrial unit.

It must regulate the voltage within limits, and the frequency. And have low noise.

At that point, the decision has to be made.

Even a pulley replacement involves a strip down, reassembly after a new machined pulley is installed.

You have to obtain the metal block and have it machined.

At UK rates, 8 hours work at how much per hour? So how much money?

You do get drives for motors, the smallest will be around rated 500W, and that will be stepping down the voltage, and multiplying the frequency, and will cost quite a lot of money, if it is extreme quality medical grade, $1000 will be an approximate figure...$200 for a good quality industrial unit.

It must regulate the voltage within limits, and the frequency. And have low noise.

At that point, the decision has to be made.

Even a pulley replacement involves a strip down, reassembly after a new machined pulley is installed.

You have to obtain the metal block and have it machined.

At UK rates, 8 hours work at how much per hour? So how much money?

See if the unit is made in the Far East...those were out sourced, and intended for world wide sales, it might just be a matter of changing pulleys and voltage selector.

No, I have not taken the trouble of going through the user and service manuals.

So I may be wrong about saying this.

Apologies in advance if that is the case.

No, I have not taken the trouble of going through the user and service manuals.

So I may be wrong about saying this.

Apologies in advance if that is the case.

According to the service manuals (both Japanese an International) the motor does not have any voltage adjustment, but that's not difficult to fix, just a suitable transformer. The next issue is the different motor speeds when running on a 50 or 60 Hz supply. The Japanese service manual indicates the availability of two pullies, one with a diameter of 44mm (50 Hz), the other of 37mm (60Hz), (these are the diameters for 45rpm, not specified for 33rpm). These are part numbers listed for the 50Hz pulley (90M31BW262010, or SS-T15/032 from Jap s/m) and SS-T15/031 from Int. s/m.

Whether it's easier to get a replacement pulley or use a variable frequency drive is the next question.

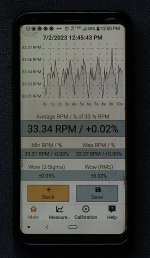

VFDs designed for use as portable power stations (as shown above) may work, but I'm very doubtful whether the output is accurate or stable enough to drive a turntable to its best. The links I provided above are both designed to do exactly that, but sadly do need a bit more expertise.

Whether it's easier to get a replacement pulley or use a variable frequency drive is the next question.

VFDs designed for use as portable power stations (as shown above) may work, but I'm very doubtful whether the output is accurate or stable enough to drive a turntable to its best. The links I provided above are both designed to do exactly that, but sadly do need a bit more expertise.

The other option of a DC drive seems easier to achieve, it may be possible that a DC motor in the same mounting and dimensions is available.

Most makers used bought out motors, go from there.

A VFD may cause noise induction in the output, remember the levels are in mV, so that will be amplified...and possibly ruin the sound.

Most makers used bought out motors, go from there.

A VFD may cause noise induction in the output, remember the levels are in mV, so that will be amplified...and possibly ruin the sound.

Agreed, that's a very decent result. Speed drift normally shows up over longer periods of time, eg an album side, and is caused by change in resistance of the windings. Some higher quality motors include a feedback circuit using a frequency generator, this, in conjunction with extra circuitry stabilises the speed.

But the electrical noise generated by the intermittent contact of the brushes on the commutator don't?A VFD may cause noise induction in the output, remember the levels are in mV, so that will be amplified...and possibly ruin the sound.

There are many threads here, some I think are OCD, about DC drives for turntables.

The OP can look at those, there are other sites about vinyl as well.

I got into music in 1980 with a cassette player, records were on their way out by then.

Now I use digital files, so this entire maintenance / conversion bit for vinyl is archaic, and more like museum piece restoration.

That said, even then commutator design, spark absorption capacitors, and BLDC drives exist, where the electronic commutation is supplied to slip rings instead of brushes.

So I think the noise can be dealt with, has been done earlier already.

The OP can look at those, there are other sites about vinyl as well.

I got into music in 1980 with a cassette player, records were on their way out by then.

Now I use digital files, so this entire maintenance / conversion bit for vinyl is archaic, and more like museum piece restoration.

That said, even then commutator design, spark absorption capacitors, and BLDC drives exist, where the electronic commutation is supplied to slip rings instead of brushes.

So I think the noise can be dealt with, has been done earlier already.

Having dug a little more it appears that the Marantz TT-15S1 is very very close to the Clearaudio Emotion SE, if not identical?

On that basis I suggest the OP contact the UK importer, Soundfowndations, or Clearaudio themselves. Either is easily found online.

I am sure there should be no problem getting hold of a replacement 50Hz pulley.

On that basis I suggest the OP contact the UK importer, Soundfowndations, or Clearaudio themselves. Either is easily found online.

I am sure there should be no problem getting hold of a replacement 50Hz pulley.

- Home

- Source & Line

- Analogue Source

- Replacement stand-alone motor (either prebuilt or kit) for Marantz turntable