LD, you raised an interesting point- surfactant. Presumably the old Lencoclean wet play liquid had some (if anyone still has any, I can figure out what it is). I'd appreciate if anyone running these tests say what the fluid was, DI/DW, water plus Photoflo, water plus IPA, whatever. Wettability is an important variable.

My friend runs water plus a little isopropyl, knowing him the mix is totally random and yes the noise reduction is obvious friction induced or not.

LD, you raised an interesting point- surfactant. Presumably the old Lencoclean wet play liquid had some (if anyone still has any, I can figure out what it is). I'd appreciate if anyone running these tests say what the fluid was, DI/DW, water plus Photoflo, water plus IPA, whatever. Wettability is an important variable.

For my tests I used 10% isopropyl alcohol in distilled water plus 2 drops of undiluted Kodak photo surfactant per litre, kept in a glass container with glass stopper as clean as possible. I used to fairly flood the record surface, and yes wetting was an issue with water alone that this mix overcame.

It was a few years ago now.

LD

I used to fairly flood the record surface

Folks trying to repeat these results should take note this aspect has not been stressed enough. My friend wishes they made TT's with gutters. Once you include the effect of actually wicking water half way up the cantilever I think things get even more complicated.

Last edited:

Here's an article from 1982 published by EMT the pro TT manufacturer. It discloses some ideas of a chemical nature as to what might be going on as to permanent degeneration of groove surface after wet playback. Interesting, tantalising......

Comments from them here skilled in the art ?

http://www.stefanopasini.it/EMT_Danger_wet_Records.htm

LD

Comments from them here skilled in the art ?

http://www.stefanopasini.it/EMT_Danger_wet_Records.htm

LD

The Swiss theory would be readily testable by examining a dry playback of a record, followed by an ultrasonic cleaning (whereupon those adsorbed species would be diluted into oblivion) followed by re-characterizing dry. Or am I misreading?

The latter suggested crystalline depositions would show up with newer SEMs, where that sort of resolution is readily available. Such crystallites might even fall within the range of an EPMA spot size for a rough idea of the surface chemical composition.

The latter suggested crystalline depositions would show up with newer SEMs, where that sort of resolution is readily available. Such crystallites might even fall within the range of an EPMA spot size for a rough idea of the surface chemical composition.

One hole in this: why doesn't the same thing happen with records that are wet-cleaned? Or wiped with damp implements like Discwashers or Parastats?

Extremely slow kinetics, thus needing the added localized heating to drive the reactions/diffusion forward en masse?

Friction heating from contact between the tip and the vinyl surface. It's a pretty small area so local temperatures might get pretty warm.

(I said earlier I don't have a good feel for the thermal situation right on the tip/vinyl interface, which might very well prove key)

I do also want to emphasize that I'm not anywhere near as well-versed in these material sets as some other members of this thread. So I might be speculating wild hulabaloo. 🙂

(I said earlier I don't have a good feel for the thermal situation right on the tip/vinyl interface, which might very well prove key)

I do also want to emphasize that I'm not anywhere near as well-versed in these material sets as some other members of this thread. So I might be speculating wild hulabaloo. 🙂

Last edited:

I don't see it. Any heat is extremely transient and there's a whole pile of thermal mass behind and around the contact point.

Yeah, it is a reaching hypothesis. I'm probably overly sensitive due to some of my more recent work, where local kinetics were a big_deal. Seeing the world as nails when all you have is a hammer. 🙂

That large of friction effect, though, would have to show up in surface morphology. I'm just surprised some enterprising academic with good access to metrology equipment hasn't characterized the effect. Wonder if I could write a grant proposal for this. 😉

That large of friction effect, though, would have to show up in surface morphology. I'm just surprised some enterprising academic with good access to metrology equipment hasn't characterized the effect. Wonder if I could write a grant proposal for this. 😉

Wondering why the Dry/Wet results are exactly the same in my case when wetted with Knostli disco.antistat, heavily applied on the very right track, I came to think whether the type of element (maybe even in combination with the shape of the needle) may have anything to do with this.

I'm almost sure the Poul Ladegaard tests were perforformed with a MM element, the popular type of element at that time.

By now I guess that the graphs published by LD were also taken from an MM element.

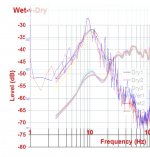

Let me show what I mean. I made an overlay of the resonance graph that LD posted and projected what I have measured with my MC element on top of that graph after having given both exactly the same scale on X and Y axes.

LD's graph has been smoothened in the low end area, but it is clearly visible that for the Dry recordings the shape around the resonance peak is the same for both.

However in my case, noise is steadily decreasing whereas the noise in LD's graph is not at all ??

The result of this is that at 100Hz the two graphs are some 30dB apart !

So let the absolute values for what they are, I'm just talking about the shape of the curves.

So when two elements are behaving so differently, Why should they not also respond differently to playing Dry/Wet?

I do not own an MM element to test, but these elements usually have a much higher compliance and are terminated with 47K, whereas my MC element has a very low compliance, terminated with several hundreds ohms, so very well damped.

Isn't that a bit like comparing a Deux Chevaux with a BMW.

Both can "play" the same road but depending on the conditions of the road they will transfer different noise from the road. And you cannot compare their different behaviour on a wet road.

Isn't that what is also visible in the graph presented here ?

That the graphs are very different is as obvious as it can be, so it seems at least a point for further investigation.

Hans

P.S. I'm not at all interested in friction, only in differing noise behaviour between Dry/Wet.

I'm almost sure the Poul Ladegaard tests were perforformed with a MM element, the popular type of element at that time.

By now I guess that the graphs published by LD were also taken from an MM element.

Let me show what I mean. I made an overlay of the resonance graph that LD posted and projected what I have measured with my MC element on top of that graph after having given both exactly the same scale on X and Y axes.

LD's graph has been smoothened in the low end area, but it is clearly visible that for the Dry recordings the shape around the resonance peak is the same for both.

However in my case, noise is steadily decreasing whereas the noise in LD's graph is not at all ??

The result of this is that at 100Hz the two graphs are some 30dB apart !

So let the absolute values for what they are, I'm just talking about the shape of the curves.

So when two elements are behaving so differently, Why should they not also respond differently to playing Dry/Wet?

I do not own an MM element to test, but these elements usually have a much higher compliance and are terminated with 47K, whereas my MC element has a very low compliance, terminated with several hundreds ohms, so very well damped.

Isn't that a bit like comparing a Deux Chevaux with a BMW.

Both can "play" the same road but depending on the conditions of the road they will transfer different noise from the road. And you cannot compare their different behaviour on a wet road.

Isn't that what is also visible in the graph presented here ?

That the graphs are very different is as obvious as it can be, so it seems at least a point for further investigation.

Hans

P.S. I'm not at all interested in friction, only in differing noise behaviour between Dry/Wet.

Last edited:

On a wet road the 2CV is less likely to aquaplane than the 2 ton BMW on huge wide tyres!

Compliance aside the water should provide at least some damping so you should see some reduction in the fundamental resonance. The fact there is none either suggests you have found a magical property of MC carts or your road was merely damp.

Interesting none theless. I don't see how (on the same test record) MM would be 30dB noisier based on measurements SY took with his AT150 when testing the EO phono.

Compliance aside the water should provide at least some damping so you should see some reduction in the fundamental resonance. The fact there is none either suggests you have found a magical property of MC carts or your road was merely damp.

Interesting none theless. I don't see how (on the same test record) MM would be 30dB noisier based on measurements SY took with his AT150 when testing the EO phono.

Wet playing reduces surface noise but at the same time damages records by pushing dirt deeper where it dries up and cannot be easily removed.

cheers,

cheers,

One hole in this: why doesn't the same thing happen with records that are wet-cleaned? Or wiped with damp implements like Discwashers or Parastats?

It can.

In 1981 Robert Pardee tested µ for mint records from various brands, using various commercial products, with mixed results. Friction coefficient, µ, was measured before/after cleaning.

Here's the result with water/detergent, the control.

Determination of Sliding Friction Between Stylus and Record Groove, Robert P. Pardee, Ball Corporation, Aerospace Division, Boulder, Co USA. JAES Vol 29 No 12 Dec 1981.

"....The comparison in Table 2 show that thoroughly cleaning a record with detergent solution will, in most cases, cause an increase in friction, sometimes a large increase. And the effect seems to vary from one brand of record to another. For example, cleaning had essentially no effect on µ of brands E and E; caused a slight µ increase on brands F and G, and caused a rather large µ increases on brand C."

Record Manufacturer, side No, µ(mint) µ(after cleaning)

A 1 0.27 0.29

A 2 0.26 0.29

A 1 0.38 0.40

A 2 0.38 0.40

A 1 0.43 0.39

B 1 0.34 0.34

C 1 0.24 0.34

C 1 0.24 0.64

D 1 0.29 0.30

D 1 0.28 0.37

D 2 0.28 0.36

E 1 0.27 0.27

F 1 0.26 0.29

F 1 0.22 0.23

G 1 0.15 0.19 "

LD

Last edited:

What was the time gap between cleaning and friction measurement? You'll understand why I ask that.

edit: also, what are the error bars on the measurement of mu?

edit: also, what are the error bars on the measurement of mu?

Compliance aside the water should provide at least some damping so you should see some reduction in the fundamental resonance. The fact there is none either suggests you have found a magical property of MC carts or your road was merely damp.

Interesting none theless. I don't see how (on the same test record) MM would be 30dB noisier based on measurements SY took with his AT150 when testing the EO phono.

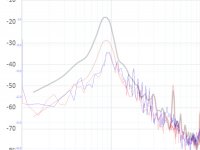

Going back in this very thread to Posting #58, I found a complete different set of Dry/wet recordings from some 3rd party and posted by LD.

When again carefully projecting my recording with the same scale on this graph, aligning it with the Wet recording in that graph, all at the sudden one can see that apart from the height of the resonance peak, the two recordings are almost identical with the same descending slope.

So for whatever reason LD's recording deviates complete from this, and I'm happy that at least one person in this world recorded the same shape as I did.

Was it an MC element that was used for this test, who knows ?

This person noticed a difference between Dry/Wet that I did not for whatever reason.

In fact my LP was so wet that I could not even see the tracks through the fluid, so I had to wait until the moment I saw on my scope the 1 Khz tone was beginning, and right after that moment I switched to FFT mode and averaged 11 FFT's

All the time a multimeter was connected to the output of my main amp giving a stable output from start to end as to confirm that all 11 FFT's were still on the relevant track.

So I do not see anything that can be improved on that, but nevertheless the change was nil.

Hans

The result of this is that at 100Hz the two graphs are some 30dB apart !

This is because my plot was made using a pink noise test track, ie programme material intentionally there at 100Hz, whereas you test was made using a track which was 'silent' at 100Hz !! I did label my plot as being of pink noise....... 🙄

Actually, it doesn't matter what programme content is, the LF phenomenum of significantly reduced amplitude cart-arm resonance strongly correlates with reduced friction, and is readily demonstrable between wet/dry playback IME.

Shape of the LF resonant system shows that Q is roughly the same between Hans' and my own plots. Therefore damping of the cart-arm resonant system, which mostly is provided by cartridge suspension elastomer, is about the same. Therefore, there's no indication of difference between MM and MC here.

Aside, MC often has higher generator inertia, the moving mass of the generator being higher. To obtain adequate cantilever damping requires more damping than MM. Since damping is provided by the same cartridge elastomer as provides compliance 'spring', MC carts often have stiffer suspensions and thus require to track a bit heavier. But overall, mechanics of cart-arm resonant system, including cart-arm damping ratio, end up about the same between MM and MC.

There's no evidence of wet playback affecting the Q of cart-arm resonance, quite the opposite: Q appears unaltered. So it seems wet playback doesn't affect cart-arm damping, just the resonance amplitude. Therefore one might deduce that wet playback reduces stimulus, and IME this phenomenum correlates with reduced friction coefficient no matter how that is achieved.

P.S. I'm not at all interested in friction, only in differing noise behaviour between Dry/Wet.

Whatever, but they are one and the same. Well, they certainly correlate, and there's a plausible case and explanation for them being causal.

LD

Last edited:

- Home

- Source & Line

- Analogue Source

- Reducing Record Surface Noise - I want to know all Approaches