I have to admit your hypothesis that ticks & pops are caused by 'stiction' effects between vinyl & diamond is new to me .. but I'm open to new evidence on this Jurassic subject.I suppose that increasing VTF might affect µ inversely; what really goes on as to tribology at the stylus-groove boundary is unknown, at least by me ! Increasing VTF might help to reduce crackle-pop surface noise, perhaps for the reasons already mentioned: VTF sets the threshold which momentary variation in friction has to overcome in order to induce micro-mistracking and produce crackle/pop/tick noise, but don't write home yet because average friction, at least, scales with VTF in the first place. I suppose it's quite possible that tribology is such that noise variation and/or average value of µ can vary with VTF........

Would you expect to see tiny gouges in the polished 'groove' (actually more a graded & smoothed track) under a SEM?

Interesting. I have an ADC body in my box of random carts, but no stylii.

I do need to finish my plot of compliance vs VTF for current production cartridges. As I mentioned before, with a few hundred to spend on experiments you can pretty much pick the combination you want for a cartridge (at least MM).

Expert are still in business. They have a paratrace as their top line contact diamond now. I can imagine at some stage line contacts not being as good, but with modern laser cut profiles is that still the same?

I do need to finish my plot of compliance vs VTF for current production cartridges. As I mentioned before, with a few hundred to spend on experiments you can pretty much pick the combination you want for a cartridge (at least MM).

Expert are still in business. They have a paratrace as their top line contact diamond now. I can imagine at some stage line contacts not being as good, but with modern laser cut profiles is that still the same?

There are practical problems with high >30cu compliance. These cartridges often CAN'T be used with VTF >1gm as they would hit the record.I do need to finish my plot of compliance vs VTF for current production cartridges. As I mentioned before, with a few hundred to spend on experiments you can pretty much pick the combination you want for a cartridge (at least MM).

That's good news.Expert are still in business. They have a paratrace as their top line contact diamond now. I can imagine at some stage line contacts not being as good, but with modern laser cut profiles is that still the same?

It's not so much LCs being no good .. but that the alignment is critical for them, both vertically & laterally.

If Expert Pickups re-tip your cartridge, you can be sure the tip will not be skewif. But this will be right only at ONE VTF. This is important for ellipticals too ... but vital for LCs

Another point is that the elliptical radii are often not what the makers say. eg the mid/expensive SHUREs claimed a 0.7 x 0.2 elliptical but HiFi Choice found practically all were more like 0.7 x 0.3 .. probably no bad thing 🙂

I think I might anticipate regions of non-homogeneity; patches of varying composition. For whatever reason, it seems playback causes neither much degeneration nor improvement of normal/typical 'noisy' surfaces. Except degeneration by wet playback, as discussed, though even that is reversible by resuming wetplayback. That's why I think it's not mechanical 'damage', though it might be and just very small.Would you expect to see tiny gouges in the polished 'groove' (actually more a graded & smoothed track) under a SEM?

That said, I spent some time looking microscopically at the crud which accumulates on a stylus. I know, I should socialise more 😉 I think, from its appearance such as colour and strand like structure, typically it is vinyl scrapings/shavings. Anecodatally, very noisy records do seem to 'shed' more, perhaps, but something very wrong with composition or storage might be to blame there?

LD

Thanks for the Holman article link, kgrlee.As I've said earlier, the SHURE papers deal with both the cantilever modes as well as vinyl. Don Barlow certainly didn't just analyse static vinyl.

I'm dredging up 30+ yr old memories but IIRC, elastic vinyl is necessary to explain how a low tip mass spherical stylus can have low distortion. The 'modern' example of this is Denon 103.

Over the years I've read many Shure and Barlow articles, and there's one I recall which ran a Fortran simulation of cantilever flex along the lines we are discussing. Does that ring a bell ? I have it somewhere. But, IIRC, the flex modes it examined aren't available in practice because effectively the stylus is retained by groove walls.

But I'm not aware of anything which considers the dynamic elasticity of vinyl in situ - perhaps because it was taken as read as having 'known' properties. However, from a dynamics and energy perspective, I couldn't see how vinyl can flex at all: too much energy would be left behind, and there's not enough time for compression to happen.

It is difficult to tell the difference between cantilever flex and vinyl compression, and even as far as distortion is concerned the same effect is produced.

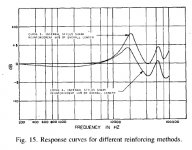

I've attached a plot of a measured mechanical only frequency response of a quad cartridge, originally from Shibata IIRC, perhaps from a Happ paper. You can clearly see what appears to be two distinct resonant systems.

However, if one simulates mechanical flex impedance for a cantilever only, using just permissible vibration modes, one can readily obtain likely candidates to match the Shibata plot shape. The first two resonances in a series, as classic physics predicts.

Given that two flex resonances must be there, ie if one if possible so must be the 2nd one, and empirically there is no other resonance observed, its safe to deduce that vinyl compression is not present I figure.

I don't think it's splitting hairs, because pulling on this loose thread unravels a lot of precepts about what is good bad and ugly in cantilevers, trackability, and distortion, record wear, tip mass etc etc.

If high cantilever rigidity and low inertia were the goal, it's hard to beat a fat hollow Al tube with thin walls. However, it is important that cantilevers flex correctly, or put it another way, present low enough mechanical impedance to the stylus. Otherwise, hf trackability, distortion, and groove damage suffer, as per Yosh's link George kindly provided.

This is why many exotic cantilevers are far less rigid and have higher inertia as a body than they could be/have. But by design, albeit empirical perhaps, they can outperform simple rigid low inertia cantilevers at hf. And some of the reasons make a little sense, to me at least. If one plays back hf groove content with high level, using a fine radius stylus coupled by a high mechanical impedance cantilever to a high mechanical impedance suspension, one has created a cutting lathe, and it will damage grooves !

You may need to have a low mass cantilever too. What is a S-120 ?

Short, wide hollow Al tube. Spherical stylus, see above.

Yes. And the bung being an elastomer, damping and spring constant tend to correlate. So high compliance suspensions tend to have low damping, hence the need for brushes.BTW, the resistance (not compliance) of the little rubber bung also provides most of the (effective) damping for the arm/cartridge.

.... The V15-IV damper brush adds to this damping without requiring a more lossy (resistive) bung .. which would reduce MF trackability. I'm in two minds about this brush. It IS audible but provides so many benefits. It IS audible but provides so many benefits.

The SHURE M24H cantilever adds a 3rd HF resonance to complicate things ... but if done right, helps HF trackability & response with sorta cheapo stuff.

I will look out for this paper. I feel a trip to the British Library coming on....! Any pointers welcome.

If tip mass is small, high VTF does NOT cause record wear ... Walton bla bla

Yes - strictly if hf mechanical impedance seen by the stylus is low, such as flex impedance of cantilever - see above.

Yes.2gm is a sensible value even with a Line Contact stylus. It's all SHURE's fault. Popularizing Trackability led to a race to have the smallest VTF to track various torture test tracks. This led to user expectations of 1gm VTF in day to day use.

All interesting stuff!

LD

Attachments

Last edited:

If high cantilever rigidity and low inertia were the goal, it's hard to beat a fat hollow Al tube with thin walls. However, it is important that cantilevers flex correctly, or put it another way, present low enough mechanical impedance to the stylus. Otherwise, hf trackability, distortion, and groove damage suffer, as per Yosh's link George kindly provided.

This is why many exotic cantilevers are far less rigid and have higher inertia as a body than they could be/have. But by design, albeit empirical perhaps, they can outperform simple rigid low inertia cantilevers at hf. And some of the reasons make a little sense, to me at least. If one plays back hf groove content with high level, using a fine radius stylus coupled by a high mechanical impedance cantilever to a high mechanical impedance suspension, one has created a cutting lathe, and it will damage grooves !

Apologies for rule bending quote. But here is something I need a little help getting my head around. Are there things we can measure to help with the information here. Both my current cartridges have boron rod cantilevers and I am intrigued with the idea of trying a sapphire at some stage. But what are the empirical measurements one can do to get useful data points. Maybe as you say thinwall Al is the best of modern materials and it would be nice to test that hypothesis. For the ortofons I would have though the DJ stylii would not be as thin wall as (say) the 2M range as they are expected to take abuse, but then again given tooling costs they will want to sweat the machines they have !

Apologies for rule bending quote. But here is something I need a little help getting my head around. Are there things we can measure to help with the information here. Both my current cartridges have boron rod cantilevers and I am intrigued with the idea of trying a sapphire at some stage. But what are the empirical measurements one can do to get useful data points. Maybe as you say thinwall Al is the best of modern materials and it would be nice to test that hypothesis. For the ortofons I would have though the DJ stylii would not be as thin wall as (say) the 2M range as they are expected to take abuse, but then again given tooling costs they will want to sweat the machines they have !

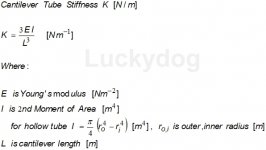

Here you go, Bill, first attachment is an equation to determine cantilever flex stiffness, ie its spring constant, given dimensions and material properties.

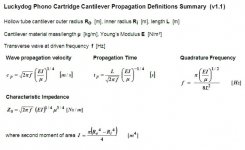

Second attachment treats the cantilever as a transmission line: if it flexes it will convey deflections as transverse waves along its length. So equations for propagation velocity, characteristic impedance, quadrature resonance, etc which might seem familiar terms to electronics engineers........

Use the force wisely, Luke......😉

LD

Attachments

Sorry was in a rush and missed out 'we can't measure the wall thickness easily for our Al cartridge'. Do you have numbers ? Actually do we even know the grade of Al used?

I'd assumed reverse engineering from measurements might be easier...

I'd assumed reverse engineering from measurements might be easier...

Sorry was in a rush and missed out 'we can't measure the wall thickness easily for our Al cartridge'. Do you have numbers ? Actually do we even know the grade of Al used?

I'd assumed reverse engineering from measurements might be easier...

My head is still exploding guys, am I allowed to enjoy my LP's on my kickstarter TT and $75 Grado cart? 🙂

Attachments

Last edited:

You’ve wisely chosen to place yourself among the 99.999% of the vinyl users. 😎

Enjoy the content, explore the medium.

🙂

George

Enjoy the content, explore the medium.

🙂

George

Of course you can Scott. But given you've solved digital RIAA and flat preamps not much else for us to do other than sweat the small stuff.

At the moment I am grateful xmas has left me skint. As too young (just) to remember the ultralight arm and high compliance cart era, but intrigued to try shoving the resonance up to the recommended 14Hz from the B&K research. Problem is light arms are tricky to come by, but I keep seeing Moerch UP-4s come up, which do have a 4g armwand and (at least to me) look lovely. that and an OM cart would be 6.5g all up.

Then I realise that the arm on my #2 turntable (kenwood KD-550) probably isn't that bad and I should get over my pathological worries about SME bayonet mounts and just crack on 🙂

At the moment I am grateful xmas has left me skint. As too young (just) to remember the ultralight arm and high compliance cart era, but intrigued to try shoving the resonance up to the recommended 14Hz from the B&K research. Problem is light arms are tricky to come by, but I keep seeing Moerch UP-4s come up, which do have a 4g armwand and (at least to me) look lovely. that and an OM cart would be 6.5g all up.

Then I realise that the arm on my #2 turntable (kenwood KD-550) probably isn't that bad and I should get over my pathological worries about SME bayonet mounts and just crack on 🙂

My head is still exploding guys, am I allowed to enjoy my LP's on my kickstarter TT and $75 Grado cart? 🙂

AFAIK Grado offered (still do?) some carts with tapered cantilevers, describing them as 'transmission lines', perhaps with some patents? I might be wrong though. I think the radius of the cantilever increased in 3 or so steps towards the generator. Maybe there's an upside in having flexible end near the stylus and rigid end near the generator ?

One property of mechanical TLs that one doesn't find in electrical TLs is dispersion: different frequencies propagate at different velocities. Prob not enough to make any difference in cantilevers, but pretty weird. It's why one hears a train coming by hf sound in the rails first.......

LD

SAW filters. I used them, but they did my head in.

Amongst tapered cantilevers Dynavector did it. (nice pic here https://www.vinylengine.com/turntable_forum/viewtopic.php?f=19&t=11431&start=4065) AT with the 15 and Jico have started doing tapered Ruby.

Of course everyone offers a different reason, some vibration modes, some mass reduction, some TL. I like my tapered armtube, so why not tapered cantilever 🙂

Amongst tapered cantilevers Dynavector did it. (nice pic here https://www.vinylengine.com/turntable_forum/viewtopic.php?f=19&t=11431&start=4065) AT with the 15 and Jico have started doing tapered Ruby.

Of course everyone offers a different reason, some vibration modes, some mass reduction, some TL. I like my tapered armtube, so why not tapered cantilever 🙂

Sorry was in a rush and missed out 'we can't measure the wall thickness easily for our Al cartridge'. Do you have numbers ? Actually do we even know the grade of Al used?

Not to hand, and because one of the terms involves 4th power of cantilever radius, it matters to be specific to the cantilever at hand, and be quite accurate.

To measure it, I used a micrometer to (carefully!) measure cantilever diameter. Then an optical microscope to observe the stylus mounting flank which is made by folding the tube flat, but has exposed end section that allows one to see the wall thickness. By comparing optically to the tube radius, one can estimate wall thickness.

It's much easier for solid rods, just measure outside radius, and use inner radius=0 in the equations.

Yes, it's another spherical cow moment, but the principles are interesting I think. And, as Yoda said on the topic, 'you must unlearn what you have learned about cantilevers'.

It's easier for MC carts: look for the 1st hf resonant system, or 'top resonance'; it's always there but sometimes ultrasonic, sometimes audioband. If one believes that to have this cause.I'd assumed reverse engineering from measurements might be easier...

See being a lazy engineer for Boron I noted that there is only one or two suppliers of rods for cartridge supply so if you can find the diameter for one you probably know it for all!

Must get good microscope!

Must get good microscope!

Well if the 2 big resonances were due solely to cantilever flex, changing the bung shouldn't really move them in frequency.Over the years I've read many Shure and Barlow articles, and there's one I recall which ran a Fortran simulation of cantilever flex along the lines we are discussing. Does that ring a bell ? I have it somewhere. But, IIRC, the flex modes it examined aren't available in practice because effectively the stylus is retained by groove walls.

But I'm not aware of anything which considers the dynamic elasticity of vinyl in situ - perhaps because it was taken as read as having 'known' properties. However, from a dynamics and energy perspective, I couldn't see how vinyl can flex at all: too much energy would be left behind, and there's not enough time for compression to happen.

Aluminium certainly does have advantages over some 'exotic' materials but I think is beaten on all grounds by boron .. especially as you can get boron tubes.

And there IS a lot of energy transmitted to the record. You can clearly hear the acoustic noise if your record mat provides minimal support like the early Thorens. The noise is correlated with the 'trackability' of the cartridge ... especially tip mass.

LD, we'll have to agree to differ on this arcane subject. I've presented my Jurassic evidence but am unlikely to do more experimental work this Millenium 🙂

____________________

I'm still trying to find Walton's little booklet.

Decca Deram

I'd forgotten he'd published a couple of AES papers on the subject.

AES E-Library Stylus Mass and Elliptical Points

AES E-Library Stylus Mass and Elliptical Points

If anyone is an AES member and can get copies, I'm really after the SEM pics in his booklet that may be in the papers too. They show the 'polishing' that occurs on first play with a low tip mass cartridge.

Pick-ups, The Key to Hi-Fi. Pitman, London, 1965

http://www.lencoheaven.net/forum/index.php?topic=705.0

Have a look at Reply #10

BTW, I'm not advocating going back to spherical stylii .. but you have to admit a Denon 103 sounds very nice indeed.

The booklet is Pick-ups, The Key to Hi-Fi. Pitman, London, 1965

There's more stuff from the book in that thread

http://www.lencoheaven.net/forum/index.php?topic=705.0

Have a look at Reply #10

BTW, I'm not advocating going back to spherical stylii .. but you have to admit a Denon 103 sounds very nice indeed.

The booklet is Pick-ups, The Key to Hi-Fi. Pitman, London, 1965

There's more stuff from the book in that thread

Last edited:

We all need at least at least one Spherical for playing our mono records!

Never heard a 103, the fact that its following seems to be due to its lack of neutrality put me off. Perhaps I should not be so biased.

Never heard a 103, the fact that its following seems to be due to its lack of neutrality put me off. Perhaps I should not be so biased.

I stick definitive with my MC, Heavy Body, Low Compliance, Aluminium Tube Cantilever,

Spherical Tip apx. 15,3 um Radi, Double polished, Grain orientation, very well inserted in Cantilever within all important angles. Tracking weight 2,2 gr. Thus Skatingforces are not really a problem.

The Thales Simplicity Arm has negligible Tracking Error, low skating force and the Phonostage has a Monoswitch.

I find the Denon DL 103 very ok for price, just use a heavy arm.

Scott Wurcers Grado is also ok for music listening pleasure.

Thanks gpapag and LD, very good informations and links. Confirms almost what my MC Maker sez. 😀

Spherical Tip apx. 15,3 um Radi, Double polished, Grain orientation, very well inserted in Cantilever within all important angles. Tracking weight 2,2 gr. Thus Skatingforces are not really a problem.

The Thales Simplicity Arm has negligible Tracking Error, low skating force and the Phonostage has a Monoswitch.

I find the Denon DL 103 very ok for price, just use a heavy arm.

Scott Wurcers Grado is also ok for music listening pleasure.

Thanks gpapag and LD, very good informations and links. Confirms almost what my MC Maker sez. 😀

Err.rh! Denon 103 was designed for the NHK (the Japanese BBC). Neutrality was high on the list of priorities. Also low record wear.Never heard a 103, the fact that its following seems to be due to its lack of neutrality put me off. Perhaps I should not be so biased.

Are there better cartridges? Of course! But today, it would be hard to beat at its price which makes it a bargain.

Even its MC requirements are quite mild compared to eg the Ortofons.

You do need to match the mass of the arm but its much easier to add mass than remove it. 🙂

And it is the best proof against those who say spherical stylii can't sound good.

_____________________

Bill, if you are after a low mass arm to play with, you can pick up a TD166 or similar Thorens vintage for a song. These are the ones which used a removable wand rather than a removable headshell.

... and comes with a rather good turntable freebie too!

Da audiophools will sneer but it was designed right after B&K did their work on arms etc.

If you are worried about the detachable wand, just glue it solid. 🙂

Don't forget to include substantial subsonic filtering in your preamp to get the greatest benefit from a low arm mass solution. The reason is in Holman. To gild the lily, you might want to match the Q of your 20Hz subsonic filter to the anticipated rise at frequencies around 20Hz.

Or you can just enjoy the "increased bass definition and stupendous power in the tympany bla bla" 🙂😱🙂

Last edited:

- Home

- Source & Line

- Analogue Source

- Reducing Record Surface Noise - I want to know all Approaches